Abstract

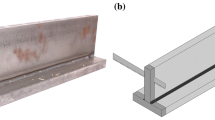

Laser-stake welding enables an economic production of all-steel sandwich panels that can be used for steel bridges as well as for decks in roll-on/roll-off ships (ferries). Deck plates of 10 mm thickness can be joined with interior web plates ensuring a weld throat thickness of 2–3 mm. In a research project, fatigue tests were performed with laser-stake welds subjected to axial, shear and multiaxial in-phase loading and assessed by the nominal and the notch stress approach. In addition to possible effects of gaps between deck and web plates or of the steel strength, the application of interaction formulae to laser-stake welds is checked as contained in Eurocode 3 and the IIW recommendations for the fatigue assessment of multiaxial loading. Furthermore, the equivalent von Mises stress is applied using the notch stress approach. In this way, the basis is provided for a safe design of laser-stake-welded T-joints.

Similar content being viewed by others

References

Roland F (1999) Laserschweißen - Chancen, Probleme, Beispiele. Schiff & Hafen 2/1999, 78–84

Frank D, Remes H, Romanoff J (2013) J-integral-based approach to fatigue assessment of laser stake-welded T-joints. Int J Fatigue 47:340–350

Frank D, Remes H, Romanoff J (2011) Fatigue assessment of laser stake-welded T-joints. Int J Fatigue 33:102–114

Kozak J (2004) Strength Tests of Steel Sandwich Panel, 9th Symposium on Practical Design of Ships and Other Floating Structures. Schiffbautechnische Gesellschaft, Lübeck-Travemünde

Baumgartner J (2009) Schwingfestigkeitsbewertung laserstrahlgeschweißter Stahlstrukturen geringer Wanddicken aus dem Automobilbau, DVS-Bericht Band 256: Festigkeit geschweißter Bauteile, 63–74, DVS Media GmbH, Düsseldorf

Germanischer Lloyd (2005) Rules & Guidelines, II Materials and Welding – Part 1 Metallic Materials – Chapter 2 Steel and Iron Materials, 2009

Eurocode 3: Design of Steel Structures – Part 1–9 Fatigue. EN 1993-1-9, European Committee for Standardisation

Hobbacher A (2009) Recommendations for fatigue design of welded joints and components. WRC Bulletin 520. Welding Research Council, New York

Sonsino CM, Bruder T, Baumgartner J (2010) S-N lines for welded thin joints – suggested slopes and FAT values for applying the notch stress concept with various reference radii. Weld World 54:R375–R392

Fricke W (2013) IIW guideline for the assessment of weld root fatigue. Weld World 57:753–791. doi:10.1007/s40194-013-0066-y

Fricke W (2012) IIW recommendations for the fatigue assessment of welded structures by notch stress analysis. Woodhead Publishing Limited, Cambridge

Haibach E (1989) Betriebsfestigkeit: Verfahren und Daten zur Bauteilberechnung. VDI-Verlag GmbH, Düsseldorf

Acknowledgments

The investigations were performed within the project 16935 BG “Laser-welded T-Joints” of the Research Association for Steel Application (FOSTA) which was funded with public means within the programme “Industrial Cooperative Research” (IGF) by the German Federal Ministry of Economics and Technology via the FOSTA and the Center of Maritime Technologies (CMT). The research partners are grateful for the financial support and thank also the committee of industrial partners for their valuable comments and guidance.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended for publication by Commission XIII - Fatigue of Welded Components and Structures

Rights and permissions

About this article

Cite this article

Fricke, W., Robert, C., Peters, R. et al. Fatigue strength of laser-stake welded T-joints subjected to combined axial and shear loads. Weld World 60, 593–604 (2016). https://doi.org/10.1007/s40194-016-0322-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-016-0322-z