Abstract

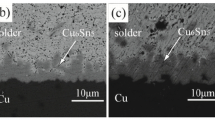

The research described in this paper developed the experimental techniques necessary for promoting intermetallic layer growth throughout the melting and solidification cycle of the solder and then measuring the thickness of these layers. Most of the literature to date reported on aged soldered joints to investigate in-service intermetallic layer growth. To observe intermetallic compound (IMC) growth during the liquid state of soldering required an experimental setup that quickly raises the temperature of the solder joint followed by fast cooling (comparable to the actual joint conditions). Temperatures at increments of 25° above the soldering temperature and times of 2, 5, and 8 s for growth were carefully controlled. After the experiments, the copper substrate/solder alloy interface was examined using light microscopy, scanning electron microscopy (SEM), and SEM-EDS (energy dispersive spectroscopy). As expected, intermetallic phases such as Cu6Sn5, Cu3Sn, and Ag3Sn were observed, with Cu6Sn5 being the major phase. Statistical analysis was performed for the IMC thickness data obtained from the long profile analysis. Empirical equations capable of predicting the IMC layer thicknesses were determined. Using Arrhenius analysis, the activation energy for intermetallic layer growth was calculated to be approximately 7 kCal/mol. This value is significantly lower than the value of approximately 24 kCal/mol reported in the literature for Cu6Sn5. Even considering the presence of Cu3Sn (counted together with Cu6Sn5) which has about 15 % higher activation energy of formation than Cu6Sn5, the experimentally measured values were still lower. The discrepancy was attributed to the fact that the values reported in the literature were mostly based on solid-state transformations while the measurements and calculations in this work were limited to the intermetallic layer formation from liquid state followed by growth.

Similar content being viewed by others

References

Humpston, G, Jacobson DM (1993) Principles of soldering and brazing, 1st Ed. ASM International

Harman AC (1978) “Rapid tin-nickel intermetallic growth: some effects of solderability”, Proceedings, InterNepcon. Brighton, U.K, p 92

Yu S, Wan M, Hon M Jan (2001) Formation of intermetallic compounds at Eutectic Sn-Zn-Al, solder/Cu interface. J Mater Res Vol. 16, No. 1

www.soselectronic.com/a_info/resource/pdf/ine/sac305.pdf (2014)

Zeng K, Tu KN (2002) Six cases of reliability study of Pb-free solder joints in electronic packaging technology. Mater Sci Eng p. 55–105

Suganuma K (2001) Advances in lead-free electronics soldering. Solid State Mater Sci p. 55–64

Siewert T, Liu S, Smith DR, Madeni JC (2002) Database for solder properties with emphasis on new lead-free solders. National Institute of Standards and Technology & Colorado School of Mines

Schmetterer C, Ipser H, Pearce J (2008) Lead-free solders: handbook of properties of SAC solders and joints

Madeni JC, Liu S (2011) “Effect of thermal aging on the interfacial reactions of tin-based solder alloys and copper substrates and kinetics of formation and growth of intermetallic compounds”, vol 16, No. 1. Soldag. Insp, Sao Paolo, pp 086–095

Zou HF, Zhang QK, and Zhang ZF (2011) Interfacial microstructure and growth kinetics of intermetallic compound layers in Sn-4 wt.% Ag/Cu-X (X = Zn, Ag, Sn) couples. J Electron Mater Vol. 40, No. 7

Madeni JC (2002) Mechanical properties and kinetics of intermetallics growth in four lead-free solder alloys, Sn-3.2Ag-0.8Cu, Sn-3.5Ag, Sn-0.7Cu, and Sn-8.9Zn, applied to cupper substrates. MSc. Thesis, Colorado School of Mines

Boetting WJ, Handweker CA, and Kattner UR (1993) Reactive wetting and intermetallic formation, the Mechanics of Solder Alloy, Wetting and Spreading. pp. 103–140

Jang YS, Kim JH, Choi SH, Yang KM, Kang YC (2012) Electrochemical properties of Cu5Sn6-C composite powders with mixture of Cu5Sn6-void-C yolk-shell, Cu5Sn6 alloy, and hollow carbon. Int J Electrochem Sci 7:12531–12544

Choi S, Bieler TR, Lucas JP, Subramanian KN (1999) Journal of Electronic Materials 28:1209

Flanders DR, Jacobs EG, Pinizzotto RF (1997) Journal of Electronic Materials Col. 26, 7

Harris PG, Chaggar MS (1998) Soldering Surface Mount Technology 10(3):38–52

Yoon JW, Lee CB, Jung SB (2003) Journal of Electronic Materials, 32(11):1201

Vianco PT, Kilgo AC, Grant R (1995) Intermetallic compound layer growth kinetics in non lead bearing solders. Sandia National Laboratories, Albuquerque

Vianco PT, Hopkins PL, Erikson KL, Frear DR, Davidson R (1997) “Design and Reliability of Solders and Solder Interconnections”, The Minerals, Metals and Materials Society, pp. 161–170

Flandorfer H. et al. (2007) Interface in lead-free solder alloys: enthalpy of formation of binary Ag-Sn, Cu-Sn and Ni-Sn intermetallic compounds

Cohen JB, Leach JSLI, Bever MB (1954) JOM 6:1257–1258

Kleppa OJ (1956) J Phys Chem 60:852–858

Hultgren R, Desai PD, Hawkins DT, Gleiser M, Kelley KK (1971) Selected values of the thermodynamic properties of binary alloys. ASM Metals Park, OH

Biltz W, Wagner W, Pieper H, Holverscheit W (1924) Z Anorg Chem 134:25–36

Kubaschewski O, Catterall JA (1956) Thermochemical data of alloys. Pergammon, New York

Saunders N, Mlodownlk AP (1990) The copper-tin system. Bulletin of Alloy Phase Diagrams Vol. 11, No 3

Gangulee A, Das GC, Bever MB (1973) Metall Trans 4:2063–2066

Author information

Authors and Affiliations

Corresponding author

Additional information

Doc. IIW-2514, recommended for publication by Commission XVII “Brazing, Soldering, and Diffusion Bonding.”

Rights and permissions

About this article

Cite this article

Madeni, J.C., Liu, S., de Andrade, P.H.S. et al. Characterization and growth kinetics of the formation of intermetallic compounds in the liquid state during soldering with lead-free solders. Weld World 59, 325–338 (2015). https://doi.org/10.1007/s40194-014-0202-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-014-0202-3