Abstract

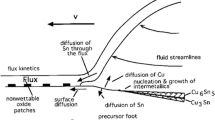

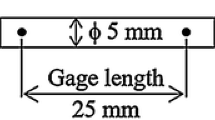

This paper evaluates the characteristics of the intermetallic compounds (IMC) that form between Indium-enriched SAC solder alloys and Copper substrate. In this study, Indium was added to a commercial SAC305 solder (96.5 wt.% Sn, 3 wt.% Ag, 0.5 wt.% Cu) at three different compositions, 0.5, 5, and 10 wt%. To observe IMC growth during the liquid state of the solder droplet, the experimental matrix consisted in three soldering temperatures (220, 275, and 300 °C), and the molten solder was kept at this temperature for 2, 5, and 8 s. Fast cooling followed each solder test to complete solidification. The same procedure was repeated for the three levels of Indium. The Copper substrate/solder alloy interface was examined using light microscopy, scanning electron microscopy, and energy dispersive spectroscopy. Statistical analysis was performed on the IMC thickness data obtained from the long profile analyses. Using Arrhenius analysis, the activation energy for IMC formation and growth was calculated to be approximately 6.7, 5.1, and 10.8 kCal/mol for the SAC305 alloys with 0.5, 5.0, and 10 wt% Indium additions, respectively. As expected, Cu6Sn5, Cu3Sn, Ag3Sn, In3Sn (β), InSn4 (γ), and AgIn2 were observed.

Similar content being viewed by others

References

Tong S, von Schirnding YE, Prapamontol T (2000) Environmental lead exposure: a public health problem of global dimensions. Bull World Health Organ 78(9):1068–1077

Abtew M, Selvaduray G (2000) Lead-free solders in microelectronics. Mater Sci Eng 27:95–141

Siewert TA, Madeni JC, Liu S et al. (2002) Database for solder properties with emphasis on new lead-free solders”, National Institute of Standards and Technology & Colorado School of Mines, http://www.msed.nist.gov/solder/NIST_LeadfreeSolder_v4.pdf.

Trumble B (1998) Get the lead out! [lead free solder]. Published in the IEEE Spectrum 35(5):55–60

Madeni JC, Liu S, Andrade PHS, Carson CH (2015) Characterization and growth kinetics of the formation of intermetallic compounds in the liquid state during soldering with lead-free solders. Published in the IIW Welding in The World Journal 59(3):325–338 . doi:10.1007/s40194-014-0202-3, ISSN 0043-2288Published online

Fallahi H, Nurulakmal MS, Fallahi A, Abdullah J (2012) Modifying the mechanical properties of lead-free solder by adding iron and indium and using a lap joint test. Published in the Journal of Mater Science: Mater Electron 23(9):1739–17492

Hodulova E (2016) Common bilateral joining project Slovakia–Portugal, presented at the 69th IIW Annual Assembly in Melbourne, Australia, and published as IIW Doc XVII-0040-16, July 11–15

Andrade PHS, Liu S, Madeni JC (2015) Characterization of Intermetallic Compound Formation and Growth Kinetics in Lead-Free Solder SAC305, presented in International Brazing & Soldering Conference 2015 (IBSC 2015), American Welding Society

Yazzie KE, Xie HX, Williams JJ, Chawla N (2012) On the relationship between solder-controlled and intermetallic compound (IMC)-controlled fracture in Sn-based solder joints. Scr Mater 66:586–589. doi:10.1016/j.scriptamat.2012.01.009

Salam B, Ekere NN, Rajkumar D (2001) Study of the interface microstructure of Sn-Ag-Cu lead-free solders and the effect of solder volume on intermetallic layer formation. Published in the Electronic Components and Technology Conference, 2001. Proceedings., 51st, pp. 471–477. doi:10.1109/ECTC.2001.927769

Pecht M (1993) Soldering processes and equipment. Wiley, New York

Tu PL, Chan YC, Lai JKL (1997) Effect of intermetallic compounds on the thermal fatigue of surface mount solder joints. Published in IEEE Transactions on Components, Packaging, and Manufacturing Technology: Part B 20(1):87–93. doi:10.1109/96.554534

Parent JOG, Chung DDL, Bernstein IM (1988) Effects of intermetallic formation at the interface between copper and lead-tin solder. J Mater Sci 23:2564. doi:10.1007/BF01111916

Li M, Du Z, Guo C, Li C (2009) Thermodynamic optimization of the Cu–Sn and Cu–Nb–Sn systems. J Alloys Compd 477:104–117

Biocca P (2006) Tin-copper based solder options for lead-free assembly. Global SMT & Packaging - November/December

White GK and Collocott SJ (1984) Heat capacity of reference materials: Cu and W. J Phys Chem Ref Data. 13(4)

Siewert TA, Madeni JC, and Liu S (2003) Formation and growth of intermetallics at the interface between lead-free solders and copper substrates. Proceedings of the APEX Conference on Electronics Manufacturing, Anaheim, California

YEH MS (2003) Effects of indium on the mechanical properties of ternary Sn–In–Ag solders. Metall Mater Trans A 34A:361–365

Kanlayasiri K, Mongkolwongrojn M, Ariga T (2009) Influence of indium addition on characteristics of Sn-0.3Ag-0.7Cu solder alloy. J Alloys Compd 485:225–230

Ohnuma I, Cui Y, Liu XJ, Inohana Y, Ishihara S, Ohtani H, Kainuma R, Ishida K (2000) Phase Equilibria of Sn-in based micro-soldering alloys. J Electron Mater 29(10):1113–1121

Liu XJ, Inohana Y, Takaku Y, Ohnuma I, Kainuma R, Ishida K, Moser Z, Gasior W, Pstrus J (2002) Experimental determination and thermodynamic calculation of the phase Equilibria and surface tension in the Sn-Ag-in system. J Electron Mater 31(11):1139–1151

Zhao Y, Zhang Z, Dang H (2004) Synthesis of In-Sn alloy nanoparticles by solution dispersion method. Journal of Material Chemistry 14:299–302

Mu D, Huang H, McDonald SD, Read J, Nogita K (2013) Investigating the mechanical properties, creep and crack pattern of Cu6Sn5 and (Cu,Ni)6Sn5 on diverse crystal planes. Materials Science and Engineering: A, Volume 566(20):126–133

Jacobson DM and Humpston G (2004) Principles of Soldering. ASM International, The Materials Information Society

Acknowledgements

The authors acknowledge the support of the Center for Welding, Joining, and Coatings Research for the completion of this research. One of the authors (FR) acknowledges the Brazilian Scientific Mobility Program for their support while interning at the Colorado School of Mines.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended for publication by Commission XVII-Brazing, Soldering and Diffusion Bonding

Rights and permissions

About this article

Cite this article

Rodrigues, F., Watson, J., Liu, S. et al. Study of intermetallic compounds (IMC) that form between indium-enriched SAC solder alloys and copper substrate. Weld World 61, 603–611 (2017). https://doi.org/10.1007/s40194-017-0445-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-017-0445-x