Abstract

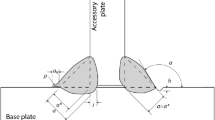

The effects of the lack of penetration flaw and misalignment on fatigue life of cruciform welded joints made of low-alloy steel were studied experimentally and theoretically. It was found that two locations of fatigue fracture were possible under cyclic tension loading, depending on the relative magnitude of the misalignment. In the absence of misalignment, all fatigue failures occurred as a result of fatigue growth of cracks emanating from the weld root. In the presence of misalignment, fatigue life depended on the fatigue growth of cracks growing from the weld toe. It has been shown that the entire fatigue life can be modeled as a fatigue growth of cracks starting either from the weld toe or the weld root. The initial crack size was selected as a small crack characteristic for a given material, i.e., being dependent only on the material. The weight function method was used to calculate the required stress intensity factors.

Similar content being viewed by others

References

Glinka G (1978) Fatigue strength of low alloy steels. Przegl Mechaniczny (Mech Eng Rev) XXXVII(13):5–8, in Polish

Chattopadhyay A, Glinka G et al (2011) Stress analysis and fatigue of welded structures. Weld World 55(07–08):2–21

Mikheevskiy S, Glinka G (2009) Elastic-plastic fatigue crack growth analysis under variable amplitude loading spectra. Int J Fatigue 31:1828–1836

Kitagawa H, Takahashi S (1976) Applicability of fracture mechanics to very small cracks in the early stage. In: Proceedings of the Second International Conference on Mechanical Behaviour of Materials, Metals Park, American Society for Metals, pp. 627-631

Glinka G (1985) A notch stress–strain analysis approach to fatigue crack growth. Eng Fract Mech 21(2):245–261

Remes H, Varsta P, Romanoff J (2012) Continuum approach to fatigue crack initiation and propagation in welded steel joints. Int J Fatigue 40:16–26

Bueckner HF (1970) A novel principle for the computation of stress intensity factors. Z Angew Math Mech 50:529–546

Glinka G, Shen G (1991) Universal features of weight functions for cracks in mode I. Eng Fract Mech 40(6):1135–1146

Moftakhar A, Glinka G (1992) Calculation of stress intensity factors by efficient integration of weight functions. Eng Fract Mech 43(5):749–756

Anderson TL, Glinka G (2006) A closed-form method for integrating weight functions for part-through cracks subject to mode I loading. Eng Fract Mech 73(15):2153–2166

Author information

Authors and Affiliations

Corresponding author

Additional information

Doc. IIW-2378, recommended for publication by Commission XIII "Fatigue of Welded Components and Structures".

Appendix

Appendix

Parameters of the weight function for a semi-elliptical crack in a finite-thickness plate

-

For the deepest point O

$$ \begin{array}{c}\hfill {m}_{\mathrm{O}}\left(x,a\right)=\frac{2F}{\sqrt{2\pi \left(a-x\right)}}\left\{1+{M}_{1\mathrm{O}}{\left(1-\frac{x}{a}\right)}^{\frac{1}{2}}+{M}_{2\mathrm{O}}\left(1-\frac{x}{a}\right)+{M}_{3\mathrm{O}}{\left(1-\frac{x}{a}\right)}^{\frac{3}{2}}\right\}\hfill \\ {}\hfill {M}_{1\mathrm{O}}=\frac{\pi }{\sqrt{2Q}}\left(4{Y}_{\mathrm{o}}-6{Y}_1\right)-\frac{24}{5}\hfill \\ {}\hfill {M}_{2\mathrm{O}}=3\hfill \\ {}\hfill {M}_{3\mathrm{O}}=2\left(\frac{\pi }{\sqrt{2Q}}{Y}_{\mathrm{O}}-{M}_{1\mathrm{O}}-4\right)\hfill \end{array} $$where for 0 < a/c < 1:

$$ \begin{array}{l}Q=1.0+1.464{\left(\frac{a}{c}\right)}^{1.65}\hfill \\ {}{Y}_0={B}_0+{B}_1{\left(\frac{a}{t}\right)}^2+{B}_2{\left(\frac{a}{t}\right)}^4+{B}_3{\left(\frac{a}{t}\right)}^6\hfill \\ {}{B}_0=1.0929+0.2581\left(\frac{a}{c}\right)-0.7703{\left(\frac{a}{c}\right)}^2+0.4394{\left(\frac{a}{c}\right)}^3\hfill \\ {}{B}_1=0.456-3.045\left(\frac{a}{c}\right)+2.007{\left(\frac{a}{c}\right)}^2+\frac{1.0}{0.147+{\left(\frac{a}{c}\right)}^{0.688}}\hfill \\ {}{B}_2=0.995-\frac{1.0}{0.027+\frac{a}{c}}+22.0{\left(1-\frac{a}{c}\right)}^{9.953}\hfill \\ {}{B}_3=-1.459+\frac{1.0}{0.014+\frac{a}{c}}-24.211{\left(1-\frac{a}{c}\right)}^{8.071}\hfill \end{array} $$And

$$ \begin{array}{l}{Y}_1={A}_0+{A}_1{\left(\frac{a}{t}\right)}^2+{A}_2{\left(\frac{a}{t}\right)}^4+{A}_3{\left(\frac{a}{t}\right)}^6\hfill \\ {}{A}_0=0.4537+0.1231\left(\frac{a}{c}\right)-0.7412{\left(\frac{a}{c}\right)}^2+0.4600{\left(\frac{a}{c}\right)}^3\hfill \\ {}{A}_1=-1.652+1.665\left(\frac{a}{c}\right)-0.534{\left(\frac{a}{c}\right)}^2+\frac{1.0}{0.198+{\left(\frac{a}{c}\right)}^{0.846}}\hfill \\ {}{A}_2=3.418-3.126\left(\frac{a}{c}\right)-\frac{1.0}{0.041+\left(\frac{a}{c}\right)}+17.259{\left(1-\frac{a}{c}\right)}^{9.286}\hfill \\ {}{A}_3=-4.228+3.643\left(\frac{a}{c}\right)+\frac{1.0}{0.020+\frac{a}{c}}-21.924{\left(1-\frac{a}{c}\right)}^{9.203}\hfill \end{array} $$and for 1 < a/c < 2

$$ \begin{array}{l}Q=1.0+1.464{\left(\frac{c}{a}\right)}^{1.65}{\left(\frac{a}{c}\right)}^2\hfill \\ {}{Y}_0={B}_0+{B}_1{\left(\frac{a}{t}\right)}^2+{B}_2{\left(\frac{a}{t}\right)}^4\hfill \\ {}{B}_0=1.12-0.09923\left(\frac{a}{c}\right)+0.02954{\left(\frac{a}{c}\right)}^2\hfill \\ {}{B}_1=1.138-1.134\left(\frac{a}{c}\right)+0.3073{\left(\frac{a}{c}\right)}^2\hfill \\ {}{B}_2=-0.9502+0.8832\left(\frac{a}{c}\right)-0.2259{\left(\frac{a}{c}\right)}^2\hfill \\ {}{Y}_1={A}_0+{A}_1{\left(\frac{a}{t}\right)}^2+{A}_2{\left(\frac{a}{t}\right)}^4\hfill \\ {}{A}_0=0.4735-0.2053\left(\frac{a}{c}\right)+0.03662{\left(\frac{a}{c}\right)}^2\hfill \\ {}{A}_1=0.7723-0.7265\left(\frac{a}{c}\right)+0.1837{\left(\frac{a}{c}\right)}^2\hfill \\ {}{A}_2=-0.2006-0.9829\left(\frac{a}{c}\right)+1.237{\left(\frac{a}{c}\right)}^2-0.3554{\left(\frac{a}{c}\right)}^3\hfill \end{array} $$ -

For the surface point D

$$ \begin{array}{c}\hfill {m}_{\mathrm{D}}\left(x,a\right)=\frac{2F}{\sqrt{\pi x}}\left\{1+{M}_{1\mathrm{D}}{\left(\frac{x}{a}\right)}^{\frac{1}{2}}+{M}_{2\mathrm{D}}{\left(\frac{x}{a}\right)}^1+{M}_{3\mathrm{D}}{\left(\frac{x}{a}\right)}^{\frac{3}{2}}\right\}\hfill \\ {}\hfill {M}_{1\mathrm{D}}=\frac{\pi }{\sqrt{4Q}}\left(30{F}_1-18{F}_{\mathrm{o}}\right)-8\hfill \\ {}\hfill {M}_{2\mathrm{D}}=\frac{\pi }{\sqrt{4Q}}\left(60{F}_0-90{F}_1\right)+15\hfill \\ {}\hfill {M}_{3\mathrm{D}}=-\left(1+{M}_{1\mathrm{D}}+{M}_{2\mathrm{D}}\right)\hfill \end{array} $$where for 0 < a/c < 1:

$$ \begin{array}{l}{F}_0=\left[{C}_0+{C}_1{\left(\frac{a}{t}\right)}^2+{C}_2{\left(\frac{a}{t}\right)}^4\right]\sqrt{\frac{a}{c}}\hfill \\ {}{C}_0=1.2972-0.1548\left(\frac{a}{c}\right)-0.0185{\left(\frac{a}{c}\right)}^2\hfill \\ {}{C}_1=1.5083-1.3219\left(\frac{a}{c}\right)+0.5128{\left(\frac{a}{c}\right)}^2\hfill \\ {}{C}_2=-1.101+\frac{0.879}{0.157+\frac{a}{c}}\hfill \end{array} $$And

$$ \begin{array}{l}{F}_1=\left[{D}_0+{D}_1{\left(\frac{a}{t}\right)}^2+{D}_2{\left(\frac{a}{t}\right)}^4\right]\sqrt{\frac{a}{c}}\hfill \\ {}{D}_0=1.2687-1.0642\left(\frac{a}{c}\right)+1.4646{\left(\frac{a}{c}\right)}^2-0.7250{\left(\frac{a}{c}\right)}^3\hfill \\ {}{D}_1=1.1207-1.2289\left(\frac{a}{c}\right)+0.5876{\left(\frac{a}{c}\right)}^2\hfill \\ {}{D}_2=0.190-0.608\left(\frac{a}{c}\right)+\frac{0.199}{0.035+\frac{a}{c}}\hfill \end{array} $$and for 1 < a/c < 2

$$ \begin{array}{l}{F}_0=\left[{C}_0+{C}_1{\left(\frac{a}{t}\right)}^2+{C}_2{\left(\frac{a}{t}\right)}^4\right]\sqrt{\frac{a}{c}}\hfill \\ {}{C}_0=1.34-0.2872\left(\frac{a}{c}\right)+0.0661{\left(\frac{a}{c}\right)}^2\hfill \\ {}{C}_1=1.882-1.7569\left(\frac{a}{c}\right)+0.4423{\left(\frac{a}{c}\right)}^2\hfill \\ {}{C}_2=-0.1493+0.01208\left(\frac{a}{c}\right)+0.02215{\left(\frac{a}{c}\right)}^2\hfill \end{array} $$And

$$ \begin{array}{l}{F}_1=\left[{D}_0+{D}_1{\left(\frac{a}{t}\right)}^2+{D}_2{\left(\frac{a}{t}\right)}^4\right]\sqrt{\frac{a}{c}}\hfill \\ {}{D}_0=1.12-0.2442\left(\frac{a}{c}\right)+0.06708{\left(\frac{a}{c}\right)}^2\hfill \\ {}{D}_1=1.251-1.173\left(\frac{a}{c}\right)+0.2973{\left(\frac{a}{c}\right)}^2\hfill \\ {}{D}_2=0.04706-0.1214\left(\frac{a}{c}\right)+0.04406{\left(\frac{a}{c}\right)}^2\hfill \end{array} $$

Rights and permissions

About this article

Cite this article

Goyal, R., Glinka, G. Fracture mechanics-based estimation of fatigue lives of welded joints. Weld World 57, 625–634 (2013). https://doi.org/10.1007/s40194-013-0060-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-013-0060-4