Abstract

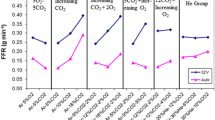

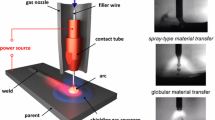

Gas metal arc welding (GMAW) of aluminium, high alloyed steel or titanium requires a shielding gas cover in order to provide preferably low parts per million concentration of oxygen at the joint. Consequently, it is necessary to be able to describe and to analyse the flow of shielding gas. The paper presents numerical and diagnostic investigations concerning the shielding gas flow in gas metal arc welding. Therefore, a numerical model and several diagnostic methods have been developed. The model used is based on ANSYS CFX and includes the effects of magneto hydrodynamic, turbulence and diffusion depending on temperature. The model is verified by Particle Image Velocimetry, Schlieren-technique, and gauging the oxygen concentration. Advantages and disadvantages of these particular methods and the potential of their combined application to analyse welding processes and torch design are shown. The methods introduced were used for the precise analysis of the shielding gas flow and the construction of torches in GMAW. The formation of turbulence by actual concepts of gas distributors and the advantages of optimised and innovative torch constructions are demonstrated. Furthermore the interaction between the process and the shielding gas flow is described and the explicit dependency of the gas cover based on the current profile employed (pulse welding) is visualised. Based on these results, the way in which different gas nozzles influence the shielding gas flow and what happens if the position of the torch or the type of joint changes is explained. In summary, the paper details the profound physical correlations between the construction of the torch and the shielding gas cover as well giving concrete advice for users of the GMAW processes.

Similar content being viewed by others

References

Baum L, Fichter V (1999) Der Schutzgasschweißer, Teil II, MIG/MAG-Schweißen. Leitfaden für Ausbildung und Praxis (GMAW, part II, MIG/MAG-welding. Guidelines for training and practice) DVS, Düsseldorf. ISBN 3-87155-539-8

Dilthey U (2006) Schweißtechnische Fertigungsverfahren–Band 1–Schweiß- und Schneidtechnologien (welding processes–part I–welding and cutting technologies). 3. Auflage. Springer, Berlin. ISBN 3-540-21673-1

GSI SLV Halle (2008) Lehrunterlagen zur Ausbildung zum Internationalen Schweißfachingenieur SFI, EWE, IWE nach DVS®-IIW. (Teaching materials for training on the international welding engineer SFI, EWE, IWE in relation to DVS®-IIW) 1170, Halle

Zschetzsche J (2007) Diagnostik von Schutzgas-schweißprozessen. (Diagnostics of gas-shielded welding processes.). Dissertation, Technische Universität Dresden. der Wissenschaften, Dresden

Füssel U, Zschetzsche J, Zosel J, Guth U (2005) Strömungsmessung in Lichtbogen- und plasmaprozessen (Flow measurement in arc and plasma processes.). Stiftung Industrieforschung, Forschungsvorhaben S 559, Abschlussbericht

Settles GS (2006) Schlieren and shadowgraph techniques. Springer, New York

Zobel TW (1936) Erhöhung der Schneidgeschwindiekeit beim Brennschneiden durch neue Düsenformen. (Increasing the cutting speed for flame cutting by new nozzle designs.). VDI, Berlin

Settles GS (1998) Visualization of liquid metal, arc and jet interactions in plasma cutting of steel sheat. 8th International Symposium on Flow Visualization

Kim J, Heberlein J, Lindsay J, Peters J (2010) Methods to evaluate arc stability in plasma arc cutting torches. J. Phys D Appl Phys. doi:10.1088/0022-3727/43/50/505202

Garcia G, McClure JC, Hou H, Nunes AC. Gas flow observation during VPPA welding using a shadowgraph technique. NASA-CR-204347

Möller F (2009) Visualization of gas flows for research and industry use. Bremer Institut für Angewandte Strahltechnik. In: BIAS Bulletin (2009)01, Bremen, p 2

Fuentes Munoz JE (2011) Einfluss der Brennergestaltung auf den WIG-Lichtbogen. (Influence of torch design on the TIG arc.), Dissertation, Dresdner Fügetechnische Berichte, Band 22/2011, ISBN 978-3-942710-41-1, Dresden

Lowke JJ, Morrow R, Haidar J (1997) A simplified unified theory of arcs and their electrodes. J Phys D Appl Phys 30(1997):2033–2042

Wendelstorf J (2000) Ab initio modeling of thermal plasma gas discharges (electric arcs)., Dissertation Technische Universität Carolo-Wilhelmina zu Braunschweig, Braunschweig

Gleize A, Gonzales JJ, Freton P (2005) Thermal plasma modeling (topical review). J Phys D Appl Phys 38(2005):R153–R183

Wang F, Hou WK, Hu SJ, Kannatey-Asibu E, Schultz WW, Wang PC (2003) Modelling and analysis of metal transfer in gas metal arc welding. J Phys D Appl Phys 36(2003):1143–1152

Schnick M, FÜssel U, Hertel M, Haessler M, Spille-Kohoff A, Murphy AB (2010) Modelling of gas-metal arc welding taking into account metal vapour. J Phys D Appl Phys 43:434008

Cooper P, Godbole A, Norrish J (2007) Modeling and simulation of gas flows in arc welding—implications for shielding efficiency and fume ex-traction. Proc. on the 60th Annual Assembly of the International Institute of Welding, Dubrovnik (Croatia)

Abicor-Binzel. parts catalogue MIG/MAG welding 2.0/V1. http://www.binzel.de. Accessed 8 Feb 2012

EWM Hightec Welding GmbH. MIG/MAG Schweißbrenner-MT-Serie (MIG/MAG welding torches -MT-series). http://www.ewm-group.com. Accessed 8 Feb 2012

Dinse GmbH. BLACKline Handschweißsysteme (BLACKline hand Torches). http://www.dinse-gmbh.com. Accessed 8 Feb 2012

TBi Industries. Classic-TBi 240 (DR)-MIG/MAG-Handschweißbrenner (classic-TBi 240 (DR)-MIG/MAG hand torches). http://www.tbi-industries.com. Accessed 8 Feb 2012

Bürkner, C. MIG/MAG Schweißbrenner. (MIG/MAG welding torch.), patent DE10314278B4

Kraus W, Gauter E. Einrichtung zur Erzielung eines homogenen Gasstroms beim Schutzgasschweißen. (Facility to obtain a homogeneous gas flow in arc welding.), paten DD133537A1

Schnick M (2010) Numerische und experimentelle Verfahrens- und Brennerentwicklung beim Plas-malichtbogenschweißen (Numerical and diagnostic torch and process development in plasma-cutting). Dissertation, Technische Universität Dresden. der Wissenschaften, Dresden

Hertel M, Schnick M, Füssel U, Gorchakov S, Uhrlandt D (2010) Numerical simulation of GMAW processes including effects of metal vapour and sheath mechanisms at the electrodes. Magneto-hydrodynamics 46(4):363–370

Murphy AB (1995) Transport coefficients of air, argon-air, nitrogen-air, and oxygen-air plasmas. Plasma Chem Plasma Process 15(2):279–307

Acknowledgments

The presented results are part of the AiF promoted research project “Strömungstechnische Auslegung von Brennersystemen zum wirtschaftlichen und emissionsreduzierten Lichtbogenschweißen (Design of Welding Torches for Efficient and Emission Reduced Arc Welding Using Fluid Mechanics)” (DVS-Nr.: 03.090 / IGF-Nr.: 15.871BR).

Author information

Authors and Affiliations

Corresponding author

Additional information

Doc. IIW-2355, recommended for publication by Commission XII “Arc Welding Processes and Production Systems”.

Rights and permissions

About this article

Cite this article

Dreher, M., Füssel, U., Rose, S. et al. Methods and results concerning the shielding gas flow in GMAW. Weld World 57, 391–410 (2013). https://doi.org/10.1007/s40194-013-0038-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-013-0038-2