Abstract

Circularity has emerged as a pivotal concept in the realm of sustainable resource management and business operations. Resource exhaustion and environmental degradation propelled by globalization and the culture of consumerism have intensified the focus on the concept of the circular economy around the world. Nevertheless, the evaluation and quantification of circularity achievements remain uncommon in corporate practices. This article employs a systematic literature review to delve into circularity measurements in the managerial life cycle. Key approaches emerging from the academic literature are examined, including life cycle costing, life cycle assessment, life cycle cost–benefit, life cycle benefit analysis, and life cycle sustainability assessment. The review seeks to offer a comprehensive overview of the methodologies employed to assess circularity in corporate processes, highlighting current challenges and opportunities for effective implementation. We adopt a conceptual model of sustainable and circular life cycle management based on specific performance indicators that allow the environmental, social, and economic impact of processes to be assessed throughout the life cycle of products or services. The implementation of Sustainable and Circular Life Cycle Management from a managerial perspective could support firms to eradicate and quantify waste, preserve the inherent value of products and materials, encourage the adoption of renewable energies, and eliminate harmful chemicals.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

As the world grapples with the urgent need to measure sustainability, flexible systems are emerging as promising approaches to resource optimisation and circularity (Sushil & Dinesh, 2022). In particular, the flexibility issue has become central to the flexible management system (D’Adamo et al., 2024), mainly in the last 2 years in the manufacturing industry (Tootell et al., 2023) and in sustainable business development (Litvinova et al., 2023). By embracing adaptability and responsiveness, these systems could effectively manage the flow of materials, energy, and information throughout their lifespan, minimizing waste and maximizing resource utilization (Singh et al., 2023). Harnessing the power of flexibility in Life Cycle Management (LCM) offers a transformative path towards a more sustainable future (Sushil, 2015). LCM encompasses the entire life cycle of a product, from its design and production to its use, maintenance, end-of-life treatment, and recycling. By integrating flexibility into each stage of LCM, businesses and organizations can unlock a wealth of opportunities to reduce their environmental footprint and promote sustainable practices. Considering this transformative scenario, the primary goal of the European Green Deal is to achieve climate neutrality by 2050. This plan focuses on identifying leading companies in the field of green technologies and products while simultaneously stimulating the development of new markets for products that promote recycling and have a climate-neutral impact. The central objective is to develop an economy based on circularity, with a particular focus on biodiversity conservation and the creation of an equitable and socially just transition process. Europe has positioned itself as a leader in both the industrial and political spheres to drive global change. Moreover, according to Saidani et al. (2022), elevating the degree of circularity within the economy enhances the chances of attaining the Sustainable Development Goals (SDGs) outlined by the United Nations (UN, 2015), especially in terms of responsible production and consumption (SDG 12). The need to promote such change arises from the evidence in the Global Resources Outlook 2019 (Oberle et al., 2019) that global annual resource extraction tripled from 1970 to 2017 and continues to rise. Resource extraction and transformation account for more than 90% of both biodiversity loss and water imbalances (UNEP IRP, 2019), and despite the circular economy (CE) action plan initiated by the European Commission in 2015, a mere 12% of the materials utilised by industries within the European Union are sourced from recycling. Full implementation of circular processes has only been applied to nine per cent of the global economy, leaving ample room for improvement. Over the last decade, the notion of a CE has garnered increased interest from governments, businesses, researchers, and politicians and has been perceived as a fundamental step towards achieving sustainable development (Corona et al., 2019). Globally, the circular economy is recognized for its ability to promote resource efficiency (Ellen MacArthur Foundation, 2015). Through practices such as reuse, recycling, and regeneration, it maximizes the value of products and materials, reducing waste and contributing to mitigating climate change (European Environment Agency, 2020). In the European context, the circular economy is gaining prominence as a key strategy for achieving sustainability goals. The European Union has developed ambitious plans, such as the Circular Economy Action Plan, to transition towards a more circular economy (European Commission, 2020). This includes measures to promote eco-design, resource efficiency, and waste reduction across member states. Italy, with its rich cultural and industrial heritage, is well-positioned to embrace the principles of the circular economy. Key sectors such as fashion, automotive, and furniture can benefit from adopting circular practices, improving resource efficiency, and reducing production costs (Pozzo, 2021). The Italian government has also recognized the importance of the circular economy through policies such as the National Strategy for the Circular Economy, providing a strategic framework for transitioning towards a more sustainable and resource-efficient economy (Italian Ministry of Economic Development, 2017). For Italian businesses, embracing the circular economy offers tangible benefits. Besides the economic savings resulting from resource efficiency and waste reduction, there are also opportunities for market differentiation and brand reputation enhancement (Carlisle & Faulkner, 2005). Furthermore, innovation in product design and sustainable business models (Basile et al., 2021a, 2021b) can create new business opportunities (Boston Consulting Group, 2019). The circular economy represents a significant opportunity to promote sustainability and economic prosperity, both globally, within Europe, and in the Italian context. Businesses that adopt circular economy principles can benefit from cost savings, market differentiation opportunities, and regulatory compliance, positioning themselves for long-term success in an increasingly circular economy (PricewaterhouseCoopers, 2021). While there are numerous accredited definitions of the CE, and despite the introduction of the concept many decades ago, a specific definition and conceptual framework remain subjects of ongoing debate and uncertainty, as highlighted by Reike et al. (2018). In a recent literature review (Kirchherr et al., 2017), 114 interpretations of the CE were identified from various sources, including peer-reviewed articles, policy papers, and consulting reports. As the World Economic Forum argues, “The circular economy is a model of economic development that aims to rethink how we create economic value. Instead of a “take, make, dispose” philosophy, it promotes a “take, make, reuse, repair, recycle” perspective” (World Economic Forum, 2014). In addition, the European Commission explains that “The circular economy focuses on waste reduction, material reuse, and recycling, as well as the regeneration of natural systems. This results in economic and environmental benefits, such as increased competitiveness and supply chain security, greater economic resilience to shocks, and a reduction in greenhouse gas emissions and pollution” (European Commission, 2015).

The most widely recognized definition of the CE was formulated by the Ellen MacArthur Foundation (2013): “A circular economy is a regenerative system in which materials and resources retain their value and utility for as long as possible, and waste and resource usage is minimized. It involves the extraction of materials, production, use, and regeneration, aiming to keep products, components, and materials at their highest value and utility at every stage of their lifecycle”. The measurement of circularity is important in managerial disciplines because it is connected to several fundamental dimensions of the success of organizations and businesses. Circularity involves the adoption of practices and business models focused on diminishing environmental impact, promoting resource efficiency, preventing waste, and emphasizing the value of reuse and recycling. In other words, circular management aims to create a more sustainable and long-term economy. The measuring of circularity helps companies identify and monitor their environmental impact. With a better understanding of how resources are used and managed, organizations can reduce pollution, waste production, and natural resource depletion. The adoption of circular practices can lead to a more efficient use of resources, thereby reducing operational costs. For example, reusing and recycling can decrease the need to purchase new raw materials, thereby contributing to cost savings. Companies distinguished by their circular management can gain a competitive advantage, as consumers and business partners are increasingly attentive to sustainability and prefer to do business with environmentally responsible organizations. Companies adopting circular business models tend to be more resilient to fluctuations in raw material prices and environmental shocks, as they have a greater capacity to adapt to resource-related challenges. This work aims to examine, through a systematic literature review, the various approaches proposed so far to investigate the measurement of circularity in the managerial life cycle. Furthermore, it aims to provide guidelines for defining the dimensions and variables to consider in the development of a comprehensive methodology to measure and evaluate the degree of circularity of a system throughout its life cycle. The article is structured as follows: Sect. "Method and research model" describes the research methodology and criteria employed to analyse documents related to performance assessment in the context of the CE. Section "Measuring circularity in life cycle management" presents the results of the review, highlighting the approaches that have been presented thus far as well as the differences and similarities in these specific fields. Section "Results" first discusses the limitations of the various approaches and highlights the theoretical implications for performance evaluation in the CE. Finally, Sect. "Theoretical implications" concludes the contribution, presenting the main observations and outlining future research suggestions.

Circularity and Life Cycle Management for Flexible Firms

Measuring circularity in LCM is crucial to fostering flexibility and enhancing an organisation’s ability to adapt to changing market demands and environmental conditions (Saidani et al., 2017). By tracking key circularity metrics (CMs), such as material reuse rates, the proportion of waste diversion, and energy efficiency, organizations can gain valuable insights into their resource consumption patterns and identify areas for improvement (Corona et al., 2019). This information empowers decision-makers to make informed choices about product design, manufacturing processes, and waste management strategies, enabling them to transition towards more circular business models. Specifically, circularity measurement helps organisations:

Reduce Material Dependency (Gebhardt et al., 2022). By quantifying the materials that are used and reused, organizations can identify specific areas where they can decrease their dependence on virgin resources, thus minimizing their environmental footprint. This flexibility allows them to adapt to fluctuations in resource availability and cost, ensuring a secure and sustainable supply chain.

Improve Waste Management Efficiency (Kurdve et al., 2015). Tracking waste generation and diversion rates provides organizations with actionable data to optimize their waste management practices, enabling them to pinpoint the most effective waste reduction and recycling strategies, thereby diminishing the volume of waste directed to landfills and redirecting resources back into the production cycle. This flexibility enhances their ability to comply with environmental regulations and demonstrate their commitment to sustainable practices.

Enhance Energy Efficiency (Halkos & Petrou, 2019). Evaluating energy consumption and efficiency metrics allows organisations to identify opportunities to reduce their energy footprint and lower operating costs. This adaptability allows them to shift towards renewable energy sources, diminishing their dependence on fossil fuels and contributing to a more sustainable and cleaner environment.

Promote Innovation and Collaboration (Köhler et al., 2022). Measuring circularity sparks innovation and collaboration within organizations. By understanding their resource flows and inefficiencies, they can develop new products, processes, and partnerships to improve circularity.

Flexible firms foster a culture of continuous improvement and drive the development of cutting-edge circular solutions (Srivastava & Bag, 2023; Volberda, 1999). To conclude, assessing circularity in LCM serves as a potent tool for fostering flexibility and empowering organizations to flourish in a dynamic and resource-constrained environment. By tracking key metrics, organizations gain the insights they need to optimize resource use, reduce waste, enhance energy efficiency, and promote innovation. This flexibility empowers them to adapt to evolving market trends, environmental challenges, and regulatory changes, ensuring their long-term sustainability and success.

Method and Research Model

To analyse the most important ways to measure circularity in Life Cycle Assessment (LCA) and summarize the findings to date (Hellweg et al., 2014), a systematic literature review was performed on scientific articles related to the measurement of circularity in LCM. The review was carried out with scientific articles collected from the academic search engine Scopus based on a selection of keywords. The choice of keywords was based on our aim to examine tools developed and used mainly in the European context; consequently, we searched for various methods based on the life cycle thinking approach to which these tools belong. The keywords were created by combining the word “measurement” without the final “t” and, instead, using an asterisk “measurement*” with the keyword circularity, followed by five of the most well-known types of LCA:

-

LCC = Life cycle costing

-

LCA = Life cycle assessment

-

LCCB = Life cycle cost–benefit

-

LCBA = Life cycle benefit analysis

-

LCSA = Life cycle sustainability assessment

The results from the five combinations were collected without considering limitations related to the document type, time, and field content. To maintain an inclusive approach and leverage the diversity of the knowledge base, we initially guided the relevant criteria based on the formulation of the research question by specifically considering the study context. The review resulted in the selection of 164 articles for a total of five keywords. To provide an accurate analysis, for each list of articles, we selected those articles that were much more meaningful for the scope of the study. Table 1 shows the number of scientific articles collected and selected for analysis.

The relevant column indicates the number of papers subsequently selected for this literature analysis. The selection process began with choices based on titles, abstracts, and keywords, followed by a second screening of entire manuscripts. One hundred sixty-four articles were selected, and by the second screening, they were divided based on the five keywords, as illustrated in Table 1.

Measuring Circularity in Life Cycle Management

Numerous strategies have been suggested for the shift from a linear to a circular economy, with the primary implementation carried out by industrial actors. These strategies are based on concepts such as sustainability and ecological design to optimize the use of energy and materials as well as the adoption of approaches defined within the hierarchy of the “three Rs” (reduce, reuse, recycle, and sometimes eleven additional related strategies). Other initiatives include business model innovation and the promotion of industrial symbiosis. Typically, the impacts or benefits resulting from these circular strategies are assessed using circularity indicators (Corona et al., 2019; Reich et al., 2023). Circularity metrics (CMs) are intended to offer insight into the degree to which the CE principle is implemented in a product or service. Nevertheless, many of the circularity measurements that have been made available to the public have faced criticism. They are seen as inadequate in capturing the holistic and interdisciplinary essence of the CE, as highlighted by Saidani et al. (2017) and tend to focus solely on gauging the closure of material cycles. Consequently, these methodologies frequently neglect the various characteristics of circular processes, such as their length, and they fail to address the comprehensive sustainability performance encompassing environmental, economic, and social aspects (Corona et al., 2019).

There is a heated debate on the best methodologies for assessing the level of the CE. Nevertheless, a complete shared framework about the right assessment methodology remains wanting. There are several methods for measuring circularity in managerial disciplines. Often, metrics and indicators show discrepancies in both their form and meaning (Corona et al., 2019). Moreover, due to the complexity of the CE concept, its evaluation gives rise to various interpretations (Saidani et al., 2019). Consequently, different classifications have been proposed for circularity indicators (Corona et al., 2019; Elia et al., 2017; Sassanelli et al., 2019). For an overview of the most frequently used methods to measure the level of circularity, we chose to report the results of a literature review by Corona et al. (2019), which revealed a recent increase in the number of publications related to measuring the level of circularity. Most of these articles (48 of 72) were related to the evaluation of products and services, and half of them were related to the analysis and assessment of existing methodologies, such as LCA or material flow analysis. These metrics aim to assess an organization’s performance in adopting circular practices and its contribution to the CE. Corona et al. (2019) provide an analysis of the most known and utilized methods, as illustrated in Fig. 1.

Source: Corona et al. (2019)

Classification of circularity metrics

Circularity assessments can be performed at the micro, meso, and macro levels. Circularity indicators serve as tools to gauge the capacity of a product or system to preserve both the quantity and quality of materials (Bracquené et al., 2020). These tools can also be employed to assess how efficiently a company transitions from a linear to a circular model. At the product level, indicators prove valuable for designing new products, internal documentation, and establishing sourcing targets. At the company level, indicators can be used internally to compare different product lines or monitor progress. Furthermore, they can be used externally to evaluate the degree of circularity between companies (Rigamonti & Mancini, 2021). Within this myriad of measures, LCA plays a pivotal role. A thorough evaluation of the environmental sustainability of a production system requires the integration of indicators that address complementary aspects, including the material circularity and performance derived from eco-efficiency. For instance, indicators found in LCA can contribute to this comprehensive assessment. As expressed by Weidema et al. (2008), using indicators based on LCA is essential in sectors correlated with a carbon footprint, integrating indicators related to material efficiency, or the end-of-life management of products. In the following literature review, we clarify the well-known methods in the literature to measure circularity in LCM (Guillaume et al., 2023). The criteria for inclusion in the research mainly concerned the analysis of existing parameters used to measure circularity. The review therefore focused on the criteria used to qualitatively measure CE strategies in products and services. Also included are parameters for monitoring frameworks and those applied in regional, national, or global contexts. The inclusion of the methods studied depended on the fact that more than 70% of scientific publications dealt with them in the last 5 years (Corona et al., 2019). The parameters considered primarily fulfilled the requirements of validity, indicating the extent to which a metric measured its intended purpose; reliability, signifying the metric’s capability for consistency; and utility, addressing the metric’s practicality. Therefore, to be able to maintain inclusivity in the selection of articles, the contributions selected for the systemic review provided theoretical as well as contextual views on aspects of circularity (Corona et al., 2019). All articles that dealt with the topic in a generic form were excluded from the research; therefore, other measurement criteria in these articles were not considered, as they were outdated and rarely used in the European context in recent years. Further, other criteria used once by small- and medium-sized companies in Europe were not considered (Corona et al., 2019; Kravchenko et al., 2020).

Life Cycle Assessment

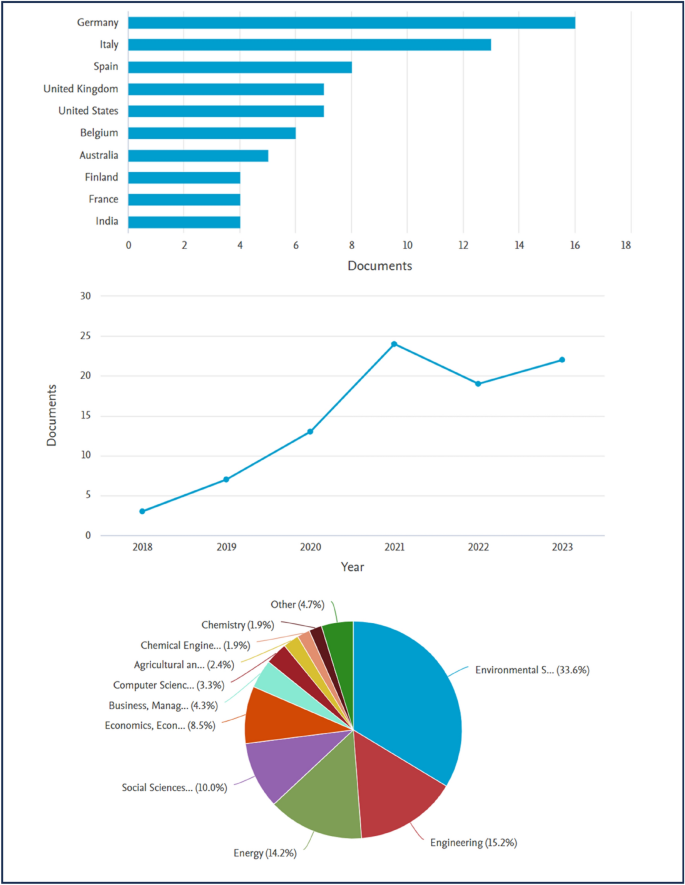

Sassanelli et al., (2019) identified the Life Cycle Assessment (LCA) standardized by ISO 14040/44:2006 as the most commonly used tool for assessing the environmental consequences of EC. However, even though today the focus is on environmental and economic aspects, the social dimension as the third pillar of sustainability cannot be overlooked in the context of a holistic sustainability assessment (Arodudu et al., 2017; Rodriguez, et al., 2020). LCA is a thorough, internationally standardized (ISO 14040-14044, 2006) method. It assesses the environmental impact of a product or service across its life cycle and encompasses stages from raw material extraction to disposal or recycling. LCA can help identify opportunities for circular improvements in product design and material selection. The concept of LCA was proposed for the first time in the 1960s and has proven highly valuable for comparing alternative approaches and understanding trade-offs between the advantages and consequences of various systems, thus enabling the formulation of well-informed choices (Li et al., 2023; Saidani et al., 2019). Life Cycle Assessment (LCA) is a crucial scientific methodological tool used to assess the environmental impacts of materials. However, its effectiveness in evaluating material circularity is hindered by several challenges, such as the lack of practical application in the design and development phase, challenges with system boundaries and impact allocation, the inability to assess the social implications of materials, and biases and inconsistencies in the results (Antwi-Afari et al., 2023). The literature review on the LCA method was carried out using the keywords “measure* AND Circularity AND Life Cycle Assessment” in the academic search engine Scopus. The search resulted in 86 scientific articles on this topic from 2018 to date. However, based on the scope of this work, 14 scientific articles were selected from the total. Table 2 reports on the authors, title, year of publication, and publisher of each of the selected items.

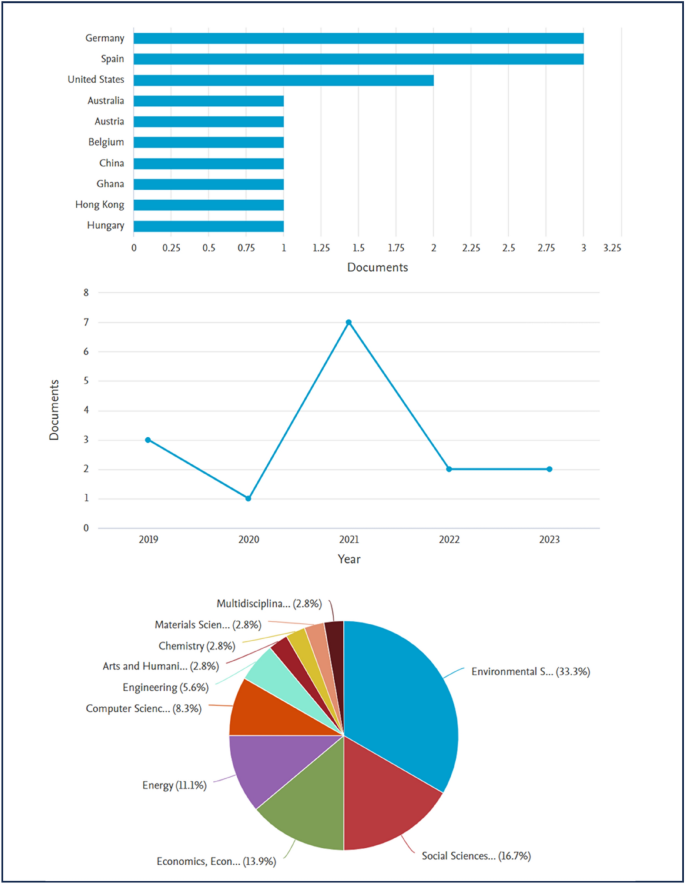

Figure 2 in appendix shows the number of papers and their territories of origin. One can observe that 16 of the 86 articles originated from Germany. This was followed by Italy (13 articles), then Spain (8 publications). Importantly, no filter was entered regarding the year of publication, and the search engine naturally returned articles from 2018. It can be noted that the number of publications on this topic has been on the rise from 2018 to date. Figure 2 shows that a majority of the published works were related to environmental sustainability and that all three aspects of sustainable development were featured, though not in a detailed manner. This potentially indicates that a majority of the methods employed for assessing circularity lacked multifunctionality and did not integrate economic and social aspects, in addition to environmental considerations. As stated in a document on the life cycle initiative (Peña et al., 2021), the LCA methodology is valuable in identifying strategies that can improve production and consumption patterns from a CE perspective, thus enhancing sustainability. According to Rigamonti and Mancini (2021), there are various circularity indicators, each designed to evaluate circularity at the micro-, meso-, or macro-level. This includes evaluations at the individual product level, material quality, a company’s circularity, or comparisons among multiple companies. LCA can be employed to provide a systemic perspective on decision-making processes (Peña et al., 2021) or in the construction of a CE strategy from scratch. However, the latter argued that LCA alone cannot comprehensively measure circularity because its considerations are rooted in a linear economy, initially designed to assess products within a birth-to-death cycle. Only later were principles developed to evaluate reuse or refurbishment. Nevertheless, as we will explore further, LCA remains one of the most widely used methods for selecting the best CE strategy, especially due to its primary objective of avoiding burden shifting (Corona et al., 2019; Sassanelli et al., 2019). It is essential to note that some studies examining the relationship between circularity indicators and LCA (Bracquené et al., 2020; Pauer et al., 2019) have argued that the best choice of circularity may not always be environmentally preferable; therefore, separate evaluations have been used to avoid conflicting results. In other cases, such as Niero and Kalbar (2019), attempts have been made to reconcile potential discrepancies between certain circularity indicators and LCA results by considering them in an integrated manner. Niero and Kalbar (2019) underscored the pivotal role of the LCA tool as a metric for assessing the CE at the product level. Through a case study on beer packaging, they illustrated that when comparing contrasting situations, a successful approach can involve combining different types of indicators using multi-criteria analysis. In this scenario, they integrated material circularity indicators with LCA indicators through the application of multi-criteria analysis. Corona et al. (2019) conducted a review aimed at describing developments related to the methodologies used for circularity metrics for products or services. The review sought to evaluate the most commonly used metrics, starting from the concept of the CE and closely linked to that of sustainable development. Based on the selected criteria, none of the circularity parameters addressed all of them, but LCA and its indicators proved to be the most suitable because they have a high potential for meeting all the selected CE requirements in their classical application, that is, at the product or service level. Nevertheless, there is still ongoing work to extend the application of these assessments from the product or service level to the macro level. According to Sassanelli et al. (2019), LCA is among the most commonly used methodologies for measuring levels of circularity, both about materials and resources and energy and pollution. LCA tends to consider all the variables involved throughout the life cycle, from development to disposal. The 45 selected scientific articles in the literature review indicate a growing interest in CE topics, especially from 2015 onwards. However, a lack of methodologies was identified regarding a comprehensive evaluation of the potential benefits of adopting CE practices. There is also a challenge in navigating different, sometimes conflicting methodologies that may influence various levels of analysis, ranging from environmental, which is more prevalent, to social and economic considerations. Vimal et al. (2021) also conducted a literature review focused on the available toolkits for circularity assessment. They argued that there is a minimal presence of industrial-level circularity assessment studies and that there is currently no straightforward method in the existing literature that comprehensively and systematically assesses circularity. This model has a three-level structure. The initial level encompasses five circularity enablers, followed by the second level with 16 circularity criteria. The third level is made up of 44 circularity attributes. The model has successfully been applied to a case study. Hatzfeld et al. (2022) acknowledged that accurately measuring circularity is a complex challenge and that there are limitations in the currently available metrics. Consequently, they proposed a new conceptual perspective to address this difficulty, suggesting that circularity ought to be interpreted in terms of how long a product or service maintains its functionality throughout its use time. In other words, rather than exclusively focusing on the material life cycle, the authors proposed evaluating how long a product or service can remain effectively functional before becoming obsolete or requiring replacement. This approach allows for the examination of new circularity indicators that go beyond simple material recycling measurements. For example, factors such as product lifespan, ease of repair, upgradeability, and component reuse could be considered. This way, a more comprehensive view of circularity can be captured by focusing on the extended longevity and positive contribution of products to the CE. In summary, the authors introduced a new concept that views circularity as the ability of a product or service to maintain its functionality over time, prompting a reflection on new circularity indicators that surpass the limitations of traditional metrics based solely on material LCA. Kravchenko et al. (2020) examined the relationship between CE indicators and sustainability, focusing in particular on the use of LCA as the main tool for assessing circularity. They evaluated how well these indicators truly reflect overall sustainability and highlighted that the implementation of practices related to the CE often aims to reduce environmental impacts but may not fully consider all aspects of sustainability, such as those of a social and economic nature. Additionally, we noted that some circularity metrics may focus primarily on the amount of material recycled or the closure of material loops, overlooking broader aspects of sustainability. Overall, Kravchenko et al. (2020) questioned the degree to which CE indicators comprehensively and accurately reflect sustainability in all of its dimensions. We suggest that a more comprehensive assessment may require the integration of additional indicators or approaches to capture a more complete and global view of sustainability in the CE context. For example, Harris et al. (2021) conducted a scoping review of the methodologies used to evaluate environmental performance in the CE. They explored how the environmental performance of CE practices was measured and evaluated and focused on the fact that adopting circular strategies, such as recycling and reusing materials, should lead to effective and sustainable environmental improvements. Their findings suggest that there is limited research comparing circularity indicators with environmental performance or studies establishing connections between circularity indicators at different societal levels, such as the micro- and macro-levels. LCA is generally considered the most reliable method for assessing the environmental impacts of product designs based on circular principles or system changes. Studies based on LCA have explored an extensive array of products encompassing diverse practices associated with the CE. These practices include recycling, product life extension, reuse, regeneration, and “product-as-a-service” systems. At the micro-level, LCA is the primary method of environmental assessment used to examine the specific environmental impacts of various circular approaches. However, it is important to note that few studies have analysed the correlation between circularity indicators or tools and environmental implications through the use of LCA. This literature review has underscored a scarcity of studies in the CE field that have compared circularity indicators with environmental implications or those establishing connections across different system levels. At the micro-level, LCA has a long history of environmental assessment across a wide range of products, but further research is needed to compare linear products with their circular counterparts to fully understand the environmental impact of such approaches. Matos et al. (2023) conducted a comparative analysis of micro-level indicators for evaluating progress towards the CE. They evaluated the performance of companies or organizations relating to the adoption of CE practices at the micro-level. This work, starting from the categorization provided by Kristensen and Mosgaard (2020), sought to determine which indicators are most effective in analysing and measuring progress towards the CE at the company level. The results showed an imbalance between indicators focusing on environmental or economic (rather than social) dimensions. In particular, the indicators included more than one dimension exclusively for end-of-life management or remanufacturing. Moreover, a major portion of the micro-indicators outlined in the literature for evaluating product circularity concentrated primarily on the recycling, refurbishment, and end-of-life management categories, with a notable emphasis on recycling. The indicators in the recycling category were predominantly (though not exclusively) quantitative, most of which focused on a single dimension, especially the environmental dimension. Roos Lindgreen et al. (2021) investigated the efficacy of “grey literature indicators” and LCA in evaluating the CE at the micro-level and sought to understand which method offered a more complete and accurate evaluation. The overall results indicate that grey literature provides various approaches for companies to assess their progress toward the CE. However, specific CE indicators may not always be suitable, especially when the analysis focuses on specific sectors, particularly those involving biological cycles. Nevertheless, the LCA method is capable of covering the key features of a corporate-level CE metric and is suitable for assessing a wide range of environmental impacts, including product circularity. However, it is important to consider that LCA is more complex, requires more detailed data, and is more time-consuming than CE indicators, which may pose challenges when applied at the corporate level. Gallo et al. (2023) focused on the integration of various approaches: a metric for the CE and LCA. They proposed an interaction that correlated circularity and environmental impacts. To achieve this, they conducted a comparison of various case studies to assess and evaluate the applicability of these approaches as effective tools for environmental–circular product assessments. The aim was to determine whether the application of circular principles could lead to improvements or exacerbations in the environmental impacts of products. This methodology established the phases and procedures for assessing the circularity of agri-food products by employing circular indicators and integrating the results into an LCA. The article showed that the enhanced benefit of utilizing a material circularity indicator and LCA in the integrated methodology outlined in the study lay in its capacity to facilitate a thorough and all-encompassing evaluation. This approach introduced an inventive circular assessment that encompassed both biological and technical cycles, along with an environmental assessment panel for products, which encompassed associated scenarios, all within the same product category. Therefore, the integration of CE metrics with LCA can offer a more complete view of the environmental performance of agri-food products. This can help drive more sustainable decisions and choices in the food supply chain.

Life Cycle Sustainability Assessment

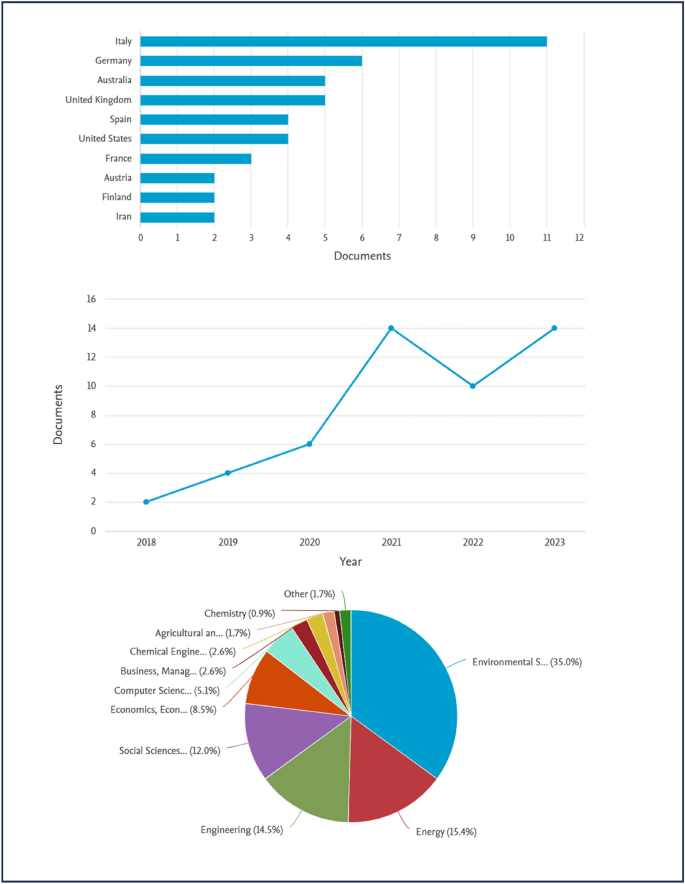

The Life Cycle Sustainability Assessment (LCSA) is a method designed to holistically evaluate the environmental, economic, and social aspects of a specific product, process, or system throughout its life cycle. Unlike traditional assessments, such as LCA, which focus mainly on environmental impacts or economic aspects, the LCSA also seeks to incorporate social dimensions and analyse how these three spheres interact with each other (Finkbeiner et al., 2010). The motivation behind the development of the LCSA lies in the awareness of the limitations of traditional assessments, which often do not adequately take social and economic aspects into account. Therefore, the objective of the LCSA is to offer a more complete and integrated vision of sustainability by considering the interrelationships between the environment, economy, and society (Peña et al., 2021). The LCSA is composed as follows: LCSA = LCA + LCC + S − LCA, where LCC plus S-LCA refer, respectively, to life cycle costing plus social life cycle assessment (Luthin et al., 2023). The literature review related to the LCSA was carried out using the keywords “measure* AND Circularity AND Life Cycle Sustainability Assessment” in the academic search engine Scopus. The search revealed 48 relevant scientific articles from 2018 to date. From the 48 scientific articles, 14 were selected based on the scope of this work, seven of which were considered in the previous section. Table 3 reports on the authors, title, year of publication, and publisher of each of the selected items.

Figure 3 in appendix shows the number of papers and their territories of origin. It shows that Italy had the most publications (11 articles), followed by Germany with six publications. No filter was entered regarding the year of publication, and the search engine naturally returned articles from 2018. It can also be noted that the number of publications on this topic has been on the rise from 2018 to date. Figure 3 also shows that most of the published works were related to environmental sustainability. All three aspects related to sustainable development were addressed, albeit not explicitly. Researchers have recently shown increased interest in methodological issues, specifically focused on identifying opportunities to integrate LCA with circularity assessment methodologies. This approach seeks to harness the potential of both methods to drive ecological transition (Peña et al., 2021). Pagotto et al. (2021) analysed the sustainability of production in a feedlot (fattening shed) in Australia using the LCSA framework. The main objective of the article was to provide a holistic assessment of feedlot sustainability in Australia, thus enabling stakeholders, such as meat producers and government authorities, to make more informed decisions about managing and improving the feedlot production practice. Stillitano et al. (2022) attempted to overcome the complexity surrounding circularity with an approach that includes social and environmental aspects in the LCA. This model was implemented in the olive oil sector to address the challenges associated with managing numerous by-products. The study introduced a multi-cycle approach for the comprehensive evaluation of a product’s environmental, economic, and social aspects. It considered the environmental LCA in terms of costs (external and internal) and the social LCA in terms of validating the impact on the agro-industrial system relating to the management of by-products. Abadi and Sammuneh (2020) developed a conceptual framework and indicators aimed at analysing “circularity” within the life cycle of an object or process. This concept is closely linked to the CE, which promotes waste reduction and the efficient reuse of resources. The scope of the article was to combine two research ambitions—CE and constructability—through the creation of an evaluation tool designed to measure the degree of circularity associated with construction projects and processes. Within the context of LCA, the authors engaged in the development of new indicators and measurement methods that allowed them to assess the extent to which a project or construction process was aligned with the principles and fundamentals of the CE. This involved looking into aspects such as recycling of materials, extending the useful life of products, reusing components, and other practices that promote circularity within the life cycle of construction projects.

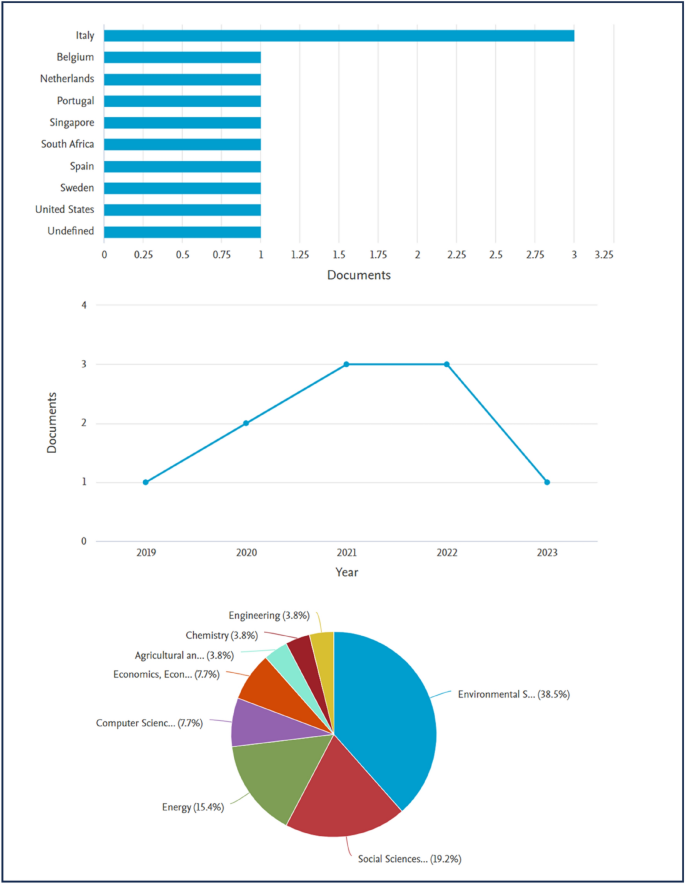

Life Cycle Costing

LCC is an analytical method utilized to assess the complete range of costs linked to a particular product or system throughout its life cycle. This life cycle begins with its design and production, continues through daily usage and maintenance, and concludes with its disposal or the end of its utility. The principal objective of LCC is to offer a comprehensive view of costs, enabling more informed and sustainability-oriented decision-making (Hunkeler et al., 2008). The literature review on LCC was carried out using the keywords “measure* AND Circularity AND Life Cycle Costing” in the academic search engine Scopus. The search revealed 10 scientific articles on this topic from 2018 to date. From these 10 scientific articles, six were selected based on the scope of this work, seven of which were addressed and collected in the Table 4.

Figure 4 in appendix shows the number of papers and their territories of origin. It shows that Italy was the primary publication country (with 3 articles), followed by Belgium with 1 publication. No filter was entered regarding the year of publication, and the search engine naturally returned articles from 2018. Figure 4 also shows that, in this case, most of the published works were related to environmental sustainability. All three aspects related to sustainable development were present, albeit not in a detailed manner. Kambanou and Sakao (2020) provided a guideline based on LCC to guide companies on the best choice to implement a CE and evaluate profitability. This guideline was formulated using design research methodology, as outlined by Blessing and Chakrabarti (2009). The LCC method was chosen because of its simplicity, including for Small and Medium Enterprises (SMEs), and it is inexpensive. This paper drew from various case studies, all advocating that LCC is pertinent for decision-making about circularity. It highlighted two primary areas where LCC could offer crucial information: financial and environmental perspectives. Mehta et al. (2023) provided an Internet-based sustainability assessment model known as BEVSIM, which was developed to assess the ecological, circular, and economic performance of various elements of electric vehicles batteries and internal combustion vehicles, including materials, subsystems, parts, and individual components. The tool enables the measurement and comparison of impacts related to different recycling technologies, end-of-life scenarios, and future scenarios resulting from changes in the composition of the energy network. BEVSIM could include different LCA models, and the level of analysis is customizable. The tool was designed to assess different design alternatives in the R&D phase to evaluate the complete LCA, LCC, and the level of circularity of a product. LCC analysis can be viewed from two angles: the first concerns the consumer’s point of view and involves the costs related to the purchase of the vehicle, its use, and maintenance, together with the associated costs at the end of life. The second perspective is that of the manufacturer and includes costs related to design and production (including materials, processes, and assembly), distribution costs, and costs arising during the use of the vehicle, such as recall costs. Braakman et al. (2021) sought to increase circularity in the building sector and correlated the level of circularity (LoC) of a single house with its LCC. They demonstrated that it is possible to double the LoC in this sector without increasing the LCC or modifying the design project. The data highlighted a relatively modest increase in initial costs for some circular building projects compared to the reference context. Furthermore, the results illustrated a significant 11% reduction in operating costs for circular building designs compared to traditional building designs. Falcone et al. (2022) considered LCC in its environmental meaning, called environmental LCC (ELCC). They proposed a methodology based on different LC methods and circularity indicators to consider the environmental and economic impacts of agri-food production systems, in particular, to evaluate sustainability in the olive oil sector. They compared linear and circular production types and found that the environmental impact of the circular production type was very low compared with the linear type. At the economic level, the circular pathway demonstrated lower production costs, thanks to the reuse of various under-products.

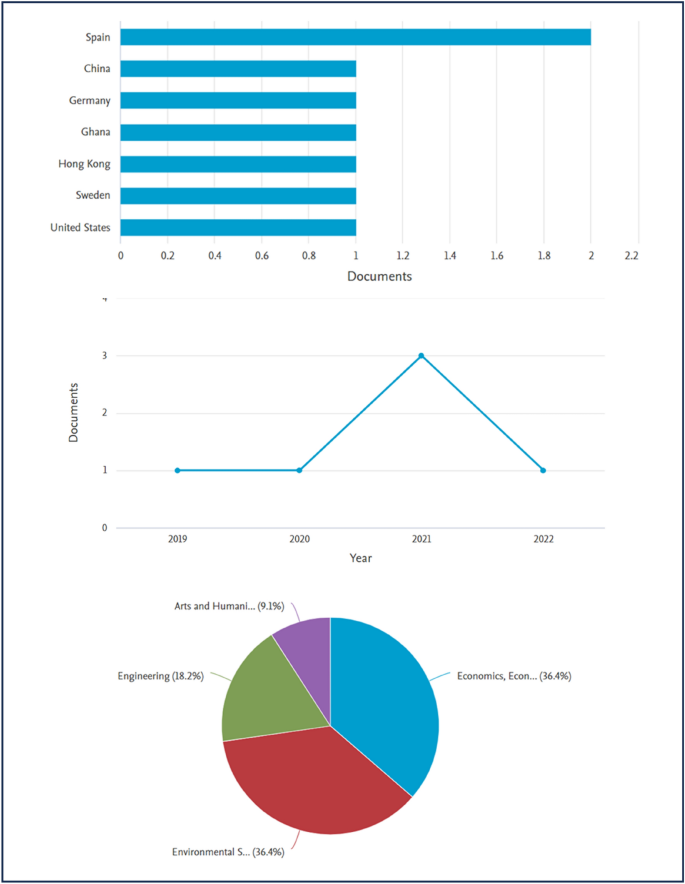

Life Cycle Cost–Benefit (LCCB) and Life Cycle Benefit Analysis (LCBA)

The Life Cycle Cost–Benefit Analysis (LC-CBA) is an analytical approach that focuses on evaluating the costs and benefits associated with a project, product, or system throughout its life cycle. In practical terms, it represents an evolution of the LCC concept, as it also integrates an analysis of the benefits deriving from an action or investment (Boardman, 2008). The Life Cycle Benefit Analysis (LCBA) is an evaluation methodology that aims to measure and quantify the benefits obtained from a product, service, or project during the life cycle, from the production phase to the use and end of use. This approach, in line with LCC analysis, considers a wide range of factors but places greater emphasis on benefits rather than costs. In the LCBA context, benefits can take many forms, such as economic, environmental, social, and health-related. For example, when evaluating an electric car, benefits could include fuel cost savings, a reduction in greenhouse gas emissions, improved air quality, and reduced noise pollution (Cabeza & Castell, 2019). The literature review related to the LCCB analysis was carried out using the keywords “measure* AND Circularity AND Life Cycle Cost–Benefit” and Circularity AND Life Cycle Benefit analysis” in the academic search engine Scopus. The search revealed 21 scientific articles on this topic from 2018 to date. Eight of these articles were selected based on the scope of this work, seven of which were examined and collected in the Table 5.

Figures 5 and 6 in appendix report on the number of papers and their territories of origin. They show that Spain and Germany were the primary publication countries (5 articles in total). Furthermore, no filter was entered regarding the year of publication, and the search engine naturally returned articles from 2019. Figures 5 and 6 also show that most of the published works were related to environmental sustainability except for the LCCB indicator. All three aspects related to sustainable development were present, though not in a detailed manner. Sommer et al. (2022) conducted a study on plastic and glass management and devised a decision support tool using mathematical optimization to systematically analyse the influence of political regulations on the design of essential treatment infrastructures. Because regular evaluations were not adapted to these types of analyses, the authors conducted a study using LCCB analysis to consider the relation between the costs and benefits of these types of infrastructures. González et al. (2021) introduced a pioneering methodology for assessing the LoC in building construction and renovation, recognized as one of the most costly and impactful economic activities. The methodology was developed with an approach that considers the entire life cycle, incorporating all material flows into the analysis and considering the social, environmental, and economic impacts from the beginning to the end of the cycle, that is, from the acquisition of resources to the treatment processes or disposal at the end of their useful life. Jones et al. (2022) developed automated software to assess the unsustainability of the LCA for buildings. Through case studies, they sought to demonstrate how sustainability education can be improved through LCBA. The analysis focused on quantifying developmental gains within the safe operating space of planetary boundaries. The advantage of LCBA lies in its systematic quantification of positive development, enabling the comprehensive reporting of essential gains and losses in sustainable market investments.

Results

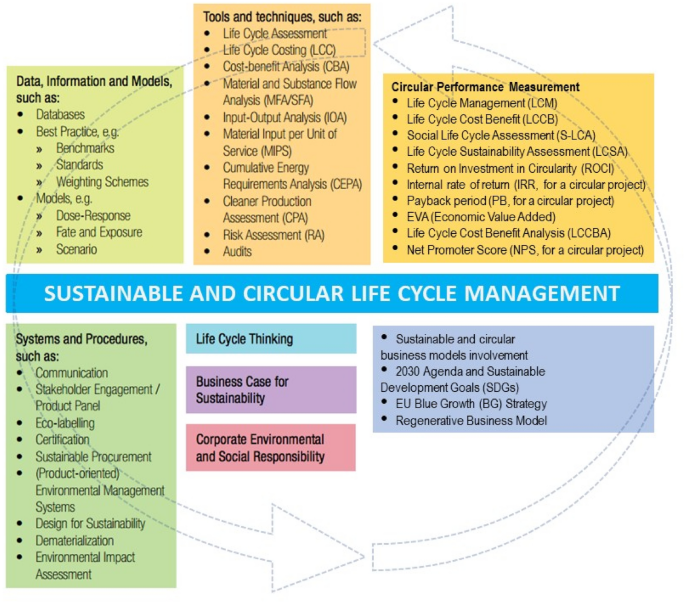

The ultimate aim of measuring company processes in terms of sustainability is to offer a holistic tool for measuring corporate sustainability and circularity, that is, the conceptual model of sustainable and circular life cycle management (SC-LCM) in Fig. 7, constructed based on the adoption of specific performance indicators. The environmental, social, and economic impacts of processes were assessed throughout the life cycle of products or services, as described by Basile et al., (2021a, 2021b).

Below are some key aspects of measuring business processes using SC-LCM:

Environmental Impact Indicators: In assessing the environmental impact of business processes, indicators such as greenhouse gas emissions, energy consumption, water resource utilization, waste generation, and air pollution are employed. These indicators offer a quantitative measure of the environmental impacts of business processes, enabling the identification of areas that necessitate improvements.

Social Impact Indicators: Sustainability concerns not only pertain to the environment but also to social aspects. Therefore, when measuring company processes in terms of sustainability, social impact indicators are also considered. These may include workplace safety, human resource management, protection of workers’ rights, impact on the local community, and commitment to corporate social responsibility.

Economic Impact Indicators: Sustainability cannot be separated from economics. The measurement of business processes in terms of sustainability through SC-LCM also includes the analysis of economic impacts. Economic indicators can include responsible financial management, shared value creation, sustainable innovation, and financial resource efficiency.

Life Cycle Assessment: A fundamental aspect of measuring company processes through SC-LCM is the application of LCA, which enables the evaluation of environmental impacts associated with all phases of the life cycle of products or services. LCA provides a holistic perspective to identify environmental impact hotspots across the life cycle and drive business process optimization. Measuring business processes in terms of sustainability using SC-LCM requires the use of specific indicators, accurate and reliable data, and a long-term commitment to continuous improvement. Measurement results can be used to inform business decisions, monitor progress towards sustainability goals, and communicate transparently to internal and external stakeholders. An SC-LCM framework is built on the following pillars:

-

a.

Data, information and models

-

b.

Tools and techniques

-

c.

LCCB analysis and asset integrity management

-

d.

System and procedures

-

e.

Life cycle thinking, the business case for sustainability

-

f.

Corporate environmental and social responsibility

-

g.

Sustainable and circular business model

Theoretical Implications

Transitioning to a CE holds immense importance in the contemporary world for a variety of compelling reasons and offers a multitude of advantages to enterprises. As the global population expands and the demand for resources escalates, conventional linear economies (extract, produce, discard) exhaust finite resources at an unsustainable pace. The CE seeks to curtail resource consumption and reduce waste generation, advocating for more sustainable resource utilization. Linear economies generate vast quantities of waste and pollutants, contributing to environmental challenges, such as climate change and loss of biodiversity (Lizundia et al., 2022). In contrast, the CE emphasizes diminishing environmental repercussions through practices such as recycling, reusing, and regenerating materials and products. Shifting towards a CE can yield significant contributions in curtailing greenhouse gas emissions. Employing resources with greater efficiency and harnessing renewable energy sources can play a crucial role in the battle against climate change. CEs have the potential to bolster economic resilience by diminishing reliance on volatile raw materials and fortifying supply chains via local sourcing and recycling initiatives (Vegter et al., 2023). This work aimed to examine, through a systematic literature review, the various approaches proposed so far to investigate the measurements of circularity in the managerial life cycle. Overall, it recognizes the potential of LCA as a decision-support tool for assessing the effects of CE strategies on the environment but highlights that this potential has not yet been fully exploited. Another crucial point to consider is the need to combine measurements to obtain a complete assessment of circularity. As indicated by Rigamonti and Mancini (2021), relying solely on circularity indicators may not be sufficient for a comprehensive assessment of the environmental performance of circular strategies. Therefore, a study utilizing circularity indicators should be complemented by an LCA to ascertain whether the adoption of a circular system can result in an improvement in environmental performance. Similarly, LCA studies focusing on products or services that incorporate CE elements (e.g. increased recycled content, enhanced recyclability, improved recycling efficiency, extended life cycle, or greater opportunities to reuse the product or its components) can benefit from evaluations of the circularity of the system. Thus, there is a need to establish a shared approach within the scientific community to integrate sustainability aspects into CE initiatives, providing guidelines for the implementation and interpretation of results from collaborative studies based on LCA and circularity.

Managerial Implications

Measuring circularity in LCM could bring several managerial implications, impacting different aspects of a business innovation. Measuring circularity in LCM could have several managerial implications, impacting different aspects of a business innovation. In strategic decision-making, by improving resource efficiency (Namany et al., 2019), circularity metrics (CMs) can be looped back into the system, reducing dependence on virgin materials and minimizing waste. This latter impacts strategies for product design, sourcing, and manufacturing processes (Lin & Zhou, 2011). Moreover, data on circularity help track progress towards sustainability goals and identify areas for improvement. This can allow managers to demonstrate environmental responsibility and potentially unlock access to sustainable markets (Heikkurinen & Bonnedahl, 2013). In product development and design, measuring circularity encourages designing products for easier disassembly and material recovery at the end-of-life stage. Besides, product lifespan, CMs can reveal opportunities to extend product lifespan through repairs, upgrades, or remanufacturing (Linder et al., 2017). This can improve customer satisfaction and brand image. Regarding supply chain management, in supplier selection, CMs can be used to evaluate suppliers based on their circular practices, promoting responsible sourcing and potentially reducing supply chain risks (Govindan & Hasanagic, 2018). Thus, measurement encourages collaboration between different departments (design, procurement, operations) to optimize the product life cycle for circularity. Concerning marketing and sales, by improving transparency and credibility, data on circularity allow companies to communicate their commitment to resource efficiency and sustainability to customers, potentially enhancing brand image. Lastly in product differentiation, items with high CMs can be marketed as environmentally responsible choices, attracting eco-conscious consumers (Gao & Souza, 2022). Currently, there is no universally accepted (standardization) method for measuring circularity. This can make comparisons between firms difficult. Implementing circularity measurement requires collecting data across the entire life cycle, which can be complex and resource-intensive. Transitioning to circular practices might require upfront investments. Measuring circularity could help managers assess the long-term cost benefits of resource efficiency (Konash & Nasr, 2022). Overall, measuring circularity in life cycle management provides valuable insights that can inform strategic decision-making across different functions within a company. Fostering a more sustainable approach to business can lead to competitive advantages in the long run.

Policymakers Implications

LCM can impact policymakers by developing effective, evidence-based policies (De Marchi et al., 2016). Circularity metrics provide data to assess the effectiveness of existing policies aimed at reducing waste and promoting resource conservation. This allows policymakers to make data-driven adjustments and target specific areas in the life cycle (Plevin et al., 2014). Data on circularity can inform the design of new policies that incentivize or mandate circular practices. This could include Extended Producer Responsibility (EPR) schemes that hold manufacturers accountable for the end-of-life management of their products (Park et al., 2018). Moreover, governments could introduce tax breaks or subsidies for businesses adopting circular design principles and take-back programs. The final aim should be to promote investment in recycling infrastructure and research into new circular technologies. Furthermore, policymakers can encourage or even mandate standardized methods for measuring circularity (Tecchio et al., 2017). This allows for better comparisons between companies and industries, facilitating progress tracking. By requiring firms to report on CMs, policymakers can promote transparency and hold businesses accountable for their environmental impact (Dagiliene et al., 2020). This empowers consumers to make informed choices. Lastly, policymakers need to ensure access to reliable and comparable circularity data from businesses. This might involve establishing reporting requirements or collaborating with industry bodies. Ideally, circularity measurement should be standardized on a global scale to facilitate international comparisons and collaboration. Ren and Albrecht (2023) stated that introducing mandatory circularity measurement could impose an administrative burden on businesses, particularly small and medium enterprises (SMEs). Policymakers need to consider this and potentially offer support or simplified reporting structures. Therefore, measuring circularity in life cycle management equips policymakers with valuable data to design and monitor effective policies that promote a more circular economy. According to Lim et al. (2018), this approach can contribute to achieving broader sustainability goals like resource conservation and waste reduction.

Limitations and Future Research Directions

First and foremost, we report the limitations related to the methodological approach adopted for this literature review. First, for some of the proposed indicators, the number of articles was limited or irrelevant. Furthermore, the analysis was conducted using only the Scopus search engine; therefore, further analysis could include searches of other well-known databases. Moreover, the choice of indicators influenced our analysis and narrowed the number of available publications. Finally, all keywords were used with only one combination of words, which likely limited the search results. Moreover, as contended by Saidani et al. (2022), performing an LCA is frequently a complex and expert-level undertaking. Communicating the results also demands a certain level of expertise or support from environmental experts. Data collection and compilation (life cycle inventory) can be time-consuming and costly. Additionally, LCA does not facilitate the swift identification of critical points or improvement scenarios and does not enable straightforward decision-making in environmental trade-offs. As indicated by Corona et al. (2019), LCA is frequently utilized as an assessment tool at the product level. However, it can be extended to a macro-level approach when employed to inform decisions regarding national policies or sectoral strategies related to technologies, services, or groups of products. Nevertheless, it is important to emphasize that LCA is not a suitable tool for evaluating the overall performance of the economy. In this review, it emerged that most parameters were still far from representing the benefits of various circularity measurement options. There will be a challenge in measuring CE goals across all dimensions of sustainability to fill in the coming years. Even for established tools such as the LCA, there is no universal agreement on how to address the complexity of certain measurements. As proposed by Niero and Kalbar (2019) and Corona et al. (2022), a metric for assessing the degree of circularity to gauge the contribution of circular strategies to sustainability should be comprehensive. It should avoid merely shifting issues from reduced material consumption to increased environmental, economic, or social impacts. The next metrics should indicate how recycling benefits are distributed among recyclers and users of recycled materials and should measure the increase in value through enhanced product utility and the assessment of added economic value. Therefore, the future of measuring circularity in LCM is expected to be more sophisticated, data-driven, and holistic, considering these advancements: Standardized Frameworks and Metrics (Kühnen & Hahn, 2017); Integration with LCA (Life Cycle Assessment) (França et al., 2021); Digitalization and Big Data (Li et al., 2015; Xin & Ojanen, 2017); Focus on Cascading and Design for Longevity (Ortiz-de-Montellano et al., 2023); Blockchain for Transparency and Traceability (Leng et al., 2020); Consumer-centric Measurement; Policy and Regulation (Farooque et al., 2020; Watts et al., 2022).

Conclusions

Circularity indicators, taken individually, are not sufficient for carrying out an overall evaluation of circular strategies. Therefore, for a study to be able to verify whether circularity leads to an improvement in environmental performance, it must be supported by an LCA. However, a complete analysis is quite complex, as it requires specific skills and the use of important tools. At the same time, the interpretation and subsequent communication of the results could also be difficult. It is clear that the strong environmental pressures and effects on the ecosystem represent an urgency and push professionals to continuously improve production and consumption systems (Rigamonti & Mancini, 2021). The scientific community must, therefore, develop a model that is shared by all, one that is capable of integrating aspects of sustainability into all CE initiatives and establishing guidelines for the implementation and interpretation of the results of scientific studies (Rigamonti & Mancini, 2021). Furthermore, the adoption of a circularity tool in life cycle measurement could be useful for flexible management by improving the dynamic resource management system (D’Adamo et al., 2023).

References

Abadi, M., Moore, D. R., & Sammuneh, M. A. (2021). A framework of indicators to measure project circularity in construction circular economy. Proceedings of the Institution of Civil Engineers-Management, Procurement and Law, 175(2), 54–66.

Abadi, M., & Sammuneh, M. A. (2020). Integrating circular economy and constructability research: An initial development of a lifecycle ‘circularity’assessment framework and indicators. Management, 516, 525.

Antwi-Afari, P., Ng, S. T., Chen, J., Oluleye, B. I., Antwi-Afari, M. F., & Ababio, B. K. (2023). Enhancing life cycle assessment for circular economy measurement of different case scenarios of modular steel slab. Building and Environment, 239, 110411. https://doi.org/10.1016/j.buildenv.2023.110411

Arodudu, O., Helming, K., Wiggering, H., & Voinov, A. (2017). Towards a more holistic sustainability assessment framework for agro-bioenergy systems—A review. Environmental Impact Assessment Review, 62, 61–75. https://doi.org/10.1016/j.eiar.2016.07.008

Basile, V., Capobianco, N., Loia, F., & Vona, R., (2021). Sustainable Decommissioning of Offshore Platforms: A Proposal of Life-Cycle Cost-Benefit Analysis in Italian Oil and Gas Industry. In: Arts for Business Institute, Proceedings IFKAD 2021 Conference. ISBN: 978–88–96687–14–7.

Basile, V., Capobianco, N., & Vona, R. (2021b). The usefulness of sustainable business models: Analysis from oil and gas industry. Corporate Social Responsibility and Environmental Management, 28(6), 1801–1821. https://doi.org/10.1002/csr.2153

Blessing, L. T., & Chakrabarti, A. (2009). DRM: A design reseach methodology (pp. 13-42). Springer, London

Boardman, A. E. (2008). Cost benefit analysis. Pearson Education.

Boston Consulting Group. (2019). BCG report. The Most Innovative Companies 2019: The Rise of AI, Platforms, and Ecosystems. March 21, 2019. https://www.bcg.com/publications/2019/most-innovative-companies-innovation.

Braakman, L., Bhochhibhoya, S., & de Graaf, R. (2021). Exploring the relationship between the level of circularity and the life cycle costs of a one-family house. Resources, Conservation and Recycling, 164, 105149. https://doi.org/10.1016/j.resconrec.2020.105149

Bracquené, E., Dewulf, W., & Duflou, J. R. (2020). Measuring the performance of more circular complex product supply chains. Resources, Conservation and Recycling, 154, 104608. https://doi.org/10.1016/j.resconrec.2019.104608

Cabeza, L. F., & Castell, A. (2019). Life cycle assessment (LCA) and life cycle energy analysis (LCEA) of buildings and the building sector: A review. Renewable and Sustainable Energy Reviews, 23, 426–435. https://doi.org/10.1016/j.rser.2013.08.037

Carlisle, Y. M., & Faulkner, D. O. (2005). The strategy of reputation. Strategic Change, 14(8), 413–422.

Corona, B., Hoefnagels, R., Gürsel, I. V., Moretti, C., van Veen, M., & Junginger, M. (2022). Metrics for minimising environmental impacts while maximising circularity in biobased products: The case of lignin-based asphalt. Journal of Cleaner Production, 379, 134829. https://doi.org/10.1016/j.jclepro.2022.134829

Corona, B., Shen, L., Reike, D., Carreón, J. R., & Worrell, E. (2019). Towards sustainable development through the circular economy–A review and critical assessment on current circularity metrics. Resources, Conservation and Recycling, 151, 104498.

D’Adamo, I., Favari, D., Gastaldi, M., & Kirchherr, J. (2024). Towards circular economy indicators: Evidence from the European Union. Waste Management & Research, 0734242X241237171.

D’Adamo, I., Gastaldi, M., Piccioni, J., & Rosa, P. (2023). The role of automotive flexibility in supporting the diffusion of sustainable mobility initiatives: A stakeholder attitudes assessment. Global Journal of Flexible Systems Management, 24(3), 459–481. https://doi.org/10.1007/s40171-023-00349-w

Dagiliene, L., Frendzel, M., Sutiene, K., & Wnuk-Pel, T. (2020). Wise managers think about circular economy, wiser report and analyze it. Research of environmental reporting practices in EU manufacturing companies. Journal of Cleaner Production, 274, 121968. https://doi.org/10.1016/j.jclepro.2020.121968

De Marchi, G., Lucertini, G., & Tsoukiàs, A. (2016). From evidence-based policy making to policy analytics. Annals of Operations Research, 236(1), 15–38. https://doi.org/10.1007/s10479-014-1578-6

De Oliveira, C. T., & Oliveira, G. G. A. (2023). What Circular economy indicators really measure? An overview of circular economy principles and sustainable development goals. Resources, Conservation and Recycling, 190, 106850. https://doi.org/10.1016/j.resconrec.2022.106850

Elia, V., Gnoni, M. G., & Tornese, F. (2017). Measuring circular economy strategies through index methods: A critical analysis. Journal of Cleaner Production, 142, 2741–2751. https://doi.org/10.1016/j.jclepro.2016.10.196

Ellen MacArthur Foundation. (2013). Towards the Circular Economy. Disponibile in: https://www.aquafil.com/assets/uploads/ellen-macarthur-foundation.pdf, ult. cons. 18/07/2023.

Ellen MacArthur Foundation. (2015). Towards a Circular Economy: Business rationale for an accelerated transition. Disponibile in: https://www.werktrends.nl/app/uploads/2015/06/Rapport_McKinsey-Towards_A_Circular_Economy.pdf, ult. cons. 05/07/2023.

European Commission. (2015). Closing the loop - An EU action plan for the Circular Economy. Disponibile in: https://www.werktrends.nl/app/uploads/2015/06/Rapport_McKinsey-Towards_A_Circular_Economy.pdf, ult. cons. 05/07/2023.

European Commission. (2015). Closing the loop - An EU action plan for the Circular Economy. Disponibile in: https://eur-lex.europa.eu/resource.html?uri=cellar:8a8ef5e8-99a0-11e5-b3b7-01aa75ed71a1.0012.02/DOC_1&format=PDF, ult. cons. 13/09/2023.

European Commission. (2017). Measuring circular economy - Harmonized framework and indicators. Disponibile in: https://onlinelibrary.wiley.com/doi/full/10.1111/jiec.12809, ult. cons. 07/07/2023.

European Environment Agency. (2020). The European environment: State and Outlook 2020. Office for Official Publ. of the European Communities, Published 11 May 2020. https://www.eea.europa.eu/soer/2020.

European Commission. (2020). A strategy for smart, sustainable and inclusive growth. Brussels, 3.3.2010 COM(2010) 2020. https://ec.europa.eu/eu2020/pdf/COMPLET%20EN%20BARROSO%20%20%20007%20-%20Europe%202020%20-%20EN%20version.pdf.

Falcone, G., Stillitano, T., Iofrida, N., Spada, E., Bernardi, B., Gulisano, G., & De Luca, A. I. (2022). Life cycle and circularity metrics to measure the sustainability of closed-loop agri-food pathways. Frontiers in Sustainable Food Systems, 6, 1014228. https://doi.org/10.3389/fsufs.2022.1014228

Farooque, M., Jain, V., Zhang, A., & Li, Z. (2020). Fuzzy DEMATEL analysis of barriers to Blockchain-based life cycle assessment in China. Computers & Industrial Engineering, 147, 106684. https://doi.org/10.1016/j.cie.2020.106684

Finkbeiner, M., Schau, E. M., Lehmann, A., & Traverso, M. (2010). Towards life cycle sustainability assessment. Sustainability, 2(10), 3309–3322. https://doi.org/10.3390/su2103309

França, W. T., Barros, M. V., Salvador, R., de Francisco, A. C., Moreira, M. T., & Piekarski, C. M. (2021). Integrating life cycle assessment and life cycle cost: A review of environmental-economic studies. The International Journal of Life Cycle Assessment, 26, 244–274. https://doi.org/10.1007/s11367-020-01857-y

Gallo, F., Manzardo, A., Camana, D., Fedele, A., & Scipioni, A. (2023). Integration of a circular economy metric with life cycle assessment: methodological proposal of compared agri-food products. The International Journal of Life Cycle Assessment, 1–21. https://doi.org/10.1007/s11367-022-02130-0.

Gao, F., & Souza, G. C. (2022). Carbon offsetting with eco-conscious consumers. Management Science, 68(11), 7879–7897. https://doi.org/10.1287/mnsc.2021.4293

Gebhardt, M., Spieske, A., & Birkel, H. (2022). The future of the circular economy and its effect on supply chain dependencies: Empirical evidence from a Delphi study. Transportation Research Part e: Logistics and Transportation Review, 157, 102570. https://doi.org/10.1016/j.tre.2021.102570

González, A., Sendra, C., Herena, A., Rosquillas, M., & Vaz, D. (2021). Methodology to assess the circularity in building construction and refurbishment activities. Resources, Conservation & Recycling Advances, 12, 200051. https://doi.org/10.1016/j.rcradv.2021.200051

Govindan, K., & Hasanagic, M. (2018). A systematic review on drivers, barriers, and practices towards circular economy: A supply chain perspective. International Journal of Production Research, 56(1–2), 278–311. https://doi.org/10.1080/00207543.2017.1402141

Guillaume, A., Appels, L., & Kočí, V. (2023). Life cycle assessment of municipal biowaste management-a Czech case study. Journal of Environmental Management, 339, 117894. https://doi.org/10.1016/j.jenvman.2023.117894

Halkos, G., & Petrou, K. N. (2019). Analysing the energy efficiency of EU member states: The potential of energy recovery from waste in the circular economy. Energies, 12(19), 3718. https://doi.org/10.3390/en12193718

Harris, S., Martin, M., & Diener, D. (2021). Circularity for circularity’s sake? Scoping review of assessment methods for environmental performance in the circular economy. Sustainable Production and Consumption, 26, 172–186. https://doi.org/10.1016/j.spc.2020.09.018

Hatzfeld, T., Backes, J. G., Guenther, E., & Traverso, M. (2022). Modeling circularity as functionality over use-time to reflect on circularity indicator challenges and identify new indicators for the circular economy. Journal of Cleaner Production, 379, 134797. https://doi.org/10.1016/j.jclepro.2022.134797

Heikkurinen, P., & Bonnedahl, K. J. (2013). Corporate responsibility for sustainable development: A review and conceptual comparison of market-and stakeholder-oriented strategies. Journal of Cleaner Production, 43, 191–198. https://doi.org/10.1016/j.jclepro.2012.12.021

Hellweg, S., & Milà I Canals, L. (2014). Emerging approaches, challenges and opportunities in life cycle assessment. Science, 344(6188), 1109–1113. https://doi.org/10.1126/science.1248361

Hunkeler, D., Lichtenvort, K., & Rebitzer, G. (2008). Environmental life cycle costing. Crc press

Italian Ministry of Economic Development. (2017). Towards a Model of Circular Economy for Italy Overview and Strategic Framework. Publication Date November, 2017. https://circulareconomy.europa.eu/platform/sites/default/files/strategy_-_towards_a_model_eng_completo_0.pdf.

Jones, D., Vlieg, M., Ashar, S., Friend, L., & Gomez, C. C. (2022). Learning to quantify positive futures. International Journal of Environmental Impacts, 5(2), 128–145. https://doi.org/10.2495/EI-V5-N2-128-145

Kambanou, M. L., & Sakao, T. (2020). Using life cycle costing (LCC) to select circular measures: A discussion and practical approach. Resources, Conservation and Recycling, 155, 104650. https://doi.org/10.1016/j.resconrec.2019.104650

Kirchherr, J., Reike, D., & Hekkert, M. (2017). Conceptualizing the circular economy: An analysis of 114 definitions. Resources, Conservation, and Recycling, 127, 221–232. https://doi.org/10.1016/j.resconrec.2017.09.005

Köhler, J., Sönnichsen, S. D., & Beske-Jansen, P. (2022). Towards a collaboration framework for circular economy: The role of dynamic capabilities and open innovation. Business Strategy and the Environment, 31(6), 2700–2713. https://doi.org/10.1002/bse.3000

Konash, A., & Nasr, N. (2022). The circular economy and resource use reduction: A case study of long-term resource efficiency measures in a medium manufacturing company. Cleaner Production Letters, 3, 100025.

Kravchenko, M., McAloone, T. C., & Pigosso, D. C. (2020). To what extent do circular economy indicators capture sustainability? Procedia CIRP, 90, 31–36.

Kristensen, H. S., & Mosgaard, M. A. (2020). A review of micro level indicators for a circular economy–moving away from the three dimensions of sustainability? Journal of Cleaner Production, 243, 118531. https://doi.org/10.1016/j.jclepro.2019.118531

Kühnen, M., & Hahn, R. (2017). Indicators in social life cycle assessment: A review of frameworks, theories, and empirical experience. Journal of Industrial Ecology, 21(6), 1547–1565. https://doi.org/10.1111/jiec.12663

Kurdve, M., Shahbazi, S., Wendin, M., Bengtsson, C., & Wiktorsson, M. (2015). Waste flow mapping to improve sustainability of waste management: A case study approach. Journal of Cleaner Production, 98, 304–315. https://doi.org/10.1016/j.jclepro.2014.06.076

Leng, J., Ruan, G., Jiang, P., Xu, K., Liu, Q., Zhou, X., & Liu, C. (2020). Blockchain-empowered sustainable manufacturing and product lifecycle management in industry 4.0: A survey. Renewable and Sustainable Energy Reviews, 132, 110112. https://doi.org/10.1016/j.rser.2020.110112

Li, J., Tao, F., Cheng, Y., & Zhao, L. (2015). Big data in product lifecycle management. The International Journal of Advanced Manufacturing Technology, 81, 667–684. https://doi.org/10.1007/s00170-015-7151-x

Li, Y., Zhang, Z., Wang, Q., Long, X., Cao, Y., Yang, H., & Yang, Q. (2023). The nitrogen and carbon footprints of ammonia synthesis in China based on life cycle assessment. Journal of Environmental Management, 345, 118848. https://doi.org/10.1016/j.jenvman.2023.118848

Lim, M. M., Jørgensen, P. S., & Wyborn, C. A. (2018). Reframing the sustainable development goals to achieve sustainable development in the Anthropocene—a systems approach. Ecology and Society, 23(3). https://doi.org/10.5751/ES-10182-230322.

Lin, Y., & Zhou, L. (2011). The impacts of product design changes on supply chain risk: A case study. International Journal of Physical Distribution & Logistics Management, 41(2), 162–186. https://doi.org/10.1108/09600031111118549

Linder, M., Sarasini, S., & van Loon, P. (2017). A metric for quantifying product-level circularity. Journal of Industrial Ecology, 21(3), 545–558. https://doi.org/10.1111/jiec.12552

Litvinova, T. N., Abdusalomova, N. B., Dugina, T. A., & Denisov, I. V. (2023). Change management based on smart technologies for sustainable business development. Global Journal of Flexible Systems Management, 1–14. https://doi.org/10.1007/s40171-023-00355-y