Abstract

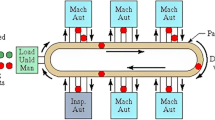

Determining key variables, which an organization can opt to initiate resource recovery from return activities with a motive to improve overall performance is a challenge. Therefore, this paper provides a multi-objective decision model using interpretive structural modeling(ISM) based approach to enrich and initiate flexible product recovery activities in an organization. Variables such as supplier commitment, cost, regulations etc. have been identified and categorized under enablers& variables such as capacity utilization, customer satisfaction, energy consumption reduction etc. under results. These enablers help to boost the performance variables, while results variables represent outcomes. Finally, this paper interprets Product Recovery System (PRS) variables in terms of their driving and dependence powers that have been carried out.

Similar content being viewed by others

References

Anonymous. (2004). Soft systems methodology. http://sern.ucalgary.ca/bowen/613/report/.

Beamon, B. M. (2005). Environmental and sustainability ethics in supply chain management. Science and Engineering Ethics, 11, 221–234.

Bonney, M., Ratchev, S., & Moualek, I. (2003). The changing relationship between production and inventory examined in a concurrent engineering context. Journal of International Economics, 81–82, 243–254.

Callahan, J. S., Dunne, R. A., & Stanaback, S. (1997). New Jersey county dismantles recycling and emissions problems. World Wastes, 40, 7–8.

Carter, C. R., & Ellram, L. M. (1998). Reverse logistics: A review of the literature and framework for future investigation. Journal of Business Logistics, 19(1), 85–102.

Chung, C.-J., & Wee, H.-M. (2008). Green-component life-cycle value on design and reverse manufacturing in semi-closed supply chain. International Journal of Production Economics, 113, 528–545.

Diabat, A., & Kannan, G. (2011). An analysis of the drivers affecting the implementation of green supply chain. Management Resources, Conservation and Recycling, 55, 659–667.

Fleischmann, M., Beullens, P., Bloemhof-Ruwaard, J. M., & van Wassenhove, L. N. (2001). The impact of product recovery on logistics network design. Production and Operations Management, 10(2), 156–173.

Georgiadis, P., & Vlachos, D. (2004). The effect of environmental parameters on product recovery. European Journal of Operational Research, 157, 449–464.

Georgiadis, P., & Vlachos, D. (2009). The effect of environmental parameters on product recovery. Greece: Department of Mechanical Engineering, Aristoteles University of Thessaloniki.

Green, K., Morton, B., & New, S. (1998). Green purchasing and supply policies: do they improve companies’ environmental performance? Supply Chain Management: An International Journal, 3(2), 89–95.

Hall, J. (2000). Environmental supply chain dynamics. Journal of Cleaner Production, 8(6), 455–471.

Ilgin, A., & Gupta, S. M. (2010). Environmentally conscious manufacturing and product recovery (ECMPRO):A review of the state of the art. Journal of Environmental Management, 91, 563–591.

Kannan, G., Haq, A. N., Kumar, P. S., & Arunachalam, S. (2008). Analysis and selection of green suppliers using interpretative structural modeling and analytic hierarchy process. International Journal of Management and Decision Making, 9(2), 163–182.

Klausne, M., & Wolfgang, M. G. (1999). Integrating product take back and technical service. In Proceedings from the IEEE international symposium on electronics and the environment, pp. 48–53.

Kudva, N. (1996). Uneasy partnership, government NGO relations in India. Working paper 673. Berkeley, CA: Institute of Urban and Regional Development.

Lippmann, S. (1999). Supply chain environmental management: elements of success. Corporate Environmental Strategy, 6(2), 175–182.

Malone, D. (1975). An introduction to the application of interpretive structural modeling. Proceedings of the Institute of Electrical and Electronics Engineers, 63, 397–404.

Olugu, E. U., & Wong, K. Y. (2009). Supply chain performance evaluation: trends and challenges. American Journal of Engineering and Applied Sciences, 2(1), 202–211.

Paulraj, A. (2009). Environmental motivations: a classification scheme and its impact on environmental strategies and practices. Business Strategy and the Environment, 18(7), 453–468.

Rao, P., & Holt, D. (2005). Do green supply chains lead to competitiveness and economic performance? International Journal of Operations and Production Management, 25(9), 898–916.

Ravi, V., & Shankar, R. (2005). Analysis of interactions among the barriers of reverse logistics International Journal of. Technological Forecasting and Social Change, 72(8), 1011–1029.

Sage, A. P. (1977). Interpretive structural modeling: methodology for large-scale systems (pp. 91–164). New York NY: McGraw-Hill.

Srivastava, K. S. (2007). Green supply-chain management: a state-of-the-art literature review. International Journal of Management Reviews, 9(1), 53–80.

Tsoulfas, G. T., & Pappis, C. P. (2008). A model for supply chains environmental performance analysis and decision making. Journal of Cleaner Production, 16(15), 1647–1657.

Vachon, S., & Klassen, R. D. (2006). Extending green practices across the supply chain: the impact of upstream and downstream integration. International Journal of Operations and Production Management, 26(7), 795–821.

Vachon, S., & Klassen, R. D. (2008). Environmental management and manufacturing performance: the role of collaboration in the supply chain. International Journal of Production Economics, 111, 299–315.

Vlachos, D., Patroklos, G., & Eleftherios, I. (2006). A system dynamics model for dynamic capacity planning of remanufacturing in closed-loop supply chains. Computers & Operations Research, 34, 367–394.

Wadhwa, S., Madaan, J., & Avneet, S. (2007). Need for flexibility and innovation in healthcare management systems. Global Journal of Flexible Systems Management, 8(1&2), 45–54.

Wadhwa, S., Madaan, J., & Chan, F. T. S. (2009a). Flexible decision modelling of reverse logistics system: A Value Adding MCDM Approach for alternative selection. International Journal of Robotics and Computer-Integrated Manufacturing, 25(2), 460–469.

Wadhwa, S., Madaan, J., & Chan, F. T. S. (2009b). Flexibility focused decision and information sharing model for product recovery system. Global Journal of Flexible Systems Management, 10(3), 15–22.

Walker, M. (1996). NGO participation in a corporatist state: The example of Indonesia. Working paper 678. Berkeley CA: Institute of Urban and Regional Development.

Walker, H., Di Sisto, L., & McBain, D. (2008). Drivers and barriers to environmental supply chain management practices: lessons from the public and private sectors. Journal of Purchasing and Supply Management, 14(1), 69–85.

Warfield, J. W. (1974). Developing interconnected matrices in structural modeling. IEEE Transaction Systems Man and Cybernetics, 4(1), 51–81.

Wei, Z. H. (2004). Economic development and energy issues in China. Working paper prepared for the First KEIO-UNU-JFIR Panel Meeting, The 21st Century Center of Excellence Program, Economic Development and Human Security, February 13–14, Tokyo.

Wells, P., & Seitz, M. (2005). Business models and closed-loop supply chains: a typology. Supply Chain Management: An International Journal, 10(4), 249–251.

Wisner, J. D. (2003). A structural equation model of supply chain management strategies and firm performance. Journal of Business Logistics, 24(1), 1–26.

Zhu, Q., & Sarkis, J. (2006). An inter-sectoral comparison of green supply chain management in China: drivers and practices. Journal of Cleaner Production, 14(5), 472–486.

Zhu, Q., Sarkis, J., & Lai, K. (2008). Confirmation of a measurement model for green supply chain management practices implementation. International Journal of Production Economics, 111(2), 261–273.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mangla, S., Madaan, J. & Chan, F.T.S. Analysis of Performance Focused Variables for Multi-Objective Flexible Decision Modeling Approach of Product Recovery Systems. Glob J Flex Syst Manag 13, 77–86 (2012). https://doi.org/10.1007/s40171-012-0007-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40171-012-0007-4