Abstract

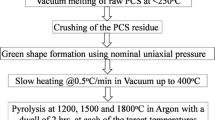

This work focused on the fabrication of silicon oxycarbide ceramic (SiOC) foams as well as dense compacts using poly(hydridomethylsiloxane) (PHMS) as a polymer precursor. The room-temperature cross-linking of PHMS was achieved by the addition of 1,4-diazabicyclo [2.2.2] octane (DABCO) with the release of hydrogen gas as a by-product. This resulted in self-blowing of the polymer precursor at room temperature and thereby offered the possibility of producing SiOC foams without the need of any external blowing agents. We also reported the fabrication of crack-free silicon oxycarbide compacts by cold compaction and pyrolysis route using polyvinyl alcohol (PVA) as a processing additive. Cylindrical-shaped pellets were pyrolysed at 1300 °C in argon atmosphere with a ceramic yield of approximately 85%. Increased resistance to phase separation and crystallization up to 1400 °C was attributed to the presence of large volume fraction of free carbon in the material which was confirmed by Raman spectroscopy.

Article PDF

Similar content being viewed by others

Avoid common mistakes on your manuscript.

References

Zhang H, Pantano CG. Synthesis and characterization of silicon oxycarbide glasses. J Am Ceram Soc 1990, 73: 958–963.

Renlund GM, Prochazka S, Doremus RH. Silicon oxycarbide glasses: Part II. Structure and properties. J Mater Res 1991, 6: 2723–2734.

Bois L, Maquet J, Babonneau F, et al. Structural characterization of sol-gel derived oxycarbide glasses. 1. Study of the pyrolysis process. Chem Mater 1994, 6: 796–802.

Corriu RJP, Leclercq D, Mutin PH, et al. 29Si nuclear magnetic resonance study of the structure of silicon oxycarbide glasses derived from organosilicon precursors. J Mater Sci 1995, 30: 2313–2318.

Mutin PH. Control of the composition and structure of silicon oxycarbide and oxynitride glasses derived from polysiloxane precursors. J Sol-Gel Sci Technol 1999, 14: 27–38.

Kleebe HJ, Turquat C, Sorarù GD. Phase separation in an SiCO glass studied by transmission electron microscopy and electron energy-loss spectroscopy. J Am Ceram Soc 2001, 84: 1073–1080.

Harshe R, Balan C, Riedel R. Amorphous Si(Al)OC ceramic from polysiloxanes: Bulk ceramic processing, crystallization and applications. J Eur Ceram Soc 2004, 24: 3471–3482.

Colombo P, Mera G, Riedel R, et al. Polymer-derived ceramics: 40 years of research and innovation in advanced ceramics. J Am Ceram Soc 2010, 93: 1805–1837.

Radovanovic E, Gozzi MF, Gonçalves MC, et al. Silicon oxycarbide glasses from silicone networks. J Non-Cryst Solids 1999, 248: 37–48.

Modena S, Sorarù GD, Blum Y, et al. Passive oxidation of an effluent system: The case of polymer-derived SiCO. J Am Ceram Soc 2005, 88: 339–345.

Liu X, Li YL, Hou F. Fabrication of SiOC ceramic microparts and patterned structures from polysiloxanes via liquid cast and pyrolysis. J Am Ceram Soc 2009, 92: 49–53.

Su D, Li YL, An HJ, et al. Pyrolytic transformation of liquid precursors to shaped bulk ceramics. J Eur Ceram Soc 2010, 30: 1503–1511.

Jiang T, Hill A, Fei W, et al. Making bulk ceramics from polymeric precursors. J Am Ceram Soc 2010, 93: 3017–3019.

Greil P. Active-filler-controlled pyrolysis of preceramic polymers. J Am Ceram Soc 1995, 78: 835–848.

Blum YD, MacQueen DB, Kleebe H-J. Synthesis and characterization of carbon-enriched silicon oxycarbides. J Eur Ceram Soc 2005, 25: 143–149.

Lavedrine A, Bahloul D, Goursat P, et al. Pyrolysis of polyvinylsilazane precursors to silicon carbonitride. J Eur Ceram Soc 1991, 8: 221–227.

Yvie NSCK, Corriu RJP, Leclerq D, et al. Silicon carbonitride from polymeric precursors: Thermal cross-linking and pyrolysis of oligosilazane model compounds. Chem Mater 1992, 4: 141–146.

Wen G, Bai H, Huang X, et al. Lotus-type porous SiOCN ceramic fabricated by undirectional solidification and pyrolysis. J Am Ceram Soc 2011, 94: 1309–1313.

Kroke E, Li Y-L, Konetschny C, et al. Silazane derived ceramics and related materials. Mat Sci Eng R 2000, 26: 97–199.

Blum YD, Schwartz KB, Laine RM. Preceramic polymer pyrolysis. J Mater Sci 1989, 24: 1707–1718.

Walter S, Soraru GD, Bréquel H, et al. Microstructural and mechanical characterization of sol-gel-derived Si-O-C glasses. J Eur Ceram Soc 2002, 22: 2389–2400.

Wang Y, Alsmeyer DC, McCreery RL. Raman spectroscopy of carbon materials: Structural basis of observed spectra. Chem Mater 1990, 2: 557–563.

Schiavon MA, Gervais C, Babonneau F, et al. Crystallization behavior of novel silicon boron oxycarbide glasses. J Am Ceram Soc 2004, 87: 203–208.

Rouxel T, Soraru G-D, Vicens J. Creep viscosity and stress relaxation of gel-derived silicon oxycarbide glasses. J Am Ceram Soc 2001, 84: 1052–1058.

Gambaryan-Roisman T, Scheffler M, Buhler P, et al. Processing of ceramic foam by pyrolysis of filler containing phenylmethyl polysiloxane precursor. Ceram Trans 2000, 108: 121–130.

Zeschky J, Goetz-Neunhoeffer F, Neubauer J, et al. Preceramic polymer derived cellular ceramics. Compos Sci Technol 2003, 63: 2361–2370.

Zeschky J, Höfner T, Arnold C, et al. Polysilsesquioxane derived ceramic foams with gradient porosity. Acta Mater 2005, 53: 927–937.

Zeschky J, Lo J, Höfner T, et al. Mg alloy infiltrated Si-O-C ceramic foams. Mat Sci Eng A 2005, 403: 215–221.

Mazo MA, Palencia C, Nistal A, et al. Dense bulk silicon oxycarbide glasses obtained by spark plasma sintering. J Eur Ceram Soc 2012, 32: 3369–3378.

Sujith R, Srinivasan N, Kumar R. Small-scale deformation of pulsed electric current sintered silicon oxycarbide polymer derived ceramics. Adv Eng Mater 2013, DOI: 10.1002/adem.201300146.

Konetschny C, Galusek D, Reschke S, et al. Dense silicon carbonitride ceramics by pyrolysis of cross-linked and warm pressed polysilazane powders. J Eur Ceram Soc 1999, 19: 2789–2796.

Weisbarth R, Jansen M. SiBN3C ceramic workpieces by pressureless pyrolysis without sintering aids: Preparation, characterization and electrical properties. J Mater Chem 2003, 13: 2975–2978.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is published with open access at Springerlink.com

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Nedunchezhian, S., Sujith, R. & Kumar, R. Processing and characterization of polymer precursor derived silicon oxycarbide ceramic foams and compacts. J Adv Ceram 2, 318–324 (2013). https://doi.org/10.1007/s40145-013-0078-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40145-013-0078-5