Abstract

Bi2WO6 nanoplates were synthesized by a simple one-step hydrothermal method using oleic acid (OA) as a green and cheap capping agent. The X-ray diffraction (XRD) analysis, scanning electron microscopy (SEM), and energy-dispersive X-ray spectroscopy (EDS) were used to characterize the products. The interaction between the precursor product and oleic acid was studied by Fourier Transform Infrared (FT-IR). In addition, the catalytic activity of prepared Bi2WO6 for the oxidation of thiols to disulfides as an important reaction in both biological and chemical processes was investigated. It was found to be an efficient catalyst for the selective oxidation of thiols to the corresponding disulfides, without over-oxidation, at room temperature.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The oxidation of thiols to disulfides without over-oxidation is a pivotal reaction in both biological and chemical processes. A number of methods for this conversion, such as potassium dichromate [1], I2/HI [2], sodium perborate [3], and nitric oxide [4], have been used. Most of these procedures suffer from drawbacks, such as generation of undesirable waste materials, low selectivity, over-oxidation, and low yield. Hence, developing economical, green, and mild approaches have attracted a great attention [5]. In accordance with these aims, previous studies suggested that metal oxides would be capable of oxidizing thiols under mild conditions [6].

Bi2WO6, the most important member in the Aurivillius family, possessing a layered structure with the perovskite-like slab of (WO4)2− and (Bi2O2)2+ has been widely studied because of its potential applications in dielectric, ion conductive, solar-energy-transfer, luminescent, and photocatalyst materials [7]. So far, different methods have been used to synthesize Bi2WO6, such as biomimetic [8], hydrothermal [9], electrospinning [10], ultrasonic spray pyrolysis [11], sol–gel [12], and microwave-assisted synthesis [13]. Among them, the hydrothermal method is an advantageous technique, since it is an environmental-friendly, low-cost method to provide highly pure products with controlled morphology [14]. The various 3D morphologies of Bi2WO6, including flower-like structure [15], clew- like microspheres [16], multilayered disk-like architecture [17], and octahedron-like structure [18] have been synthesized by the hydrothermal method. A 2D nanostructure, such as nanoplates and nanoparticles, is an important category of nanostructured materials, which have attracted much attention in recent years [19].

In this study, we report the synthesis of Bi2WO6 nanoplates by a simple hydrothermal method using oleic acid as a green and inexpensive capping agent. Furthermore, for the first time, we have studied the catalytic activity of Bi2WO6 nanoplates to oxidation of thiols by H2O2 as oxidant in non-aqueous media under neutral conditions at room temperature.

Experimental

Hydrothermal synthesis of Bi2WO6

All chemicals were of analytical grade and used without further purification. Bi2WO6 nanoplates were synthesized by the hydrothermal method as follows: 0.46 g of Bi(NO3)3·5H2O (0.95 mmol) was dissolved into a 30-mL NaNO3 solution (2 M) using a magnetic stirrer at 75 °C for 10 min. Then, 12-mL Na2WO4·2H2O (0.05 M) was added dropwise into the above solution. After 2 h, 2-mL OA was added into the above solution and stirred for 30 min. The resulted suspension was transferred into a 50-mL Teflon-lined autoclave and maintained at 175 °C for 15 h. After the autoclave cooled at room temperature, the collected yellowish white precipitate was washed with deionized water and acetone for several times and dried in oven at 100 °C for 6 h. The final product was calcined at 550 °C for 4 h.

Characterization

The morphology of Bi2WO6 nanoplates were observed by a VEGA/TESCAN microscope with an accelerating voltage of 30.00 kV. The FT-IR analyses were carried out on a Shimadzu FT-IR-8400S spectrophotometer using KBr pellets. Furthermore, the structure of particles were analyzed by a JEOL diffractometer with monochromatic Cu Kα radiation (λ = 1.5418 Å). An Oxford energy-dispersive X-ray spectroscopy (EDS) was used for the determination of Bi and W elements in the product.

Oxidation reactions

First, 1 mmol of thiol was dissolved in 10-mL dichloromethane, then 5-mg Bi2WO6 catalyst was added, and the mixture was stirred at room temperature. After the completion of the reaction (detected by TLC), the reaction mixture was filtered and the solid material was washed with 20 mL of dichloromethane. The filtrate was evaporated and the resulting material was either recrystallized or subjected to a silica-gel plate. The filtrate was then subjected to GC and GC-Mass analysis.

Results and discussion

Characterization of Bi2WO6 nanoplates

The composition and phase of Bi2WO6 nanoplates were characterized by the XRD analysis, as shown in Fig. 1a. All the diffraction peaks are indexed to the orthorhombic phase of Bi2WO6 and match well with the reported data (JCPDS card No. 73-1126, a = 5.457, b = 5.436, and c = 16.42 Å). In addition, the EDS result (Fig. 1b) showed merely the presence of Bi, W, and O elements, which is indicative of its high purity. The weight percentages of 69.19 and 30.81 were obtained for Bi and W, respectively (molar ratio of Bi:W is about 2:1).

The SEM image of Bi2WO6 reveals the production of Bi2WO6 nanoplates with the average thickness of about 90 nm and length and width of about 100–350 nm (Fig. 2).

For the investigation of the interactions between Bi2WO6 and oleic acid, the FT-IR spectra of pure oleic acid, Bi2WO6 capped by oleic acid and Bi2WO6 after calcination are compared in Fig. 3. The FT-IR spectrum of calcined Bi2WO6 (Fig. 3a) displays strong sharp bands at 734 and 579 cm−1, which belong to the stretching vibrations of W–O and Bi–O bonds, respectively [20]. Figure 3b shows the characteristic peaks of the pure OA comprising the oleyl group. The peaks at about 2925 and 2854 cm−1 were assigned to the asymmetric and symmetric CH2 stretching modes, respectively, and the C = O stretch of the carboxylic acid dimers was observed at about 1710 cm−1 [21]. It is known that in the FT-IR spectrum of the organic acids adsorbed on the metal oxides (Fig. 3c), the peaks at 1680–1710 cm−1 are attributed to the C = O stretching modes of the single hydrogen-bonded carboxylic acid groups, while in the cyclic hydrogen-bonded dimeric form, the frequency of carbonyl group shifts to higher wavenumbers by ~35 cm−1 [22, 23]. Therefore, the peak at 1745 cm−1 can be corresponded to the adsorbed OA in the form of cyclic hydrogen-bonded dimeric structure. Although the Bi2WO6 treated with OA was washed several times with acetone, the peak at 1710 cm−1 was remained which indicates that a fraction of the OA was physically adsorbed on the Bi2WO6 particles through the van der Waals forces (the possible formation mechanism of Bi2WO6 nanoplates is discussed in SI).

Catalytic study

The catalytic performance of Bi2WO6 was studied for the oxidation of thiols using H2O2 as oxidant. To optimize reaction conditions for the oxidation of sulfides, thiophenol was taken as a model compound and different reaction conditions including catalyst loading and solvent were studied. As shown in Table 1, the reaction was performed in various solvents. The conversion of thiophenol is 5, 60, and 97 % when water, ethanol, and dichloromethane are used as solvent, respectively (Entries 1–3). The effect of catalyst loading on the conversion of thiophenol is also investigated. As shown in Table 2, the conversion of thiophenol without catalyst is about 8 % (Entry 1); ’while, in the presence of catalyst, the conversion was increased from 61 to 97 % when the amounts of catalyst were varied from 2.5 to 5 mg (Entries 2, 3). These results suggested that the progress of thiophenol oxidation is strongly dependent upon the catalyst loading.

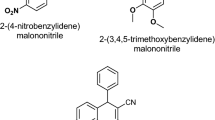

Under optimal conditions, aromatic thiols with different substituents have been converted to their corresponding disulfides in the presence of Bi2WO6 (Table 3). As can be seen, aromatic thiols with various substituents in ortho and para positions resulted in good yields of the corresponding disulfides without any other by-products (no peaks of by-products for thiophenol oxidation were observed in GC-Mass chromatogram, supporting information, Fig S1).

Conclusion

In summary, we have synthesized Bi2WO6 nanoplates by a simple one-spot hydrothermal method using oleic acid as a capping agent. The FT-IR studies revealed that oleic acid was chemically adsorbed by cyclic hydrogen-bonded carbonyl groups on Bi2WO6 surface, and also, there is physically adsorbed oleic acid via van der Waals forces. Furthermore, the catalytic activity of Bi2WO6 for the synthesis of disulfides via oxidative coupling of thiols was studied. For the use of a nontoxic and inexpensive catalyst, the mild conditions and relatively short reaction time and excellent yields are some of the notable advantages of this method.

References

Patel, S., Mishra, B.K.: Cetyltrimethylammonium dichromate: a mild oxidant for coupling amines and thiols. Tetrahedron Lett. 44, 1371–1372 (2004)

Wu, X., Rieke, R.D., Zhu, L.: Preparation of disulfides by the oxidation of thiols using bromine. Synth. Commun. 26, 191–196 (1996)

McKillop, A., Koyuncu, D., Krief, A., Dumont, W., Renier, P., Trabelsi, M.: Efficicient, high yield, oxidation of thiols and selenols to disulphides and diselenides. Tetrahedron Lett. 31, 5007–5010 (1990)

Pryor, W.A., Church, D.F., Govindan, C.K., Crank, G.: Oxidation of thiols by nitric oxide and nitrogen dioxide: synthetic utility and toxicological implications. J. Org. Chem. 47, 156–159 (1982)

Soleiman-Beigi, M., Taherinia, Z.: Simple and efficient oxidative transformation of thiols to disulfides using Cu (NO3) 2·3H2O in H2O/AcOEt. Monatsh. Chem. 145, 1151–1154 (2014)

Wallace, T.J.: Reactions of thiols with metals. I. Low-temperature oxidation by metal oxides 1. J. Org. Chem. 31, 1217–1221 (1996)

Huang, H., Chen, H., Xia, Y., Tao, X., Gan, Y., Weng, X.: Controllable synthesis and visible-light-responsive photocatalytic activity of Bi2WO6 fluffy microsphere with hierarchical architecture. J. Colloid Interf. Sci. 370, 132–138 (2012)

Yao, F., Yang, Q., Yin, C., Zhu, S., Zhang, D., Moon, W.-J.: Biomimetic Bi2WO6 with hierarchical structures from butterfly wings for visible light absorption. Mater. Lett. 77, 21–24 (2012)

Shang, M., Wang, W., Sun, S., Zhou, L., Zhang, L.: Bi2WO6 nanocrystals with high photocatalytic activities under visible light. J. Phys. Chem. 112, 10407–10411 (2008)

Shang, M., Wang, W., Ren, J., Sun, S., Wang, L., Zhang, L.: A practical visible-light-driven Bi2WO6 nanofibrous mat prepared by electrospinning. J. Mater. Chem. 19, 6213–6218 (2009)

Mann, A.K., Skrabalak, S.E.: Synthesis of single-crystalline nanoplates by spray pyrolysis: a metathesis route to Bi2WO6. Chem. Mater. 23, 1017–1022 (2011)

Liu, Y., Lv, H., Hu, J., Li, Z.: Synthesis and characterization of Bi2WO6 nanoplates using egg white as a biotemplate through sol-gel method. Mater. Lett. 139, 401–404 (2015)

Cao, X.F., Zhang, L., Chen, X.T., Xue, Z.L.: Microwave-assisted solution-phase preparation of flower-like Bi2WO6 and its visible-light-driven photocatalytic properties. Cryst. Eng. Comm. 13, 306–311 (2011)

Yoshimura, M., Byrappa, K.: Hydrothermal processing of materials: past, present and future. J. Mater. Sci. 43, 2085–2103 (2008)

Dumrongrojthanath, P., Thongtem, T., Phuruangrat, A., Thongtem, S.: Hydrothermal synthesis of Bi2WO6 hierarchical flowers with their photonic and photocatalytic properties. Superlattice Microst. 54, 71–77 (2013)

He, D., Wang, L., Li, H., Yan, T., Wang, D., Xie, T.: Self-assembled 3D hierarchical clew-like Bi2WO6 microspheres: synthesis, photo-induced charges transfer properties, and photocatalytic activities. Cryst. Eng. Comm. 13, 4053–4059 (2011)

Tang, P., Chen, H., Cao, F.: One-step preparation of bismuth tungstate nanodisks with visible-light photocatalytic activity. Mater. Lett. 68, 171–173 (2012)

Li, Y., Liu, J., Huang, X.: Synthesis and visible-light photocatalytic property of Bi2WO6 hierarchical octahedron-like structures. Nanoscale Res. Lett. 3, 365–371 (2008)

Zhang, C., Zhu, Y.: Synthesis of square Bi2WO6 nanoplates as high-activity visible-light-driven photocatalysts. Chem. Mater. 17, 3537–3545 (2005)

Geng, Y., Zhang, P., Kuang, S.: Fabrication and enhanced visible-light photocatalytic activities of BiVO4/Bi2WO6 composites. RSC Adv. 4, 46054–46059 (2014)

Pawsey, S., Yach, K., Reven, L.: Self-assembly of carboxyalkylphosphonic acids on metal oxide powders. Langmuir 18, 5205–5212 (2002)

Shukla, N., Liu, C., Jones, P.M., Weller, D.: FTIR study of surfactant bonding to FePt nanoparticles. J. Magn. Magn. Mater. 266, 178–184 (2003)

Blyholder, G., Adhikar, C., Proctor, A.: Structure and orientation of oleic acid adsorbed onto silica gel. Colloids Surf. A 105, 151–158 (1995)

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Rahimi, R., Pordel, S. & Rabbani, M. Synthesis of Bi2WO6 nanoplates using oleic acid as a green capping agent and its application for thiols oxidation. J Nanostruct Chem 6, 191–196 (2016). https://doi.org/10.1007/s40097-016-0195-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40097-016-0195-0