Abstract

The nanopore arrays were fabricated by a two-step anodization of aluminum in an aqueous solution of 0.3 M oxalic acid at the temperature of 6 °C by applying a constant direct current (DC) of 40 V. A template-assisted synthesis of Co nanowire arrays was carried out by electrodeposition into the pores of prepared AAO templates. Cobalt (Co) nanowires of high density and uniformity were synthesized via an electrochemical deposition of metallic Co nanoparticles using a nanoporous template of anodized aluminum oxide, by applying an alternative current (AC).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In recent years, the fabrication of nanoscale structures has received much attention owning to their potential applications in optical, high-density magnetic memories, single electron devices, and prospective applications in catalysis, sensors, and biological separation and transport [1, 2]. Numerous synthetic ways such as soft lithography, molecular beam epitaxy, laser ablation, sol-gel method, have been developed to prepare highly ordered this type of nanostructured materials [3, 4]. Among the various methods used for preparation of nanowire, electrochemical deposition of metals on anodic aluminum oxide (AAO) templates has been proven to be a low-cost and high-yield technique [5, 6]. Electrochemical anodization of aluminum has resulted in successful fabrication of highly ordered nanoporous aluminum oxide structures, which is called AAO [7], and used as a suitable template for growing metal nanowires. There are numerous advantages of this method to preparing an appreciate nanoporous template in comparison to conventional lithography-based fabrication methods including cost effectiveness, wide accessibility, and the capability of top–bottom fabrication with nanoscale precision and access to high aspect ratio structures [7].Two methods have been developed for electrochemical deposition of metals into the nanopores [3, 5]. In the first method, a direct current (DC) is used for deposition of metal nanowires into nanoholes of AAO template which is covered from one side with conducting metal layer [3, 5]. Alternatively, DC electrodeposition can be used for filling the nanopores of AAO layer still attached to the remaining Al substrate only after an effective removal of barrier layer [3]. In the second method, an alternating current (AC) or a pulsed current is applied during the electrochemical deposition to produce ordered metal nanowires [5]. AC and pulse electrodeposition techniques do not strictly require barrier layer removal but, to achieve a better quality of metallic deposit electrochemical thinning or chemical etching of barrier layer is usually performed prior electrochemical deposition [3].

In this study, we report a two-step anodizing method at 40 V and 6 °C for preparing AAO templates. We also demonstrated the production of large-area, high-density Co nanowire arrays were grown in nanochannels of AAO template via the AC electrodeposition method.

Experimental

Materials

High-purity (99.9995 %) aluminum foil, perchloric acid, ethanol, oxalic acid, phosphoric acid, copper sulfate, chloridric acid, Cobalt sulfate heptahydrate, boric acid, sulphuric acid, and sodium sulfate were obtained from Merck (Darmstadt, Germany), and they were used as received. Choromic anhydrate was purchased from KANTO chemical Co., INC (Tokyo, Japan). Finally, doubly ionized water was obtained from an OES water purification system (Oklahoma, USA).

Equipments

A DC power supplier (MP6003, Megatek, Germany) was used to apply electric field during two-step anodization process in preparation of AAO template. The morphology and their EDX analysis of the resultant AAO templates before and after deposition of Co NWs were performed using a scanning electron microscopy (FE-SEM/EDX) (TESCAN, Mira II LMU, Czech Republic).

Preparation of AAO template

First, a high-purity aluminum sheet with dimensions of 30 mm × 30 mm × 0.3 mm was degreased in acetone ultrasound and rinsed in an ethanol solution, followed by annealing at 500 °C for 5 h to remove the mechanical stress and obtain homogenous conditions for pore growth over a large area [8]. Before anodization, the annealed sample was electropolished in a 1:4 volume mixture of perchloric acid (60 wt%) and ethanol (96 wt%) at 3 °C, and constant dc voltage of 20 V for 1 min. The first anodizing process was carried out under a constant voltage of 40 V dc in a 0.3 M oxalic acid solution at 6 °C for 20 h. The AAO film was chemically etched in a mixture of chromic acid (1.8 wt%) and phosphoric acid (6 wt%) at 75 °C for 3 h, then the second anodizing process was done for 1 h, under the same conditions as the first anodization step, which resulted in formation of a highly ordered porous AAO template with a pore depth of about 2 μm [3, 6]. To facilitate the uniform electrodeposition of cobalt nanowires, the voltage was dropped from 40 to 14 V, which was done immediately at the end of the second anodization. Because the thickness of the barrier layer is proportional to applied voltage, the barrier layer was almost completely removed when the voltage reached 14 V [9, 10].

Finally, the resulting AAO template was immersed in a 1.0 M aqueous phosphoric acid solution at a room temperature for 40 min to eliminate the barrier layer on the bottom side, and simultaneously widen the pores [8].

Fabrication of Co nanowire arrays

Immediately after preparation of alumina substrate, the Co nanowires were electrochemically deposited at the pores of AAO template in an aqueous solution of 0.18 M CoSO4 7H2O, and 0.5 M H3BO3 under 18 V alternating current for 60 s. To have the better results in electrodeposition of Co nanowires in the bottom of pores, the pH value of the electrolyte was adjusted between 2.0 and 4.0. The electrochemical deposition of Co nanowires was done in a two-electrode system, where resulting AAO template with exposed area of 1 cm × 1 cm, and untreated aluminum sheet with an exposed area of 2 cm × 2 cm were used as two electrodes. These two electrodes were adjusted parallel to each other in an electrochemical deposition cell with an electrode gap of 1 cm.

Results and discussions

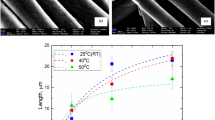

The surface morphology and cross-sectional views of prepared AAO template are presented in Fig. 1a, b, respectively. As we can see, the AAO template exhibits hexagonally arranged nanopore arrays with the cylindrical pore diameter and pore depth of the prepared templates were about 50 nm and 2 μm, respectively. In addition, the pore density of the prepared templates was 2 × 108 pores/cm−2, which defines the production of large-area, high-density porous AAO template.

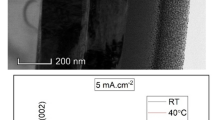

Figure 2a, b illustrates the cross-sectional image and EDX spectrum of the AAO template after electrodeposition of Co nanowires in the bottom of pores, respectively. The EDX results are trustworthy evidence that Co nanowires were uniformly electrodeposited filling the pores in the AAO template.

Based on our experimental results, we can claim that the junction between the electrode surface and the bottom edge of the template pore serves as a preferential site for the deposition of metal ions, because the inner walls of the nanochannels have surface adsorption energy [11].

Conclusion

In summery, we obtained large-area, high-density, and well-ordered arrays of cobalt nanowires which were deposited homogenously in the pores of AAO template using an AC current during the metal deposition. The diameter and length of the grown Co nanowires were about 50 nm and 2 μm, respectively, which were tightly controlled by the AAO template structure. So, we can obtain desire Co nanowire arrays by controlling the diameter, and depth of the nanopores of AAO template. It is remarkable that the regular nano-arrays of Cobalt nanowire arrays with very similar dimensions can be obtained by etching of the AAO template.

References

Nielsch, K., Müller, F., Li, A.P., Gösele, U.: Uniform nickel deposition into ordered alumina pores by pulsed electrodeposition. Adv. Mater. 12(8), 582–586 (2000)

Lee, W., Scholz, R., Nielsch, K., Gösele, U.: A template-based electrochemical method for the synthesis of multisegmented metallic nanotubes. Angew. Chem. 117(37), 6204–6208 (2005)

Sulka, G.D., Brzózka, A., Zaraska, L., Jaskuła, M.: Through-hole membranes of nanoporous alumina formed by anodizing in oxalic acid and their applications in fabrication of nanowire arrays. Electrochim. Acta 55(14), 4368–4376 (2010)

Cortés, A., Riveros, G., Palma, J.L., Denardin, J.C., Marotti, R.E., Dalchiele, E.A., Gómez, H.: Single-crystal growth of nickel nanowires: influence of deposition conditions on structural and magnetic properties. J. Nanosci. Nanotechnol. 9(3), 1992–2000 (2009)

Zhou, Z.F., Zhou, Y.C., Pan, Y., Wang, X.G.: Growth of the nickel nanorod arrays fabricated using electrochemical deposition on anodized Al templates. Mater. Lett. 62(19), 3419–3421 (2008)

Meng, G., Cao, A., Cheng, J.Y., Vijayaraghavan, A., Jung, Y.J., Shima, M., Ajayan, P.M.: Ordered Ni nanowire tip arrays sticking out of the anodic aluminum oxide template. J. Appl. Phys. 97, 064303 (2005)

Md Jani, A.M., Losic, D., Voelcker, N.H.: Nanoporous anodic aluminium oxide: advances in surface engineering and emerging applications. Prog. Mater. Sci. 58(5), 636–704 (2013)

Jin, C.G., Liu, W.F., Jia, C., Xiang, X.Q., Cai, W.L., Yao, L.Z., Li, X.G.: High-filling, large-area Ni nanowire arrays and the magnetic properties. J. Cryst. Growth 258(3–4), 337–341 (2003)

Hu, W., Yuan, L., Chen, Z., Gong, D., Saito, K.: Fabrication and characterization of vertically aligned carbon nanotubes on silicon substrates using porous alumina nanotemplates. J. Nanosci. Nanotechnol. 2(2), 203–207 (2002)

Ciuculescu, D., Dumestre, F., Comesaña-Hermo, M., Chaudret, B., Marina Spasova, M., Farle, M., Catherine Amiens, C.: Single-crystalline Co nanowires: synthesis, thermal stability, and carbon coating. Chem. Mater. 21(17), 3987–3995 (2009)

Li, X., Wang, Y., Song, G., Peng, Z., Yu, Y., Xilin She, X., Li, J.: Synthesis and growth mechanism of Ni nanotubes and nanowires. Nanoscale Res. Lett. 4, 1015–1020 (2009)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

This article is published under license to BioMed Central Ltd. Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Hekmat, F., Sohrabi, B. & Rahmanifar, M.S. Growth of the cobalt nanowires using AC electrochemical deposition on anodized aluminum oxide templates. J Nanostruct Chem 4, 105 (2014). https://doi.org/10.1007/s40097-014-0105-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40097-014-0105-2