Abstract

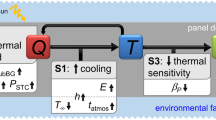

It is widely known that organic and inorganic coatings absorb more of the solar spectrum, and due to a considerable share of 45% infrared radiation, the energy efficiency drop by the increasing of temperature should be considered. The purpose of this study is to implement a system to characterize silicon solar cell performance and increasing energy efficiency by imposing such coatings as infrared wave absorber to overcome the Shockley–Queisser limit. In other words, this research efforts to improve cell efficiency (coating effects) in addition to imposing the efficiency decreasing effects (temperature increasing). The core of the study is laboratory and experimental set-up measurements to find an organic absorber with the highest absorbance. Ruthenium-based dye, N719, has shown the best performance in experimental conditions and heat extraction to enhance cell energy efficiency. Due to increased absorption in a solar cell (SC), to control the temperature rise of the system, the fan is used as a cooling system. The imposing of N719 results in increasing energy efficiency by up to 1.38%. It is worth noting that a 1.60% increase in energy efficiency is observed due to temperature reduction by 2 degrees.

Similar content being viewed by others

Introduction

In terms of energy, sunlight at earth’s surface is measured to be 1 kilowatt.m−2 that consists of 527 watts infrared, 445 watts visible, and 28 watts ultraviolet radiation, in which almost all infrared and near-infrared radiation are shorter than 4 µm [1]. Due to the research on the environmental effects of solar power deployment, it can be mentioned that technological improvements were made last decade. Furthermore, climate change and acidification were some of the parameters that in countries like the United Kingdom and Spain were declined. This decline is nearly 8–34% if countries like China use PV systems instead of current manufacturing systems [2].

First-generation silicon solar cells are currently exhibiting power conversion efficiencies of ~ 22% so that cost-effective photovoltaics have brought about the rapid growth of research and development in the use of silicon in the photovoltaic market. Colloidal semiconductor nanocrystals (NCs) are promising materials not only for solar cells, because of the enhanced absorption spectrum, but also for increased conversion efficiency [3].

Concerning the infrared absorber material, lead selenide, indium arsenide, mercury tellurium, and lead sulfide can be considered as narrow bandgap semiconductors. Due to limitations of silicon, which means a high energy bandgap of 1.1 eV, lead sulfide with a tunable bandgap, with simple manufacturing processes, is considered as a promising candidate for solar cell applications [4].

For bridging the gap between first-generation high-efficiency silicon solar cells with third-generation solar cells, organic semiconductor materials can be chosen, which are cost-effective. However, low yielding efficiencies hinder the real usage of such materials. Another candidate used to reduce recombination in the silicon surface, with results similar to surface passivation method’s conclusion, is poly-(3-hexylthiophene) [5]. Previous research to overcome silicon solar cell efficiency limitation and because of the low absorbance of the infrared part of the spectrum, tandem solar cells were used. To increase electron charge, dye-sensitized solar cell (DSSC) with silicon substrate of (with 8% efficiency) ruthenium-based dye, N719 was used in this project [6]. Due to this increased harvesting, temperature independency of performance parameters (Jsc, Voc, FF, and ɳ) of c-Si solar cells should be taken into account [7].

NREL researchers conducted a series of investigations in this context; briefly, the most NREL relevant studies are introduced after this.

McGehee et al. have deposited thin films of perovskite semiconductors with bandgaps ranging from 1.6 to 2.3 eV on top of silicon solar cells to advance cell efficiency and reduce cost [8]. A major difference between the mentioned research and this work is the different spectrum that is desired for absorbance.

Marcie R Black developed a project titled intermediate band solar cell (IBSC) produced by growing the Si nanowires epitaxial on the surface of an oriented Si wafer increase coupling between specific electronic states [9]. In comparison with the current study, a similar substrate is used, but a different method is harnessed for increasing efficiency and reducing the reflection of the silicon surface.

Harry Atwater defined a targeted project to combine wafered crystalline silicon (c-Si) with the cost and simplicity of thin-film technologies by applying wide-bandgap absorber layers, which further resulted in high-efficiency multi-junction solar cells [10]. The aim of their project was providing a combination of the first and second generation of solar cells, which contrasts in the generation investigated (the first and third) to this study.

Chang-Hasnain invented a unique method to grow [11]. The common idea with the current study is the silicon substrate and developing semiconductor, but their method cost (which is relatively high) should be minimized.

James Sturm is developing silicon/organic heterojunctions (SOH) to absorb light in such a way that it happened in the conventional crystalline and multi-crystalline silicon photovoltaic. However, no p–n junction was available [12]. This low-cost room-temperature process eliminates the need for any expensive high-temperature diffusion steps required to fabricate p–n junctions. The similarity lies in enhancing the light absorbance feature using inexpensive organic materials and eliminating the p–n junction.

Andrew Ferguson dramatically improved solar photoconversion efficiency in amorphous silicon (a-Si) and organic-based photovoltaic (PV) technologies by breaking the Shockley–Queisser limit. The team was implementing a strategy that allows single-junction solar cells to harvest a wider portion of the solar spectrum effectively with a system that can convert low-energy (red to near-infrared) photons to higher-energy (visible) photons. This harvesting of a wider portion of the solar spectrum with low-energy photons and breaking Shockley–Queisser limit is of interest. Still, the significant difference lies in the use of the amorphous silicon (a-Si) substrate instead of a c-Si cell in this work.

Birkmire et al. were addressing the efficiency limit and high fabrication cost of current light-trapping methods by developing novel low-symmetry gratings (LSG) for thin crystalline silicon (c-Si) and copper indium gallium selenide (Cu(InGa)Se2 or CIGS) photovoltaic solar cells. The researchers were also using deposited high refractive index glass materials for low-temperature LSG processing [13]. The same technique of light harvesting for first-generation solar cells is used, but the material employed differs from the stated one.

Taking into consideration that experimental set-up measurement is substantially different from STC conditions (AM1.5), the operating temperature should be considered as an altering factor. For instance, in a similar project for experimental set-up measurement with a radiation range of 400–1002 watts·m−2, cell operating temperature was in the range of 42–60 °C [14], and the results have shown the efficiency, and another photovoltaic characterization is less compared with laboratory conditions. As a result of the fact that the determination of simulation parameters such as wind speed, ambient temperature, and other experimental set-up conditions are not feasible, optimum temperature performance cannot be measured. Hence, the results of these conditions are incomparable [14]. Thanks to increased absorbance, especially infrared radiation, heat accumulation in the solar cell resulting in increased cell surface temperature, devising a technique to mitigate the heat surplus should be considered [15]. Although in the above activities, two conditions were not considered; first trial experiments in real experimental set-up conditions and at the second trial, the possibility of energy efficiency drop due to increased absorbance and consequently temperature in comparison to nominal cell temperature. The current conversion efficiency of 1.3% at λ = 805 nm. Under 1 sun AM 1.5 illumination, the infrared response (780 nm < λ < 1600 nm) of the embedded nanocrystals contributes to 33% of the overall photocurrent of the photovoltaic cell. In literature, infrared absorber material was investigated thoroughly, but the effect of the cooling system on the environment has been not considered. By employing a cooling system, excess heat can be used to overcome the drop within efficiency. In other words, this research efforts to increase the cell efficiency (coating effects) in addition to impose with the efficiency decreasing effects (temperature rising).

It is noteworthy to mention that parameters such as the effect of wind, the type of coating, and deposition methods have not investigated in this study. Also, the ideal set-up similar to the standard model for in situ measurements was not harnessed. It should be considered that the effect of each factor can act as the source of errors and can be very undesirable and should be considered in future research [16].

In this study, for evaluating the overall performance of silicon solar cells with and without applying the coating in an experimental set-up condition (by considering cooling effects), the tests were performed on different consecutive days. The knowledge gap addressed in comparison with other works is the integration of two generations of solar cells due to the absorption spectrum besides the cooling system. In other words, the novelty of this study is considering the two conditions that were not evaluated in previous works. First, it was performed in real experimental set-up conditions, and second, the possibility of energy efficiency drop due to increased absorbance, and consequently, the temperature in comparison to nominal cell temperature were assessed. To implement this idea, the new approach was used to evaluate the performance of electrical and thermal devices simultaneously.

Testing methods and relevant standards

In this work, various organic and inorganic infrared-absorbing coatings were deposited on the silicon-based solar cells substrate distinct methods. The monocrystalline silicon solar cell with an area of 156.25 cm2 was selected as the substrate, primary cell. At the first step, photovoltaic characteristics were measured prior and after coating and then, such characteristics were evaluated after applying cooling system [17]. Selected dye-sensitized material, ruthenium-based complex, N719 as an organic coating (Solaronix SA company) was prepared and coated by the spraying technique. After deposition, experiments were conducted in a framework that can be divided into two distinct scenarios:

Scenario (I). Measurement of photovoltaic characteristics was performed with the sun light? The simulator in laboratory condition (light source, tungsten halogen lamps), with a radiation source, positioned at a certain standard distance from the cell surface to simulate the STC condition.

Scenario (II). Measurement of characteristics of photovoltaic was performed in standard test time intervals (required time to achieve the equilibrium and stability of the radiation).

To examine the effects of harvesting infrared solar radiation and hence increasing the heat absorption on the energy efficiency of solar cells, contributed experiments were performed. Finally, based on the results of the above scenarios, the best coating with cooling considerations were chosen.

It is noteworthy to mention that the lab experiment [scenario (I)] was repeatable based on an environmental variable the procedure can control those, so the effects of test experiments within the lab experiment in the first scenario prove to us the increased efficiency though with the research procedure. Nevertheless, the experimental set-up variable within the second scenario was not precisely repeatable because of the changing environmental variables. To avoid the errors, the measured data near the first scenario are gathered between the pools of data that has been measured.

In Table 1, the kind of coatings that were evaluated in this study provide their characteristic parameters, and the specific conditions of each scenario are specified.

Scenario (I): measurement in laboratory condition

It should be noted that the standard of measurement in the laboratory requires temperature stability in which either the temperature controller is applied, otherwise standard tests should be performed in a shortened time. Applying both conditions need solar simulator condition so that such surveys suffer from two problems; (1) solar simulator only consists of visible or infrared part and not both ones, (2) in case of more accurate monitoring systems, the radiation zone covers 5 cm2 of surface area, which is far smaller than the real cell surface area harnessed in this research, so temperature stability cannot be investigated as a controlled parameter. For the purpose realization of this scenario, photovoltaic solar cells with similar measurement tools were characterized in laboratory conditions. In comparison with scenario II, these series of experiments were conducted at shortened time intervals. As a result of this, their photovoltaic characterization and resulting system performance were measured more accurately. To achieve an accurate measurement, the constant adjustment was applied to all samples that are simulated within standard conditions, as shown in Fig. 1. Based on the ASTM E927 standard, the 1000-watt tungsten halogen lamp given with standard radiation was employed to cover the purpose. Samples were placed in a sealed case box, and a cooling fan in the floor chamber was also installed. Concerning the relationship between temperature and the energy efficiency of the cell, the thermocouple contact probe was placed to sense the cell surface temperature.

Scenario (II): measurement in experimental set-up condition

In this scenario, the test conditions are as follows; set-up angle according to the latitude angle of MERC (Materials and Energy Research Center),Footnote 1 the tilt angle was set to 36.65 degrees. A temperature difference of the cell with the coating before and after cooling is one of the effective specifications. So to measure both cell surface temperature and ambient temperature, the thermocouple was applied by the positioning of the probe on the surface of cells. Pyranometer (TES 1333 Solar Power Meter, Taiwan) and anemometers (DT-619 CFM/CMM Thermo Anemometer, China) were also executed to measure the radiation and wind speed, respectively. In the photovoltaic characterization method, controlled experimental set-up conditions had not been meeting; therefore, the factors should be carefully evaluated during testing [19]. To modify the results, validate numerical models can be derived. Independent variables in this scenario are radiation, temperature, and for the dependent variable, short-circuit current (ISC), open-circuit voltage (VOC), maximum power (Pmax), and cell electrical efficiency (η) are considered. As mentioned before, experiments were repeated on consecutive days in the same radiation for verifying the results. At the outset, variable resistor rheostat (manufacturer, country) was set in minimum value. Current (A) and voltage (V) were measured using a multimeter (PROVA 801/803 Digital Multi-Meter, Taiwan) with an accuracy of four decimal places. Current and voltage were measured in 50 steps based on variable resistance increment. Finally, these data were combined to calculate the power at each step; the current versus voltage curves have been plotted to render the maximum power. Experiments are measured all day through (during daylight) in which radiation values were in the range of 700–1000 watts·m2 measured by pyranometer [20, 21]. The schematic equipment map for the experimental set-up condition is presented in Fig. 2.

As can be seen in Fig. 2, an anemometer, a thermometer, a rheostat, a multimeter, and a pyranometer, were connected combined to the solar cell in series.

Results and discussion

Summary of quantitative results

A summary of quantitative results with regards to organic coating, N719, is presented in Table. 2. It can be concluded that the lack of consistency in the implementation of the indoor and outdoor measurements, and considering the effects of “harvesting infrared radiation on the overall performance solar cells” experimental set-up condition for the test is crucial [22]. In experimental set-up conditions, we are faced with different scenarios because the differences between the two systems are that the input of the system (solar radiation) in the experimental set-up test is not a controlled variable, so we continued with the integrated tests modelling standard conditions of the laboratory. In addition to experimental set-up, by changing the circumstances, taking into account the heat of the solar spectrum, the infrared spectrum, on the energy efficiency of solar cells in laboratory conditions is not possible [23, 24].

Despite attempts to adapt to experimental set-up conditions, the temperature of the cell surface at the same ambient radiation and excess heat are not simulated outputs. Therefore the fan cooling effect is not sensible.

Choosing best coating, n droplets (based on current–voltage curves)

N719 at each step of testing was deposited with a rate of 0.4 CC (about 9 gr·cm−1) by spraying technique, whereas photovoltaic characterization at each step was compared with the primary silicon solar cell. In the following steps, concerning quality, we compared and analyzed the different amount of coating (based on number of droplets) in terms of;

-

1.

Plotting I–V curve using current and voltage data,

-

2.

Determining the short-circuit current and open-circuit voltage (ISC and VOC) to calculate the power and energy efficiency of photovoltaic cells,

-

3.

Calculating the area under the I–V curves (integral calculation), equivalent to input cell power to the voltage and the test time durations.

-

4.

Determining and filtering out cases where a cooling fan had made a significant positive impact, in other words, when the current–voltage curve is up-lifted due to the cooling fan effect.

As the result of 1–4, (Table 3 and Fig. 3), in most cases, a positive effect on the performance of solar cells compared to the uncoated solar cell (orange color curve) can be observed, especially, for 80 and 100 droplet number (36.49 and 45.61 gr·cm−1) of the coating layer. As can be seen in Fig. 3, distributed data around short-circuit current are very low that can be related to parallel resistance and, consequently, connections. According to the experimental set-up conditions and the use of variable resistance in parallel with time-varying radiation, changes from the maximum current (ISC) to maximum power point current (IMPP) are very high; This pattern was synchronized with the coherent behaviour of the solar cell tested, that issues accurate measurements are taking place. As also can be seen in Table 3, organic absorbent N719 with absorber amounts of 80 and 100 droplets (by volume 1.6 and 2 CC, respectively) has shown the highest quantities of short circuit current and the energy efficiency.

In conclusion, the positive effect of the coating can be seen in the two situations.

Cooling performance analysis

To target cooling, the air flows related to the back channel of photovoltaic panels result in a decrease in temperature of the photovoltaic cell and its components [25]. It is also noted that the typical value of the temperature coefficient for crystalline silicon solar cells is approximately − 0.45% per °C [25]. To assess cool performance analysis, the following calculation was engaged within the experimental results after the cooling fan experiment argues, the process of calculation is as follows:

δ0 calculation for uncoated solar cell (the ratio of input power to the temperature difference between the cell surface and ambient temperature)

According to the formula (1) and including input power integral, in the period of 1 min for voltage and current measurement (\(dt\) equals to 60 s), IdV, i.e., area under the curve, enabled us to calculate the power input of the solar cell, assumed to be constant in a stable environment.

δ calculation for coated solar cell (δ for the coated solar cell before applying fan, and δ’ in the case of using the cooling fan for coated solar cell)

It should be noted that the variable δ (delta) definition is to understand the correlation of coating (organic absorbent in this study), radiation, the combined effect of radiation, and temperature difference on each other. This variable indicates the ratio of input power for simultaneous applying of the coating and cooling fan, to temperature difference and in fact, potential heat for solar cells; The purpose of the coating application was not only “increasing input heat and electrical energy efficiency”, but also applying fan system is proposed to extract heat and increase of electrical efficiency. The higher the value of the variable δ, it is more desirable, which can be achieved by increasing the input power of the solar cell, reducing the temperature difference, or both. For example, organic complex coating, N719, in different radiation, and thus temperature difference are shown in Table 4.

Plotting δ and δ’ to the amount of coating

First, to investigate the effect of coating (and then cooling effect) must go separately to the variables, of course, to compare the best result corresponds to the uncoated solar cell, as a criterion, so the best results of δ0 could be selected. As shown in Fig. 4, the lowest and highest amount of δ0 are 0.62405 and 0.980538, respectively. In this range between these two amounts, the highest frequency of δ and δ’ in terms of the droplet number, is the positive response of the coating effect on the performance of solar cells. The result reveals the positive effect of coating based on band value colored in Fig. 4, 80, and 100 droplets provided the best results.

Plotting (δ’–δ), (minus value) to solar radiation (G)

It goes without saying that the difference between δ and δ’, which means (δ’–δ), (minus value) shows the positive or negative effect of the cooling fan on the coated solar cell. The maximum amount of δ in each coating condition means an ideal mode for which the experiment was conducted under cooling conditions. Its positive effect on the increasing power depended on decreasing temperature is the signed value in this pattern.

However, to be careful at each step to enhance the accuracy, a new filter on data was applied. In the first step, More than 60 experiments and observations were excluded due to absurd temperature differences (due to lack of balance with ambient temperature or probe error). Subsequently, in the second step, it was necessary to define a function between 0 and 1, by means of coated solar cells with a cooling effect, to find resulted experiments in which increasing temperature reduces electrical performance (function equals zero value). So with this new filter agreement, less than 40 observations were found as accurate candidates in values. In the third step, by defining δ, we were looking for circumstances that applying for the cooling fan and coating. Those show the most positive effect rather than an uncoated solar cell. In this case, less than ten observations are obtained and, therefore, graph chart in Fig. 5 is plotted. Final notable points as a result mentioned in Fig. 5 were 100 droplets (45.61 gr·cm−1) of absorber shown best results due to coating, and cooling effects and ratio of input power to temperature difference were noteworthy.

Calculating correction factor (δ’–δ/δ0) (the combined effect on the coating and cooling fan on the overall energy efficiency of the solar cell)

This ratio meaning (δ’–δ/δ0) indicates the ratio of input power to temperature difference induced by coating and cooling fan in comparison to uncoated solar cell without a cooling system. In this case, as the last filter for confirming optimal coating, some observations were minimum, and due to Fig. 5, which summarize results, the highest ratio value replies to our questions about the best coating (equally means on the amount of absorber).

Labels defined the number of a droplet of the absorber, as mentioned in Fig. 5, and it is visible that the best response value is 100 droplets of absorber that confirms all conclusions.

It should be noted that after 100 droplets, 80 droplets of the absorber was the second choice, and generally, almost all values in Fig. 5 has shown the second-best performance aside 100 droplets, so it can be concluded that 100 droplets (with a difference of 5 CC close to 80 droplets) and with the approval of the near amounts of the absorber, would be the most suitable criteria.

The result is expressed as a computational process, to find the optimal amount of organic coating on solar cells leads to the conclusion that 100 droplet performs best if the cooling effect applies to the solar cells.

Conclusion

In this research, laboratory and experimental set-up scenarios to estimate the performance of photovoltaic characterization are studied in detail. Conditions are matched as closely as possible with different parameters to measure the performance of the solar cell, accurately. In the scenario of non-laboratory conditions, with and without cooling effect, to assess the impact of variables on energy efficiency, the experimental set-up condition is designed to measure performance.

In the mentioned analysis, quantification of the effect contributed to the coating and finally quantified the overall efficiency of solar cells with consideration of the cooling effect was performed. The results indicate that the application of organic absorbent, complex coating substance, with regards to operational errors, has been positive, in tutorials. In the quantification of this effect, the new variable (δ) is harnessed which shows the input power relative to the temperature difference between the cell and the ambient (indicating heat extraction of the system) and this variable represents an increase in total system efficiency with regards to the mentioned type of coating. Outcoming results of the performance of each segment are summarized as follows;

-

Qualitative comparison of current–voltage curves is 80 droplets and droplets 100.

-

Quantitative comparison of the variable delta frequency (before and after cooling) in terms of droplets, number: 80, 100, and 140 droplets.

-

The final quantitative issue value of delta variables before and after cooling in terms of solar radiation is 100 droplets.

-

A quantitative comparison of the defined correction factor in terms of solar radiation is 100 droplets.

Seeking the best condition, by applying this coating with spraying 100 droplets or 2 CC of the solution on the solar cell, the best result was achieved in which energy efficiency increased up to 1.4% and considering 2 °C temperature decline after cooling condition, 1.6% energy efficiency move-up is followed.

It is recommended, 100 droplets (45.61 gr·cm−1) as the best result is not a proper value, and it should be noted that 80 droplets (36.49 gr·cm−1) are approach point, so short intervals between these two values are recommended in future investigations.

Finally, it can be said that the study of solar cells concerning all effects is targeted to be proper research for coatings (in terms of amount and method of coating), which is valuable in the field of cell efficiency. Also, it is beneficial for the research and development of companies to product/promote photovoltaic panels.

Data availability

The datasets analyzed during the current study are available from the corresponding author on reasonable request.

Notes

35.7483° N, 50.9578° E.

Abbreviations

- A :

-

The total surface area of solar cell for the conversion of solar energy (m2)

- i mp :

-

Current in maximum power (amps)

- i sc :

-

Short-circuit current (amps)

- J :

-

Electric current flux; current through solar cell per unit cross-sectional area (Amps/cm2)

- P mp :

-

Maximum power; the maximum output of a PV cell at the optimal combination of current and voltage (W or kW)

- P solar :

-

The instantaneous power output of the solar energy system (kW)

- R series :

-

Solar cell resistance in series with the load (ohms)

- R shunt :

-

Solar cell resistance in parallel with the load (ohms)

- T ambient :

-

Ambient temperature; the temperature of surrounding air (C)

- T cell :

-

PV cell temperature (C)

- v mp :

-

Maximum power voltage; voltage that maximizes the power output of a PV cell (volts)

- v oc :

-

Open-circuit voltage (volts)

- ∆T :

-

Temperature difference, Tcell, and Tambient (C)

- t :

-

PV characterization time (sec)

- γ :

-

Solar azimuth; angular displacement of the sun from due south in the horizontal plane (degrees)

- δ :

-

Defined variable, the ratio of input power to ∆T

- η :

-

Energy efficiency; power energy out divided by power energy in PV array

- θ :

-

Incident angle; the angle between the surface normal and a line to the sun (degrees)

- λ :

-

The wavelength of incident light waves (m)

- (δ)’:

-

(δ) After cooling

- mp:

-

Maximum power point

- cell:

-

Solar cell

- oc:

-

Open circuit

- sc:

-

Short circuit

- 0:

-

Initial

References

N. R. E. Laboratory: Reference solar spectral irradiance: air mass 1.5, (2009)

Stamford, L., Azapagic, A.: Environmental impacts of photovoltaics: the effects of technological improvements and transfer of manufacturing from Europe to China. Energy Technol 6, 1148–1160 (2018)

Yaacobi-Gross, N., et al.: Colloidal semiconductor nanocrystals based solar cells: Technion-Israel Institute of Technology, Faculty of Electrical Engineering, 2012.

Konstantatos, G., Sargent, E. H.: Colloidal quantum dot optoelectronics and photovoltaics. Cambridge University Press, Cambridge (2013)

Avasthi, S.: Crystalline-silicon/organic heterojunctions for solar photovoltaics, Citeseer, 2011.

Barber, G.D., Lee, S.H.A., Perez-Blanco, J., Hoch, L.B., Mallouk, T.E.,: Tandem hybrid solar energy system.

Khan, F., Baek, S.-H., Kim, J.H.: Wide range temperature dependence of analytical photovoltaic cell parameters for silicon solar cells under high illumination conditions. Appl Energy 183, 715–724 (2016)

Barile, C.J., Slotcavage, D.J., Hou, J., Strand, M.T., Hernandez, T.S., McGehee, M.D.: Dynamic windows with neutral color, high contrast, and excellent durability using reversible metal electrodeposition. Joule 1, 133–145 (2017)

Black, M.: Intermediate bandgap solar cells from nanostructured silicon, Bandgap Engineering, Lincoln, MA (United States), (2014)

Yalamanchili, S., Emmer, H.S., Lewis,N.S., Atwater, H.A.,: Highly absorbing and high lifetime tapered silicon microwire arrays as an alternative for thin film crystalline silicon solar cells, in 2016 IEEE 43rd Photovoltaic Specialists Conference (PVSC), pp. 2999–3003, (2016)

Lu, F., Bhattacharya, I., Sun, H., Tran, T.T.D., Ng, K.W., Malheiros-Silveira, G.N., et al.: Nanopillar quantum well lasers directly grown on silicon and emitting at silicon-transparent wavelengths. Optica, vol. 4, pp. 717–723, (2017)

Sturm, J.: Hole-blocking layers for silicon/organic heterojunctions: a new class of high-efficiency low-Cost PV. Princeton Univ., NJ (United States) DOE-PRINCETON-EE0005315 United States 10.2172/1421786 GFO English, 2017.

Birkmirea, R.W., Kazmerskib, L. L.: Harnessing the sun with thin-film photovoltaics, In Photovoltaics for the 21st Century: Proceedings of the International Symposium, p. 24, (1999)

Agroui, K.: Indoor and outdoor characterizations of photovoltaic module based on mulicrystalline solar cells. Energy Proc 18, 857–866 (2012)

Owrak, M., Aminy, M., Jamal-Abad, M.T., Dehghan, M.: Experiments and simulations on the thermal performance of a sunspace attached to a room including heat-storing porous bed and water tanks. Build Environ 92, 142–151 (2015)

Rad, A.H., Haghgou, H., Ghadamian, H., Sarhaddi, F.: A review on recently development of photovoltaic-thermal (PV/T) air based collector (2017)

Van Sark, W., Meijerink, A., Schropp, R.: Solar spectrum conversion for photovoltaics using nanoparticles. Third Generation Photovoltaics, p. 4, (2012)

Toor, F., Miller, J.B., Davidson, L.M., Nichols, L., Duan, W., Jura, M.P., et al.: Nanostructured silicon via metal assisted catalyzed etch (MACE): chemistry fundamentals and pattern engineering. Nanotechnology 27, 412003 (2016)

Ebrahim Asghari, F., Ghadamian, H., Aminy, M.: Energy modeling and simulation including particle technologies within single and double pass solar air heaters. J Particle Sci Technol, vol. 2, pp. 95–102, (2016)

Fortuin, S., Hermann, M., Stryi-Hipp, G., Nitz, P., Platzer, W.: Hybrid PV-Thermal collector development: concepts, experiences, results and research needs. Energy Proc 48, 37–47 (2014)

Tyagi, V., Kaushik, S., Tyagi, S.: Advancement in solar photovoltaic/thermal (PV/T) hybrid collector technology. Renew Sustain Energy Rev 16, 1383–1398 (2012)

Matuska, T.: Performance and economic analysis of hybrid PVT collectors in solar DHW system. Energy Proc 48, 150–156 (2014)

Zaoui, F., Titaouine, A., Becherif, M., Emziane, M., Aboubou, A.: A combined experimental and simulation study on the effects of irradiance and temperature on photovoltaic modules. Energy Proc 75, 373–380 (2015)

Donovan, M., Bourne, B., Roche, J.: Efficiency vs. irradiance characterization of PV modules requires angle-of-incidence and spectral corrections, in 2010 35th IEEE Photovoltaic Specialists Conference, pp. 002301–002305, (2010)

Dehra, H.: An investigation on energy performance assessment of a photovoltaic solar wall under buoyancy-induced and fan-assisted ventilation system. Appl Energy 191, 55–74 (2017)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Bahrizadeh, S., Ghadamian, H., Aminy, M. et al. Quantitative trade-off analysis of infrared light absorber effects contributed to photovoltaic cells performance. Int J Energy Environ Eng 11, 299–309 (2020). https://doi.org/10.1007/s40095-019-00334-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40095-019-00334-z