Abstract

In this study, ZnO was doped with 0.01% Mn and it is grown on p-Si by the sol–gel spin-coating method. Obtained the thin film was studied that to understand the effect of 0.01% Mn-doping ratio on the optical and electrical properties of ZnO structure. In this context, first, the morphological structure of the thin film was studied with the use of atomic force microscopy (AFM). The surface structure was obtained homogeneous, and roughness and fiber size were calculated between 27.2–33.6 and 0.595–0.673 nm, respectively. Second, the optical properties were characterized via ultraviolet–visible (UV–Vis) spectrophotometry. Third, the effect of light intensity on junction properties of the photodiode was studied. The current–voltage (I–V) of the photodiode was measured under dark and at the different intensities of illumination. Obtained results showed that the current of photodiode was increased with the intensity of illumination from 6.41 × 10−7 to 5.32 × 10−4 A. These results indicate that photocurrent under illumination is higher than the dark current. After that, the other parameters of the photodiode such as barrier height and ideality factor were determined from forwarding I–V plots using the thermionic emission model that the barrier height and the ideality factor were found 0.74 eV and 5.3, respectively. On the other hand, the capacitance–voltage (C–V) was measured at the different frequencies. The C–V characteristic shown that C–V characteristic of the photodiode was changed depends on increasing frequency. In addition, the interface density (Dit) value was decreased by increasing frequency too. Similarly, the serial resistance of the photodiode was also decreased by increasing frequency. Received all these results indicated that Mn-doped ZnO thin film sensitive to light and due to this property, it can be used for different optoelectronic applications as a photodiode and photosensor.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In the recent years, there is a lot of research on the nanostructure materials, because properties of the nanostructure materials could be controlled by the use of doping ratio of the different materials [10,11,12,13]. Because of these properties, nanostructure materials can be adapted to different applications for optoelectronic devices [1,2,3]. Especially, among nanostructures materials that ZnO is attractive and widely studied as a transparent kind of II–VI semiconductor materials. To date, many materials were doped to ZnO that to change optical and electrical properties of its. When we check the literature among these materials, there are a few studies that Mn-doped ZnO had been investigated optical and electrical properties. Therefore, in this study, we have investigated electrical and optical properties of the 0.01% Mn-doped ZnO nanostructure the thin film. ZnO is available for this research, because ZnO is an n-type semiconductor material [15,16,17,18], bandgap (Eg) is 3.37 eV at room temperature, and exciton binding energy is 60 meV [2,3,4,5,6]. Therefore, ZnO is well known for different electronics applications, for example, gas sensor, varistors, transistor, optic sensor, solar cell etc. [3,4,5,6,7,8]. In addition, ZnO has a lot of advantages; for instance, it is not expensive, and it can easy processability etc. Due to these properties, it has been attractive by most of the researchers and it has been using for different applications [7,8,9,10].

The main aim of this study is investigating the effect of 0.01% Mn-doping ratio on the electrical and optical properties of ZnO. For this, 0.01% ratio Mn-doped to ZnO that was obtained Mn-doped ZnO solution and using this solution that thin film was deposited on the surface of p-Si and Al/p-Si/MnZnO/Al photodiode was produced. And then, the optical and electrical properties of the photodiode were investigated and obtained the results showed that the optical and electrical properties of the ZnO were changed by 0.01% Mn-doping ratio. The current–voltage (I–V), the capacitance–voltage (C–V), the conductance–voltage (G–V), the series resistance–voltage (Rs–V), and the density of interface states (Dit) of the Al/p-Si/MnZnO/Al photodiode were drawn graphs using received results. All results showed that the Al/p-Si/MnZnO/Al photodiode can be used not only as a photodiode but also an optical sensor for different applications in the optoelectronic devices.

Experimental details

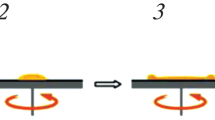

The p-Si wafer and Mn-doped ZnO solution were used to produce Al/p-Si/MnZnO/Al photodiode. For this process, first, HF solution was prepared to clean p-Si wafer, and then, it was dipped into this solution left for 10 s. After that, to the clean p-Si wafer, RC-cleaning procedure was applied [10,11,12,13,14,15]. For this, process was used acetone, methanol, and deionized water, respectively, with an ultrasonic bath for 5–10 min [13,14,15,16,17,18]. After the chemically cleaning process is completed, Al ohmic contact was formed on the rear surface of the p-Si wafer with the use of VAKSIS thermal evaporator system at the pressure of 5 × 10−5 T. On the other hand, to obtain Mn-doped ZnO homogeneous solution, 2-methoxethanol was used as a solvent and monoethanolamine (MEA) was used as a stabilizer. For this process, first, Zink acetate dehydrate Zn (CH3CO2)2 2H2O was dissolved in 2-methoxethanol for 10 min and second, manganese acetate (CH3CO2)2 4H2O has been added this solution and stirring 10 min together. Finally, monoethanolamine has added this solution and it was stirred for 1 h at the 60 °C temperature. After 1 h, a homogeneous solution was obtained which this solution was used to produce Al/p-Si/MnZnO/Al photodiode. For this, first, Mn-doped ZnO solution was grown onto the p-Si wafer with the use of a spin coating that speed was set 1100 rpm for 25 s. The p-Si substrate was put on the hotplate at 150 °C for 5 min this was repeated three times. And then, followed by a secondary anneal in the oven at 450 °C for 1 h to obtain a fully cured thin film on the p-Si substrate. After that, Al ohmic contact was formed on to MnZnO thin film. In this way, the production of the Al/p-Si/MnZnO/Al photodiode was completed and its schematic diagram is shown in Fig. 1. In addition, the characteristic of the I–V, I–t, C–V, G–V, and R–S has been measured via Keithley semiconductor characterization system. Moreover, the surface morphology of the thin film was investigated via PARK system XE 100E atomic force microscopy (AFM) that the roughness of film was determined via PARK system XEI analysis software. The optical measurements of the thin film were taken with the use of Shimadzu UV–Vis–NIR 3600 spectrophotometer. Obtained all the results were shown on the plotted graphs.

Results and discussion

Surface morphology

Atomic force microscopy (AFM) was used to measure the surface roughness of the Mn-doped ZnO thin film over 5 µm × 5 µm area using a PARK system AFM XEI software programming. Surface image of the thin film is shown in Fig. 2. As shown in Fig. 2, the thin film has composed of nanofibers. When we compared this result to another study in the literature, for example, Yang and Fri (http://dx.doi.org/10.1016/j.jmmm.2013.01.026), they had been studied Mn-doped ZnO for different doping ratios that in their study, the image of AFM has obtained nanoparticle that grain size had been found 36 and 32 nm (for x = 0.01 and x = 0.03), respectively. Mansour and Fri had been studied ZnO thin film is formed nanofibers and the diameter of the fibers had been found from 250 to 475 nm. In this study, obtained the thin films include in nanofibers and its average size was measured from 0.595 to 0.673 nm. This shows the size of nanofiber small than another study.

Optical properties

Optical properties of the thin film were studied to determine transmittance, absorbance, reflectance, and bandgap with the use of UV3600 SHIMADZU UV–Vis–NIR Spectrophotometer. As known, by the transmittance is determined the transparency of the thin film, by the reflectance is determined the reflection of the thin film, and by the absorbance is determined the absorption of the thin film. To determine these properties of the thin film using received optical results drawn transmittance, absorbance, reflectance, and bandgap spectra of the thin film. The transmittance of the thin film is shown in Fig. 3. As shown in Fig. 3a, the thin film has transparent, especially between 400 and 700 nm wavelength. That average percentage of the transmittance was determined about between 87 and 90.2% and between 470 and 600 nm wavelength. This shows that the thin film is a well transparent. The reflectance of the thin film is shown in Fig. 3b. As shown in Fig. 3b, the reflection of the thin film has a peak at the about 400 nm wavelength. This shows that the thin film has maximum reflection point and is about at the 380–410 nm wavelength. On the other hand, the absorbance of the thin film is shown in Fig. 3c. As shown in Fig. 3c, the absorption of the thin film showed a limit of absorption at the about 400 nm wavelength. This shows that the thin film has a limit of absorption in the visible region.

The bandgap of the Mn-doped ZnO thin film was calculated data of the transmittance versus wavelength plot. The absorption coefficient (α) of the thin film is determined by the following equation:

where T is transmittance and d is the thickness of the film. The absorption coefficient and the incident photon energy are related to the following equation:

where A is constant, Eg is the bandgap of the film, and n is depending on the type of transition. The bandgap of the Mn-doped ZnO thin film was determined by plotting (αhv)2 versus h. As shown in Fig. 3d, the bandgap was calculated 3.28 eV. In this study obtained the bandgap value, when compare to the literature that with undoped ZnO value, this value is smaller than undoped ZnO bandgap value. This showed that the doping ratio of Mn was decreased the bandgap of ZnO value.

Furthermore, not only in the dark but also under the different intensities of light was studied to determine a current–voltage characteristic of the photodiode. Obtained I–V results are shown in Fig. 4. As shown in Fig. 4, the photodiode showed behavior to light sensitive. This optical behavior of the I–V characteristic can be analyzed by the following equation:

where n is ideality factor, q is an electronic charge, k is Boltzmann constant, T is temperature, V is applied voltage, Rs is series resistance, and I0 is reverse saturation current analyzed by the following equation [1]:

where ϕb is barrier height, A* is effective Richardson constant that it is equal to 32 A/cm2 K2 for p-Si, and A is active contact area. The ideality factor and barrier height of the Al/p-Si/MnZnO/Al photodiode were found to be 5.3 and 0.74, respectively. As shown in Fig. 4, the reverse current of the Al/p-Si/MnZnO/Al photodiode increased with increasing light intensity. This change is from 6.4 × 10−7 to 5.32 × 10−4 A. This situation was showed that the current has been changed via the intensity of illumination. Because of this, it can be used for different optoelectronic applications.

The variation photocurrent of the Al/p-Si/MnZnO/Al photodiode is shown in Fig. 5 and the photocurrent of photodiode was analyzed by the following equation [5]:

where Iph is photocurrent, A is constant, m is an exponent, and P is the light intensity. The value of m was determined from the slope of Log(Iph) versus Log(P) plot and was found 1.3.

To better understand the effect of Mn doping on the photodiode characteristics of the devices, the transient photocurrent measurements were performed under different light intensities. This current is shown in Fig. 6a. As shown in Fig. 6a when the light turned on, the current quickly rises to a certain value, and then, when the light turned off the current decreased to the initial state again. The transient photocurrent of the photodiode Ion/Ioff is shown in Fig. 6b. This showed that the current has been changing with the use of light intensity, and because of this situation, it can be used as an optical sensor in different electronic circuits to detect the light.

The capacitance–voltage (C–V) was measured at the different frequencies and it is shown in Fig. 7. As shown in Fig. 7, the capacitance does not change with frequency in the positive region, but at the negative region not only changed but also increased with decreasing frequency.

As shown in Fig. 8a, C–V and b, G–V curve of Al/p-Si/MnZnO/Al photodiode were corrected by following equation [5,6,7,8,9,10]:

where Cadj is corrected capacitance, Gadj is corrected conductance, Cm is measured capacitance, Gm is measured conductance, w is angular frequency, and a is variable parameter, and it is depending on the Cm, the Gm, and the Rs parameters and it can be defined by the following equation:

As shown in Fig. 8b, Gadj plots were showed a peak that this had confirmed the presence of interface states and the interface state density (Dit) which it can be defined by the following equation:

where Cm is the measured capacitance, Cox is the capacitance of insulator layer, w is the angular frequency, and A is the contact area of the photodiode. The Dit values of the photodiode were calculated from Gadj–V plots using Eq. (9). The plot of Dit is shown in Fig. 9. As shown in Fig. 9, the density of the interface states was decreased with increasing frequency. This behavior is indicated that the interface states change with the use of the frequency. This shows that the interface states density strongly depends on frequency.

The Rs–V plot is shown in Fig. 10. Rs value was calculated from capacitance and conductance values in the accumulation region. As shown in Fig. 10, the series resistance depends on the bias voltage as well as on the applied frequency. In addition, the serial resistance is higher at the low frequency. This is because of the interface states can follow the Ac signal at the low frequency. Whereas at the high frequencies, the low serial resistance is because the interface states cannot follow the AC signal and do not contribute to interface states [3,4,5,6,7,8,9,10]. The Rs plots were indicated a peak that the peak position shifted with increasing frequency. This shows that the series resistance of the Al/p-Si/MnZnO/Al photodiode is decreased with increasing frequency.

Conclusion

The Mn-doped ZnO thin film was fabricated using sol–gel spin-coating technique. After obtaining the homogeneous solution, it is grown on the p-Si substrate with the use of the spin-coating technique. After that, the Al contact was formed on the thin film and produced Al/p-Si/MnZnO/Al photodiode. After this process was completed that investigated electrical and optical properties of the thin film. Surface morphology of the Mn-doped ZnO thin film was studied with the use of PARK system XE 100E atomic force microscopy (AFM). The roughness of the Mn-doped ZnO thin film was determined using a PARK system XEI analysis software programming. The optical measurements were taken with the use of Shimadzu UV–Vis–NIR 3600 spectrophotometer. The current–voltage (I–V) characteristic of the photodiode was performed using Keithley semiconductor characterization system. As a result, obtained all outcomes from this study showed that the Al/p-Si/MnZnO/Al photodiode indicated that an optical behavior depends on the light intensity. Because of this sensitive to light, it can be improved and used for different applications of the optoelectronic devices.

References

Wang, Zhang, L., Chen, Z., et al.: Semiconductor heterojunction photocatalysts: design, construction, and photocatalytic performances. Chem. Soc. Rev. 43(15), 5234–5244 (2014)

Fan, J.C., Sreekanth, K.M., Xie, Z., et al.: p-type ZnO materials: theory, growth, properties and devices. Prog. Mater. Sci. 58(6), 874e985 (2013)

Ahmad, M., Ahmed, E., Ahmed, W., et al.: Enhancing visible light responsive photocatalytic activity by decorating Mn-doped ZnO nanoparticles on graphene. Ceram. Int. 40(7), 10085–10097 (2014)

Mary Jacob, N., Madras, G., Kottam, N., et al.: Multivalent Cu-doped ZnO nanoparticles with full solar spectrum absorbance and enhanced photoactivity. Ind. Eng. Chem. Res. 53(14), 5895–5904 (2014)

Lu, Y., Lin, Y., Xie, T., et al.: Enhancement of visible-light-driven photoresponse of Mn/ZnO system: photogenerated charge transfer properties and photocatalytic activity. Nanoscale 4(20), 6393–6400 (2012)

Singh, A.K., Thool, G.S., Bangal, P.R., et al.: Low temperature Mn doped ZnO nanorod array: synthesis and its photoluminescence behavior. Ind. Eng. Chem. Res. 53(22), 9383–9390 (2014)

Kumar, V., Singh, R.G., Singh, N., Kapoor, A., Mehra, R.M., Purohit, L.P.: Synthesis and characterization of aluminum boron co-doped ZnO nanostructures. Mater. Res. Bull. 48, 362–366 (2013)

Alaria, J., Bouloudenine, M., Schmerber, G., Colis, S., Dinia, A., Turek, P., et al.: Pure paramagnetic behavior in Mn-doped ZnO semiconductors. J. Appl. Phys. 99, 08M118-1–08M118-3 (2006)

Wang, X.L., Luan, C.Y., Shao, Q., Pruna, A., Leung, C.W., Lortz, R., Zapien, J.A., Ruotolo, A.: Effect of the magnetic order on the room-temperature band-gap of Mn-doped ZnO thin films. Appl. Phys. Lett. 102, 102112–102124 (2013)

Rajalakshmi, R., Angappane, S.: Synthesis, characterization, and photoresponse study of undoped and transition metal (Co, Ni, Mn) doped ZnO thin films. Mater. Sci. Eng. B 178, 1068–1075 (2013)

Singh, A.K., Thool, G.S., Bangal, P.R., Madhavendra, S.S., Singh, S.P.: Low temperature Mn doped ZnO nanorod array: synthesis and its photoluminescence behavior. Ind. Eng. Chem. Res. 53, 9383–9390 (2014)

Rusu, G.G., Rambu, A.P., Buta, V.E., Dobromir, M., Luca, D., Rusu, M.: Structural and optical characterization of Al-doped ZnO films prepared by thermal oxidation of evaporated Zn/Al multilayered films. Mater. Chem. Phys. 123, 314–321 (2010)

Khalil, B., Labrim, H., Mounkachi, O., Belhorma, B., Benyoussef, A., El Kenz, A., Belha, A.: Ferromagnetism from acceptors of native point defects in (Zn, Mn)O doped systems. J. Supercond. Nov. Magn. 26, 151–156 (2013)

Yang, Z., Zuo, Z., Zhou, H.M., Beyermann, W.P., Liu, J.L.: EpitaxialMn-doped ZnO diluted magnetic semiconductor thin films grown by plasma-assisted molecular-beam epitaxy. J. Cryst. Growth 314, 97–103 (2011)

Mote, V.D., Purushotham, Y., Dole, B.N.: Structural, morphological, physical and dielectric properties of Mn-doped ZnO nanocrystals synthesized by a sol–gel method. Mater. Des. 96, 99–105 (2016)

Li, Q., Wang, Y., Liu, J., Kong, W., Ye, B.: Structural and magnetic properties in Mn-doped ZnO films prepared by pulsed-laser deposition. Appl. Surf. Sci. 289, 42–46 (2014)

Abdullahi, S.S., Kösoglu, Y., Güner, S., Kazan, S., Kocaman, B., Ndikilar, C.E.: Synthesis and characterization of Mn and Co codoped ZnO nanoparticles. Superlattices Microstruct. 83, 342–352 (2015)

Hu, D., Liu, X., Deng, S., Liu, Y., Feng, Z., Han, B., Wang, Y., Wang, Y.: Structural and optical properties of Mn-doped ZnO nanocrystalline thin films with the different dopant concentrations. Phys. E Low Dimens. Syst. Nanostruct. 61, 14–22 (2014)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Çavaş, M. Investigation morphological, electrical, and optical properties of Mn-doped ZnO thin film by sol–gel spin-coating method. J Theor Appl Phys 11, 325–331 (2017). https://doi.org/10.1007/s40094-018-0274-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40094-018-0274-3