Abstract

Purpose

Nitrogen loss as ammonia (NH3) in a waste cocoa pod co-composting process was determined following the addition of three potential chemical amendments that could lower NH3 loss. Further, amended compost products were assessed for quality and possible phytotoxicity in a pot experiment.

Methods

Pod borer damaged cocoa pods were co-composted in lab-scale vessels under ambient conditions with double superphosphate, phosphoric acid, and gypsum at 2%, 5% and 1% of fresh weight, respectively. NH3 emitted during composting was trapped in standard H2SO4 and determined titrimetrically. Composting mixtures were sampled on days 0, 7, 56 and 90 to monitor pH, total C, total N, and C:N ratio. Mature co-composts were incorporated to the soil at 20 t ha−1 and growth response of Chinese cabbage plants (Brassica rapa chinensis) assessed for the phytotoxicity.

Results

The chemical amendments were ineffective (p > 0.05) in preventing loss of NH3 but the quality of composting mixtures were significantly (p < 0.0001) improved. The manure compost generated had acceptable parameters (C, 31.2–31.9% and C:N ratio, 9–10:1) and were free from phytotoxicity for soil application as revealed by the response of Chinese cabbage crop.

Conclusions

Chemical amendments used in the co-composting process mainly modulated pH without any detrimental effects on quality. The results also demonstrated that the NH3 loss is insignificant from the cocoa waste-composting process. Further studies are required with increased rates of acidifying amendments like phosphoric acid to further augment the quality of cocoa pod composts.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Cocoa (Theobroma cacao L., family: Sterculiaceae) is a major cash crop in Papua New Guinea (PNG) and many developing economies in the tropics. After cocoa beans are extracted, huge amounts of pod husks are left unused in the cocoa farms. The global burden of pod husk waste continues to increase well over 40 million tons (Vriesmann et al. 2012). Cocoa pod husk waste valorization has been attempted by recycling into various products including compost (Fidelis and Rajashekhar Rao 2017). Generally, agro-wastes need conversion into compost or farm-yard manure before being used in crop production to improve soil fertility (Meena and Biswas 2014). Promotion of recycling and use of compost partly substitute mineral fertilizer requirements (Adamtey et al. 2009), improve soil organic matter stocks, augment soil quality and helps to combat N pollution. Agriculture is one of the main contributors of N pollution through emission of ammonia (NH3) and nitrous oxide (N2O) to the atmosphere and nitrates (NO3−) into water bodies (Behera et al. 2013). Mineral N fertilizers used in agriculture have inevitable losses of N from volatilization that can be offset to some extent by the enhanced usage of composts (DeLaune et al. 2004; Steiner et al. 2010).

Proper waste-recycling strategy has become all the more important with the outbreak of cocoa pod borer (Conopomorpha cramerella Snellen; family: Gracillariidae) in PNG (Yen et al. 2010). The cocoa pod borer (CPB) larva causes damage to cocoa by boring into the pod and disrupting the development of the beans. Although the burial of infested pods is the recommended practice for the control of CPB infestation, the majority of growers find this as a cumbersome activity (Fidelis and Rajashekhar Rao 2017). Hence, many of cocoa growers abandon CPB-infested pods and opened husks in piles scattered which can be a good source of raw material for composting and recycling.

The process of generation and use of compost manure will create employment, generate income, lower waste products, and at a global level contribute to a more healthy and sustained environment with a reduction in N emission to the atmosphere. Exposure to NH3 is a health hazard and in the atmosphere a pollutant (Naseem and King 2018). However, some N is lost while composting through volatilization of ammonia (NH3) in aerobic composting facilities (Steiner et al. 2010; Tuomela et al. 2000; Askri et al. 2016). Our earlier studies on the co-composting cocoa pod with animal manures and mineral fertilizer additives indicated potential emission of NH3 during composting (Fidelis and Rajashekhar Rao 2017). NH3 losses through volatilization could be significant when alkaline waste materials are composted and were exponentially proportional to the temperature of the composting mixtures (Pagans et al. 2006). Several approaches were successfully used to contain NH3 loss from compost including biofiltration, incineration, scrubbing, absorption and biological methods (Sheridan et al. 2002). Certain studies have indicated the potential to use chemical amendments such as phosphoric acid, alum, phosphogypsum, superphosphate, zeolite, and biochar which are effective to a various extent (Kithome et al. 1999; Steiner et al. 2010).

There are no specific studies as yet to estimate N loss as NH3 from waste cocoa pods composting. The objectives of this study were to (1) quantify nitrogen loss as volatile NH3 during composting of cocoa pods; (2) evaluate possible chemical amendments for reducing NH3 losses, and (3) assess important maturity indices and quality of manure compost in a short-term pot experiment with a test crop.

Materials and methods

Raw material collection and pre-treatments

CPB-infected cocoa pods were randomly collected from the Orogawi Model Farm, Cocoa Coconut Institute of Papua New Guinea (CCI PNG), located at 40 miles from Lae City, Papua New Guinea. Waste pods collected for the study came from polyclonal varieties HC1-B and HC1-S. The infected pods were a mix of mature and immature pods. About 70 kg cocoa pods were diced into 2 cm × 2 cm pieces using a locally designed contraption (Fig. 1). These were immediately bagged into 20 kg transparent polythene bags and quarantined in the farm site for 7 days. During this time, the bags are left exposed to the sun, covered by a black polythene sheet for solarization (Sultanbawa 2005). Further, solarized materials were air-dried for a week in an open shed to remove the moisture build-up from the solarization. Waste pods were sampled in triplicate to assess the moisture content. Once the moisture content reached 60%, vessels were filled with the waste.

Composting of CPB-infected cocoa pod

Composting study was performed in a completely randomized design, under laboratory conditions (at 25 ± 5 °C) in polyvinyl chloride (PVC) bins or vessels. The vessels used had a diameter of 30 cm at the base and a top diameter of 45 cm. The vessels had a height of 60 cm and an approximate volume of 60 L. These bins securely closed with air-tight lids. Ventilation holes (× 3) of 2 mm diameter drilled into the wall of the composting vessel, 15 cm from the bottom, aided in aeration. The simple schematic diagram of the composting vessel setup is illustrated in Fig. 2.

The design of the experiment allowed the concomitant measurement of NH3 loss during the composting process. About 4 kg of chopped CPB-infected cocoa pods were filled in the vessels. About 280 g goat manure was dispersed in water to form a slurry and mixed with the chemical amendments (treatments). Goat manure was collected from the University’s goat farm, air-dried, crushed, sieved with a 2-mm sieve and used as a starter. Goat manure and amendments if any were prepared as slurry and mixed with cocoa pods. The moisture content of the composting materials was adjusted to about 70% throughout. After filling with composting material, a 50 ml beaker with 20 ml of standard sulfuric acid (H2SO4) was placed on the tripod stand supported by wire mesh and the composting vessels were covered with a lid. Triplicate representative samples of the cocoa pods and the goat manure were analyzed for moisture content, pH, total N, and total C contents at the beginning of the experiment. The chemical properties of raw materials used in compost preparation are presented in Table 1.

The following chemical additives were used as N retention promoters in the composting:

Treatment 1: Cocoa pod waste and goat manure (no chemical amendment) (CPW)

Treatment 2: Cocoa pod waste and goat manure with double superphosphate [Ca (H2PO4)2; 34% P2O5] at 2% of fresh weight of cocoa pod waste (DSP)

Treatment 3: Cocoa pod waste and goat manure with gypsum (CaSO4.2H2O) at 5% of fresh weight of waste (GYP)

Treatment 4: Cocoa pod waste and goat manure with phosphoric acid [H3PO4] at 1% of fresh weight of waste (PHA).

Each treatment was replicated three times. Composting mixture was turned once a week to ensure optimum aeration. Composting mass was sampled immediately after each turning for moisture content. The compost pile was mixed well, and about 100–150 g composite samples of each vessel were taken out for analysis, representing the top, bottom and middle portions of the composting mass. Whenever required, moisture content was replenished with distilled water. On day 90, the composting experiment was terminated by spreading the mixtures on clean polythene sheets for air-drying.

Monitoring of N loss and measurement of evolved NH3

Effect of addition of chemical amendments on the loss of N as ammonia (NH3) gas was monitored from the composting mixtures at weekly intervals (Mandal et al. 2016). The NH3 lost from the composting mass and trapped in the standard sulfuric acid was determined on a weekly basis by back-titrating against standard NaOH solution. Thereafter, each beaker was replaced with fresh acid. The quantity of NH3 trapped was measured by the following equation:

where A is the NH3 emission mg/vessel, B is the weight of composting mass per vessel, C is the volume of NaOH used for blank titration in ml, X is the molarity of H2SO4 used to capture ammonia, Y is the volume of H2SO4 used to capture ammonia emission both in the compost and blank in ml.

Sampling for quality indices

The chemical quality characters of the composting mixtures were studied by analyzing mixtures and mature compost for pH, total carbon (TC), and total nitrogen (TN) contents on days 0, 7, 56 and 90. At each instance of sample collection, the fresh weight of the samples was recorded, oven-dried at 105 °C for 48 h and re-weighed. Later, the compost was sieved in a 5-mm sieve and collected for further work.

Analysis of composts and soil sample

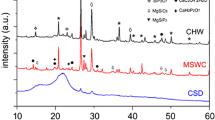

The moisture content of the compost mixture was determined by gravimetric method. For all other analytical work, oven-dry compost was further manually ground to pass through a 2-mm sieve and used. The oven-dried compost samples were suspended in deionized water (1:5 sample: water, w/v) mechanically shaken on an end-over-end shaker for 30 min and pH of the suspension was measured in a Mettler Toledo SK20 potentiometer (Baker et al. 1983). Samples were ground using a mortar to a particle size less than 0.18 mm (< 0.18 mm) and were then analyzed in a LECO TruSpec Nitrogen and Carbon Analyzer.

Bioassay with compost

The biosafety of composted material was assessed in a pot trial. Bulk soil sample (0–15 cm) (an Entisol) was collected from University of Technology farm situated between 6°41′S and 146°98′E at an elevation of 65 masl. Bulk soil was transported to the laboratory, air-dried for a week, gently crushed and passed through 2-mm sieve. A sub-sample of the soil was analyzed for pH, electrical conductivity (EC), total nitrogen and organic carbon contents. The soil reaction was slightly acidic (6.5 ± 0.06) with an electrical conductivity value of 34.9 µS/cm. The organic carbon and total nitrogen contents were 3.9% and 0.30%, respectively. About 2 kg of sieved (2 mm) soil was filled in polythene pots (base, 11 cm; top, 14 cm and height, 14.5 cm). The four types of manure composts produced were applied at 20 ton ha−1 and incorporated well into the soil (Fidelis and Rajashekhar Rao 2017). A control without any compost was also maintained. All treatments were replicated three times. Later six seeds of Chinese cabbage (Bok Choy) (Brassica rapa chinensis Cultivar: Saladeer) were planted, watered and grown under greenhouse conditions. One week after planting, seedlings were thinned and two healthy and uniform seedlings were retained. The Chinese cabbage plants were harvested on the 49th day of planting with a knife close to the soil. The fresh weight of aerial biomass was taken, oven-dried at 60 °C for 3 days, after which the dry weight was recorded.

Statistical analysis

Effect of chemical treatments (amendments) and sampling interval (days) on the parameters such as cumulative NH3 released, pH, total N, and C were determined by Factorial Analysis of Variance (ANOVA) test using Statistix 8.0. Chemical amendments and sampling intervals were treated as two factors or variables. The data on fresh weight and dry weight were subjected to one-way ANOVA. Whenever F test was significant, the means of the treatments were separated by a Least Significant Differences (LSD) test.

Results and discussion

Ammonia emission pattern

In the present study, three chemical amendments (double superphosphate, gypsum, and phosphoric acid) were used to decrease N loss through NH3 volatilization and to improve retention of N during composting. The cumulative mean ammonia loss from each chemical co-compost mixture is presented in Fig. 3. Monitoring was discontinued after day 77 due to negligible NH3 production. There was little effect of chemical amendments (p > 0.05) on the cumulative loss of nitrogen as NH3 from the composting mixture. Yet, the composting mixture without chemical amendment has had a relatively higher ammonia emission over other treatments during the composting period. Phosphoric acid-amended composting mixture had the lowest cumulative ammonia emission on day 7 (1.08 mg/vessel) but in later sampling intervals double superphosphate showed the lowest NH3 emission.

The reduction of N loss by double superphosphate is believed to be due to a chemical reaction of NH3 with monocalcium phosphate present in double superphosphate and the formation of more stable ammonium compounds (Reddy 2005). Urea and other nitrogenous compounds in cocoa pod wastes can be converted and emitted as NH3 by microbial decomposition (Hao et al. 2001), which could react with carbonic acid to yield ammonium carbonate as shown in the following equation:

Double superphosphate is a mixture of superphosphate and triple superphosphate and contains up to 34% P2O5 and variable amounts of gypsum. The reaction with ammonium carbonate formed in the composting mass with monocalcium phosphate and gypsum present in double superphosphate could be expressed as in the following equation:

The use of gypsum reduces the loss of N by the formation of ammonium sulfate and calcium carbonate, thus preserving N as shown in the following equation (Hao et al. 2005; Reddy 2005):

The role of H3PO4 in reducing the NH3 losses is believed to be due to modulation of pH of the composting mixtures. The NH3 emission is greatest at pH values of composts above 8. By decreasing compost pH, acidifying additives could reduce NH3 volatilization (McCrory and Hobbs 2001).

The reason for insignificant NH3 emission amongst treatments could be due to the poor N content of the composting mixtures, unlike studies reported from elsewhere utilizing feedstock of very high N content (DeLaune et al. 2004; Kithome et al. 1999). Most of the studies reporting N losses involved composting of poultry manures which has a different pH, high N content and decomposition rate (DeLaune et al. 2004). The addition of chemical amendments can reduce ammonia losses without affecting the composting process (Kithome et al. 1999). Co-composting is a promising approach embarked on for various purposes (Benito-Mora et al. 2018) and in this study, we used chemical compounds together with cocoa wastes to slow down possible emission of NH3. The NH3 emission pattern was more or less stable during the 60-day period of the composting (Fig. 3). About 50–90% of all NH3 losses occur during the 1st weeks of thermophilic composting, which coincide with high pH (Li et al. 2006).

Double superphosphate amendment recorded the lowest cumulative ammonia emission over the 90-day composting period (Fig. 3) which was ~ 10% reduction from the unamended composting mixture. The addition of phosphate as superphosphate reduced nitrogen losses, balanced the compost and supplied nutrients for microbial digestion of organic substrates (DeLaune et al. 2004). The rate of amendment addition is also critical in effective loss prevention. Single superphosphate decreased the volatilization up to 4.8 times, while, the triple superphosphate was the additive that best controlled NH3 volatilization when applied in low rates, but in the highest rate its efficiency was similar to that of single superphosphate (Prochnow et al. 2001). Gypsum-amended composting mixtures slightly suppressed (2%) loss of NH3 over 77 days when compared with the unamended control. Similar results were obtained by Prochnow et al. (2001). Gypsum at different rates has varied effects on reducing ammonia volatility; rates applied at 17% (dry weight basis) were most effective (Tubail et al. 2008). Phosphoric acid-amended compost reduced ammonia emission by 5% compared to the unamended control. DeLaune et al. (2004) reported that phosphoric acid reduced volatile ammonia from composting poultry litter by as much as 54%. In the same study, topical applied phosphoric acid reduced ammonia volatilization more than integrated application.

Evolution of compost quality

Compost quality parameters (pH, total C, total N and C:N ratio) varied significantly (p < 0.001) during composting (Table 2). The total C content of the composting mixtures decreased significantly within 90 days. A similar trend was noted for C:N ratio. On the contrary, the total N content of the composting mixtures increased with the composting period. The use of various chemical amendments was able to significantly (p < 0.001) affect the pH values. The increase in pH recorded with time is a characteristic of the composting process. This is mainly due to the increased N mineralization rates and production of NH3. As composting progresses, the pH increases with a concomitant increase in the potential for NH3 volatilization (Liyanage et al. 2014). The temporary drop in the pH on day 56 could be due to the production of organic acids during the decomposition of organic matter. The pH rise in the later stages (day 56 and 90) could be due to the decomposition of easily degradable organic acids, mineralization of organic compounds, degradation of proteins by microorganisms, elimination of carbon dioxide, the conversion of ammonium to ammonia and the consequential increase in volatilization (Tuomela et al. 2000). The phosphoric acid amendment was effective to suppress initial pH surge but on day 90, the pH values went above the starting pH values with phosphoric acid. The highest recorded final pH (day 90) was for the unamended control (pH 9.0) followed by double superphosphate-amended treatment (pH 8.6), and gypsum and phosphoric acid amendments culminated in composts with similar pH (~ 7.75). As per the norms, well decomposed, mature compost shall have a practicably favorable pH range of 5.5–7.0 (Allen and Kariuki 2014). The cocoa pods mixtures were co-composted with goat manures as the starter cultures, which could also partly be responsible for the finished composts with higher pH values (Irshad et al. 2013).

Carbon is lost from the composting pile as CO2 when organic matter decomposes due to the microbial consumption of C as an energy source. The mineralization process contributes to C loss from the compost and is related to the microbial population increase (Tuomela et al. 2000). The total C loss profiles in the different chemical amendments were behaving relatively similar (p > 0.05) with losses ranging from 22 to 25% of the initial total carbon content (Table 2). There is no ideal organic matter content for finished compost, but 30% by weight organic matter is common (Allen and Kariuki 2014). The total nitrogen content of the composting mixtures increased during the composting process in the current study. This could be related to the mass loss of the cocoa pod substrate.

A perusal of data on C:N ratio revealed that cocoa pods had a C:N ratio of 27.8 (Table 1) which is an ideal value for any wastes to compost. Normally, composting or decomposability of raw materials decreases above C:N ratio of 30 (Allen and Kariuki 2014). The C:N ratio profile for all treatments showed a reduction or loss range from 61 to 64% of the initial value. Microbes use carbon as an energy source releasing carbon dioxide. In the process, C:N ratio decreases with time and a final value between 15 and 20% is desirable. The final C:N ratio of composts harvested in the study was ~ 9 and were considered as mature composts (Allen and Kariuki 2014).

Biosafety of compost

Soil incorporation of various composts at 20 t ha−1 did not show any deleterious effects (p > 0.05) on the plant growth as measured by fresh and dry biomass yields of Chinese cabbage crops (Table 3). Soil receiving double superphosphate-enriched compost produced twofold greater dry biomass (9.90 g) compared to soil without any compost addition (4.00 g). Biomasses produced by the remaining treatments were relatively similar to ~ 8.00 g. The compost incorporation to soil increased marketable fresh weight and dry biomass production of Chinese cabbage crop over control although statistically non-significant (p > 0.05).

Chemical amendment use in composting did not result in growth suppression of the crop. Phytotoxicity issues with compost have been reported previously due to factors including heavy metal content, soluble salts, organic acids and oxygen-deprivation related to the incomplete decomposition of composted materials (Blewett et al. 2005; Jacob and Banerjee 2017). The reason for the non-significant results observed in the current study could be due to two possible reasons. First, the compost application is found to give the good responses in soils with lower organic matter status whereas soil used in the study had very high organic matter content. In the present study, the soil used for the pot trial had a fairly high organic carbon and organic matter status (% OC, 3.90%). Second, the study was conducted for a short period. The Chinese cabbage crop was harvested by day 49. The benefits of compost application are pronounced in long-term trials due to improved soil physical properties such as aggregate stability, bulk density, soil–water relations, soil chemical properties as soil pH and nutrients content and biological properties such as enzyme activities, microbial biomass C and N and diversity of microbes (Chang et al. 2014; Fidelis and Rajashekhar Rao 2017).

Conclusions

The results of the study demonstrated that the addition of either gypsum (5%), phosphoric acid (1%) or double superphosphate (2%) has very little effect on preventing loss of ammonia during the composting of pod borer-infected waste cocoa pods. Chemical amendments could be particularly useful if cocoa pods have to be co-composted with N-rich animal manures, and composting mixtures involving a greater proportion of N-rich substrates. The final composts produced showed pH values slightly towards the higher side of an acceptable level, indicating caution in the choice of starters for the cocoa pod waste. In addition, chemical amendments like phosphoric acid could be used to obtain manure composts of desirable pH. Amended composts produced from cocoa pod wastes did not have any deleterious effect on plant growth at an application rate of 20 ton ha−1 in a pot culture study and were safe for use. Further studies are needed to evaluate the use of acidifying amendments or acidic wastes as a co-composting substrate with cocoa pod waste.

References

Adamtey N, Cofie O, Ofosu-Budu GK, Danso SKA, Forster D (2009) Production and storage of N-enriched co-compost. Waste Manage 29:2429–2436. https://doi.org/10.1016/j.wasman.2009.04.014

Allen T, Kariuki S (2014) Interpreting your compost test results. University of Massachusetts, Amherst

Askri A, Laville P, Trémier A, Houot S (2016) Influence of origin and post-treatment on greenhouse gas emissions after anaerobic digestate application to soil. Waste Biomass Valoriz 7(2):293–306. https://doi.org/10.1007/s12649-015-9452-6

Baker DE, Rayment GE, Reid RE (1983) Predictive relationships between pH and sodicity in soils of tropical Queensland. Commun Soil Sci Plant Anal 14(11):1063–1073. https://doi.org/10.1080/00103628309367432

Behera SN, Sharma M, Aneja VP, Balasubramanian R (2013) Ammonia in the atmosphere: a review on emission sources, atmospheric chemistry and deposition on terrestrial bodies. Environ Sci Pollut Res 20(11):8092–8131. https://doi.org/10.1007/s11356-013-2051-9

Benito-Mora C, Alonso-Contreras AJ, Garvi D, Pozo-Morales L, Morón MC, Lebrato J (2018) Olive mill industrial waste as co-substrate in anaerobic digestion with aim at its energetic exploitation. Inter J Environ Res 12(5):713–723. https://doi.org/10.1007/s41742-018-0123-x

Blewett TC, Roberts DW, Brinton WF (2005) Phytotoxicity factors and herbicide contamination in relation to compost quality management practices. Renew Agri Food Syst 20(02):67–72. https://doi.org/10.1079/RAF200498

Chang EH, Wang CH, Chen CL, Chung RS (2014) Effects of long-term treatments of different organic fertilizers complemented with chemical N fertilizer on the chemical and biological properties of soils. Soil Sci Plant Nutri 60(4):499–511. https://doi.org/10.1080/00380768.2014.917333

DeLaune PB, Moore PA, Daniel TC Jr, Lemunyon JL (2004) Effect of chemical and microbial amendments on ammonia volatilization from composting poultry litter. J Environ Qual 33(2):728–734. https://doi.org/10.2134/jeq2004.7280

Fidelis C, Rajashekhar Rao BK (2017) Enriched cocoa pod composts and their fertilizing effects on hybrid cocoa seedlings. Int J Recycl Org Waste Agric 6:99–106. https://doi.org/10.1007/s40093-017-0156-8

Hao X, Chang C, Larney FJ, Travis GR (2001) Greenhouse gas emissions during cattle feed lot manure composting. J Environ Qual 30(2):376–386. https://doi.org/10.2134/jeq2001.302376x

Hao X, Larney FJ, Chang C, Travis GR, Nichol CK, Bremer E (2005) The effect of phosphogypsum on greenhouse gas emissions during cattle manure composting. J Environ Qual 34(3):376–386. https://doi.org/10.2134/jeq2004.0388

Irshad M, Eneji AE, Hussain Z, Ashraf M (2013) Chemical characterization of fresh and composted livestock manures. J Soil Sci Plant Nutr 13(1):115–121

Jacob S, Banerjee R (2017) Nutrient enrichment of organic manure through biotechnological means. Waste Biomass Valoriz 8(3):645–657. https://doi.org/10.1007/s12649-016-9650-x

Kithome M, Paul JW, Bomke AA (1999) Reducing nitrogen losses during simulated composting of poultry manure using adsorbents or chemical amendments. J Environ Qual 28(1):194–201. https://doi.org/10.2134/jeq1999.00472425002800010023x

Li H, Xin H, Burns RT (2006) Reduction of ammonia emission from stored poultry manure using additives: zeolite, Al + clear, Ferix-3 and PLT. In: Agricultural and biosystems engineering conference proceedings and presentations, ASAE annual meeting, Paper No. 064188 held at Iowa State University, USA

Liyanage LR, Jayakody AN, Gunaratne GP (2014) Ammonia volatilization from frequently applied fertilizers for the low-country tea growing soils of Sri Lanka. Trop Agric Res 26(1):48–61. https://doi.org/10.4038/tar.v26i1.8071

Mandal S, Thangarajan R, Bolan NS, Sarkar B, Khan N, Ok YS, Naidu R (2016) Biochar-induced concomitant decrease in ammonia volatilisation and increase in nitrogen use efficiency by wheat. Chemosphere 142:120–127. https://doi.org/10.1016/j.chemosphere.2015.04.086

McCrory DF, Hobbs PJ (2001) Additives to reduce ammonia and odor emissions from livestock wastes: a review. J Environ Qual 30:345–355. https://doi.org/10.2134/jeq2001.302345x

Meena MD, Biswas DR (2014) Changes in biological properties in soil amended with rock phosphate and waste mica enriched compost using biological amendments and chemical fertilizers under wheat-soybean rotation. J Plant Nutr 37:2050–2073. https://doi.org/10.1080/01904167.2014.920368

Naseem S, King AJ (2018) Ammonia production in poultry houses can affect health of humans, birds, and the environment-techniques for its reduction during poultry production. Environ Sci Pollut Res 25(16):15269–15293. https://doi.org/10.1007/s11356-018-2018-y

Pagans E, Barrena R, Font X, Sanchez A (2006) Ammonia emissions from the composting of different organic wastes: dependency on process temperature. Chemosphere 62(9):1534–1542. https://doi.org/10.1016/j.chemosphere.2005.06.044

Prochnow LI, Cunha CF, Kiehl JC, Alcarde JC (2001) Controlling ammonia losses during composting by adding phosphogypsum and superphosphates with different levels of residual acidity. Rev Bras Ciênc Solo 25(1):65–70. https://doi.org/10.1590/S0100-06832001000100007

Reddy SR (2005) Principles of agronomy. Kalyani Publisher, Ludhiana

Sheridan B, Curran T, Dodd V, Colligan J (2002) Biofiltration of odour and ammonia from a pig unit a pilot-scale study. Biosyst Eng 82(4):441–453. https://doi.org/10.1006/bioe.2002.0083

Steiner C, Das KC, Melear N, Lakly D (2010) Reducing nitrogen loss during poultry litter composting using biochar. J Environ Qual 39(4):1236–1242. https://doi.org/10.2134/jeq2009.0337

Sultanbawa F (2005) Selected country paper—Sri Lanka (1). In: Ooi PA (ed) Nonpesticide methods for controlling diseases and insect pests. Asian Productivity Organization, Tokyo, pp 138–142

Tubail K, Chen L, Michel FC Jr, Keener HM, Rigot JF, Klingman M, Kost D, Dick WA (2008) Gypsum additions reduce ammonia nitrogen losses during composting of dairy manure and biosolids. Compost Sci Utiliz 16(4):285–293. https://doi.org/10.1080/1065657X.2008.10702390

Tuomela M, Vikman M, Hatakka A, Itavaara M (2000) Biodegradation of lignin in a compost environment: a review. Bioresour Technol 72(2):169–183. https://doi.org/10.1016/S0960-8524(99)00104-2

Vriesmann LC, Teo´filo RF, Petkowic CLV (2012) Extraction and characterization of pectin from cacao pod husks (Theobroma cacao L.) with citric acid. LWT Food Sci Technol 49(1):108–116. https://doi.org/10.1016/j.lwt.2012.04.018

Yen JD, Waters EK, Hamilton AJ (2010) Cocoa pod borer (Conopomorpha cramerella Snellen) in Papua New Guinea: biosecurity models for New Ireland and the autonomous region of Bougainville. Risk Anal 30(2):293–309. https://doi.org/10.1111/j.1539-6924.2009.01297.x

Acknowledgements

The European Union scholarship through BULA program awarded to the first author and the generous funding support of the Research Committee, PNG University of Technology are thankfully acknowledged.

Author information

Authors and Affiliations

Contributions

RV performed the experiments, collected the data, performed the statistical analysis and tabulated the data. BKRR concieved and designed the experiments and wrote the paper.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Vitinaqailevu, R., Rajashekhar Rao, B.K. The role of chemical amendments on modulating ammonia loss and quality parameters of co-composts from waste cocoa pods. Int J Recycl Org Waste Agricult 8 (Suppl 1), 153–160 (2019). https://doi.org/10.1007/s40093-019-0285-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40093-019-0285-3