Abstract

Purpose

The research was performed to assess the effect of vermicompost and tuber size on the storage behavior of potato during the ambient condition.

Methods

The research was consisted of two factors, i.e., factor A: vermicompost level (Vm-4): Vm1: 0 t ha−1 (control), Vm2: 3 t ha−1, Vm3: 6 t ha−1, and Vm4: 9 t ha−1; factor B: tuber size (T-5): T1: 5–10 g, T2: 10–20 g, T3: 20–30 g, T4: 30–40 g, and T5: > 40 g. The research was conducted in a split-plot design where vermicompost levels were assigned to the main plots and tuber sizes to the subplots.

Results

Vermicompost had a significant effect on most of the processing quality contributing parameters of potato. Processing quality parameters increased with increasing vermicompost level irrespective of tuber size. Among the 20 treatment combinations, vermicompost @ 9 t ha−1 with tuber size > 40 g exhibited the highest starch (23.81 mg g−1 FW), antioxidant (478.84 Trolox µMol 100 g−1 FW), polyphenol (96.133 GA mg 100 g−1 FW), and the lowest reducing sugar (0.1020 mg g−1 FW). In respect of ambient storage condition, starch decreased with increasing storage time; reducing sugar gradually increased with increasing storage time up to 40 days after storage (DAS) and after that slightly decreased and finally, potato became non-suitable for both table and processing purpose; antioxidant and polyphenol slightly increased up to 20 DAS and after that gradually decreased with increasing storage time.

Conclusions

Potato growers may use vermicompost for increasing and improving processing quality of potato.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Potato (Solanum tuberosum L.) belonging to the Solanaceae family is cultivated in almost 150 countries and is the world’s single most vital tuberous vegetable with an important part in the worldwide food network and food security (Singh 2010). It is the world’s fourth largest harvested crop following maize, wheat, and rice. The entire global potato production was estimated at 388,190,674 ton in 2017 (FAOSTAT 2017). It is the most highly cultivated tuber crop in the world with more than half of entire global production harvested in densely populated developing countries, like China and India (CIP 2019). In the world’s top 10 potato producing countries, Bangladesh ranks 7th position (FAOSTAT 2017; Mostofa 2019). In Bangladesh, potato is one of the main vegetable crops (Hoque 2010), and it positions second following rice in production (FAOSTAT 2017; Mostofa 2019). The total area, total production, and per ha yield of the potato crop in Bangladesh were 499,725 ha; 10,215,957 metric ton; and 22.53 t ha−1, respectively during 2017 (FAOSTAT 2017). The total production and consumption of potato are increasing day by day because of a substitute food crop and also a nutrient-rich crop as an alternative of rice and wheat (BBS 2015).

Potato is also characterized by high amounts of starch and lower content of sugars. It is a significant source of energy as well as various minerals and vitamins; including vitamin B6, folate, vitamin C, niacin, phosphorus, iron, magnesium, and potassium (Galdón et al. 2012; Gibson and Kurilich 2013). Potato is a significant source of natural antioxidants and demonstrates antioxidant activity as determined in the current time by many researchers (Navarre et al. 2011; Zarzecka and Gugala 2011). These substances have a beneficial effect on the human being, as they protect against cardiovascular disease, and cancer, as well as reduce blood cholesterol level (Liu 2013). Potato is unique compared to other vegetables in that they are exclusively consumed in processed forms. Potato tuber quality is one of the essential quality attributes for consumers and industrial demand (Pedreschi et al. 2016). Due to the increasing demand of consumers and foreign importers on this important crop, special attention should be given to increase its quality. Good processing qualities of potatoes are determined by high dry matter, high starch, high antioxidant, high polyphenol, and low reducing sugar and non-reducing sugar content (Abong et al. 2009). Low reducing sugar content is required to avoid dark color and bitter taste of processed products during frying, that negatively influence consumer acceptance (Wiltshire and Cobb 1996). In domestic consumption, also a high amount of reducing sugar content is not desirable. Vermicompost (organic fertilizer) is an excellent source of different macro- and micronutrients notably N, P, K, and S. It helps to increase microbial activity by improving the availability of soil phosphorus and nitrogen to plant. Due to the application of vermicompost in the soil, it functions as a cement like agent between soil particles and water holding clay to bind together; as a result, the crumb structures of the soil produce resistant against soil erosion and binds micronutrient metal ions in the soil to check leaching out from surface soils. It also contains humic acids, N-fixing, and P-solubilizing bacteria, plant growth stimulating substance such as auxins, cytokinins, and gibberellins (Chatterjee et al. 2014; Najar et al. 2015). Sometimes, potato produces in Bangladesh is not good quality enough in respect of starch content, reducing sugar content, antioxidant, and polyphenol content. Therefore, using a different amount of vermicompost may keep an outstanding contribution for increasing the processing quality of potato in Bangladesh. The objective of this research was to find out the influence of vermicompost and tuber size on bio-active compounds (starch, reducing sugar, antioxidant, and polyphenol) of potato under ambient storage condition.

Materials and methods

Experimental location

The research was performed at the experimental agronomy field of Sher-e-Bangla Agricultural University, throughout the duration from November 1, 2014 to April 30, 2015 and November 1, 2015 to April 30, 2016 in Rabi season (winter season). The research area was located at 23°77′N latitude and 90°38′E longitudes, and an altitude of 8.6 m from the sea level.

Soil condition and weather

The soil of the research area was of the common soil type series of shallow red brown terrace soils under Tejgaon series. Upper level soils were clay loam in texture, olive-gray through regular fine to average distinct dark yellowish-brown mottles under the Agro-ecological Zone (AEZ)-28 and belonged to the Madhupur Tract (Mostofa et al. 2019). Soil pH was 5.6 and had organic carbon 0.45%. Weather and soil condition are presented in Table 1.

Experimental treatment

The research consisted of two factors, viz., factor (A): vermicompost level (Vm1: 0 t ha−1 (control); Vm2: 3 t ha−1; Vm3: 6 t ha−1; Vm4: 9 t ha−1) and factor (B): seedling tuber size (S1: 5–10 g; S2: 10–20 g; S3: 20–30 g; S4: 30–40 g; S5: > 40 g). The seedling tuber of “BARI TPS-1” (True potato Seed Variety—1, released by Bangladesh Agricultural Research Institute) was used for the study.

Experimental design and layout

The research was conducted with three replications in a split-plot design. The vermicompost was assigned to the main plots and seedling tuber size to the subplots. The distance between row and row was 50 cm, plant and plant was 25 cm, and plot and plot was 75 cm. The area of a single plot was 2 m × 1.5 m and the total number of plots was 60.

Crop management

Collected potato seed tubers were graded according to the size 5–10 g, 10–20 g, 20–30 g, 30–40 g, > 40 g and kept in room temperature to assist good sprouting. Finally, uniformly sprouted seed tubers were used as planting material. The allocated plots were fertilized by recommended doses of Urea, Muriate of Potash (MOP), Triple Super Phosphate (TSP), Zinc Sulfate, Gypsum, and Boric Acid (Mondal et al. 2011) except treatment. The total amount of vermicompost was applied at 7 days before planting as per treatment. All the intercultural activities and plant protection measures were done as per when needed. After haulm cutting, the potato tubers were kept under the soil for 7 days to harden the skin.

Parameters determined

Data on different quality and processing parameters were determined. The same study was conducted under the same treatment under the same field condition in both years, and finally, the means were taken from those two experiments.

Extraction of starch and sugar

Potato flesh was extracted for the analysis of starch content and sugar content like reducing sugar (glucose). For each extraction, 1 g fresh sample of chopped potato was taken uniformly from tuber samples and smashed properly in a motor. Sugar was extracted using 5 ml of 80% EtOH (Ethanol) heated at 80 °C for 30 min using a dry block heat bath. Then, the extracts were centrifuged at 5000 rpm for 10 min and decanted the supernatant. It was repeated four-to-five times in total. All the supernatants were mixed properly, and the final volume was made up to 25 ml using 80% ethanol. The residues were collected from the extraction for starch analysis.

Determination of starch content

Starch content of potato was determined by the Somogyi–Nelson technique (Nelson 1944) with some modification. First, phosphate-buffered solution was prepared through diluted 0.74 g NaH2PO4·2H2O and 0.09 g Na2HPO4·12H2O into 100 ml double-distilled water. Then, 0.1 g enzyme (Amyloglucosidase) was added and blended properly. Then, it was preserved at − 20 °C. Second, the residues remained after sugar extraction were washed for several times with distilled water to make sure that there was no more soluble sugar in the residues. After that, using distilled water marked up to 250 ml in a beaker and stirred properly on a magnetic stirrer. Then, 0.5 ml solution was taken from the beaker during stirring into a test tube and boiled the test tube for 10 min at 100 °C. Then, 1 ml preserved solution was added, mixed properly, and heated at 50–60 °C for 120 min in hot water. After cooling, 0.5 ml copper solution was added, mixed properly, and heated at 100 °C for 10 min.; then, it was cooled in tap water, 0.5 ml Nelson solution was added, again mixed properly, 7 ml distilled water was added, mixed properly, and finally made the volume 9.5 ml. Then, the absorbance at 660 nm wavelength (Abs) was measured in a spectrophotometer against a blank sample. Starch content was calculated using the glucose standard curve. Calculated value is demonstrated as mg per g Fresh Weight (mg g−1 FW). Calculation of starch content, Starch = Abs × 0.9

Determination of reducing sugar content

Reducing sugar was determined by the photometric adaptation of the Somogyi technique (Nelson 1944) with some moderation. Standard glucose solution (0.5 ml), Nelson reagent, and copper solution were used for this method. First, 3 ml of the extracted solution was taken into a small glass container and properly dried up on an electric heater. Then, 3 ml distilled water was added and stirred properly in a vortex mixture. Second, 0.5 ml solution was taken in a test tube from the glass container. Then, 0.5 ml Copper solution was added and boiled at 100 °C for 10 min. After boiling, the test tube was cooled in tap water immediately. Then, 0.5 ml Nelson reagent was added and mixed properly. After 20 min, 8 ml distilled water was added and mixed properly, and finally, the total volume was made 9.5 ml. After that, the absorbance was calculated at 660 nm wavelength (Abs) in a spectrophotometer against a blank sample. From the absorbance reading, reducing sugar was calculated. Calculated value is demonstrated as mg per g Fresh Weight (mg g−1 FW).

Determination of antioxidant content

Different techniques are used to calculate the radical scavenging effects of antioxidants. The DPPH technique is a popular method, because it is quick, simple, reliable, and does not need a special reaction and sophisticated implement. DPPH is a stable, synthetic radical that does not degenerate in alcohol or water. Free radical scavenging activities of extracts rely on the capacity of antioxidant compounds to lose hydrogen and the structural conformation of these components. The DPPH free radical can simply collect an electron or hydrogen from antioxidant molecules to become a stable diamagnetic molecule at its highest wavelength at 517 nm. Total antioxidant capacity of fresh potato was calculated using the DPPH (2, 2-diphenyl-1-picrylhydrazyl) technique (Kedare and Singh 2011). Each blend was kept in darkness area for 30 min; then, the absorbance was calculated in a spectrophotometer at 517 nm wavelength against a blank sample (Shimada et al. 1992). Calculated values of antioxidant were expressed as Trolox equivalent µMol per 100 g Fresh Weight (Trolox µMol 100 g−1 FW) using a nonlinear regression algorithm from Trolox standard curve.

Determination of polyphenol content

The total polyphenol content was calculated in a spectrophotometer using the Folin–Ciocalteu technique (Singleton et al. 1999) with slight modification. The absorbance of the solution was calculated at 760 nm wavelength in a spectrophotometer against a blank sample. The measurement was compared to a standard curve of gallic acid solutions and calculated as milligram of gallic acid equivalent per 100 g Fresh Weight (mg GA 100 g−1 FW).

Statistical data analysis

The data acquired for different characters were statistically calculated based on the method of analysis of variance (ANOVA) using Statistix 10 (2013) analytical software. The significant variation among the treatment means was compared by Least Significant Difference (LSD) at 5% level of probability. The correlation (Pearson correlation method) was calculated based on data from 0 days of storage condition, i.e., at harvesting day. The available correlation graphs were plotted using Microsoft Excel 2016.

Results and discussion

Starch content

Significant variation was obtained among different levels of vermicompost on the starch content of tuber at different storage time. The highest starch content was taken by Vm4 (22.864 mg g−1 FW, 20.334 mg g−1 FW, 18.312 mg g−1 FW, and 14.407 mg g−1 FW) and minimum starch content was taken by Vm1 (17.892 mg g−1 FW, 14.809 mg g−1 FW, 12.031 mg g−1 FW, and 7.711 mg g−1 FW), at 0, 20, 40, and 60 DAS, respectively (Table 2). Profound dissimilarity was observed among different tuber sizes on the starch content of tuber at different storage time. The highest starch content was obtained by T5 (21.427 mg g−1 FW, 18.671 mg g−1 FW, 16.212 mg g−1 FW, and 12.270 mg g−1 FW) and minimum was obtained by T1 (19.408 mg g−1 FW, 16.916 mg g−1 FW, and 14.457 mg g−1 FW, 10.350 mg g−1 FW), at 0, 20, 40, and 60 DAS, respectively (Table 2). Among different interaction of vermicompost levels and tuber sizes, significant dissimilarity was shown on starch content at different storage time. At 0 DAS, maximum starch content (23.813 mg g−1 FW) was observed by Vm4T5 which was analytically similar to Vm4T4 and minimum (17.353 mg g−1 FW) was contained by Vm1T1 which was analytically similar to Vm1T2. At 20 DAS, maximum starch content (21.050 mg g−1 FW) was contained by Vm4T5 which was analytically similar to Vm4T4 and minimum (14.410 mg g−1 FW) was contained by Vm1T1 which was analytically similar to Vm1T2. At 40 DAS, maximum starch content (18.913 mg g−1 FW) was contained by Vm4T5 which was analytically similar to Vm4T4 and the minimum (11.793 mg g−1 FW) was contained by Vm1T1 which was analytically similar to Vm1T2. At 60 DAS, maximum starch content (14.977 mg g−1 FW) was contained by Vm4T5 which was analytically similar to Vm4T4 and the minimum (7.213 mg g−1 FW) was contained by Vm1T1 which was analytically similar to Vm1T2 (Table 2).

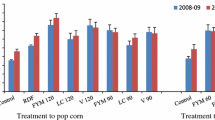

During ambient storage condition, starch content was decreased according to increasing storage time because of increased respiration, metabolism, and physiological aging of potato tubers. During ambient storage condition, sprouting was accelerated higher carbohydrate consumption and breakdown of starch into glucose and fructose (Wiltshire and Cobb 1996). A negative linear relation (r = − 0.94) was found between starch content and reducing sugar content (Fig. 1a). A direct association was found between dry matter content and starch content. When sprouting of potato tuber was started, high rates of starch hydrolysis and reducing sugar accumulation were required to provide carbon and energy used for sprout growth and development, which negatively affected potato processing quality by decreasing dry matter content and increasing dark color of potato chips (Wiltshire and Cobb 1996; Bisognin et al. 2008).

Reducing sugar content

Significant dissimilarity was got among different levels of vermicompost on reducing sugar content of tuber at different storage time. The maximum reducing sugar content was contained by Vm1 (0.4205 mg g−1 FW, 0.5831 mg g−1 FW, 0.9561 mg g−1 FW, and 0.7842 mg g−1 FW) and minimum reducing sugar content was contained by Vm4 (0.1178 mg g−1 FW, 0.2347 mg g−1 FW, 0.4200 mg g−1 FW, and 0.3528 mg g−1 FW), at 0, 20, 40, and 60 DAS, respectively (Table 3). Noteworthy, variation was obtained among different tuber sizes on reducing sugar content of tuber at different storage time. At 0 DAS, maximum reducing sugar content (0.2838 mg g−1 FW) of tuber was taken by T1 and minimum (0.2540 mg g−1 FW) was taken by T5 which was analytically similar to T4. At 20 DAS, maximum reducing sugar content (0.4140 mg g−1 FW) of tuber was taken by T1 which was analytically similar to T2 and the minimum (0.3982 mg g−1 FW) was taken by T5 which was analytically similar to T4. At 40 DAS, maximum reducing sugar content (0.6791 mg g−1 FW) of tuber was taken by T1 and minimum (0.6481 mg g−1 FW) was taken by T5 which was analytically similar to T4. At 60 DAS, maximum reducing sugar content (0.5641 mg g−1 FW) of tuber was taken by T1 and minimum (0.5397 mg g−1 FW) was taken by T5 which was analytically similar to T4. Significant variation was found among different interaction of vermicompost levels and tuber sizes on reducing sugar content of tuber at different storage time. At 0 DAS, maximum reducing sugar content (0.4317 mg g−1 FW) of tuber was contained by Vm1T1 and minimum (0.1020 mg g−1 FW) was contained by Vm4T5 which was analytically similar to Vm4T4. At 20 DAS, maximum (0.5960 mg g−1 FW) reducing sugar content of tuber was contained by Vm1T1 which was analytically similar to Vm1T2 and minimum (0.2280 mg g−1 FW) was contained by Vm4T5 which was analytically similar to Vm4T4 and Vm4T3. At 40 DAS, maximum reducing sugar content (0.9933 mg g−1 FW) of tuber was contained by Vm1T1 and minimum (0.4110 mg g−1 FW) was contained by Vm4T5 which was analytically similar to Vm4T4. At 60 DAS, maximum reducing sugar content (0.7950 mg g−1 FW) of tuber was contained by Vm1T1 which was analytically similar to Vm1T2 and minimum (0.3447 mg g−1 FW) was contained by Vm4T5 which was analytically similar to Vm4T4 (Table 3).

There was a positive correlation between the quantity of nitrogen accessible for plants and nitrate concentration in leaves (Drews et al. 1996). Besides, there was an opposite correlation between nitrates and reducing sugar concentration. This happening could be connected to the conservation of osmotic potential in plants when photosynthetic activity was reduced; as a result, the sugar concentration in the tissues was increased; the presence of nitrates would compensate the decrease of the osmotic potential (Leon et al. 2012). The significant increase in reducing sugar content was reported here later in the storage period due to earlier sprouting and the associated depletion of carbohydrate reserves in the tuber (Abbasi et al. 2016).

Antioxidant content

Profound dissimilarity was found among different levels of vermicompost on the antioxidant content of tuber at different storage time. The highest antioxidant content was taken by Vm4 (472.51 Trolox µMol 100 g−1 FW, 494.38 Trolox µMol 100 g−1 FW, 393.86 Trolox µMol 100 g−1 FW, and 319.38 Trolox µMol 100 g−1 FW) and minimum antioxidant content was observed by Vm1 (391.09 Trolox µMol 100 g−1 FW, 405.34 Trolox µMol 100 g−1 FW, 335.42 Trolox µMol 100 g−1 FW, and 218.60 Trolox µMol 100 g−1 FW), at 0, 20, 40, and 60 DAS, respectively (Table 4). Significant variation was got among different tuber sizes on antioxidant of tuber at different storage time. The highest antioxidant content was contained by T5 (452.53 Trolox µMol 100 g−1 FW, 476.21 Trolox µMol 100 g−1 FW, 376.61 Trolox µMol 100 g−1 FW, and 272.73 Trolox µMol 100 g−1 FW) and lowest was obtained by T1 (426.79 Trolox µMol 100 g−1 FW, 445.90 Trolox µMol 100 g−1 FW, 349.16 Trolox µMol 100 g−1 FW, and 244.82 Trolox µMol 100 g−1 FW), at 0, 20, 40, and 60 DAS respectively (Table 4). Significant variation was found among the different combination of vermicompost levels and tuber sizes on the antioxidant content of tuber at different storage time. The maximum antioxidant content was taken from Vm4T5 (478.84 Trolox µMol 100 g−1 FW, 516.59 Trolox µMol 100 g−1 FW, 420.93 Trolox µMol 100 g−1 FW, and 344.18 Trolox µMol 100 g−1 FW), and minimum was taken from Vm1T1 (366.09 Trolox µMol 100 g−1 FW, 385.27 Trolox µMol 100 g−1 FW, 296.96 Trolox µMol 100 g−1 FW, and 205.84 Trolox µMol 100 g−1 FW), at 0, 20, 40, and 60 DAS, respectively (Table 4).

Total antioxidant activity (AA) was decreased in potato due to the unavailability of the substrate and its subsequent reduction during storage. Prominent antioxidant activity was increased in different treatments, after the first month till the end of the storage time might be associated with a decreased substrate (antioxidant) reduction (Delaplace et al. 2009). A positive correlation (r = 0.87) was found between antioxidant content and starch content (Fig. 1b).

Polyphenol content

Noteworthy, dissimilarity was observed among different levels of vermicompost on polyphenol content of tuber at different storage time. The maximum polyphenol content was contained by Vm4 (86.070 GA mg 100 g−1 FW, 88.924 GA mg 100 g−1 FW, 82.631 GA mg 100 g−1 FW, and 71.579 GA mg 100 g−1 FW), and minimum polyphenol content was contained by Vm1 (35.561 GA mg 100 g−1 FW, 39.099 GA mg 100 g−1 FW, 32.293 GA mg 100 g−1 FW, and 24.168 GA mg 100 g−1 FW), at 0, 20, 40 and 60 DAS, respectively (Table 5). Remarkable difference was obtained among different tuber sizes on the polyphenol content of tuber at different storage time. The highest polyphenol content was taken by T5 (69.932 GA mg 100 g−1 FW, 72.913 GA mg 100 g−1 FW, 66.257 GA mg 100 g−1 FW, and 55.411 GA mg 100 g−1 FW), and minimum polyphenol content was taken by T1 (61.643 GA mg 100 g−1 FW, 64.677 GA mg 100 g−1 FW, 58.254 GA mg 100 g−1 FW, and 49.792 GA mg 100 g−1 FW), at 0, 20, 40, and 60 DAS, respectively (Table 5). Significant variation was found among dissimilar interaction of vermicompost levels and tuber sizes on polyphenol content of tuber at different storage time. The maximum polyphenol content was observed by Vm4T5 (96.133 GA mg 100 g−1 FW, 99.487 GA mg 100 g−1 FW, and 92.877 GA mg 100 g−1 FW), and minimum was observed by Vm1T1 (34.420 GA mg 100 g−1 FW, 37.930 GA mg 100 g−1 FW, and 31.133 GA mg 100 g−1 FW), at 0, 20, and 40 DAS, respectively. At 60 DAS, maximum polyphenol content (74.380 GA mg 100 g−1 FW) of tuber collected by Vm4T5 and minimum antioxidant content (23.210 GA mg 100 g−1 FW) was found by Vm1T1 which was analytically similar to Vm1T2 (Table 5).

Polyphenol oxidase (PO) activity was increased in potato due to the availability of substrate and its subsequent oxidation during storage. Prominent PO activity was increased in different treatments after the first month till the end of the storage period might be associated with an increased substrate (polyphenol) oxidation. A high amount of phenolics during storage was attributed to low PO and high antioxidant activity in potatoes (Chizzola et al. 2008; Lachman et al. 2008). A strong positive correlation (r = 0.95) was observed between antioxidant and polyphenol content (Albishi et al. 2013) (Fig. 1c). The experiment revealed that the polyphenol content in potato continued to increase during storage period until the onset of PO activity (Madiwale et al. 2011); for this reason, storage time and condition are also critical factors for phenolic compounds (Kulen et al. 2013). A strong positive correlation (r = 0.92) was observed between polyphenol content and starch content (Fig. 1d).

Conclusion

From this experiment, it may be concluded that vermicompost performed excellent compatibility on BARI TPS-1 as a source of good organic manure in combination with conventional recommended doses of chemical fertilizers. Vermicompost also played a vital role in improving the processing quality of potato. Results also concluded that higher tuber weight might improve potato quality. Among the twenty (20) treatment combinations though, Vm4T5 that is vermicompost 9 t ha−1 and tuber size > 40 g exhibited the superior quality that is highest starch content, antioxidant content, and polyphenol content, and also exhibited lowest reducing sugar content compared to those of other treatments. Moreover, the potato growers of Bangladesh may be benefited for potato cultivation using vermicompost; they can produce high-quality potato tuber and can store without decreasing processing quality at ambient storage condition up to 40 DAS. Ultimately, they can sell their quality products to high profitable processing and exporting industries with a fair and high price.

References

Abbasi KS, Masud T, Qayyum A, Khan SU, Ahmad A, Mehmood A, Farid A, Jenks MA (2016) Transition in quality attributes of potato (Solanum tuberosum L.) under different packaging systems during storage. J Appl Bot Food Qual 89:142–149. https://doi.org/10.5073/JABFQ.2016.089.017

Abong GO, Okoth MW, Karuri EG, Kabira JN, Mathooko FM (2009) Evaluation of selected Kenyan potato cultivars for processing into french fries. J Anim Plant Sci 2(3):141–147

Albishi T, John JA, Al-Khalifa AS, Shahidi F (2013) Phenolic content and antioxidant activities of selected potato varieties and their processing by-products. J Funct Foods 5(2):590–600. https://doi.org/10.1016/j.jff.2012.11.019

BBS (2015) Bangladesh Bureau of Statistics, Yearbook of Agricultural Statistics. Ministry of Planning, Govt. Peoples Repub, Bangladesh

Bisognin DA, Freitas STD, Brackmann A, Andriolo JL, Pereira EIP, Muller DR, Bandinelli MG (2008) Physiological aging of potato tubers produced during fall and spring growing seasons and stored under different temperatures. Bragantia 67(1):59–65

Chatterjee R, Bandyopadhyay S, Jana JC (2014) Evaluation of vegetable wastes recycled for vermicomposting and its response on yield and quality of carrot (Daucus carota L.). Int J Recycl Org Waste Agric 3(2):60. https://doi.org/10.1007/s40093-014-0060-4

Chizzola R, Michitsch H, Franz C (2008) Antioxidative properties of Thymus vulgaris leaves: comparison of different extracts and essential oil chemotypes. J Agric Food Chem 56(16):6897–6904. https://doi.org/10.1021/jf800617g

CIP (2019) potato facts and figures. https://cipotato.org/crops/potato/potato-facts-and-figures. Accessed 19 Apr 2019

Delaplace P, Fauconnier ML, Sergeant K, Dierick JF, Oufir M, Van der Wal F, Du Jardin P (2009) Potato (Solanum tuberosum L.) tuber ageing induces changes in the proteome and antioxidants associated with the sprouting pattern. J Exp Bot 60(4):1273–1288. https://doi.org/10.1093/jxb/erp008

Drews M, Schonhof I, Krumbein A (1996) Nitrate, vitamin C and sugar content of lettuce (Lactuca sativa) depending on cultivar and stage of head development. Gartenbauwissenschaft 61(3):122–129

FAOSTAT (2017) Statistical database. Food and Agricultural Organization of United Nations, Rome, Italy. http://www.fao.org/faostat/en/#data. Accessed 13 Sept 2018

Galdón BR, Rodríguez LH, Mesa DR, León HL, Pérez NL, Rodríguez Rodríguez EM, Romero CD (2012) Differentiation of potato cultivars experimentally cultivated based on their chemical composition and by applying linear discriminant analysis. Food Chem 133(4):1241–1248. https://doi.org/10.1016/j.foodchem.2011.10.016

Gibson S, Kurilich AC (2013) The nutritional value of potatoes and potato products in the UK diet. Nutr Bull 38(4):389–399. https://doi.org/10.1111/nbu.12057

Hoque ME (2010) In vitro tuberization in potato (Solanum tuberosum L.). Plant Omics J 3(1):7–11

Kedare SB, Singh RP (2011) Genesis and development of DPPH method of antioxidant assay. J Food Sci Technol 48(4):412–422. https://doi.org/10.1007/s13197-011-0251-1

Kulen O, Stushnoff C, Holm DG (2013) Effect of cold storage on total phenolics content, antioxidant activity and vitamin C level of selected potato clones. J Sci Food Agric 93(10):2437–2444. https://doi.org/10.1002/jsfa.6053

Lachman J, Hamouz K, Orsak M, Pivec V, Dvorak P (2008) The influence of flesh colour and growing locality on polyphenolic content and antioxidant activity in potatoes. Sci Hortic 117(2):109–114. https://doi.org/10.1016/j.scienta.2008.03.030

Leon AP, Martin JP, Chiesa A (2012) Vermicompost application and growth patterns of lettuce (Lactuca sativa L.). Agricultura Tropica et Subtropica 45(3):134–139. https://doi.org/10.2478/v10295-012-0022-7

Liu RH (2013) Health-promoting components of fruits and vegetables in the diet. Adv Nutr 4(3):384S–392S. https://doi.org/10.3945/an.112.003517

Madiwale GP, Reddivari L, Holm DG, Vanamala J (2011) Storage elevates phenolic content and antioxidant activity but suppresses antiproliferative and pro-apoptotic properties of colored-flesh potatoes against human colon cancer cell lines. J Agric Food Chem 59(15):8155–8166. https://doi.org/10.1021/jf201073g

Metrological Centre (Climate Division), Agargaon, Dhaka, Bangladesh. Retrieved on January 6, 2017. http://www.bmd.gov.bd/

Mondal MRI, Islam MS, Jalil MAB, Rahman MM, Alam MS, Rahman MHH (2011) Krishi Projukti Hat boi (handbook of agro-technology), 5th edn. Bangladesh Agricultural Research Institute, Gazipur-1701, Bangladesh, p 307

Mostofa M (2019) An introduction to bioethanol and its prospects in Bangladesh: a review. J Energy Res Rev 2(2):1–12. https://doi.org/10.9734/JENRR/2019/v2i229738

Mostofa M, Roy TS, Chakraborty R, Modak S, Kundu PK, Zaman MS, Rahman M, Shamsuzzoha M (2019) Effect of vermicompost and tuber size on processing quality of potato during ambient storage condition. Int J Plant Soil Sci 26(3):1–18. https://doi.org/10.9734/ijpss/2018/46554

Najar IA, Khan AB, Hai A (2015) Effect of macrophyte vermicompost on growth and productivity of brinjal (Solanum melongena) under field conditions. Int J Recycl Org Waste Agric 4(2):73–83. https://doi.org/10.1007/s40093-015-0087-1

Navarre DA, Pillai SS, Shakya R, Holden MJ (2011) HPLC profiling of phenolics in diverse potato genotypes. Food Chem 127(1):34–41. https://doi.org/10.1016/j.foodchem.2010.12.080

Nelson N (1944) A photometric adaptation of the Somogyi method for the determination of glucose. J Biol Chem 153:375–380

Pedreschi F, Mery D, Marique T (2016) Grading of potatoes. In: Sun DW (ed) Computer vision technology for food quality evaluation, 2nd edn. Academic Press, London, pp 369–382. https://doi.org/10.1016/B978-0-12-802232-0.00015-3

Shimada K, Fujikawa K, Yahara K, Nakamura T (1992) Antioxidative properties of xanthone on the auto oxidation of soybean in cyclodextrin emulsion. J Agric Food Chem 40(6):945–948. https://doi.org/10.1021/jf00018a005

Singh M (2010) Projection of potato export from India: a Markov chain approach. potato J 37(1–2):48–55

Singleton VL, Orthofer R, Lamuela-Raventós RM (1999) Analysis of total phenols and other oxidation substrates and antioxidants by means of Folin–Ciocalteu reagent. Methods Enzymol 299:152–178. https://doi.org/10.1016/s0076-6879(99)99017-1

Statistix R (2013) Statistix 10 analytical software, Tallahassee, FL, USA

Wiltshire JJJ, Cobb AH (1996) A review of the physiology of potato tuber dormancy. Ann Appl Biol 129(3):553–569. https://doi.org/10.1111/j.1744-7348.1996.tb05776.x

Zarzecka K, Gugala M (2011) The effect of herbicides and soil tillage systems on the content of polyphenols in potato tubers. Pol J Environ Stud 20(2):513–517

Acknowledgements

The authors thankfully acknowledged the Ministry of Education, Government of the People’s Republic of Bangladesh for supporting to conduct the experiment.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest with this research.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Mostofa, M., Roy, T.S. & Chakraborty, R. Bio-active compounds of potato influenced by vermicompost and tuber size during ambient storage condition. Int J Recycl Org Waste Agricult 8 (Suppl 1), 225–234 (2019). https://doi.org/10.1007/s40093-019-00293-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40093-019-00293-9