Abstract

The aim of the present study is to examine the behaviour of cold-formed steel (CFS) lipped channel built-up I-section with edge and intermediate web stiffeners under bending. Initially, the section dimension of length, width of the flange and depth of the sections are optimized numerically and finally, it is validated with the test results. All the select cross-section dimensions have satisfied the pre-qualified beam dimensions. Numerical analysis is carried out using the software ABAQUS. Totally, four section geometries are tested experimentally. After validation, a total of 75 parametric studies are carried out using the verified finite element model. All the results are compared with the direct strength method specifications for CFS structures and the suitable design modifications are detailed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Cold-formed steel (CFS) members have become ready for the action of building products in modern building construction due to their inherent constructive uniqueness over conventional hot-rolled steel members. The reason is that, the CFS members provide enormous advantages such as high strength-to-weight ratio, high structural efficiency and so on over hot-rolled members. The load capacity of CFS beam depends on buckling mode like local buckling (LB), distortional buckling (DB), lateral torsional buckling (LTB), flexural buckling (FB) or interactions among them.

Experimental and numerical investigations on CFS C-section flexural member were carried out by Wang and Zhang (2008). An experimental study on laser-welded CFS built-up beams was conducted by Landolfo et al. (2008). Paczos and Wasilewicz (2009) have investigated the buckling studies on lipped CFS I-shaped beam with anti-symmetrical bends, which increase the load capacity, and while designing, special attention needs to be paid to their size. Magnucka-Blandzi (2010) has studied the behaviour of CFS channel beams with double-box flange beams. Magnucka-Blandzi and Magnucki (2010) have investigated the global–local buckling behaviour of thin-walled channel beams. The LTB behaviour of CFS lipped channel beams under bending was examined by Kankanamge and Mahendran (2010). Anapayan and Mahendran (2010) have presented the behaviour and capacity of light steel flexural members subject to LTB. Numerical investigation of CFS members subjected to bending and compression of built-up double Z-members has been discussed by Georgieva et al. (2011).

Similarly, Madulia et al. (2012) have developed the new design rules for in-elastic bending capacity of CFS channel sections. Haidarali and Nethercot (2012a, b) have investigated the true buckling behaviour of beam with both edge and intermediate stiffeners in their compression flanges on the post-buckling of laterally restrained CFS Z-section beam. Manikandan et al. (2014, 2015, 2016) have investigated the behaviour of thin-walled built-up I beams in pure bending. Experimental and numerical studies on the flexural behaviour of CFS built-up section were performed by Alex and Iyappan (2016), Yang et al. (2017) and Hassan et al. (2017).

There are only a minimal amount of studies available on the behaviour of the CFS built-up section under bending and it is observed that studies on built-up beam with intermediate stiffener are almost nil. Hence, in the current study, the lipped channel built-up sections with intermediate web stiffeners are chosen. Totally, four section geometries are tested and the results are validated numerically. A total of 75 parametric studies were carried out using finite element analysis (FEA) software ABAQUS. The aim of the study is to examine the behaviour of CFS built-up I-section with edge and intermediate stiffeners under bending. All the parametric results are compared with the DSM specifications for CFS structures and a suitable design modification is proposed.

Experimental investigation

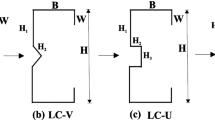

Totally, four types of built-up cross-section are tested: first is the simple lipped channel (SLC), second is the simple lipped channel with intermediate web stiffener (SLC-I), third is the complex lipped channel (CLC) and fourth is the complex lipped channel with intermediate web stiffener (CLC-I). Material properties of the specimens are determined by conducting tensile tests on steel coupons as per the IS standard (IS 1608 -2006).

Totally, three coupons are tested and the average results of yield stress, Young’s modulus are presented in Table 1 and Fig. 1. The select cross-section profile with defined nomenclature is illustrated Fig. 2 and the corresponding dimensions are listed in Table 2.

The entire cross-section dimensions satisfy the limitations of pre-qualified sections in DSM. Based on the literature support (Kankanamge and Mahendran 2012) and fabrication requirements, the sizes of lips and intermediate stiffeners are limited to 20 mm. Built-up I-section consists of two identical C-channel sections connected back-to-back using self-tapping screws with a spacing of 100 mm. Specimens are tested in a loading frame with a capacity of 250 kN under the simply supported boundary condition subject to two-point loading. Loads are applied using screw jack with a capacity of 100 kN. Lateral restraints are provided at the support as shown in Fig. 2. During the tests, a proving ring and dial gauges are used to measure the applied load and deformations, respectively. A typical experimental test set-up is illustrated in Fig. 3. All the specimens are tested up to the failure.

Finite element modelling

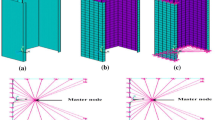

The finite element model (FEM) is developed using the numerical analysis software ABAQUS. In this study, material and geometric non-linearities are incorporated, whereas residual stress and cold-forming process are not incorporated (Xu et al. 2009). For defining the material non-linearity, multi-linear stress–strain behaviour is adopted. The numerical investigation involves two types of analysis. One is linear and the other one is non-linear. In the linear analysis, the sections are considered to have a perfect geometry to determine the probable buckling behaviour. In the non-linear analysis, both geometric and material non-linearities are incorporated (Manikandan et al. 2014; Manikandan and Sukumar 2015, 2016, Kankanamge and Mahendran 2012).

The numerical models are discredited using shell element (S4R) with a mesh size of 10 mm × 10 mm (Manikandan and Sukumar 2015). All the beams are analysed under simply supported boundary condition with two-point loading condition. The lateral restraints are provided at the supports as shown in Fig. 4. To make a built-up section numerically, the fastener option is used (Kankanamge and Mahendran 2012). The detailed FEM model is shown in Fig. 3. In this study, initial imperfection is not measured; however, a magnitude of L/1000 is incorporated (Manikandan et al. 2014; Manikandan and Sukumar 2015, 2016; Kankanamge and Mahendran 2012, GB 2002).

Selection of section dimensions

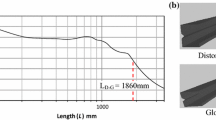

For arriving at the section dimensions, initially, 33 FEMs are analysed. To minimize the LB, in the entire study, the dimension of the lips (d1), flange width of the section (b), depth of the section (H), length of the member (L), bolt spacing and thickness of the section are taken as 20, 40, 75, and 1200 mm, respectively, and the variations of these dimensions are specified in the appropriate places.

Basic properties of the cross-sections and buckling plots are obtained from the software CUFSM as shown in Fig. 5. Length (L), depth (H), flange width (b), size of the lips (d1) and bolt spacing (S) are identified from the specimen labelling. For example, in “L900’’, the first letter L defines the length and the second value defines the corresponding dimensions in milimeter. The effect of variation of section dimensions of the dimension of the lips (d1), flange width of the section (b), depth of the section (H), length of the member (L), bolt spacing is displayed in Fig. 6 and Table 3. From Fig. 5, it is observed that the optimal length, depth, width, bolt spacing and lip size are 1200, 75, 40, 50 and 20 mm, respectively. From this parametric study, it is observed that length, depth, width, bolt spacing and lip size significantly affect the strength of the section.

Result and discussion

Totally, four types of cross-section are tested and the results are displayed in Table 4, while the load–deflection curve for specimens SLC-I and CLC is illustrated in Fig. 6. In this study, the interaction of LB and LTB is investigated and given in Fig. 7. The flexural strength of the specimens SLC, SLC-I, CLC and CLC-I is 5.06 kN.m, 7.88 kN.m, 7.38 kN.m and 10.21 kN.m, respectively. From Table 4 and Fig. 7, it is observed that the strength of the section increased by improving the section geometries from simple lip to complex lip. Figure 8 shows the load–deflection behaviour of simple and complex lipped channel section with and without intermediate web stiffeners. From Fig. 8, it is observed that CLC-I and CLC perform well in all aspects compared to SLC-I and SLC, because a complex lip improves the torsional rigidity of the section and intermediate web stiffeners reduce the LB of the web element. Another important observation noted is that compared to CLC-I, CLC offers more post-buckling strength. The mean and standard deviation of MEXP and MFEM are 0.98 and 0.01, respectively. From Figs. 8 and 9 and Table 4, it seems that the numerical analysis agrees well with the test results. Consequently, an extensive parametric study is carried out to examine the factors which affect the behaviour and strength of all the tested sections.

Parametric study

The effect of length variation of the sections SLC, SLC-I, CLC and CLC-I is investigated and the results are shown in Table 5. The load–deformation curve for SLC and CLC series of specimens is shown in Fig. 10. The failure modes such as LTB and the interaction of LTB and FB are investigated. From this study, the strength of the section is noted to decrease with an increase in the member length.

Theoretical investigation

As per the DSM (22) for CFS structures, the nominal flexural strength (MDSM) is the minimum of lateral–torsional buckling (Mne), local buckling (Mnl) and distortional buckling (Mnd) as given below.

The lateral–torsional buckling strength (Mne) is

The local buckling strength (Mnl) is

The distortional buckling strength (Mnd)

The comparison of results of MFEA and MDSM is shown in Table 5 and Fig. 11. Except CLC-I series, DSM specification provides conservative results in the beam length that is less than 1500 mm and this is elaborately discussed in Figs. 11 and 12. The mean and standard deviation between MFEA and MDSM are 0.96 and 0.07, respectively. From this theoretical investigation, it is concluded that generally DSM specification provides moderate results for built-up flexural members. Hence, in this study, a new design equation is developed as represented in Fig. 13) for the CFS built-up structures.

Conclusion

The FEM using ABAQUS software is perfect in predicting the strength and the behaviour of the beams. Therefore, the FEM developed can be used with a high level of assurance in predicting the capacity of the beams. Design of CFS built-up I beam with and without intermediate web stiffeners requires the consideration of FB and interaction of FB and LTB. Keeping the length and cross-sectional area the same by adding the intermediate web stiffeners has a considerable effect on the strength and the behaviour of the beam, which is due to minimizing the LB and the increase in the moment of inertia about a symmetrical axis and the increase in resistance against torsional buckling. Adding the complex edge stiffener at the flange has a considerable result in terms of the strength and behaviour of the beams. This study has shown that the provision of intermediate web stiffeners and edge stiffeners improves the behaviour and increases the strength of the section.

Abbreviations

- b :

-

Breadth of flange

- CFS:

-

Cold-formed steel

- H :

-

Depth of the section

- L :

-

Length of the section

- d1:

-

Lip size

- d1:

-

Size of return lip

- S :

-

Size of intermediate stiffener

- t :

-

Thickness of the section

- PFEA :

-

Ultimate load from FEA

- MEXP :

-

Ultimate moment from experiment

- MFEA :

-

Ultimate moment from FEA

- MDSM :

-

Ultimate moment from DSM

- My :

-

Yield moment

- DSM:

-

Direct strength method

- FEA:

-

Finite element analysis

- FEM:

-

Finite element model

- EXP:

-

Experimental result

References

Alex J, Iyappan GR (2016) Experimental study on flexural behaviour of cold formed steel section. Int J Res Sci Engg Tech 40:219–222

Anapayan T, Mahendran M (2010) Mahaarachchi D Lateral distortional buckling tests of a new hollow flange channel beam. Thin Walled Struct. 49:13–25

GB 50018-2002, Technical code of cold-formed thin- walled steel structures. Beijing, China; 2002

Georgieva I, Schueremans L, Pyl L, Vandewalle L (2011) Numerical study of built-up double- z members in bending and compression. Thin Walled Struct 60:85–97

Haidarali MR, Nethercot DA (2012a) Local and distortional buckling of cold-formed steel beams with edge-stiffened flanges. J Constr Steel Res 54:106–111

Haidarali MR, Nethercot DA (2012b) Local and distortional buckling of cold formed steel beams with both edge and intermediate stiffeners in their compression flanges. Thin Walled Struct 73:37–42

Hassan EM, Serror MH, Mourad SA (2017) Numerical prediction of available rotation capacity of cold-formed steel beams. J Constr Steel Res 128:84–98

IS: 1608–2006, Indian specification, Mechanical testing of materials- Tensile testing, India

Kankanamge ND, Mahendran M (2010) Behaviour and design of cold-formed steel beams subject to lateral-torsional buckling. Thin Walled Struct 51:25–38

Kankanamge ND, Mahendran M (2012) Behaviour and design of cold-formed steel beams subject to lateral- torsional buckling. Thin Walled Struct 51:25–38

Landolfo R, Mammanaa O, DI Portioli F, Lorenzo G, Guerrieri MR (2008) Laser welded built-up cold-formed steel beams: experimental investigations. Thin Walled Struct 46:781–791

Madulia S, Bambach MR, Zhao XL (2012) Inelastic behaviour and design of cold- formed channel sections in bending. Thin Walled Struct 51:158–166

Magnucka-Blandzi E (2010) Effective shaping of cold-formed thin-walled channel beams with double-box flanges in pure bending. Thin Walled Struct 49:121–128

Magnucka-Blandzi E, Magnucki K (2010) Buckling and optimal design of cold-formed thin-walled beams: review of selected problems. Thin Walled Struct 49:554–561

Manikandan P, Sukumar S (2015) Behaviour of stiffened cold-formed steel built-up sections with complex edge stiffeners under bending. KSCE J Civil Engg 19(7):2108–2115

Manikandan P, Sukumar S (2016) Effect of stiffened element and edge stiffener in strength and behaviour of cold formed steel built-up beams. J. Adv Comput Design An Int J1(2):207–220

Manikandan P, Sukumar P, Balaji TU (2014) Effective shaping of cold-formed thin- walled built-up beams in pure bending. Arabian J Sci Engg 39:6043–6054

Paczos P, Wasilewicz P (2009) Experimental investigations of buckling of lipped, cold- formed thin walled beams with I-section. Thin Walled strut 47:1354–1362

Wang H, Zhang Y (2008) Experimental and numerical investigation of cold-formed steel C-section flexural members. J Constr Steel Res 65:1225–1235

Xu L, Sultana P, Zhou X (2009) Flexural strength of cold-formed steel built-up sections. Thin Walled Struct 47:807–815

Yang B, Kang S, Xiong G, Nie S, Hu Y, Wang S, Bai J, Dai G (2017) Experimental and numerical study on lateral-torsional buckling of singly symmetric Q460GJ steel I-shaped beams. Thin Walled Struct 113:205–216

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Manikandan, P., Thulasi, M. Investigation on cold-formed steel lipped channel built-up I beam with intermediate web stiffener. Int J Adv Struct Eng 11, 97–107 (2019). https://doi.org/10.1007/s40091-019-0220-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40091-019-0220-x