Abstract

Background

Adsorption of lead(II) ions onto activated carbons prepared from the marine green Ulva fasciata sp. (CCUC, SSUC and SCUC) and commercially activated carbon (CAC) was investigated with the variation in the parameters of pH, contact time, lead(II) ions concentration and the adsorbent dose. The Langmuir, Freundlich and Temkin models have been applied.

Results

Results showed that the adsorption process was better described by the Langmuir model. Adsorption kinetics data obtained for the metal ions sorption were investigated using reversible first order, pseudo-first order, pseudo-second order and intraparticle diffusion model. The maximum adsorption capacities (Q0) were 22.93 mg/g for CCUC, 24.15 mg/g for SSUC, 23.47 mg/g for SSUC and 15.62 mg/g for CAC.

Conclusions

It was found that the kinetics data fitted well into the pseudo second-order kinetics and SSUC is a superior adsorbent for the removal of Pb(II) ions from aqueous solution.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Background

The presence of heavy metals in the aquatic environmental has been a big deal to scientists and engineers due to their increased discharge, toxic nature, and other adverse effects on receiving waters [1, 2]. Lead is widely used in many important industrial applications, such as storage battery, manufacturing, printing pigments, fuels, photographic materials, and explosive manufacturing [3]. Lead exposure causes weakness in fingers, wrists and ankles. The effects of lead toxicity are very wide ranging and include impaired blood synthesis, hypertension, severe stomach-ache, brain, kidney damage and even can cause miscarriage in pregnant women [4]. The permissible level for lead in drinking water is 0.05 mg L−1 according to the US Environmental Protection Agency (EPA). Therefore, a very low concentration of lead in water is very toxic [5].

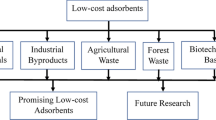

The removal of such a heavy metal from contaminated water bodies has been attempted by several scientists employing a wide variety of techniques including chemical precipitation, ion-exchange, electro flotation, membrane filtration, reverse osmosis, etc. All these methods are generally expensive. For this reason, there is a need for developing economic and eco-friendly methods for waste minimization and fine-tuning of the wastewater [6]. The most popular of these technologies is activated carbon adsorption and widely used, but it is expensive. Therefore, there is a growing interest in using low-cost, easily available materials for the adsorption of metal ions. A low-cost adsorbent is defined as one which is abundant in nature, or is a by-product or waste material from another industry. Many algae, yeasts, bacteria and other fungi are known to be capable of concentrating metal species from dilute aqueous solutions and accumulating them within their cell structure [7]. Recently, green algae are attractive as they are ubiquitous in natural environment, have large surface area-to-volume ratio and high binding affinity to pollutants [8]. Ulva fasciata sp. algal cell walls are porous and allow the free passage of molecules and ions in aqueous solutions. The constituents of the cell wall provide an array of ligands with different functional groups capable of binding various heavy metals [9].

The objective of this work is to study the adsorption of lead (II) ions from aqueous solutions onto activated carbons from marine green U. fasciata and commercially activated carbon (CAC). The effects of pH, contact time, initial lead (II) ion concentration and adsorbent dose were examined. The adsorption isotherm, kinetic and thermodynamic parameters were deduced from the adsorption measurements.

Methods

Preparation of adsorbent

The green marine algae U. fasciata in the present study were collected from the coastal area of Kanyakumari district, Tamil Nadu, India. The collected algae were washed with tap water and further by deionized water several times to remove impurities. The washing process was continued till the removal of all dirt. The washed algae were then completely dried in sun light for 7 days.

Calcium chloride-treated U. fasciata carbon (CCUC)

The dried algae U. fasciata to be carbonized is impregnated with solution of chloride salts such as calcium chloride for 24 h. Accordingly, sufficient quantities were soaked well with 10 % chloride solution of 5 L capacity, respectively, so that the solution get well adsorbed for a period of 24 h. At the end of 24 h the excess solution was decanted off and air dried. Then, the materials were placed in muffle furnace carbonized at 400 °C. The dried materials were powdered and activated in a muffle furnace kept at 800 °C for a period of 10 min. After activation, the carbon was washed sufficiently with 4 N HCl to remove the cations. Then, the materials were washed with plenty of water to remove excess acid, dried and powdered [10].

Sodium carbonate treated U. fasciata carbon (SCUC)

In this method the dried algae U. fasciata to be carbonized were soaked in 10 % sodium carbonate solution for a period of 24 h. After impregnation, the liquid portion was decanted off and the material dried. The dried mass was subjected to carbonization process at 400 °C, powdered well and finally thermally activated at 800 °C for a period of 10 min [10].

Sodium sulphate-treated U. fasciata carbon (SSUC)

In this method the dried algae U. fasciata to be carbonized were soaked in 10 % solutions of sodium sulphate for a period of 24 h. After impregnation, the liquid portion was decanted off and then dried. The dried mass was subjected to carbonization process at 400 °C powdered well and finally thermally activated at 800 °C for a period of 10 min [10]. In the present study, the powdered activated carbons (CCUC, SSUC and SCUC) of algae U. fasciata in the range of 150 μm particle size and particle size of CAC in the range of 150 µm were used as adsorbents.

Preparation of metal ion solution

A stock solution of lead (II) ions concentration 1,000 mg/L was prepared by dissolving an accurate quantity of 1.6 g Pb(NO3)2 (Merck) in deionized water. Other concentrations prepared from stock solution by dilution varied between 10 and 80 mg/L and the pH of the working solutions was adjusted to desired values with 0.1 N HCl or 0.1 N NaOH. Fresh dilutions were used for each experiment.

Batch adsorption studies

Batch adsorption equilibrium experiments were conducted for the adsorption of lead on activated carbons of green algae U. fasciata and CAC as a function of initial pH, initial Pb(II) concentration, adsorbent dose and contact time by adding 0.2 g of dried carbon to 100 mL of lead solution with different concentrations in 250-mL stoppered reagent bottles at a constant shaking speed (250 rpm). All the experiments were carried out at room temperature (28 ± 2 °C). For studying the influence of pH on the adsorption of Pb(II), the experiments were conducted at various initial metal solution pH values of 1–10. The pH of each solution was adjusted to different values with either 0.1 N NaOH or 0.1 N HCl. The concentrations of Pb(II) ions in solution before and after adsorption were determined using atomic adsorption spectrophotometer (Model Elico-SL 163, India) by monitoring the absorbance for the metal ion used. All adsorption experiments were carried out in triplicates to check the reproducibility of results. The equilibrium and kinetics data were obtained from batch experiments.

During the adsorption, a rapid equilibrium established between adsorbed metal ions on the active cites of adsorbent (qe) and unabsorbed metal ion in the solution. The amount of adsorption at equilibrium (qe) (mg/g) and the percentage adsorption (%) were computed as follows:

where C0 and represented the initial and equilibrium concentrations (mg/L), V is the volume of solution and X the weight of adsorbent (g).

Results and discussion

Effect of pH on Pb(II) adsorption

The pH of aqueous solution is an important factor and influences the metal speciation in aqueous solution as well as the surface properties of adsorbent and therefore can affect the extent of adsorption [11]. Thus, the adsorption behaviour of Pb(II) on the surface of activated carbons prepared from U. fasciata (CCUC, SSUC and SCUC) and commercially available activated carbon (CAC) has been investigated over a pH range of 1.0–10.0 at room temperature with 100 mL of Pb(II) ion concentration 20 mg/L containing 0.2 g activated carbon and contact time 2 h. The results are shown in Fig. 1, from the graph it is observed that the adsorption of Pb(II) varies with pH and hence Pb(II) adsorption on CCUC, SSUC, SCUC and CAC is highly pH dependent. The percentage of Pb(II) adsorption on CCUC, SSUC, SCUC and CAC increased with increasing pH and reached a plateau value at around pH range 4. Around pH 4, the surface of activated carbon is negative and there is a strong electrostatic attraction between surface groups and Pb(II) species. As a result, at pH 4 the adsorption of Pb(II) is high. Below and above of this pH value 4 the adsorption process was decreased. At highly acidic pH, the overall surface charge on the active sites became positive and metal cations and protons compete for binding sites on cell wall, which results in lower uptake of metal [12]. As pH increases, more ligands such as amino, phosphate and carboxyl groups would be exposed and carry negative charges with subsequent attraction of metal ions [13, 14]. The maximum adsorption for CCUC was found to 91.54.62 %, for SSUC it was about 97.24 %, for SCUC was found to 95.37 % and attaining maximum value of 74.87 %, respectively, at pH 4. Hence, further adsorption experiments were carried out an optimum pH 4 for CCUC, SCUC, SSUC and CAC.

Effect of contact time

Effect of contact time on the adsorbed amount of Pb(II) by CCUC, SSUC, SCUC and CAC was studied in the range of 30–300 min. The experiments were carried out using 100 mL of Pb(II) concentration 20 mg/L containing 0.2 g activated carbon at pH 4 for CCUC, SCUC, SSUC and CAC with agitation speed 250 rpm at room temperature. The results are shown in Fig. 2 and it is evident from the figure that the rate of adsorption of Pb(II) by CCUC, SSUC, SCUC and CAC was rapid and more than 90 % Pb(II) ions were adsorbed within 30 min, thereafter adsorption process was decreased gradually and became constant when equilibrium was reached. The equilibrium times for activated carbons made from U. fasciata and CAC were 60 and 90 min, respectively. After it reached the equilibrium, there were no significance changes in lead concentration in the solution. However, as can be seen, the rate of adsorption of Pb(II) ions on CCUC, SSUC and SCUC surface was faster than CAC. From the results, it has been observed that 60 min time was sufficient for attaining the equilibrium for activated carbons of U. fasciata, the removal of 91.24 % Pb(II) by CCUC, 97.34 % Pb(II) by SSUC and 95.47 % Pb(II) by SCUC. However, 75.19 % of Pb(II) was removed by CAC in a period of 90 min.

Initial Pb(II) concentration

The dependence of the adsorption process of lead adsorption from different initial concentrations (10–80 mg L−1) by the adsorbents is shown in Fig. 3. The experiments were carried out using 100 mL of Pb(II) concentrations varying from 10 to 80 mg/L at pH 4 for CCUC, SSUC, SCUC and CAC, an amount of 0.2 g/100 mL of adsorbent was used for each adsorption experiment and contact time 2 h. Analysis of percentage adsorption versus initial varying concentration of Pb(II) ions showed that the percentage adsorption decreased with increase in initial concentration of the adsorbate, but the uptake capacity increased with increase in initial concentration. At lower concentrations of lead ions, the number of lead ions which are available in the solution is less as compared to the available sites on the adsorbent. However, at higher concentrations the available sites for adsorption become fewer and the percentage removal of lead ions depends on the initial concentration. The maximum removal of Pb(II) was achieved at 10 mg/L of lead solution on CCUC, SSUC, SCUC and CAC were 93.45, 99.24, 97.84 and 80.25 %, respectively.

Effect of adsorbent dose

To find out the effect of adsorbent dose for the adsorption of Pb(II) from aqueous solution, adsorption studies were carried out by varying the amount of adsorbents while keeping pH 4 for both activated carbons of U. fasciata and CAC, initial metal concentration (20 mg/L), shaking speed 250 rpm and at room temperature. The percentage of adsorption increases for an increase in adsorbent dose and remains constant as shown in Fig. 4. Higher percentage of adsorption with the increase of adsorbent concentration can be attributed to increase in surface area and the availability of more binding sites for adsorption. This suggests that after a certain dose of adsorbent, the maximum adsorption sets in and hence the amount of ions bound to the adsorbent and the amount of free ions remains constant even with further addition of the dose of adsorbent [15]. It is known that a minimum carbon dosage of 0.15 g/100 mL was sufficient for the maximum removal of 91.84 % lead by CCUC, 97.65 % lead by SSUC and 95.48 % lead by SCUC. But 0.20 g/100 mL of CAC required for maximum removal of 75.42 % lead. The results show that SSUC was found to be superior adsorbent than other activated carbons.

Adsorption isotherms

Adsorption isotherms express the relation between the amount of adsorbed metal ions per unit mass of biosorbent (qeq) and the metal concentration in solution (Ceq) at equilibrium. The data of sorption equilibrium in this work was tested with Langmuir, Freundlich and Temkin isotherms as expressed in Eqs. (3), (5) and (6), respectively. The experimental data on the effect of an initial concentration of metal on the carbon of the test medium were fitted to the isotherm models and all of the constants are presented in Table 1.

Langmuir adsorption isotherm

The Langmuir adsorption model is based on the assumption of surface homogeneity such as equally available adsorption sites, monolayer surface coverage, and no interaction between adsorbed species [16, 17]. The mathematical description of this model is

Based on the further analysis of Langmuir equation, the essential features of the Langmuir isotherm can be expressed in terms of a dimensionless constant, separation factor, or equilibrium parameter RL, which is defined by the following equation [18, 19]

where C0 (mg L−1) is the initial amount of adsorbate and b (L mg−1) is the Langmuir constant described above. The RL parameter is considered as a more reliable indicator of the adsorption There are four probabilities for the RL value: (1) for favourable adsorption 0 < RL < 1; (2) for unfavourable adsorption RL > 1; (3) for linear adsorption RL = 1, and (4) for irreversible adsorption RL = 0.

The plot of Ce/qe versus Ce showed that the experimental data fitted reasonably well to the linearised equation of the Langmuir isotherm over the whole Pb(II) concentration range studied. The correlation coefficient R2, Q0 and b were evaluated from the slope and intercept of the plot and are shown in Table 1. The maximum adsorption capacities (Q0) were 22.935 mg/g for CCUC, 24.154 mg/g for SSUC, 23.474 mg/g for SSUC and 15.625 mg/g for CAC. It is also known from the Table 1 that SSUC show maximum values of Q0 (24.154 mg/g) and b (0.238 L/mg), respectively. Therefore, SSUC could be a better adsorbent for Pb(II) ions removal from aqueous solutions than CCUC, SCUC and CAC. In this study, the RL values were found to be 0.117 for CCUC, 0.076 for SSUC, 0.0842 for SCUC and 0.156 in the case of CAC, respectively. Thus, RL values are representing that adsorption of Pb(II) is favourable to Langmuir isotherm.

Freundlich adsorption isotherm

The Freundlich equation is the empirical relationship whereby it is assumed that the adsorption energy of binding to a site on an adsorbent depends on whether or not the adjacent sites are already occupied. One limitation of the Freundlich model is that the amount of adsorbed solute increases indefinitely with the concentration of solute in the solution. This empirical equation takes the form

The linear plots of log X/m versus log Ce give that the Freundlich isotherm was also representative for the Pb(II) adsorption by the activated carbon adsorbents. The correlation coefficient R2, KF and 1/n were calculated from the slopes of the Freundlich plots and 1/n values were found to be 0.353, 0.238, 0.284 and 0.347 for CCUC, SSUC, SSUC and CAC, respectively. The magnitude of KF and 1/n shows easy separation of Pb(II) ion from water solution and high adsorption capacity. The value of 1/n, which is related to the distribution of bonded ions on the adsorbent surface, represents beneficial adsorption if it is between 0.1 and 1. The 1/n values for the carbon adsorbents are indicating that adsorption of Pb(II) is favourable.

Temkin adsorption isotherm

Another model, Temkin isotherm, was also used to fit the experimental data. Unlike the Langmuir and Freundlich equation, the Temkin isotherm takes into account the interactions between adsorbents and metal ions to be adsorbed and is based on the assumption that the free energy of sorption is a function of the surface coverage [20]. The isotherm is as follows:

The Temkin isotherm assumes that the heat of adsorption of all the molecules in a layer decreases linearly due to adsorbent–adsorbate interactions and that adsorption is characterized by a uniform distribution of binding energies, up to some maximum binding energy [21]. A plot of qe versus ln Ce enables the determination of the isotherm constants B and KT from the slope and the intercept, respectively. Temkin constants are given in Table 1. The correlation factors show that the Langmuir model approximation to the experimental results is better than Freundlich and Temkin model. Since the value of R2 values nearer to one, indicating that the respective Langmuir and Temkin isotherm models are better fits for the experimental data.

Kinetics of adsorption

Kinetics analysis is required to get an insight of the rate of adsorption and the rate-limiting step of the transport mechanism, which are primarily used in the modelling, and design of the process. The Lagergren’s pseudo-first-order, first-order reversible and pseudo-second-order model were performed to the experimental data to clarify the adsorption kinetics of Pb(II) ions onto activated carbons of U. fasciata and CAC.

Pseudo-first-order kinetic model

The experimental data were fitted with the linear form of the pseudo-first-order rate equation by the Lagergren [22] is given as

where qe and q t are the amounts of metal adsorbed (mg g−1) at equilibrium and at time t (min), k1 (min−1) is the rate constant of pseudo-first-order adsorption rate. The linear plots of log (qe − q t ) versus ‘t’ drawn for the pseudo-first-order model is shown in Fig. 5. The rate constant k1 can be obtained from the plot of experimental data. The plot for first-order rate equation (Eq. 6) was made at different adsorption parameters. The rate constant along with the statistical parameters such as coefficient of determination and the values from the pseudo-first-order kinetic model are given in Table 2. From the table it is observed that there is hardly any change in the value of rate constant at various adsorption parameters.

First-order reversible reaction model

The sorption of metal ion from liquid phase to solid may be considered as reversible reaction with an equilibrium state between two phases [23].

where U(t) is called the fractional attainment of equilibrium and is given by ‘CAe’ and ‘CBe’ are the equilibrium concentrations of adsorbate and adsorbent, respectively. The plot of ln (1−U t ) against ‘t’ for the first-order reversible rate as shown in Fig. 6 was drawn for Pb(II) adsorption on activated carbons of U. fasciata and CAC. The values of the first-order reversible kinetic parameters such as ‘k’ ‘k1’ and ‘k2’ were calculated using Eqs. (7) and (8) are given in Table 2.

The pseudo-second-order kinetic model

Experimental data were also tested by the pseudo-second-order kinetic model which is given in the following form [24]:

where k2 (g/mg min) is the rate constant of the second-order equation, q t (mg/g) is the amount of adsorption time t (min) and qe is the amount of adsorption equilibrium (mg/g). The values of k2 and were calculated from the plots between t/q t vs. t, which is represented in Fig. 7. The values of rate constants along with the statistical parameters are listed in following Table 2. From Table 2, it can be seen that the linear correlation of pseudo-second-order kinetic model for Pb(II) are high. However, indicated the first-order reversible and pseudo-first-order kinetic models were poor fit for Pb(II) adsorption. It can also be found from Table 2 that qe values for the pseudo-second-order kinetic model are all very high. These suggested that the adsorption processes of activated carbons of U. fasciata and CAC for Pb(II) can be well described by the pseudo-second-order kinetic model rather than the pseudo-first-order and first-order reversible kinetic models.

Intra-particle diffusion model

Due to porous nature of the adsorbent used in this study, pore diffusion is also expected in addition to surface adsorption. The contact time variation experiments were used to study the rate-determining step in the adsorption process. Intra-particle diffusion model used here refers to the theory proposed by Weber and Morris. The initial rate of intra-particle diffusion can be obtained by linearization of the curve according to equation [25, 26]

where (mg/g) is the amount of the metal adsorbed at time t and is the intra-particle diffusion rate constant (mg/g min1/2). Figure 8 depicts that intra-particle diffusion is slow and the slope of the linear portion of the curve gives the value of .

The values were found to be 0.0387, 0.0416, 0.0352 and 0.0763 for activated carbons CCUC, SCUC, SSUC and CAC, respectively. The linear portions of the curves did not pass through the origin, hence the mechanism of lead adsorption on activated carbons (CCUC, SCUC, SSUC and CAC) is both the surface adsorption as well as intra-particle diffusion.

Thermodynamic studies

Temperature dependence of the adsorption process is associated with several thermodynamic parameters. In order to describe the thermodynamic behaviour of the adsorption of Pb(II) ions onto activated carbons, the standard Gibbs free energy is calculated by using the following equation:

where R is the universal gas constant (8.314 J mol−1 K−1), T is the temperature in Kelvin and K is the equilibrium constant, calculated as the surface and solution metal distribution ratio (K = 1/b). The negative values of (−2.785 kJ/mol for CCUC, −2.354 kJ/mol for SSUC, −2.625 kJ/mol for SCUC and −4.404 kJ/mol for CAC) indicate the spontaneous nature of the adsorption process. However, the negative value of decreases with an increase in temperature, indicating that the spontaneous nature of adsorption is inversely proportional to the temperature.

Conclusions

In this study, the use of activated carbons (CCUC, SSUC and SCUC) prepared from marine green algae U. fasciata and CAC were tested as adsorbents for removal of Pb(II) ions from aqueous solution. The batch study parameters, pH of solution, contact time, initial Pb(II) concentration, adsorbent dose were found to be effective on the adsorption efficiency of Pb(II). The Langmuir, Freundlich and Temkin isotherm models were used for the mathematical description of the adsorption of lead (II) ions onto activated carbons and the isotherm constants were evaluated from these isotherms. Results indicated that the adsorption equilibrium data fitted well the Langmuir and Temkin isotherm models. The results show that the pseudo-second-order mechanism is predominant and that chemisorption might be the rate-limiting step that controls the adsorption process. Intra-particle diffusion should also be taken into account, but it was observed that intra-particle diffusion is not a rate-determining step. While comparing the percentage removal and adsorption capacity of activated carbons made from U. fasciata (CCUC, SCUC and SSUC) with CAC, the activated carbons of U. fasciata are superior adsorbents than CAC. This is due to more negatively charged binding sites in U. fasciata activated carbons than that of CAC. The study revealed that activated carbon (SSUC) from U. fasciata has much potential as an adsorbent for the removal of Pb(II) ions from aqueous solution.

References

Sekar M, Sakthi V, Rengaraj S (2004) Kinetics and equilibrium adsorption study of lead (II) onto activated carbon prepared from coconut shell. J Colloid Interf Sci 279:307–313

Volesky B (1990) Removal and recovery of heavy metals by biosorption. CRC Press, Boca Raton, pp 7–43

Jalali R, Ghafourian H, Asef Y, Davarpanah SJ, Sepehr S (2002) Removal and recovery of lead using non-living biomass of marine algae. J Hazard Mater 92:253–262

Toxicological profile for lead (1999) US Department of Health and Human Services, Public Health Services (Agency for Toxic Substances and Diseases Registry). Atlanta

Bhattacharjee S, Chakrabarty S, Maity S, Kar S, Thakur P, Bhattacharyya G (2003) Removal of lead from contaminated water bodies using sea nodule as an adsorbent. Water Res 37:3954–3966

Ayyappan R, Carmalin Sophia A, Swaminathan K, Sandhya S (2005) Removal of Pb(II) from aqueous solution using carbon derived from agricultural wastes. Process Biochem 40:1293–1299

Akthar N, Sastry S, Mohan M (1995) Biosorption of silver ions by processed Aspergillus niger biomass. Biotechnol Lett 17:551–556

Chong AMY, Wong YS, Tam NFY (2000) Performance of different microalgal species in removing nickel and zinc from industrial wastewater. Chemosphere 41:251–257

Gong R, Ding YD, Liu H, Chen Q, Liu Z (2005) Lead biosorption by intact and pretreated spirulina maxima biomass. Chemosphere 58:125–130

Karthikeyan S, Sivakumar P, Palanisamy PN (2008) Novel activated carbons from agricultural wastes and their characterization. Electron J Chem 5:409–426

Sreejalekshmi KG, Krishnan KA, Anirudhan TS (2009) Adsorption of Pb(II) and Pb(II)-citric acid on sawdust activated carbon: kinetic and equilibrium isotherm studies. J Hazard Mater 161:1506–1513

Iqbal M, Edyvean R (2004) Biosorption of lead, copper and zinc ions on loofa sponge immobilized biomass of Phanerochaete chrysosporium. Miner Eng 17:217–223

Onmez GCD, Aksu Z, Ozturk A, Kutsal T (1999) A comparative study on heavy metal biosorption characteristics of some algae process. Biochem 34:885–889

Aksu Z (2001) Equilibrium and kinetic modelling of cadmium(II) biosorption by C. vulgaris in a batch system: effect of temperature. Sep Purif Technol 21:285–294

Nomanbhay SF, Palanisamy K (2005) Removal of heavy metal from industrial wastewater using chitosan coated oil palm shell charcoal. Electron J Biotechnol 8:44–53

Arica MY, Bayramoglu G, Yılmaz M, Genc O, Bektas S (2004) Biosorption of Hg2+, Cd2+ and Zn2+ by Ca-alginate and immobilized wood-rotting fungus Funalia trogii. J Hazard Mater 109:191–199

Sheng PX, Ting YP, Chen JP, Hong L (2004) Sorption of lead, copper, cadmium, zinc, and nickel by marine algal biomass: characterization of biosorptive capacity and investigation of mechanisms. J Colloid Interface Sci 27:131–141

Malkoc E, Nuhoglu Y (2007) Potential of tea factory waste for Cr(VI) removal from aqueous solution: thermodynamic and kinetic studies. Sep Purif Technol 54:291–298

Ozer A, Ozer D (2004) The adsorption of copper (II) ions on to dehydrated wheat bran (DWB): determination of the equilibrium and thermodynamic parameters. Process Biochem 39(12):2183–2191

Deng SB, Ting YP (2005) Fungal biomass with grafted poly (acrylic acid) for enhancement of Cu(II) and Cd(II) biosorption. Langmuir 21:5940–5948

Areco MM, Afonso MS (2010) Copper, zinc, cadmium and lead biosorption by Gymnogongrus torulosus. Thermodynamics and kinetics studies. Biointerfaces 81:620–628

Lagergren S, Svenska BK (1898) Zur theorie dersogenannten adsorption geloester stoffe Vetenskapsakad Handlingar. Band 24:1–39

Michelsen L, Gideon P, Pace E, Kutal L (1975) Removal of soluble Hg from water by complexing techniques, United States Department of Interior (U. S. D. I) Office of Water Research and Technology, Bull No 74

Ho YS, McKay G (1999) Pseudo-second order model for sorption processes. Process Biochem 34:451–465

Guibal E (1998) Metal-anion sorption by chitosan beads: equilibrium and kinetic studies. Ind Eng Chem Res 37:1454–1463

Weber W (1963) Kinetics of adsorption on carbon from solution Sanit. Eng Div Am Soc Civ Eng 89 (SA2:31–40)

Conflict of interest

The authors declare that they have no competing interests.

Authors’ contributions

RPSJK carried out the experiments and analysis, VC participated in interpretation of results and drafted the manuscript and also helped in the experiments and analysis. Both authors have read and approved the final manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

This article is published under license to BioMed Central Ltd. Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Jeyakumar, R.P.S., Chandrasekaran, V. Adsorption of lead (II) ions by activated carbons prepared from marine green algae: equilibrium and kinetics studies. Int J Ind Chem 5, 10 (2014). https://doi.org/10.1007/s40090-014-0010-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40090-014-0010-z