Abstract

The water immersion through-transmission method is widely used owing to its simplicity and high precision in measuring sound speed. However, when measuring the sound speed of a compound material whose host medium is water, such as hydrogel tissue-mimicking material (TMM), the reproducibility and reliability of the measurements obtained under the state of water immersion method were found to be low. To solve this problem, the application of contact transmission method instead of the water immersion method was examined in this study. Unlike the water immersion method, the direct-contact method requires stability in target stiffness, which is difficult in TMM hydrogels due to their low-stiffness properties. Therefore, it is important to find a material that acts as a propagation medium, maintains thickness, and prevents percentage change of the material component in TMM. As a propagation medium, it is necessary for the material to have a low attenuation coefficient value to increase the signal-to-noise ratio. Among the investigated candidate materials, polymethyl methacrylate (PMMA) was selected, owing to its lowest signal attenuation value compared to other candidate materials. A measuring jig was designed and manufactured with this material. The sound speeds of agar and gelatin TMMs were measured by the conventional water immersion through-transmission method and the proposed indirect contact-type method for comparison. In the case of the conventional water immersion method, as the measurement was repeated, the measured sound speeds showed a decreasing trend. By contrast, the indirect contact-type measurements using the PMMA jig showed relatively high reproducibility and reliability.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Tissue-mimicking material (TMM), which closely mimics the physical properties of human tissue [1], is widely used for the performance testing and optimization of medical ultrasound for ultrasonic phantom [2], such as experiments to demonstrate scientific theories [3], validate computational models [4], train sonographers [5], and supply reference material for calibration [6]. Although the detailed physical properties required for the TMMs can be different by application, the most important acoustic properties are the speed of sound and attenuation coefficient in the material as a function of frequency, which can be measured by the conventional water immersion through-transmission method.

The basic concept of the through-transmission method is to compare two signals (reference signal and test signal) that have passed between the transmitter and the receiver facing each other on the opposite sides of the reference and test materials. The method is carried out either by direct contact of the transducers on the test material or by indirect contact using a propagation medium. In the case of direct contact, it is difficult to handle soft TMM due to the deformation of the sample during mounting of the transducer. Hence, indirect contact using water as the propagation medium and reference material is commonly used for convenience so that one can replace the materials simply by removing the test sample from of the water [17,18,19].

Among the various types of TMM materials, hydrogel TMMs, such as agar and gelatin have similar sound speeds as human tissue [6,7,8,9,10,11,12,13]. However, past experimental results showed that when agar TMM is placed in water, the glycerol leaches out of the sample, which changes the speed of sound in the material [10]. In the case of gelatin TMM, volumetric expansion occurs due to water absorption, which also restricts the accurate measurement of sound speed using the water immersion through-transmission method [11,12,13,14,15,16]. Thus, despite the simplicity of the through-transmission method in water, accurate measurement of the sound speed of hydrogel TMM is not simple, and it requires an alternative propagation medium. Hence, in this study, a solid material made of polymethyl methacrylate (PMMA) was suggested as a propagation medium instead of water due to its stability, definite shape, fixed volume, and low attenuation coefficient value, which provides sufficient signal-to-noise ratio (SNR) [20, 21]. This study provided the precise measurement of the sound speed of hydrogel TMM adopting PMMA as a propagation medium instead of water using the through-transmission method. Basic equations to determine the sound speed of the sample with the method are described in Sect. 2.1. Experimental setup using a transducer jig and preparation of the hydrogel TMMs, agar and gelatin are explained in Sects. 2.2 and 2.3. For comparison, measurement of sound speed using water as a propagation medium was also carried out, and it was shown that using PMMA as a propagation medium resolved the problems observed for hydrogel TMMs in the water environment and provided a more reliable and accurate sound speed value, as discussed in Sects. 3.1 and 3.2. It was hypothesized that the frequency dependence of the sound speed in hydrogel TMMs would be negligible due to the high concentration of water, which was more than 80%, and was validated in the frequency range from 1 to 10 MHz, as discussed in Sect. 3.2.

2 Materials and methods

2.1 Sound speed measurement using the through-transmission method

The through-transmission method is a conventional way of measuring the sound speed of a sample, which is also adopted in this study for the sound speed measurement of hydrogel TMMs. This method compares the traveled signals from the transmitter to the receiver through the reference (water or PMMA) and test material (water or sample), as shown in Fig. 1 [22]. A tone-burst signal with 5 cycles was used as the transmitting signal to improve SNR and reduce the shift of the peak frequency instead of a broadband pulse [23, 24]. By this method, the sound speed of the sample in the frequency domain can be expressed as:

where \({v}_{w}\) denotes the intrinsic sound speed of water described by Del Grosso [18], \(f\) denotes the frequency, \({\theta }_{s}(f)\) and \({\theta }_{w}(f)\) denote the phases of the received signals with and without the sample, respectively. Equation (1) remains valid even when the propagation medium between the transmitter and receiver is substituted from water to PMMA. Although the alternative propagation medium does not affect Eq. (1), it is important to minimize the attenuation of the transmitted signals to get a sufficient SNR. The total travel distance in the propagation medium, \(X,\) is obtained by the summation of distances \({x}_{1}\) (from transmitter to the front face of the material) and \({x}_{2}\) (from the real face of the material to the receiver). When the reference material (water) is tested in pure water or PMMA, the magnitude of the acoustic pressure that arrives at the receiver is \({P}_{0}{e}^{-{\alpha }_{w}\left(X+L\right)}\) or \({P}_{0}{e}^{-\left[{\alpha }_{m}X+{\alpha }_{w}L\right]}\), where \({P}_{0}\) is the magnitude of the transmitting acoustic pressure, \(L \mathrm{is sample thickness}, \mathrm{and} {\alpha }_{w} \mathrm{and} {\alpha }_{m}\) are the attenuation coefficients of water and PMMA, respectively. Then, the difference in the sound pressure level (SPL) between the two pressures becomes:

The attenuation coefficient of water is proportional to the square of the frequency by the following equation:

\(\alpha_{w} = \alpha_{w0} \times f^{2} ,\) where \({\alpha }_{w0}\) is a function of water temperature defined as \(\alpha_{w0} = \left( {56.8524 {-} 3.02545T + 0.117416T^{2} {-} 0.00295430T^{3} + 3.96985 \times 10^{ - 5} T^{4} {-} 2.11091 \times 10^{ - 7} T^{5} } \right) \times 10^{ - 5} {\text{ Np cm}}^{ - 1} {\text{MHz}}^{ - 2} ,\)and T is temperature in degree Celsius [25,26,27]. At 22.5 °C, \({\alpha }_{w0}=2\times {10}^{-3}\) \(\mathrm{dB }{\mathrm{cm}}^{-1}{\mathrm{MHz}}^{-2}\). To get the lowest signal attenuator material as an alternative propagation medium in the indirect transmission method, the evaluation of SNR produced by each candidate material can be easily denoted by a comparison of the sound pressure level difference between water and the candidate material (dB) using Eq. (2).

2.2 Experimental setup

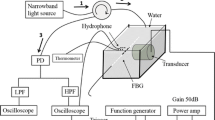

Figure 2 is the block diagram of the measurement system using the through-transmission method. An N-cycled tone-burst signal with a 1 ms pulse repetition time is generated by the waveform generator (33600A, Keysight Technologies, California, United States) and is amplified by the Radio-Frequency power amplifier (3100LA, Electronics & Innovation, Ltd., NY 14,623, United States). The optimal number of cycles was chosen depending on the sample thickness and frequency [23]. The amplified signal travels from the transmitter (Tx) to the receiver (Rx) passing through the tested material (either reference or sample). The waveform was recorded using a digital oscilloscope (HDO6104, Teledyne Technologies Inc., California, United States) with a 1 MΩ electric impedance. Six pairs of immersion transducers and contact transducers with a diameter of 1/2 inch were used for transmitting and receiving the signal at the same central frequency [28], as summarized in Table 1. The immersion and contact types of the transducers were used for the measurements in the water and PMMA mediums, respectively.

Two types of jigs based on the types of transducers were used in the measurements. Immersion transducers were mounted on the rigid jig with about 10 mm spacing between the transmitter and receiver in the water medium (denoted as (3) in Fig. 2). Contact transducers were mounted on the airtight PMMA jig with about 20 mm spacing between the transmitter and receiver (denoted as (4) in Fig. 2). The immersion and contact transducers used water and PMMA as propagation media, respectively, but water was used as the common reference material.

As a comparison of the through-transmission method, measurements using the reflection method on the PMMA jig were also carried out. In principle, the reflection method is to use a transducer that acts as a transmitter as well as a receiver and a reflected signal will be obtained when the signal passes through two mediums with different acoustic impedance values [28]. The airtight PMMA jig with a larger spacing of about 50 mm is used to separate the reflected signal from the PMMA and from the sample. One contact transducer is placed on one side of the PMMA, transmits the signal generated by the pulser/receiver device (5077PR, Olympus, Massachusetts, U.S.A.), and receives the reflected signal. The time difference between the signal reflected by the first reflection (PMMA sample) and the second reflected (PMMA sample) can be used to define the sound speed of the sample.

To maintain the purity of the water, dissolved oxygen concentration and conductivity indication of total dissolved solids (TDS) of water were checked at each measurement. The temperature of water was kept at 22.51 ± 0.03 °C by a chiller and precision thermometer (F250 MK II, Automatic Systems Laboratories, Leighton Buzzard, United Kingdom).

2.3 Fabrication of hydrogel TMMs

Agar TMM was prepared according to the standard recipe reported in IEC60601-2–37 with the components as shown in Table 2 that make the acoustical properties of agar gel similar to that of human tissue [16, 29, 30]. In this work, Germall Plus (Halal Everyday) was used as a preservative instead of benzalkonium chloride because it is relatively harmless and easily available. Two types of powders, aluminum oxide with 3 µm and 0.3 µm diameter and silicon carbide with 37 µm diameter, were used as scatterers, and, thus, the attenuation of the agar TMM was set. Glycerol, which is miscible in water and absorbs water (hygroscopic), was used to set the sound speed of agar TMM. An analytical balance (PM1200, Mettler Toledo, Ohio, United States) with a readability of 1 mg was used to weigh the required amount of ingredients. The thickness and density of the sample were measured using a height gauge with a resolution of 0.01 mm (Digimar 814, Mahr Inc., Rhode Island, United States) and density kit with a resolution of 0.001 g (XSE205 Dual Range, Mettler Toledo, Ohio, United States), respectively.

The preparation of gelatin TMM was slightly different from that of the agar TMM because of the boiling point of each component. The gelatin TMM used in this study was made according to the method provided by [31] with the components displayed in Table 3. To prevent the attachment of the gelatin TMM to the mold, it was necessary to spray the releasing agent on the mold for a few minutes before the mold was used. The mixture was then put into molds and allowed to congeal for 3–4 days. The thickness and density of the sample were measured using the same device as described previously.

3 Results and discussion

3.1 Effect of the submersion duration of hydrogel TMMs in water

The sound speed of agar TMM in water was measured in the frequency range between 1 and 10 MHz as shown in Fig. 3. Figure 3(a) shows that the sound speed of agar TMM at 1 MHz decreases over time when the sample is kept in the water tank. Within 2.5 h, the measurement value of the sound speed dropped from 1532 to 1512 m/s. Thus, the temporal falling ratio of the sound speed was approximately 0.1 m/s per minute.

Hysteresis of the sound speed measurement for the agar TMM in water was also examined. It was measured from 1 to 10 MHz in steps of 1 MHz, followed by backward measurement from 10 to 1 MHz; the sound speed value for both sequences at each frequency did not match, as shown in Fig. 3(b), indicating hysteresis of the sound speed measurement. If backward sequence measurements were not performed, it would have been mistakenly concluded that the sound speed of the agar TMM decreases as frequency increases, which goes against the physics of the Kramers–Kronig relation [32].

The agar and gelatin TMMs were immersed in water for approximately 1.5 h, and the density was measured every 30 min at 22.4 °C. Both hydrogel TMMs showed a decrease in density on immersion in water as shown in Fig. 4. This decrease proved the change in weight composition of both hydrogel TMMs. When immersed in water, the density of agar TMM declined from 1063 to 1046 kg/m3 and gelatin TMM dropped from 1021 to 1017 kg/m3 in 1.5 h. The density reductions of agar and gelatin TMMs were 17 and 4.4 kg/m3, respectively, and the temporal ratio of falling density was approximately 0.19 and 0.05 kg/m3 per minute, respectively. The decrease in density of agar TMM was greater than that of gelatin TMM. Therefore, in the case of agar TMM, it can be inferred that there are other factors besides volume expansion due to water absorption. Changes in the weight composition of agar TMM dissolved in water are thought to be caused by glycerol, one of the main components of the agar TMM. However, the water absorbed by the hydrogel TMM is suspected to cause changes in the volume, resulting in lesser change in the density of the gelatin TMM as compared to that of agar TMM.

3.2 Rationale of PMMA as a propagation medium

The difference in sound pressure level (SPL) between the propagation medium and water depends on their attenuation coefficients and the length of the material used as the propagation medium, as shown in Eq. (2). The length of the propagation medium is considered equal to the total thickness of the PMMA jig, which is 4 cm. The calculated difference in SPL between water and several materials, such as metals, ceramics, rubbers, and plastics are presented in Table 4. As seen in the table, PMMA has a relatively low difference in sound pressure level compared to the other materials at the same frequency. The low difference in sound pressure level indicates that the signal obtained via pass-through of the material does not have much difference with that obtained via pass-through of the water, both in terms of amplitude and distortion. The detailed measurement results of the acoustic properties of PMMA are provided in Appendix 1.

3.3 Sound speed of hydrogel TMM

The sound speed of hydrogel TMM with approximately 10 mm thickness was measured in the frequency range between 1 and 10 MHz. The hydrogel TMM contains more than 80% of water by weight, and hence, it is expected that the sound speed does not explicitly depend on the frequency. The measurement of sound speed from the hydrogel TMM was carried out in two propagation media: water and PMMA. To give more evidence, the agar TMM wrapped by 0.05 mm polyimide was also observed and experimental result shows the sound speed rapidly dropping during measurement in the water medium. Figure 5 shows the measurement results of sound speed on agar and gelatin TMMs. Under the assumption that the sound speed of hydrogel TMM does not have frequency dependence, the average values of sound speed and standard deviation for each condition are also included in Fig. 5 as a dashed line and dotted line, respectively.

The agar TMM was measured for its sound speed in the water (with and without polyimide as a wrap) and PMMA as a propagation medium, as shown in Fig. 5(a). The measurement was performed in a temperature-controlled bath in the range of 22.99 ± 0.01 °C. The open squares indicate the sound speed value produced when the measurement was carried out in water as the propagation medium. The sound speed decreased from 1532.2 m/s at 1 MHz to 1520.2 m/s at 10 MHz. The sound speeds of agar TMM in the water medium (open squares), with polyimide wrap (asterisks), and PMMA medium (open circles) were measured as 1524.1 ± 4.1 m/s, 1538.6 ± 2.3 m/s, and 1548.8 ± 0.9 m/s, respectively. Although using polyimide as a wrap showed a slight improvement compared to unwrapping, the measurement in PMMA still showed a better value, as seen from the standard deviation value of only 0.06%.

Figure 5(b) shows the sound speed of the gelatin TMM measured in water and PMMA as an alternative medium. In the gelatin TMM, the decrease in sound speed in the fourth time measurement in the water was not obvious because its value fluctuated. This happened because the size of the gelatin was unstable due to water absorption and dehydration processes during measurement. However, a slight decrease with a gradient of − 0.0887 is shown in Fig. 5(b) by plotting the linear trend line. Similarly, measuring the sound speed of gelatin TMM using PMMA as a propagation medium also gave better values. The average value and standard deviation of sound speed when measured in water as the propagation medium was 1520.3 ± 2.2 m/s, which improved to 1531.13 ± 0.83 m/s when measured in PMMA.

Experiments using reflection mode on PMMA medium were also carried out. Unlike the through-transmission method which compares the difference in travel time between the reference material and the sample, the reflection method uses the difference in delay time generated after bouncing the front face of the sample with the back face of the sample. This delay time is obtained by the maximum time difference between the front and back signals after being transformed using the Hilbert transform. The average value and standard deviation of sound speed (open triangle) are 1543.2 ± 3 m/s and 1524.1 ± 2.4 m/s for agar TMM (Fig. 5a) and gelatin TMM (Fig. 5b), respectively.

3.4 Comparison of the time-domain signal analysis in water and PMMA

The comparison between time-domain signals produced when measurements are made in water as a propagation medium and PMMA as an alternative propagation medium at low and high frequencies is shown in Fig. 6. At the low frequency of 1 MHz, the resulting signal shapes when using water and PMMA are slightly different as seen in Figs. 6(a) and (b), respectively. By contrast, at the high frequency of 10 MHz, the signal shapes when using water and PMMA are considerably different as seen in Figs. 6(c) and (d), respectively. This indicates that the signal passing through PMMA suffers from greater distortion than when passing through water. Therefore, measuring the attenuation coefficient using PMMA as the propagation medium is not recommended. However, in the case of sound speed measurement, since the phase information in Eq. (1) is dominant to the time of flight and weakly perturbed by the Fourier transform, the influence of signal distortion is relatively small. The time of flight can consistently be obtained using a first zero-crossing point of the signal [36].

4 Conclusion

In this study, we have reported our observations of the difficulties encountered in measuring the sound speed of hydrogel TMM using the water immersion through-transmission method, and offered an alternate method configuration. The reasons for the inconsistent sound speed measurement results when water is used as a propagation medium in the conventional method are summarized as follows. First, hydrogel TMMs absorb water and expand in volume over time, and second, some of the ingredients used in the composition dissolve in the water. This has been observed and verified through density measurement comparisons. Based on the fact that the sound speed of water does not depend on the frequency, we hypothesized that the sound speed of hydrogel TMMs has very weak or no frequency-dependent characteristics to solve this measurement problem. In addition, by examining different propagation media in the configuration of the measurement system, PMMA was adopted as a material with relatively weak signal distortion due to attenuation. An alternative configuration of the measuring device was made by using a contact transducer in PMMA, and the sound speed measurement results were compared with the existing configuration. As shown in the previously measured results and discussion, the standard deviation of the sound speed measurements in the alternative configuration was smaller and showed negligible dispersion, which complies with the hypothesis.

References

C. Sun et al., Ultrasound Med Biol. 38, 1262 (2012)

A. Cafarelli et al., J. Ultrasound. 19, 251 (2016)

S. Dasgupta, R.K. Banerjee, P. Hariharan, M.R. Myers, Ultrasonics 51, 171 (2011)

K. Hamaluik, W. Moussa, M. Ferguson-Pell, IEEE Trans. Med. Imaging. 33, 1410 (2014)

S.F. Sultan, G. Shorten, G. Iohom, Med. Ultrason. 15, 125 (2013)

J.E. Browne, K.V. Ramnarine, A.J. Watson, P.R. Hoskins, Ultrasound Med Biol. 29, 1053 (2003)

T. Drakos et al., Ultrasonics 113, 106357 (2021)

C.K. McGarry et al. 2020 Phys. Med 65.

M.O. Culjat, D. Goldenberg, P. Tewari, R.S. Singh, Ultrasound Med Biol. 36, 861 (2010)

M.P. Brewin, L.C. Pike, D.E. Rowland, M.J. Birch, Ultrasound Med Biol. 34, 1292 (2008)

A.I. Farrer et al., J. Ther. Ultrasound. 3, 9 (2015)

E.L. Madsen, J.A. Zagzebski, R.A. Banjavie, R.E. Jutila, Med. Phys. 5, 391 (1978)

K. Zell et al., Phys. Med. Biol. 52, N475 (2007)

E.L. Madsen, J.A. Zagzebski, G.R. Frank, Ultrasound Med Biol. 8, 277 (1982)

A. Thouvenot, T. Poepping, T.M. Peters, E.C.S. Chen, Proc. 2016 SPIE 9783, Medical Imaging 2016: Physics of Medical Imaging, 97835E. https://doi.org/10.1117/12.2218160

S. Rajagopal, N. Sadhoo, B. Zeqiri, Ultrasound Med Biol. 41, 317 (2015)

J. Lubbers, R. Graaff, Ultrasound Med Biol. 24, 1065 (1998)

V.A. Del Grosso, J. Acoust. Soc. Am. 56, 1084 (1974)

W. Marczak, J. Acoust. Soc. Am. 102, 2776 (1997)

P. Chen et al., Ultrasound in Med and Biol. 48, 124 (2022)

P.E. Bloomfield, IEEE Trans. Ultrason. Ferroelectr. Freq. Control 47, 1397 (2000)

I.Y. Kuo, B. Hete, K.K. Shung, J. Acoust. Soc. Am. 88, 1679 (1990)

N.M. Yusof, S.M. Kim, Y.T. Kim, Korean Soc. Nondestruc. 41, 155 (2021)

N.M. Yusof et al., J. Korean Phys. Soc. 78, 784 (2021)

J.M.M. Pinkerton, Proc. Phys. Soc. B. 62, 129 (1949)

B.A. Herman, G.R.C. Harris, J. Acoust. Soc. Am. 72, 1357 (1982)

Y.T. Kim et al., Ultrasound in Med and Biol. 35, 472 (2009)

C.J.R. Hernandez, L.L. Salas, A.V. Hernandez, Global medical engineering physics exchanges/pan American health care exchanges (GMEPE/PAHCE), Vol. 1. (2018), pp. 1–14. https://doi.org/10.1109/GMEPEPAHCE

International Electrotechnical Commission [IEC]. Medical electrical equipment: Part 2–37. Particular requirements for the basic safety and essential performance of ultrasonic medical diagnostic and monitoring equipment. IEC Publication 60601. 2nd edn. (Geneva, 2007)

R.M. Souza et al., J. Phys. Conf. Ser. 733, 012044 (2016)

T.Z. Pavan et al., Phys. Med. Biol. 55, 2679 (2010)

M. O’Donnell, E.T. Jaynes, J.G. Miller, J. Acoust. Soc. Am. 69(3), 696 (1981)

K. Ono, Appl. Sci. 10(7), 2230 (2020)

A.R. Selfridge, IEEE Trans. Sonics Ultrason. 32, 381 (1985)

J.E. Carlson et al., IEEE Ultrason. Symp. 1, 885 (2003)

P. He, J. Acoust. Soc. Am. 107, 801 (2000)

Acknowledgements

This work was supported by the Korea Medical Device Development Fund grant funded by the Korean government (the Ministry of Science and ICT, the Ministry of Trade, Industry and Energy, the Ministry of Health & Welfare, and the Ministry of Food and Drug Safety) (NTIS Project Number: 9991007024, KMDF Project Number: KMDF_PR_202011B03-04) and by Enhancement of Measurement Standards and Technologies in Physics funded by the Korea Research Institute of Standards and Science (KRISS-2021-GP2021-0002).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

APPENDIX A

APPENDIX A

The acoustic properties of the PMMA used to make the jig in the present work were measured in the frequency range between 1 and 10 MHz as shown in Table

5. The thickness and density of the PMMA sample were 9.99 ± 0.01 mm and 1176 ± 0.08 kg/m3, respectively. The measurements were performed in water at a temperature of 22.5 ± 0.02 °C. The sound speed of the PMMA increased with frequency from 2617.4 ± 1.8 m/s at 1 MHz to 2639.8 ± 0.4 m/s at 10 MHz and the attenuation coefficient increased linearly with frequency from 2.2 ± 0.17 dB/cm at 1 MHz to 15.5 ± 0.18 dB/cm at 10 MHz. The measurement result was slightly different from some previous studies [20, 21, 34, 35]. This was due to several factors, such as the correction factors used for calculations, experimental temperature, and density of the material. The correction factors used in this study are diffraction loss, transmission loss, and correction of the sound velocity and attenuation coefficient of water according to temperature. The different PMMA manufacturers and manufacturing processes can also be considered as possible causes.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Elmina, B.C.F., Baik, K., Kim, S.M. et al. Precise measurement of sound speed in hydrogel tissue-mimicking material by a through-transmission method. J. Korean Phys. Soc. 81, 921–930 (2022). https://doi.org/10.1007/s40042-022-00631-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40042-022-00631-7