Abstract

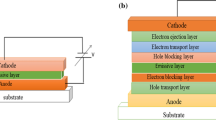

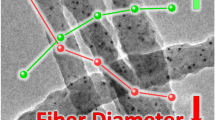

Quantum dot light-emitting diode (QLED) can be directly patterned for pixel array by solution processing, while the limitation of resolution and device stability exists unless a proper solvent system and multilayer design are established. With a small-sized nozzle inkjet printing process, solvent formulation effects on the morphology and precision of printing for the quantum dot layer were investigated. Drop formation as well as ink spreading and wetting behavior on the non-crosslinked organic hole-transporting polymer were optimized with a non-erosive solvent formulation composed of octane and cyclohexane. While the ink composition formed low-contact angle droplet on the surface and was not completely ideal for the defectless pixelating process of high-resolution inkjet, its controllability of wetting at a small-scale nozzle, uniform drying, and orthogonal characteristics with an effective hole transport layer resulted in a high-performance green inkjet QLED with 6.13 cd/A at 19,550 nits highly bright region. This amounted to about 50% of efficiency performance compared to an identical device prepared with spin-coating, but one of the best green inkjet QLED properties reported with less than 120-μm sub-pixel pitch.

Similar content being viewed by others

References

H.M. Haverinen, R.A. Myllylä, G.E. Jabbour, Appl. Phys. Lett. 94, 073108 (2009)

H.M. Haverinen, R.A. Myllylä, G.E. Jabbour, J. Disp. Technol. 6, 87 (2010)

B.H. Kim, M.S. Onses, J.B. Lim, S. Nam, N. Oh, H. Kim, K.J. Yu, J.W. Lee, J.-H. Kim, S.-K. Kang, C.H. Lee, J. Lee, J.H. Shin, N.H. Kim, C. Leal, M. Shim, J.A. Rogers, Nano Lett. 15, 969 (2015)

J. Han, D. Ko, M. Park, J. Roh, H. Jung, Y. Lee, Y. Kwon, J. Sohn, W.K. Bae, B.D. Chin, C. Lee, J. SID 24, 545 (2016)

C. Jiang, Mu.J. Lan, Z. Zou, Z. He, L. Zhong, M. Wang, J. Xu, J. Wang, Y. Peng, Cao Sci. China Chem. 60, 1349 (2017)

X. Li, Q. Lin, J. Song, H. Shen, H. Zhang, L.S. Li, X. Li, Z. Du, Adv. Opt. Mater. 8, 1901145 (2020)

Y. Yang, Y. Zheng, W. Cao, A. Titov, J. Hyvonen, J.R. Manders, J. Xue, P.H. Holloway, L. Qian, Nat. Photon. 9, 259 (2015)

L. Wang, J. Lin, Y. Hu, X. Guo, Y. Lv, Z. Tang, J. Zhao, Y. Fan, N. Zhang, Y. Wang, X. Liu, A.C.S. Appl, Mater. Interfaces 9, 38755 (2017)

Y.-H. Won, O. Cho, T. Kim, D.-Y. Chung, T. Kim, H. Chung, H. Jang, J. Lee, D. Kim, E. Jang, Nature 575, 634 (2019)

C. Pu, X. Dai, Y. Shu, M. Zhu, Y. Deng, Y. Jin, X. Peng, Nat. Comm. 11, 937 (2020)

M.K. Choi, J. Yang, K. Kang, D.C. Kim, C. Choi, C. Park, S.J. Kim, S.I. Chae, T.-H. Kim, J.H. Kim, T. Hyeon, D.-H. Kim, Nat. Comm. 6, 7149 (2015)

J. Lim, B.G. Jeong, M. Park, J.K. Kim, J.M. Pietryga, Y.-S. Park, V.I. Klimov, C. Lee, D.C. Lee, W.K. Bae, Adv. Mater. 26, 8034 (2014)

Y. Zou, M. Ban, W. Cui, Q. Huang, C. Wu, J. Liu, H. Wu, T. Song, B. Sun, Adv. Funct. Mater. 27, 1603325 (2017)

S.A. Park, W.H. Jung, J.Y. Yoo, C.W. Lee, J.S. Kim, J.G. Kim, B.D. Chin, Org. Electron. 87, 105955 (2020)

C. Xiang, L. Wu, Z. Lu, M. Li, Y. Wen, Y. Yang, W. Liu, T. Zhang, W. Cao, S.-W. Tsang, B. Shan, X. Yan, L. Qian, Nat. Comm. 11, 1646 (2020)

C. Jiang, Z. Zhong, B. Liu, Z. He, J. Zou, L. Wang, J. Wang, J. Peng, Y. Cao, A.C.S. Appl, Mater. Interfaces 8, 26162 (2016)

Y. Liu, F. Li, Z. Xu, C. Zheng, T. Guo, X. Xie, L. Qian, D. Fu, X. Yan, A.C.S. Appl, Mater. Interfaces 9, 25506 (2017)

P. Yang, L. Zhang, D.J. Kang, R. Strahl, T. Kraus, Adv. Opt. Mater. 8, 1901429 (2020)

S. Chen, W. Cao, T. Liu, S.-W. Tsang, Y. Yang, X. Yan, L. Qian, Nat. Commun. 10, 765 (2019)

L. Wang, J. Pan, J. Qian, W. Lei, Y. Wu, W. Zhang, D.K. Gotoc, J. Chen, J. Mater. Chem. C 6, 8099 (2018)

Y.-F. Liu, M.-H. Tsai, Y.-F. Pai, W.-S. Hwang, Appl. Phys. A 111, 509 (2013)

Y. Zhong, H. Fang, Q. Ma, X. Dong, J. Fluid Mech 845, 378 (2018)

R. Macy, J. Chem. Educ. 12, 573 (1935)

D. Derby, Engineering 1, 113 (2015)

Y. Liu, B. Derby, Phys. Fluids 31, 032004 (2019)

R.D. Deegan, O. Bakajin, T.F. Dupont, G. Huber, S.R. Nagel, T.A. Witten, Nature 389, 827 (2017)

H. Hu, R.G. Larson, J. Phys. Chem. B 110, 7090 (2016)

J.A. Lim, W.H. Lee, H.S. Lee, J.H. Lee, Y.D. Park, K. Cho, Adv. Funct. Mater. 18, 229 (2008)

D. Soltman, V. Subramanian, Langmuir 24, 2224 (2008)

H.H. Fong, A. Papadimitratos, G.G. Malliaras, Appl. Phys. Lett. 89, 172116 (2006)

G. Zaiats, S. Ikeda, S. Kinge, P.V. Kamat, A.C.S. Appl, Mater. Interfaces 9, 30741 (2017)

J. Liang, L. Ying, W. Yang, J. Peng, Y. Cao J. Mater. Chem. C 5, 5096 (2017)

K.P. Acharya, A. Titov, J. Hyvonen, C. Wang, J. Tokarza, P.H. Holloway, Nanoscale 9, 14451 (2017)

M.K. Choi, J. Yang, D.C. Kim, Z. Dai, J. Kim, H. Seung, V.S. Kale, S.J. Sung, C.R. Park, N. Lu, T. Hyeon, D.-H. Kim, Adv. Mater. 30, 1703279 (2018)

Acknowledgements

This work was supported by the Dankook University Research Fund (award no. R201800356) in 2018.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Kim, J.H., Kang, Y.J. & Chin, B.D. Solvent mixture formulation for orthogonal inkjet processing and uniform pixel patterning of quantum dot light-emitting diode. J. Korean Phys. Soc. 78, 1116–1127 (2021). https://doi.org/10.1007/s40042-021-00153-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40042-021-00153-8