Abstract

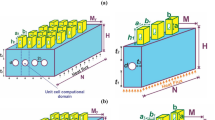

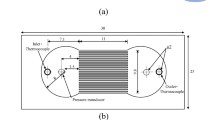

This paper details the numerical analysis of combined microchannels with solid and perforated rectangular fins. The goal of the numerical process is to maximise global thermal conductance in the geometric configurations studied. Three scenarios are investigated: a microchannel with solid rectangular fins, a microheat sink with single square perforation on the fins and a combined microchannel with two square perforations. The volume and axial length of the combined microchannel are fixed, while the width varies. An imposed high-density heat flux \({q}^{{\prime\prime}}\) of 250 W/cm2 is applied at the bottom surface of the combined microchannels with fins. Water is used as a coolant to remove the heat deposited at the channel walls and the entire microchannel heat sink. The finite volume method in Ansys Fluent is employed to discretise the computational domain and the thermal and fluid fields solved. The results showed that hydraulic diameter, external aspect ratio and Reynolds number of water \(({\mathrm{Re}}_{{w}})\) have an effect on minimised temperature and global thermal conductance. When the Reynolds number of fluid increases by 20%, the minimised temperature diminishes by 2.6, 2.5 and 2.1%, in the three configurations investigated. The numerical optimisation shows that the combined microchannel with two square perforations on fins is the best. The design technique and innovation employed to reduce the volume, weight, cost of production and solid substrate used in the heat sink manufacturing enhanced the performance and increased heat transfer. The numerical code validation is carried out using analytical results.

Similar content being viewed by others

Abbreviations

- A :

-

Cross-sectional area of a channel

- C :

-

Dimensionless thermal conductance

- d :

-

Diameter

- d h :

-

Hydraulic diameter

- H :

-

Height of heat sink

- k f :

-

Fluid thermal conductivity

- k s :

-

Solid wall thermal conductivity

- MCH:

-

Microchannel

- N :

-

Heat sink axial length

- n :

-

Number of channels

- \({q}^{{\prime\prime}}\) :

-

Heat flux

- Rew :

-

Reynolds number of water

- T w,L :

-

Exit temperature

- T in :

-

Inlet temperature

- T max :

-

Maximum temperature

- t 1 :

-

Channel distance from bottom

- t 2 :

-

Channel distance from the top microheat sink

- t 3 :

-

Thickness from channel to channel

- v in :

-

Inlet velocity

- V :

-

Volume

- v el :

-

Elemental volume

- W :

-

Width of a microchannel heat sink

- α :

-

Thermal diffusivity

- C p :

-

Specific heat

- µ :

-

Viscosity

- ν :

-

Kinematic viscosity

- ρ :

-

Density

- ϕ :

-

Porosity

- τ :

-

Shear stress

- in:

-

Inlet

- max:

-

Maximum

- min:

-

Minimum

- opt:

-

Optimum

- out:

-

Outlet

References

ANSYS 18.1 Design Xplorer, User’s Guide. (2017). www.fluent.com.

A.I. Khuri, S. Mukhopadhyay, Response surface methodology. Wiley Interdiscip. Rev. Comput. Stat. 2(2), 128–149 (2010). https://doi.org/10.1002/wics.73

G.E.P. Box, K.B. Wilson, On the experimental attainment of optimum conditions. J. R. Stat. Soc. B 13(1), 1–45 (1951). https://doi.org/10.1111/j.2517-6161.1951.tb00067.x

S.J. Kahil, F. Maugeri, M.I. Rodrigues, Response surface analysis and simulation as a tool for bioprocess design and optimization. Process Biochem. 35(6), 539–550 (2000). https://doi.org/10.1016/S0032-9592(99)00101-6

J.S. Shang, S. Li, P. Tadikamalla, Operational design of a supply chain system using the Taguchi method, response surface methodology, simulation, and optimization. Int. J. Prod. Res. 42(18), 3823–3825 (2004). https://doi.org/10.1080/00207540410001704050

R.R. Barton, Metamodels for simulation input–output relations, in Proc. Winter Simul Conf., Arlington, VA, (1992), pp. 289–299. https://doi.org/10.1145/167293.167352

R.R. Barton, Simulation metamodels, in Proceeding Winter Simul Conf., Washington, DC (1998), pp. 167–174. https://doi.org/10.1109/WSC.1998.744912

J.H. Noguera, E.F. Watson, Response surface analysis of a multi-product batch processing facility using a simulation metamodel. Int. J. Econ. Prod. 102(2), 333–343 (2006). https://doi.org/10.1504/EJIE.2014.059351

T.W. Simpson, J.D. Peplinski, P.N. Koch, J.K. Allen, Metamodels for computer-based engineering design: survey and recommendations, in ASME Des. Eng. Tech. Conf., Sacramento, California USA (1997), pp. 1–14. https://doi.org/10.1007/PL00007198

R.R. Barton, Simulation experiment design, in Proceedings of the 2010 Winter Simulation Conference, ed. by B. Johansson, S. Jain, J. Montoya-Tones, J. Hugan, E. Yucesan (2010), pp. 75–86. https://doi.org/10.1109/WSC.2010.5679171

D.Q. Kern, A.D. Kraus, Extended Surface Heat Transfer (McGraw-Hill book, New York, 1972). https://doi.org/10.4236/epe.2011.32022

Y. Han, Y. Liua, M. Liaa, J. Huanga, A review of development of micro-channel heat exchanger applied in air-conditioning system. Energy Procedia 14(2012), 148–153 (2012)

T.S. Ravigururajan, J. Cuta, C.E. McDonald, M.K. Drost, Effects of heat flux on two-phase flow characteristics of refrigerant flows in a micro-channel heat exchanger. National heat transfer conference, American Society of Mechanical Engineers, Houston, TX (United States), USA, 3–6 Aug 1996 (1996), p. 261.

J. Li, G.P. Peterson, 3-Dimensional numerical optimization of silicon-based high performance parallel microchannel heat sink with liquid flow. Int. J. Heat Mass Transf. 50(15–16), 2895–2904 (2007). https://doi.org/10.1109/TCAPT.2005.853170

W. Qu, I. Mudawar, Experimental and numerical study of pressure drop and heat transfer in a single-phase micro-channel heat sink. Int. J. Heat Mass Transf. 45(12), 2549–2565 (2001). https://doi.org/10.1016/S0017-9310(01)00337-4

T. Bello-Ochende, O.T. Olakoyejo, J.P. Meyer, A. Benjan, S. Lorente, Constructal flow orientation in conjugate cooling channels with internal heat generation. Int. J. Heat Mass Transf. 57(1), 241–249 (2013). https://doi.org/10.1016/j.ijheatmasstransfer.2012.10.021

K.K. Ambatipudi, M.M. Rahman, Analysis of conjugate heat transfer in microchannel heat sinks. Numer. Heat Transf. Part A Appl. 37(7), 711–731 (2000). https://doi.org/10.1080/104077800274046

A.K. Pramanick, The Nature of Motive Force (Springer, New York, 2014)

A.K. Pramanick, Philosophy of Nature, Reflection Magazine, (R. E. College Durgapur, 1991), pp. 2–5.

S. Carnot, Reflections on the Motive Power of Fire (trans: R. H. Thurston) (Dover, New York, 2005).

M.J. Klein, Carnot’s contribution to thermodynamics. Phys. Today 27, 23–28 (1974). https://doi.org/10.1063/1.3128802

A.K. Pramanick, An asymptotic approach to law of motive force and constructal law. Rev. Roum. Sci. Techn. – Électrotechn. et Énerg. 64(3), 293–296 (2019). https://doi.org/10.1115/1.2204075

A.K. Pramanick, Heat and Mass Transfer: The Law of Motive Force (Springer, Heidelberg, 2014)

A. Bejan, Advanced Engineering Thermodynamics (Wiley, New York, 1997), p.807

O.T. Olakoyejo, T. Bello-Ochende, J.P. Meyer, Constructal conjugate cooling channels with internal heat generation. Int. J. Heat Mass Transf. 55(15), 4385–4396 (2012). https://doi.org/10.1016/j.ijheatmasstransfer.2012.04.007

A. Bejan, S. Lorente, The constructal law and the evolution of design in nature. Phys. Life Rev. 8(3), 209–240 (2011). https://doi.org/10.1016/j.plrev.2011.05.010

O.T. Olakoyejo, T. Bello-Ochende, J.P. Meyer, Mathematical optimization of laminar forced convection heat transfer through a vascularised solid with square channels. Int. J. Heat Mass Transf. 55(9), 2402–2411 (2012). https://doi.org/10.1016/j.ijheatmasstransfer.2011.12.036

M.R. Salimpour, M. Sharifhasan, E. Shirani, Constructal optimization of the geometry of an array of micro-channels. Int. Heat Mass Transf. 38(1), 93–99 (2011). https://doi.org/10.1080/01457632.2012.746552

M.R. Salimpour, M. Sharifhasan, E. Shirani, Constructal optimization of microchannel heat sinks with noncircular cross sections. Heat Transf. Eng. 34(10), 863–874 (2013). https://doi.org/10.1080/01457632.2012.746552

J.H. Ryu, D.H. Choi, S.J. Kim, Three-dimensional numerical optimization of a manifold micro channel heat sink. PERGAMON 46(9), 1553–1562 (2003). https://doi.org/10.1016/S0017-9310(02)00443-X

A. Bejan, Heat Transfer (John Willey & Son, New Jersey, 1993)

B. Prabhakar, P.K. Yogesh, Thermal performance of open microchannel heat sink with variable pin fin height. Int. J. Therm. Sci. 159, 1066 (2021)

Y.K. Prajapati, Influence of fin height on heat transfer and fluid flow characteristics of rectangular microchannel heat sink. Int. J. Heat Mass Transf. 137, 1041–1052 (2019)

M. Tahat, Z.H. Kodah, B.A. Jarrah, S.D. Probert, Heat transfers from pin-fin arrays experiencing forced convection. Appl. Energy 67(4), 419–422 (2000)

A. Kosar, C. Mishra, Y. Peles, Laminar flow across a bank of low aspect ratio micro pin fins. J. Fluids Eng. 127(3), 419 (2005)

A. Kosar, Y. Peles, Thermal- hydraulic performance of MEMS-based pin fin heat sink. J. Heat Transfer 128(2), 121–131 (2006)

A.M. Siu-Ho, W. Qu, F. Pfefferkom, Experimental study of pressure drop and heat transfer in a single-phase micropin-fin heat sink. J. Electron. Packag. 129(4), 479–487 (2007)

N.Y. Godi, M.O. Petinrin, Heat transfer analysis in constructal designed microchannels with perforated micro fins. J. Inst. Eng. India Ser. C (2023). https://doi.org/10.1007/s40032-023-00943-y

R.H. Yeh, An analytical study of the optimum dimension of rectangular fins and cylindrical pin fins. Int. J. Heat Mass Transf. 40, 3607–3615 (1997). https://doi.org/10.1016/s0017-9310(97)00010-0

Y. Peles, A. Kosar, C. Mishra, K. Chih-Jung, S. Brandon, Forced convective heat transfer across a pin fin micro heat sink. Int. J. Heat Mass Transf. 48, 3615–3627 (2005). https://doi.org/10.1016/j.ijheatmasstransfer.2005.03.017

V.S. Achanta, An experimental study of end wall heat transfer enhancement or flow staggered non-conducting pin fin arrays, PhD Thesis, Department of Mechanical Engineering, Texas A & M University, U.S.A (2003).

M.E. Lyall. Heat transfer from low aspect ratio pin fin, PhD thesis, Department of Mechanical Engineering, Virginia Polytechnic Institute and State University (2006).

M. Vilarrubí, S. Riera, M. Ibañez, M. Omri, G. Lagun, L. Fréchette, J. Barra, Experimental and numerical study of micro-pin-fin heat sinks with variable density for increased temperature uniformity. Int. J. Therm. Sci. 132, 424–434 (2018). https://doi.org/10.1016/j.ijthermalsci.2018.06.019

B. Sahin, A. Demir, Thermal performance analysis and optimum design parameters of heat exchanger having perforated pin fins. Energy Convers. Manag. 49, 1684–1695 (2008)

M. Yaghoubi, E. Velayati, Undeveloped convective heat transfer from an array of cubes in cross-stream direction. Int. J. Therm. Sci. 44, 756–765 (2005). https://doi.org/10.1016/j.ijheatmasstransfer.2005.03.017

M.R. Sheri, M. Yaghoubi, K. Jafarpur, Heat transfer analysis of lateral perforated fin heat sinks. Appl. Energy 86, 2019–2029 (2009). https://doi.org/10.1016/j.enconman.2009.01.021

O.O. Adewumi, T. Bello-Ochende, J.P. Meyer, Constructal design of combined microchannel and micro pin fins for electronic cooling. Int. J. Heat Mass Transf. 66, 215–323 (2013). https://doi.org/10.1016/j.ijheatmasstransfer.2013.07.039

F. Laermer, A. Urban, Challenges, development and applications of silicon deep reactive ion etching. Microelectron. Eng. 67–68, 349–355 (2003). https://doi.org/10.1016/S0167-9317(03)00089-3

M.J. Madon, in: MEMS Handb, ed. by M. Gad-el-Hak (CRC Press, Taylor & Francis Group, 2002), p. 1368. https://doi.org/10.1201/9780429103872

F.U. Ighalo, Optimisation of microchannels and micro pin-fin heat sinks with computational fluid dynamics in combination with a mathematical optimisation algorithm, MSc. Thesis Department of Mechanical and Aeronautical Engineering, University of Pretoria, (2010).

C.L. Chen, C.H. Cheng, Numerical study of the effects of lid oscillation on the periodic flow pattern and convection heat transfer in a triangular cavity. Int. Commun. Heat Mass Transf. 36, 590–596 (2009). https://doi.org/10.1016/j.icheatmasstransfer.2009.03.006

L. Chai, G.D. Xia, M.Z. Zhou et al., Numerical simulation of fluid flow and heat transfer in a microchannel heat sink with offset fan-shaped reentrant cavities in sidewall. Int. Commun. Heat Mass Transf. 38, 577–584 (2011). https://doi.org/10.1016/j.icheatmasstransfer.2010.12.037

L.S. Ismail, C. Ranganayakulu, R.K. Shah, Numerical study of flow patterns of compact plate-fin heat exchangers and generation of design data for offset and wavy fins. Int. J. Heat Mass Transf. 52, 3972–3983 (2009). https://doi.org/10.1016/j.ijheatmasstransfer.2009.03.026

S.V. Patankar, Numerical heat transfer and fluid flow. CRC Press (2018). https://doi.org/10.1201/9781482234213

F.M. White, Viscous Fluid Flow (McGraw-Hill, Inc., New York, 1991)

J. Kepler, The Six-Cornered Snowflake (Clarendon Press, Oxford, 1966)

W.A. Khan, J.R. Culham, M.M. Yovanovich, Modelling of cylindrical pin-fin heat sinks for electronic packaging. IEEE Trans. Compon. Packag. Technol. 31(3), 536–545 (2008). https://doi.org/10.2514/1.17713

O.O. Adewumi, Constructal design and optimisation of combined microchannel and micro pin fins for microelectronic cooling, University of Pretoria (2016).

Acknowledgements

The author appreciates the University of Cape Town, SA and Modibbo Adama University, Yola, for the facilities and support provided during the research.

Funding

The author has not disclosed any funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares no conflicts of interest associated with this publication

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Godi, N.Y. Constructal Solid and Perforated Fin Installation in a Combined Microchannel Heat Sink for Maximum Heat Transfer. J. Inst. Eng. India Ser. C 105, 17–30 (2024). https://doi.org/10.1007/s40032-023-01006-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40032-023-01006-y