Abstract

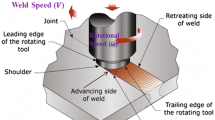

Friction Stir Welding (FSW) is a solid state joining process and is handy for welding aluminum alloys. Finite Element Method (FEM) is an important tool to predict state variables of the process but numerical simulation of FSW is highly complex due to non-linear contact interactions between tool and work piece and interdependency of displacement and temperature. In the present work, a three dimensional coupled thermo-mechanical method based on Lagrangian implicit method is proposed to study the thermal history, strain distribution and thermo-mechanical process in butt welding of Aluminum alloy 2024 using DEFORM-3D software. Workpiece is defined as rigid-visco plastic material and sticking condition between tool and work piece is defined. Adaptive re-meshing is used to tackle high mesh distortion. Effect of tool rotational and welding speed on plastic strain is studied and insight is given on asymmetric nature of FSW process. Temperature distribution on the workpiece and tool is predicted and maximum temperature is found in workpiece top surface.

Similar content being viewed by others

References

W.M. Thomas, “Patent_FrictionWelding_ThomasTWI.pdf,” (1995)

R.S. Mishra, Z.Y. Ma, Friction stir welding and processing. Mater. Sci. Eng. R Rep. 50(1–2), 1–78 (2005)

R. Jain, K. Kumari, R.K. Kesharwani, S. Kumar, S.K. Pal, S.B. Singh, S.K. Panda, A.K. Samantaray, Friction stir welding: Scope and recent developement, in Mordern manufacturing engineering, ed. by J. Paulo Davim (Springer, Berlin, 2015), pp. 179–228

Y.J. Chao, X. Qi, W. Tang, Heat transfer in friction stir welding—experimental and numerical studies. J. Manuf. Sci. Eng. 125(1), 138 (2003)

C.M. Chen, R. Kovacevic, Finite element modeling of friction stir welding—thermal and thermomechanical analysis. Int. J. Mach. Tools Manuf 43(13), 1319–1326 (2003)

M. Yu, W.Y. Li, J.L. Li, Y.J. Chao, Modelling of entire friction stir welding process by explicit finite element method. Mater. Sci. Technol. 28(7), 812–817 (2012)

H. Schmidt, J. Hattel, J. Wert, An analytical model for the heat generation in friction stir welding. Model. Simul. Mater. Sci. Eng. 12, 143–157 (2004)

A. Arora, R. Nandan, A.P. Reynolds, T. DebRoy, Torque, power requirement and stir zone geometry in friction stir welding through modeling and experiments. Scr. Mater. 60, 13–16 (2009)

A. Arora, Z. Zhang, A. De, T. DebRoy, Strains and strain rates during friction stir welding. Scr. Mater. 61(9), 863–866 (2009)

G. Buffa, J. Hua, R. Shivpuri, L. Fratini, A continuum based fem model for friction stir welding—model development. Mater. Sci. Eng., A 419(1–2), 389–396 (2006)

G. Buffa, J. Hua, R. Shivpuri, L. Fratini, Design of the friction stir welding tool using the continuum based FEM model. Mater. Sci. Eng., A 419(1–2), 381–388 (2006)

Z. Zhang, H.W. Zhang, A fully coupled thermo-mechanical model of friction stir welding. Int. J. Adv. Manuf. Technol. 37(3–4), 279–293 (2008)

K. Gök, M. Aydin, Investigations of friction stir welding process using finite element method. Int. J. Adv. Manuf. Technol. 68(1–4), 775–780 (2013)

M. Assidi, L. Fourment, S. Guerdoux, T. Nelson, Friction model for friction stir welding process simulation: calibrations from welding experiments. Int. J. Mach. Tools Manuf 50(2), 143–155 (2010)

P. Asadi, R.A. Mahdavinejad, S. Tutunchilar, Simulation and experimental investigation of FSP of AZ91 magnesium alloy. Mater. Sci. Eng., A 528(21), 6469–6477 (2011)

F. Al-Badour, N. Merah, A. Shuaib, A. Bazoune, Coupled Eulerian Lagrangian finite element modeling of friction stir welding processes. J. Mater. Process. Technol. 213(8), 1433–1439 (2013)

S. Kobayashi, S.-I. OH, T. Altan, Metal forming and the finite element method, Oxford series. (1989)

R. Nandan, G.G. Roy, T.J. Lienert, T. Debroy, Three-dimensional heat and material flow during friction stir welding of mild steel. Acta Mater. 55(3), 883–895 (2007)

V. Malik, N. Sanjeev, H.S. Hebbar, S.V. Kailas, Time efficient simulations of plunge and dwell phase of FSW and its significance in FSSW. Proc. Mater. Sci. 5, 630–639 (2014)

K. Elangovan, V. Balasubramanian, Influences of tool pin profile and tool shoulder diameter on the formation of friction stir processing zone in AA6061 aluminium alloy. Mater. Des. 29(2), 362–373 (2008)

Acknowledgments

This paper is a revised and expanded version of an article entitled, “Finite Element Simulation of Temperature and Strain Distribution in Al2024 Aluminum Alloy by Friction Stir Welding” presented in ‘5th International & 26th All India Manufacturing Technology, Design and Research Conference′, held at ‘Indian Institute of Technology Guwahati’, Guwahati, India during December 12–14, 2014.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jain, R., Pal, S.K. & Singh, S.B. Finite Element Simulation of Temperature and Strain Distribution during Friction Stir Welding of AA2024 Aluminum Alloy. J. Inst. Eng. India Ser. C 98, 37–43 (2017). https://doi.org/10.1007/s40032-016-0304-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40032-016-0304-3