Abstract

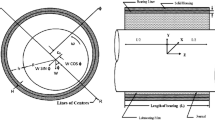

This paper presents a theoretical study of the effects of bearing shell deformation upon the performance characteristics of a capillary compensated multi-recess hydrostatic journal bearing system operating with micropolar lubricant. The finite element method has been used to solve the modified Reynolds’ equation governing the micropolar lubricant flow in the bearing and the three dimensional elasticity equations governing the displacement field in the bearing shell. The elasto-hydrostatic performance characteristics of the bearing are presented for various values of micropolar parameters (l m and N 2) and for a wide range of the deformation coefficient \(\bar{C}_{d}\) which takes into account the flexibility of the bearing shell. The computed results indicate that the influence of the bearing shell flexibility is quite significant on the performance characteristics of recessed hydrostatic journal bearing system operating with micropolar lubricant.

Similar content being viewed by others

Abbreviations

- a b :

-

Land width (m)

- c :

-

Radial clearance (m)

- D :

-

Journal diameter (m)

- E b :

-

Modulus of elasticity (N/m−2)

- F :

-

Fluid film reaction (N)

- h :

-

Fluid film thickness (m)

- l :

-

Characteristic length (m)

- L :

-

Bearing length (m)

- p :

-

Pressure (N m−2)

- p s :

-

Supply Pressure (N m−2)

- Q :

-

Bearing flow (m3 s−1)

- r :

-

Radial coordinate

- R J :

-

Journal radius (m)

- t :

-

Time (s),

- t h :

-

Shell thickness

- W 0 :

-

External load (N)

- X J , Z J :

-

Journal center coordinates

- x, y :

-

Circumferential and axial coordinates (m)

- z :

-

Coordinate across film thickness (m)

- δ :

-

Elastic deformation

- μ :

-

Dynamic viscosity (Pa. s)

- ω J :

-

Journal speed (rps)

- θ :

-

Angle of inter-recess land width (Fig. 1b)

- \(\bar{a}_{b}\) :

-

\(a_{b} /L\); Land width ratio

- \(\bar{A}^{e}\) :

-

Area of eth element

- \(\bar{C}_{d}\) :

-

\(\left( {p_{s} \,t_{h} } \right)/\left( {E_{b} c} \right)\) Elastic deformation coefficient

- \(\bar{C}_{s1}\) :

-

\(\frac{{3\pi \;a^{4} }}{{2c^{3} l_{cap} }}\)

- \(\bar{C}_{s2}\) :

-

\(\frac{{\bar{C}_{s1} }}{12}\)

- \(\bar{F}\) :

-

\(F\left( {1/p_{s} R_{J}^{2} } \right) ; Fluid film reaction\)

- \(\bar{h}\) :

-

h/c

- l m :

-

c/l

- N :

-

\(\left( {k/\left( {2\mu + k} \right)} \right)^{1/2} ; Coupling number\)

- \(\bar{p}\) :

-

p/p s

- \(\bar{Q}\) :

-

\(\left( {\mu_{r} /c^{3} p_{s} } \right)Q\)

- \(\bar{t}\) :

-

\(t\left( {c^{2} p_{s} /\mu_{r} R_{J}^{2} } \right)\)

- \(\bar{t}_{h}\) :

-

\(\frac{{t_{h} }}{{R_{J} }}\)

- \(\bar{u},\;\bar{v}\) :

-

\(\left( {u,v} \right)\left( {\mu_{r} R_{J} /c^{2} p_{s} } \right)\)

- \(\bar{w}\) :

-

\(w\left( {\mu_{r} R_{J} /c^{2} p_{s} } \right)\left( {R_{J} /c} \right)\)

- \(\bar{W}_{0}\) :

-

\(\left( {W_{o} /p_{s} R_{J}^{2} } \right)\)

- \(\bar{X}_{J} ,\bar{Z}_{J}\) :

-

\(\left( {X_{J} ,Z_{J} } \right)/c\)

- \(\bar{z}\) :

-

z/h

- (α, β):

-

(x, y)/R J , Circumferential and axial coordinates (m)

- \(\bar{\delta }\) :

-

\(\delta /c\)

- ε :

-

e/c; Eccentricity ratio

- λ :

-

L/D; Aspect ratio

- \(\bar{\mu }\) :

-

\(\mu /\mu_{r}\)

- \(\varOmega\) :

-

\(\omega_{J} \left( {\mu_{r} R_{J}^{2} /c^{2} p_{s} } \right); {\rm Speed\,parameter}\)

- b :

-

Bearing

- c :

-

Pocket

- cap:

-

Capillary

- J :

-

Journal

- R :

-

Reference value

- R :

-

Restrictor

- s :

-

Supply condition

- N i , N j :

-

Shape function matrices

- [M]:

-

Mass matrix

- \(\left\{ {\bar{p}} \right\}\) :

-

Pressure vector

- \(\left\{ {\bar{Q}} \right\}\) :

-

Flow vector

- \(\left\{ {\bar{R}_{xJ} } \right\},\;\left\{ {\bar{R}_{zJ} } \right\}\) :

-

Right hand side vectors due to journal velocity

- \(\left\{ {\bar{R}_{H} } \right\}\) :

-

Column vector (hydrodynamic term)

References

M.S. Khader, R.I. Vachon, Theoretical effects of solid particles in hydrostatic bearing lubricant. J. Lubr. Technol. Trans. ASME 95, 104–106 (1973)

S. Allen, K. Kline, Lubrication theory of micropolar fluids. J. Appl. Mech. Trans. ASME 38, 646–650 (1971)

M. Balaram, Micropolar squeeze films. J. Lubr. Technol. Trans. ASME 97, 635–637 (1975)

M.M. Khonsari, D.E. Brewe, On the performance of finite journal bearings lubricated with micropolar fluids. STLE Tribol. Trans. 32(2), 155–160 (1989)

J.B. Sukhla, M. Isa, Externally pressurized optimum bearing with micropolar fluid as lubricant. Jpn. J. Appl. Phys. 14(2), 275–279 (1974)

T.W. Hung, C. Weng, C.K. Chen, Analysis of finite width journal bearings with micropolar fluids. Wear 123, 1–12 (1988)

T.W. Hung, C. Weng, Dynamics characteristics of finite width journal bearings with micropolar fluids. Wear 141, 23–33 (1990)

J. Prakash, P. Sinha, Lubrication theory of micropolar fluids and its application to a journal bearing. Int. J. Eng. Sci. 13, 217–232 (1975)

C. Singh, P. Sinha, The three-dimensional reynolds equation for micropolar fluid lubricated bearings. Wear 76(2), 199–209 (1982)

N. Tipei, Lubrication with micropolar liquids and its application to short bearings. J. Lubr. Technol. Trans. ASME 101, 356–363 (1979)

S. Das, S.K. Guha, A.K. Chattopadhyay, On the conical whirl instability of hydrodynamic journal bearings lubricated with micropolar fluids. Proc. Inst. Mech. Eng. Part-J. 215, 431–439 (2001)

S. Das, S.K. Guha, A.K. Chattopadhyay, On the steady-state performance of misaligned hydrodynamic journal bearings lubricated with micropolar fluids. J. Tribol. Int. 35, 201–210 (2002)

Xiao-Li Wang, Ke-Qin Zhu, A study of the lubricating effectiveness of micropolar fluids in a dynamically loaded journal bearing. Tribol. Int. 37, 481–490 (2004)

Xiao-Li Wang, Ke-Qin Zhu, Numerical analysis of journal bearings lubricated with micropolar fluids including thermal and cavitating effects. Tribol. Int. 39, 227–237 (2006)

R. Sinhasan, S.C. Sharma, S.C. Jain, Performance characteristics of an externally pressurized capillary-compensated flexible journal bearing. Tribol. Int. 22(4), 283–293 (1989)

R. Sinhasan, S.C. Sharma, S.C. Jain, Performance characteristics of a constant flow valve compensated multirecess flexible hydrostatic journal bearing. Wear 134, 335–356 (1989)

R. Sinhasan, S.C. Sharma, S.C. Jain, Performance characteristics of externally pressurized orifice compensated flexible journal bearing. STLE Tribol. Trans. 34(3), 465–471 (1991)

S.C. Sharma, R. Sinhasan, S.C. Jain, Performance characteristics of multirecess hydrostatic/hybrid flexible journal bearing with membrane type variable-flow restrictor as compensating elements. Wear 152, 279–300 (1992)

S. Verma, V. Kumar, K.D. Gupta, Analysis of multirecess hydrostatic journal bearing operating with micropolar lubricant. J. Tribol. ASME. 131, 021103-1 (2009)

S. Verma, K.D. Gupta, V. Kumar, Analysis of capillary compensated hole-entry hydrostatic/hybrid journal bearing operating with micropolar lubricant, IUTAM symposium, Indian Institute of Technology, Delhi, India March 23–26, (2009)

E.R. Nicodemus, S.C. Sharma, Influence of wear on the performance of multirecess hydrostatic journal bearing operating with micropolar lubricant. J. Tribol. 132(2), 021703 (2010)

E.R. Nicodemus, S.C. Sharma, Orifice compensated multirecess hydrostatic/hybrid journal bearing system of various geometric shapes of recess operating with micropolar lubricant. Tribol. Int. 44, 284–296 (2011)

S. Verma, V. Kumar, K.D. Gupta, Analysis of capillary compensated hydrostatic journal bearing operating with micropolar lubricant. Ind. Lubr. Tribol. 63(3), 192–202 (2011)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Verma, S., Kumar, V. & Gupta, K.D. Effect of Elasticity on Capillary Compensated Flexible Multi-recess Hydrostatic Journal Bearing Operating with Micropolar Lubricant. J. Inst. Eng. India Ser. C 97, 11–23 (2016). https://doi.org/10.1007/s40032-015-0195-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40032-015-0195-8