Abstract

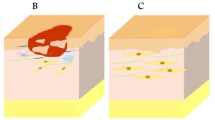

A major hurdle in engineering thick and laminated tissues such as skin is how to vascularize the tissue. This study introduces a promising strategy for generating multi-layering engineered tissue sheets consisting of fibroblasts and endothelial cells co-seeded on highly micro-fibrous, biodegradable polycaprolactone membrane. Analysis of the conditions for induction of the vessels in vivo showed that addition of endothelial cell sheets into the laminated structure increases the number of incorporated cells and promotes primitive endothelial vessel growth. In vivo analysis of 11-layered constructs showed that seeding a high number of endothelial cells resulted in better cell survival and vascularization 4 weeks after implantation. Within one week after implantation in vivo, red blood cells were detected in the middle section of three-layered engineered tissue sheets composed of polycaprolactone/collagen membranes. Our engineered tissue sheets have several advantages, such as easy handling for cell seeding, manipulation by stacking each layer, a flexible number of cells for next-step applications and versatile tissue regeneration, and automated thick tissue generation with proper vascularization.

Similar content being viewed by others

References

Ko HC, Milthorpe BK, McFarland CD. Engineering thick tissues—the vascularisation problem. Eur Cells Mater. 2007;14:1–18 (discussion-9).

Stock UA, Vacanti JP. Tissue engineering: current state and prospects. Annu Rev Med. 2001;52:443–51.

Murphy SV, Atala A. 3D bioprinting of tissues and organs. Nat Biotechnol. 2014;32:773–85.

Shim J-H, Kim M-J, Park JY, Pati RG, Yun Y-P, Kim SE, et al. Three-dimensional printing of antibiotics-loaded poly-ε-caprolactone/poly(lactic-co-glycolic acid) scaffolds for treatment of chronic osteomyelitis. Tissue Eng Regen Med. 2015;12:283–93.

Shimizu T. Cell sheet-based tissue engineering for fabricating 3-dimensional heart tissues. Circ J Off J Jpn Circ Soc. 2014;78:2594–603.

Sakaguchi K, Shimizu T, Horaguchi S, Sekine H, Yamato M, Umezu M, et al. In vitro engineering of vascularized tissue surrogates. Sci Rep. 2013;3:1316.

Kim SJ, Kim WI, Yamato M, Okano T, Kikuchi A, Kwon OH. Successive grafting of PHEMA and PIPAAm onto cell culture surface enables rapid cell sheet recovery. Tissue Eng Regen Med. 2013;10:139–45.

Nishida K, Yamato M, Hayashida Y, Watanabe K, Yamamoto K, Adachi E, et al. Corneal reconstruction with tissue-engineered cell sheets composed of autologous oral mucosal epithelium. N Engl J Med. 2004;351:1187–96.

Takagi R, Yamato M, Kanai N, Murakami D, Kondo M, Ishii T, et al. Cell sheet technology for regeneration of esophageal mucosa. World J Gastroenterol WJG. 2012;18:5145–50.

Bhattarai SR, Bhattarai N, Yi HK, Hwang PH, Cha DI, Kim HY. Novel biodegradable electrospun membrane: scaffold for tissue engineering. Biomaterials. 2004;25:2595–602.

Li H, Xu Y, Xu H, Chang J. Electrospun membranes: control of the structure and structure related applications in tissue regeneration and drug delivery. J Mater Chem B. 2014;2:5492–510.

Hu JJ, Chao WC, Lee PY, Huang CH. Construction and characterization of an electrospun tubular scaffold for small-diameter tissue-engineered vascular grafts: a scaffold membrane approach. J Mech Behav Biomed Mater. 2012;13:140–55.

Jiang S, Yan H, Fan D, Song J, Fan C. Multi-layer electrospun membrane mimicking tendon sheath for prevention of tendon adhesions. Int J Mol Sci. 2015;16:6932–44.

Li Z, Tan BH. Towards the development of polycaprolactone based amphiphilic block copolymers: molecular design, self-assembly and biomedical applications. Mater Sci Eng C Mater Biol Appl. 2014;45:620–34.

Abedalwafa M, Wang FJ, Wang L, Li CJ. Biodegradable poly-epsilon-caprolactone (PCL) for tissue engineering applications: a review. Rev Adv Mater Sci. 2013;34:123–40.

Singh S, Wu BM, Dunn JC. Accelerating vascularization in polycaprolactone scaffolds by endothelial progenitor cells. Tissue Eng Part A. 2011;17:1819–30.

Jwo SC, Chiu CH, Tang SJ, Hsieh MF. Tubular scaffolds of gelatin and poly(epsilon-caprolactone)-block-poly(gamma-glutamic acid) blending hydrogel for the proliferation of the primary intestinal smooth muscle cells of rats. Biomed Mater. 2013;8:065002.

Khil MS, Bhattarai SR, Kim HY, Kim SZ, Lee KH. Novel fabricated matrix via electrospinning for tissue engineering. J Biomed Mater Res B Appl Biomater. 2005;72:117–24.

Yoshimoto H, Shin YM, Terai H, Vacanti JP. A biodegradable nanofiber scaffold by electrospinning and its potential for bone tissue engineering. Biomaterials. 2003;24:2077–82.

Riopel M, Wang R. Collagen matrix support of pancreatic islet survival and function. Front Biosci. 2014;19:77–90.

Tao G, Levay AK, Peacock JD, Huk DJ, Both SN, Purcell NH, et al. Collagen XIV is important for growth and structural integrity of the myocardium. J Mol Cell Cardiol. 2012;53:626–38.

Grassel S, Bauer RJ. Collagen XVI in health and disease. Matrix Biol J Int Soc Matrix Biol. 2013;32:64–73.

Brizzi MF, Tarone G, Defilippi P. Extracellular matrix, integrins, and growth factors as tailors of the stem cell niche. Curr Opin Cell Biol. 2012;24:645–51.

Mafi P, Hindocha S, Mafi R, Khan WS. Evaluation of biological protein-based collagen scaffolds in cartilage and musculoskeletal tissue engineering—a systematic review of the literature. Curr Stem Cell Res Ther. 2012;7:302–9.

Huang CC, Wang TC, Lin BH, Wang YW, Johnson SL, Yu J. Collagen IX is required for the integrity of collagen II fibrils and the regulation of vascular plexus formation in Zebrafish caudal fins. Dev Biol. 2009;332:360–70.

Fu W, Liu Z, Feng B, Hu R, He X, Wang H, et al. Electrospun gelatin/PCL and collagen/PLCL scaffolds for vascular tissue engineering. Int J Nanomed. 2014;9:2335–44.

Sorrell JM, Baber MA, Caplan AI. A self-assembled fibroblast-endothelial cell co-culture system that supports in vitro vasculogenesis by both human umbilical vein endothelial cells and human dermal microvascular endothelial cells. Cells Tissues Organs. 2007;186:157–68.

Bauer SM, Bauer RJ, Velazquez OC. Angiogenesis, vasculogenesis, and induction of healing in chronic wounds. Vasc Endovasc Surg. 2005;39:293–306.

Singer AJ, Clark RA. Cutaneous wound healing. N Engl J Med. 1999;341:738–46.

Haraguchi Y, Shimizu T, Sasagawa T, Sekine H, Sakaguchi K, Kikuchi T, et al. Fabrication of functional three-dimensional tissues by stacking cell sheets in vitro. Nat Protoc. 2012;7:850–8.

Ohashi K, Yokoyama T, Yamato M, Kuge H, Kanehiro H, Tsutsumi M, et al. Engineering functional two- and three-dimensional liver systems in vivo using hepatic tissue sheets. Nat Med. 2007;13:880–5.

Masuda S, Shimizu T, Yamato M, Okano T. Cell sheet engineering for heart tissue repair. Adv Drug Deliv Rev. 2008;60:277–85.

Yamato M, Okano T, inventors; Cellseed Inc., Tokyo, assignee. Anterior ocular segment related cell sheets, three-dimensional structures, and processes for producing the same. United States patent US 8,642,338B2. 2014 Feb 4.

Bennett HS, Luft JH, Hampton JC. Morphological classifications of vertebrate blood capillaries. Am J Physiol. 1959;196:381–90.

Laib AM, Bartol A, Alajati A, Korff T, Weber H, Augustin HG. Spheroid-based human endothelial cell microvessel formation in vivo. Nat Protoc. 2009;4:1202–15.

Nehls V, Schuchardt E, Drenckhahn D. The effect of fibroblasts, vascular smooth muscle cells, and pericytes on sprout formation of endothelial cells in a fibrin gel angiogenesis system. Microvasc Res. 1994;48:349–63.

Greaves NS, Ashcroft KJ, Baguneid M, Bayat A. Current understanding of molecular and cellular mechanisms in fibroplasia and angiogenesis during acute wound healing. J Dermatol Sci. 2013;72:206–17.

Levenberg S, Rouwkema J, Macdonald M, Garfein ES, Kohane DS, Darland DC, et al. Engineering vascularized skeletal muscle tissue. Nat Biotechnol. 2005;23:879–84.

Powell HM, Boyce ST. Engineered human skin fabricated using electrospun collagen-PCL blends: morphogenesis and mechanical properties. Tissue Eng Part A. 2009;15:2177–87.

Cipitria A, Skelton A, Dargaville TR, Dalton PD, Hutmacher DW. Design, fabrication and characterization of PCL electrospun scaffolds—a review. J Mater Chem. 2011;21:9419–53.

Sell SA, Wolfe PS, Garg K, McCool JM, Rodriguez IA, Bowlin GL. The use of natural polymers in tissue engineering: a focus on electrospun extracellular matrix analogues. Polymers. 2010;2:522–53.

Acknowledgements

This study was supported by a grant from the National Research Foundation of Korea (grant number: NRF-2013R1A1A2061786) and by Ministry of Health and Welfare (HI14C-0746-040016), Republic of Korea.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no financial conflicts of interest.

Ethical Statement

The animal experiment protocol was reviewed and approved by the institutional animal care and use committee of Asan Medical Center (protocol number: 2014-12-003).

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Hong, S., Jung, B.Y. & Hwang, C. Multilayered Engineered Tissue Sheets for Vascularized Tissue Regeneration. Tissue Eng Regen Med 14, 371–381 (2017). https://doi.org/10.1007/s13770-017-0049-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13770-017-0049-y