Abstract

With the aim of facilitating easier development of guidelines for the stakeholders using porous pavements, a simple parametric mathematical model is developed for the prediction of clogging behavior, i.e., time-dependent decaying hydraulic conductivity of porous pavement dependent on two different input parameters in addition to time. Based on earlier experimental results, trends of diminishing hydraulic conductivities with time under different void ratios and particle sizes were established. It is found that for a particular particle size, the effect of void ratio on time-dependent hydraulic conductivity can be expressed with a combined linear and exponential functions. Again, for a particular void ratio, the effect of particle size on time-dependent hydraulic conductivity can be expressed with an exponential function. The particle size dependent equation was further extended to include the effect of void ratio through multiplying a linear function having void content as independent variable. Developed equation predicted results were compared with the original experimental measurements. It is found that all the three models are capable to well-predict experimental measurements with RMSE values equal or higher than 0.98. The void content dependent equation is capable to predict results having standard errors as, Root Mean Squared Error (RMSE) = 0.04, Mean Absolute Error (MAE) = 0.03 and Relative Absolute Error (RAE) = 0.09, whereas the same error statistics of the particle size dependent equation are 0.04, 0.02 and 0.08 respectively. Error statistics of the combined (particle size and void ratio) equation are, RMSE = 0.1, MAE = 0.07 and RAE = 0.22. Such modelling technique would be useful for the prediction of potential clogging in the porous pavement for any combination of input parameters.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In the modern world with the continuous push on implementing more and more sustainable features, porous pavements are increasingly being used as an integral part of urban stormwater management systems, especially for the surfaces where traffic load is very light, i.e. in parking lots and paved pedestrian walkways (Rahman et al. 2015a, b). The primary objectives of porous pavement systems are to reduce surface runoff by increasing infiltration through the surface, to treat stormwater sediments and associated nutrients, and eventually to reduce pollution of receiving water bodies through such primary physical treatment. Due to its drainage characteristics, porous asphalt (a specialized asphalt mixture comprised of both fine and coarse aggregates bound together by a bituminous binder) is commonly used as the pavement material of the porous pavements. It is obvious that such porous pavements trap sediments through its filter media. As some pollutants are trapped with the sediments, removal of sediments also helps removing some other pollutants, especially nutrients. To facilitate easy estimations of potential treatment efficiency of different stormwater treatment systems without repetitive implementations of expensive experimental measurements, a sophisticated mathematical tool (MUSIC, Model for Urban Stormwater Improvement Conceptualisation) was developed by Wong et al. (2006), although through comparisons of several experimental measurements Imteaz et al. (2013) concluded that MUSIC mostly overestimates the treatment efficiencies.

Even with several environmental benefits, there is some reluctance on widescale implementation of this sustainable feature, mainly due to its cost burden as well as users’ perception of its long-term effectiveness. Many authorities are sceptical on using this unique feature owing to uncertainty on how long the built system will be able to serve its purpose. Clogging is the main concern for such pavement, since it can obstruct the porous pavement's drainage properties, thereby converting it into an impermeable medium.

There were numerous studies on the effectiveness of porous pavements (elaborated in the following section). However, most of those are either rigorous experiments, which are expensive, time-consuming, or complex numerical modelling. Most of the stakeholders do not have the ability to conduct their own experiments or employ a complex numerical model to suit their own scenario. However, a general guideline is very helpful for the design and real-life implementation of porous pavements encompassing the specific needs of various stakeholders. In order to facilitate formulation of useful guidelines regarding the design of appropriate porous pavement system without employing complex mathematical models or implementing rigorous experimental setup, an attempt is made to derive a simple parametric equation, which would be very useful for stakeholders without engaging thorough laboratory study or mathematical modelling. Such use of parametric equation does not require expert knowledge or experience on sophisticated tool(s), which often require rigorous data. This paper discusses the development of simple mathematical formulas for the prediction of clogging for a porous material with any void content and particle size flowing through the porous medium in order to derive a generalized behaviour. Regarding porous pavement design, such simplistic approach is a pioneer attempt, which is likely to render economic and environmental benefits to the stakeholders.

Literature review

Many researchers have presented effectiveness of porous pavements in reducing stormwater runoff volume and improving the runoff quality (Zhang and Kevern 2021; Karmakar et al. 2021; Roseen et al. 2014, 2012; Dreelin et al. 2006). In recent years, Xu et al. (2020) investigated the characteristics of the clogged particles in the porous pavement and reported that clogging particles are mainly the particles resulting from wear and tear from the asphalt and aggregates within the pavement. Also, dust and wear tire particles are the major components of clogged particles arising from traffic. Through investigation on the gradation of the clogged particles, Hassan et al. (2015) and Meng et al. (2020) reported that about 90% of clogged particles collected from highway and residential streets were having less than 2.36 mm size.

Yuan et al. (2018) investigated the effects of clogging particles’ gradation, water head, and runoff velocity on the clogging behaviour of porous pavement and reported that gradation of the clogging particles is the prime parameter which significantly affects the clogging. Valerio et al. (2016) investigated the effects of sediment load and air void content of porous asphalt on clogging behaviour of porous pavement, and showed that, contrary to general perception, a drop in void content or an increase in sediment load had no effect on clogging. However, Rahman et al. (2015a) studied the clogging behaviour of porous pavement materials under varying loads of sediments and reported that with the increase in sediment load, hydraulic conductivity of the porous pavement slightly decreases. Rahman et al. (2015a) also investigated clogging behaviour under repeated cycles of sediment loadings and after 10 cycles of sediment loading found that hydraulic conductivity slightly decreased. In another study through experimenting three different types of materials Rahman et al. (2015b) found that for each of the materials hydraulic conductivity decreases with the increase of filter media particle density, which in turn is related to void content of the porous media.

All the above-mentioned studies were performed in the laboratory using rigorous experimental setup. Ji et al. (2020) investigated the drainage performance of porous asphalt pavement using a 3D Finite Element Modelling method, which is a computer simulation of the expected behaviour. Jung et al. (2012) investigated the hydraulic conductivity behaviour through porous media using X-ray imaging technique. In a recent study Li et al. (2022) investigated the microscopic seepage behaviour of porous asphalt through its void structure. They have observed the movement of water through the porous material and investigated the properties such as seepage depth, seepage velocity, and seepage path. Their study demonstrated that deposition of clogging particles in the void obstructs the movement of water and restricts the water seepage paths. They have further provided in-depth investigations of the effects of varying void contents and particle sizes on the hydraulic conductivity of the porous asphalt material. They have concluded that the seepage is more obstructed by the small particles due to their more significant water absorption effect. Also, an increased void content of the porous media is effective on reducing the clogging. Current study is on the development of simple parametric equations for the prediction of clogging under different scenario using the experimental results of Li et al. (2022). Such development of simple equations will be useful for the stakeholders who would be able to derive specific guidelines for their need(s).

Materials and methods

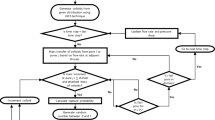

The methodology employed for the development of mathematical formulations is to derive generalized equations for the predictions of time-varying hydraulic conductivity of porous asphalt material depending on porous media void content and sediment particle size in the solute, which were established through rigorous experimental measurements conducted in the study of Li et al. (2022). The following sections provide detailed descriptions of the adopted methodology and subsequent mathematical formulations for different independent variables.

Model for variable void content

As presented by Li et al. (2022), hydraulic conductivity of the porous pavement exhibits an exponential decay over the time and similar decay patterns are observed for different void contents. The exponential decay pattern can be represented with the following equation:

where, ‘HC’ is the hydraulic conductivity (cm/s), ‘t’ is the time in hours, ‘a’ & ‘b’ are the constants for a particular void content. It is found that both the constants ‘a’ and ‘b’ can be correlated with the void content (VC) as per the following equations:

Where, m1 and C1 are the coefficient and intercept of the linear relation between ‘a’ and the void content, m2 and C2 are the coefficient and intercepts of the linear relation between ‘b’ and the void content. As such a final equation of ‘hydraulic conductivity’ can be derived having time (t) and VC as independent variables, which can be expressed as:

In the current study, values of all these coefficients and intercepts are determined through best fitting of the measured values obtained from detailed experimental study of Li et al. (2022).

Model for variable particle size

Like the effect of time on hydraulic conductivity mentioned in the previous section, i.e., hydraulic conductivity decreases exponentially with the passage of time. However, as expected with the bigger particle size the hydraulic conductivity magnitudes are higher compared to the ones with the smaller particle size. Again, the exponential decay pattern can be represented with the following equation:

where, ‘HC’ is the hydraulic conductivity (cm/s), ‘t’ is the time in hours, ‘m’ & ‘n’ are the constants for a particular particle size. It is found that ‘m’ remains constant for all the particle sizes, whereas ‘n’ can be correlated with the particle size as per the following polynomial function of second degree:

where, ‘PS’ is the particle size in ‘mm. ‘i’, ‘j’ and ‘k’ are the coefficients and intercept of the second-degree polynomial equation. As such a final equation of ‘hydraulic conductivity’ can be derived having time (t) and particle size (PS) as independent variables, which can be expressed as:

where, all the variables are defined earlier. Values of all these coefficients and intercepts are determined through best fitting of the measured values obtained from detailed experimental study of Li et al. (2022).

Model for combined variables (void content and particle size)

Equation 7 is based on a particular void content of 21%. Considering other hydraulic conductivity values for other void contents, it is found that relative effect of void content on the combined effect of particle size and void content can be represented with the following linear relationship as a function of void content:

Inserting Eq. 8 as multiplier into the Eq. 7, renders to the final equation for hydraulic conductivity considering combined effects of void content and particle size, which can be expressed as:

where, ‘g’ and ‘h’ are the constants derived through best-fitting of the experimental measurements.

The models’ performances were assessed using RMSE, MAE and RAE values between the measured and predicted hydraulic conductivity values.

RMSE is calculated using the following equation:

where, Xobs is the measured values and Xmodel is the modelled values at time step ‘i’ and ‘n’ is the total number of data/observations.

MAE is calculated using the following equation:

RAE is calculated using the following equation:

The following section describes final development of the model equations and comparisons with the corresponding measured data.

Results and discussion

Model for variable void content

Figure 1 shows the relationships of hydraulic conductivity with time under different void contents (18%, 21% and 24%). It is found that relationships of hydraulic conductivities with time are having similar pattern and exhibit exponential decay patterns. Figure 1 also separately shows the best-fit equation for each void content. The derived best-fit equations are as follow:

It is found that the coefficients (0.52, 0.70 & 1.051) and the exponents (0.88, 0.846 & 0.629) can be linearly correlated with the void content as shown in Fig. 2. It is found that the standard error (MAE) for both the linear relationships is “0.04”. The derived linear relationships are as follow:

Replacing Eqs. 16 and 17, into Eq. 4 renders the following final equation for calculating hydraulic conductivity for a fixed particle size.

where, ‘VC’ is the void content in % and ‘t’ is the time in hour. In the experimental study of Li et al. (2022), there were total 12 measurements comprising variable void contents and time. Figure 3 shows the comparison of equation/model predicted values with the original measured values for all the 12 measurements. It is found that model can closely predict the actual measured values with a correlation coefficient of 0.993. A statistical TTest on the sets of data returns the significance level of 0.99. Also, the standard error statistics of the model produced results are; RMSE = 0.04, MAE = 0.03 and RAE = 0.09.

Model for variable particle size

Figure 4 depicts the connections between hydraulic conductivity and time for various particle sizes (0.15, 0.3, 0.6 and 1.18 mm). Hydraulic conductivity relationships with time are found to have a similar pattern and display exponential decay patterns. Figure 4 also separately shows the best-fit equation for each particle size. The derived best-fit equations are as follow:

Standard errors (MAE) of the above best-fit equations are 0.034, 0.018, 0.027 and 0.004 for the particle sizes of 0.15 mm, 0.3 mm, 0.6 mm and 1.18 mm respectively. It is found that the exponents (0.786, 0.881, 0.744 and 0.394) of the above equations can be correlated with the following second order polynomial equation representing Eq. 6 and shown in Fig. 5.

The standard error (MAE) of the estimates of the Fig. 5 (i.e. Equation 23) is 0.03. Replacing Eq. 23 into Eq. 7 renders the following final equation for calculating hydraulic conductivity for a fixed void content.

where, ‘PS’ is the particle size in mm and ‘t’ is the time in hour. In the experimental study of Li et al. (2022), there were total 16 measurements comprising variable particle sizes and time. Figure 6 shows the comparison of equation/model predicted values with the original measured values for all the 16 measurements. It is found that model can closely predict the actual measured values with a correlation coefficient of 0.991. A statistical TTest on the sets of data returns the significance level of 0.95. Also, the standard error statistics of the model produced results are; RMSE = 0.04, MAE = 0.02 and RAE = 0.08.

Combined model considering void content and particle size

The combined model is the extended version of the Eq. 24 mentioned above. It is found that under all the particle sizes, variations of hydraulic conductivity with the void content can be expressed with an average linear trend as represented in Eq. 8. A factor, f(VC) was introduced to consider the effect of void content. As Eq. 24 was derived for a void content of 21%, magnitude of f(VC) was assumed to be 1.0 at the void content of 21%. Magnitudes of hydraulic conductivities at other void contents were factorized relative to the magnitude of average hydraulic conductivity at 21% void content. These factors for different void contents can be expressed with the following equation:

Multiplying the coefficient (0.76) of Eq. 24 with the above equation renders the following:

As such, the final equation for the hydraulic conductivity considering both the effects of particle size and void content becomes:

In the experimental study of Li et al. (2022), there were total 24 measurements comprising variable particle sizes, void contents, and time. Figure 7 shows the comparison of equation/model predicted values with the original measured values for all the 24 measurements. It is found that model can well-predict the actual measured values with a correlation coefficient of 0.98, a slight reduction in correlation coefficient compared to the equations with individual variables (void content and particle size) including time. The standard error statistics of the model produced results are; RMSE = 0.10, MAE = 0.07 and RAE = 0.22.

Discussions

In the earlier section three parametric equations are proposed: (i) equation for variable void content, (ii) equation for variable particle size and (iii) combined equation having both the void content and particle size as independent variables. Following table summarises all the standard error (i.e. RMSE, MAE and RAE) values obtained from different models. From the Table 1 it is clear that all the error statistics for the combined equation are higher compared to individual equations for the void ratio and particle size.

It is obvious that as the combined equation covers more variables and more measured data, the level of accuracy will be lower than the individual equations which cover only two independent variables and fewer number of measured data.

The derived equations can be utilized to forecast clogging behavior in porous pavements. This will be useful for stakeholders to adopt appropriate design parameters as well as to deduce required maintenance schedule as guidelines during the implementation of such porous pavement systems. In the field of porous pavement clogging research, no such generalized equation has yet been developed as a prediction tool.

Conclusion

It is well-established that porous pavements render enormous environmental benefits to surrounding waterways through trapping several pollutants from stormwater. However, potential clogging of porous pavement under subsequent activities such as movement of traffic, frequent storm run-off has been a concern for the stakeholders. All the earlier studies on such clogging behavior were involved with either complex mathematical modelling or rigorous experimental studies. This study presented the development of a parametric generalized model for the prediction of time-varying clogging behavior for any particle size and void content of the filter media of a porous pavement. The key focus of the study was to provide useful information for the stakeholders for their policy making or implementation of porous pavement system without involving into difficult, time-consuming, and expensive experiments. Time-varying hydraulic conductivities represent the clogging behavior of a porous pavement. Based on rigorous experimental results reported by Li et al. (2022), relationships of hydraulic conductivities with time for various void contents and fixed particle size were established. Then all these relationships were integrated into a single equation, which expresses the hydraulic conductivity for any time and any void content with a fixed particle size. Further, a set of relationships between time and hydraulic conductivity was established for varying particle sizes under a fixed void content. Again, these equations were combined to a single equation expressing hydraulic conductivity at any time for any particle size with a fixed void content. Finally, the time-dependent equation for hydraulic conductivity for any particle size was extended to include the effect of void content. The extended equation is capable to predict time-dependent hydraulic conductivity, i.e. decrease in hydraulic conductivity with time for any particle size and any void content. The accuracy of developed equation was assessed with the measured data with twenty-four different time-dependent measurements with varying void contents and particle sizes. The combined equation has achieved a correlation coefficient of “0.98” with an RMSE value of the estimations as “0.10”. However, the individual equations with void content or particle size had higher correlation coefficients. Equation with particle size achieved a correlation coefficient of “0.991” with an RMSE value of “0.04” and equation with void content achieved a correlation coefficient of “0.993” with an RMSE value of “0.04”. Although a few observations deviated from the combined equation's predictions, the equation's average accuracy is excellent. It is to be noted that developed equations are well suited for the ranges of variables used in this study. It is not certain how the equation will perform for the variables outside the studied ranges. The current equations were developed with a limited set of data available. It is recommended that further experiments to be conducted with more measurements with the same parameters, which can be used to validate the current developed equations. Also, it is recommended that future studies should endeavor to incorporate other variables (i.e., inflow sediment concentrations and filter layer depth) into such generalized equation.

Data availability

All the data used in the paper are already presented in the figures and available through contacting the corresponding author.

Abbreviations

- VC:

-

Void content

- HC:

-

Hydraulic conductivity

- PS:

-

Particle size

- t:

-

Time

- RMSE:

-

Root mean squared error

- MAE:

-

Mean absolute error

- RAE:

-

Relative absolute error

- X obs :

-

Measured values

- X model :

-

Modelled values

References

Dreelin EA, Fowler L, Carroll CR (2006) A test of porous pavement effectiveness on clay soils during natural storm events. Water Res 40:799–805

Hamzah MO, Abdullah NH, Voskuilen JLM (2013) Laboratory simulation of the clogging behaviour of single-layer and two-layer porous asphalt. Road Mater Pavement Des 14(1):107–125

Hassan NA, Abdullah NAM, Shukry NAM, Mahmud MZH, Nur MY, Putrajaya ZR, Hainin MR, Yaacob H (2015) Laboratory evaluation on the effect of clogging on permeability of porous asphalt mixtures. J Teknol 76(14):77–84

Imteaz MA, Ahsan A, Rahman A, Mekanik F (2013) Modelling Stormwater Treatment Systems using MUSIC: Accuracy. Resour Conserv Recycl 71:15–21. https://doi.org/10.1016/j.resconrec.2012.11.007

Ji TJ, Xiao L, Chen F (2020) Parametric analysis of the drainage performance of porous asphalt pavement based on a 3D FEM method. J Mater Civ Eng 32(12):1–9

Jung SY, Lim S, Lee SJ (2012) Investigation of water seepage through porous media using X-ray imaging technique. J Hydrol 452–453:83–89

Karmakar D, Das B, Pal M (2021) A study on porous bituminous pavement as an alternative method for ground water management. In: Roy PK, Roy MB, Pal S (eds) Advances in water resources management for sustainable use. Springer, Singapore, pp 75–84

Li H, Xu H, Chen F, Liu K, Tan Y, Leng B (2022) Evolution of water migration in porous asphalt due to clogging. J Clean Prod 330(129823):1–15

Meng AX, Xing C, Tan YQ, Li GN, Li JL, Lv HJ (2020) Investigation on the distributing behaviors of clogging particles in permeable asphalt mixtures from the microstructure perspective. Construct Build Mater 263:1–14

Rahman MA, Imteaz MA, Arulrajah A, Disfani MM, Horpibulsuk S (2015a) Engineering and environmental assessment of recycled construction and demolition materials used with geotextile for permeable pavements. J Environ Eng 141(9):1–8

Rahman MA, Imteaz MA, Arulrajah A, Piratheepan J, Disfani MM (2015b) Recycled construction and demolition materials in permeable pavement systems: geotechnical and hydraulic characteristics. J Clean Prod 90:183–194

Roseen RM, Ballestero TP, Houle JJ, Briggs J, Houle K (2012) Water quality and hydrologic performance of a porous asphalt pavement as a storm-water treatment strategy in a cold climate. J Environ Eng 138(1):81–89

Roseen RM, Ballestero TP, Houle K, Heath D, Houle JJ (2014) Assessment of winter maintenance of porous asphalt and its function for chloride source control. J Transp Eng 140(2):1–8

Valerio C, Mariana M, Luis SF, Filippo G, Gianfranco B (2016) Laboratory assessment of the infiltration capacity reduction in clogged porous mixture surfaces. Sustainability 8(751):1–11

Wong THF, Fletcher TD, Duncan HP, Jenkins GA (2006) Modelling urban stormwater treatment—a unified approach. J Ecol Eng 27(1):58–70

Xu S, Lu G, Hong B, Jiang X, Peng G, Wang D, Oeser M (2020) Experimental investigation on the development of pore clogging in novel porous pavement based on polyurethane. Constr Build Mater 258(120378):1–12. https://doi.org/10.1016/j.conbuildmat.2020.120378

Yuan J, Chen X, Liu S, Nan S (2018) Effect of water head, gradation of clogging agent, and horizontal flow velocity on the clogging characteristics of pervious concrete. J Mater Civ Eng 30(9):1–10

Zhang K, Kevern J (2021) Review of porous asphalt pavements in cold regions: the state of practice and case study repository in design, construction, and maintenance. J Infrastruct Preserv Resil 2(4):1–17. https://doi.org/10.1186/s43065-021-00017-2

Funding

Open Access funding enabled and organized by CAUL and its Member Institutions.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of interest to be declared.

Additional information

Editorial responsibility: Maryam Shabani.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Imteaz, M.A., Ahsan, A. & Shams, S. Parametric modelling of clogging behavior of porous pavements with time. Int. J. Environ. Sci. Technol. 21, 4037–4044 (2024). https://doi.org/10.1007/s13762-023-05251-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-023-05251-7