Abstract

Sugarcane farming and bioethanol production are water-intensive activities that result in high water competition. The competition, in turn, can exacerbate water scarcity. Therefore, this study aims to evaluate the water footprint (WF) of the sugar and bioethanol production at the Finchaa and Metehara sugarcane farms, which are located in different river basins in Ethiopia. The climatic data (minimal and maximum temperature, relative humidity, wind speed, and sunshine duration), meteorological data (rainfall), CROPWAT 8.0 model, nitrogen fertilizer application rates, sugarcane yield, and sugar and bioethanol production over 12 years (2008–2019) were used. Penman–Monteith method-based sugarcane water requirements of Finchaa and Metehara were found to be 2021.1 and 3605.4 mm/growing period, respectively. The sugarcane WF of Finchaa was 188.01 m3/t, which was composed of green (67.45 m3/t), blue (113.42 m3/t), and grey (7.14 m3/t) components, whereas the WF of Metehara was 239.11 m3/t consisting of green (29.42 m3/t), blue (204.13 m3/t), and grey (5.56 m3/t). The low sugarcane WF recorded was attributed to the high yield of sugarcane that was harvested in the study areas. Hence, the irrigation (blue WF) requirement is the major concern of water management in the basins. Similarly, the WF of bioethanol at the Finchaa distillery (2067.62 L/L) was much higher than that of the Metehara distillery (1441.54 L/L). However, both WFs were within the global range. Significant differences were observed between the two water basins. The sugarcane estate farm and bioethanol production processes require water management intervention to reduce the impact of WF in the basins.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Climate change and COVID-19 are aggravating water stress and water scarcity in many places, impacting the lives of 2 billion people and leaving about 3.4 billion people without access to safe sanitation facilities. Water stress is the availability of 1000–1700 m3 of freshwater per person per year, and water scarcity is the availability of less than 1000 m3 per person per year (Xinchun et al. 2017; Fito and Van Hulle 2021). The UN estimates that the global water deficit will be 40% by 2030 (UN-Water 2021). Water scarcity will affect 4.8–5.7 billion people by 2050 (UN-Water 2020), and the scarcity will be severe for 3.2 billion people under a business-as-usual scenario (Burek et al. 2016). Currently, severe water scarcity is attributed to rapid freshwater depletion and quality deterioration (FAO 2015; Fito and Van Hulle 2021). The pressure on water resources due to poor water resources management will place 45% of global gross domestic product and 40% of global grain production at risk by 2050 (UN-Water 2019). In the last 100 years, water use has increased sixfold and continues to increase dramatically (UN-Water 2020). Sustainability analysis indicates that global water demand will continue to increase by 20–30% between 2010 and 2050 (Burek et al. 2016; UN-Water 2021). By 2030, global water demand will rise to 6900 billion m3, exceeding current water availability by 64% (Maryam and Büyükgüngör 2019). Similarly, global water withdrawal, which was 1270 km3/yr in 2010, is estimated to be 2700 km3/yr by 2050 (Kahil et al. 2019). The largest global blue water withdrawal (> 80%) is attributed to agriculture, which is the major contributor to water stress (Xinchun et al. 2017). The rapidly increasing water demands and withdrawals make the implementation of proper water resources management methods, such as the measurement of virtual water trade and water footprint (WF), important.

The water footprint is defined as the total volume of freshwater consumed and polluted directly or indirectly in the process of producing goods (Gerbens-Leenes and Hoekstra 2009; Hoekstra et al. 2011; Cui 2021). It considers both the quality and quantity of the water resources. Water scarcity footprint (WSF) and WF are confusing terms for many audiences. Normally, WF assessment refers to the compilation and evaluation of water appropriation with its potential impacts on water resources, whereas WSF refers to the potential impact of the appropriation on the quantity of water consumed ignoring the quality component (Shi et al. 2020). The WF concept introduced by Hoekstra was employed under the WF assessment method, which was described by sub-indicators which are green, blue, and grey WF (Borsato et al. 2019). Another WF evaluation approach is the Water-focused Life Cycle Assessment method, which is mainly focused on the impact on freshwater consumption and degradation. This can be applicable for given products and activities from cradle to gate based on ISO 14040. Fundamentally, Life Cycle Assessment (ISO 14046)-based WF evaluates the impact on freshwater under various impact categories such as freshwater ecotoxicity, water quality (greywater), and eutrophication. However, this method normally ignores the blue water evaluation (Jefferies et al. 2012).

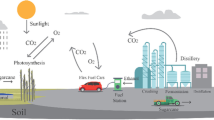

Concerning the WF of consumers, huge variations exist by geographic area. For instance, the total WF per capita in the South-East of England has been calculated at 1257 m3/yr and in the North-East of England at 597 m3/yr (Yu et al. 2010). The global average WF of the consumer was 1385 m3/yr from 1996 to 2005, but the WF of South Africa was 1255 m3/yr, far below the global average (Pahlow et al. 2015). Similarly, huge variations of consumer WF per capita have been reported in the regions of Beijing, Tianjin, and Hebei, ranging from 114 to 463 m3 (Sun 2019). Excluding the grey WF, the average global consumptive WF is expected to potentially reach 8508 km3/yr in 2090, an increase of 22% over the current level (Mekonnen and Gerbens-Leenes 2020). This figure will exceed the global blue WF capacity by 57%. The predicted 22% increase by 2090 is mainly due to climate change and land-use change (Mekonnen and Gerbens-Leenes 2020). Few scholars agree on the accuracy of WFs, the policy implications, and the benefits at the local level (Perry 2014). However, the WF is generally considered an environmental tool that nations, countries, and provinces can use to calculate the volume of water consumed by crops, processes, and industrial production. The study of agricultural WF is paramount since 70% of freshwater consumption is attributed to this sector. The rapid depletion of fossil fuels has encouraged researchers to look for renewable and sustainable sources of energy. Currently, energy users are shifting from fossil fuels to biofuels such as sugarcane-based bioethanol. Some estimate that 27% of global transportation fuel will be biofuel in 2050 (Ghani et al. 2019). Global biofuel production is expected to increase by 50% in 2050 compared to 2012 (Mekonnen and Gerbens-Leenes 2020). The sugar industry and bioethanol distilleries are growing rapidly in many parts of the world; between 2007 and 2015 bioethanol production increased by 96% sugarcane production is a water-intensive process requiring huge freshwater consumption (Fito et al. 2019). Indeed, sugarcane production accounts for about 29% of all water consumption in crop production globally (Jorrat et al. 2018). Bioethanol production results in high water depletion and pollution. Hence, meeting the water security requirements and practicing water management interventions are not easy tasks in the agroindustry (Scarpare et al. 2016; Mota-lópez et al. 2019; Deepa et al. 2021). The investigation of the WF of agricultural and industrial sectors is essential to minimizing the high appropriation of freshwater. A sugarcane WF that exceeds the local water benchmark is a good indicator of inefficient water consumption.

The top five global sugarcane-producing countries are Brazil (39%), India (19%), China (7%), Thailand (4%), and Pakistan (4%) (Jorrat et al. 2018). The sugarcane-based bioethanol WFs have been reported for Peru (1670 L/L), Cuba (6355 L/L), Brazil (2450 L/L), India (2995 L/L), and the USA (2775 L/L); the global average is 2855 L/L (Gerbens-Leenes and Hoekstra 2009; Scholten 2009). Global bioethanol WFs range between 50 and 180 m3/GJ (Gerbens-Leenes 2018). The WF of sugarcane-based bioethanol can vary based on the crop watering system. For instance, different WF values of rain-fed (1646 L/L) and irrigation estate farms (1229 L/L) of the same location have been reported in Brazil (Chico et al. 2015). Molasses-based bioethanol WFs can be lower than for sugarcane. For instance, in the provinces of Kanchanaburi and Suphanburi in Thailand, WFs of 1104.5 m3/t and 876 m3/t were reported, respectively, for molasses-based bioethanol production (Chooyok et al. 2013). Even though sugarcane and bioethanol WFs have been studied in a few countries and regions, significant studies have not been conducted in some regions of the world, including Ethiopia. The Ethiopian government is expanding sugarcane plantations and bioethanol production, aiming to replace petroleum as a fuel for transportation and thereby mitigating the effects of climate change and global warming. The sugarcane estate farms and bioethanol distilleries in Ethiopia are located in semiarid areas where the shortage of water is highly pronounced. In the semiarid areas of Ethiopia, drought is common, resulting in a decrease in agricultural yields. The major water source for these estate farms and industries is surface water distributed through sparse rainfall and irrigation.

The investigation of WF in such water-stressed catchments is essential for determining the severity of the problem and the urgency of water management in the affected regions (Perry 2014). Measurement of WF is a reliable decision-making tool for promoting the sustainability of biofuels and integrating environmental policy, water resources, and the needs of the economic sector (Bellezoni et al. 2018). But the big challenge for WF investigation is the lack of sufficient data from many sugarcane estate farms, particularly in developing countries. Moreover, many factors influence WF such as variability in climatic conditions, amount of annual rainfall, soil type and fertility, farming style, sugarcane harvesting method, crop water requirement, irrigation type, and sugarcane yield. Particularly, the hot climate and high sugarcane yield are the most dominant factors that enhance and suppress the values of WF, respectively. Indeed, only a few sugarcane WF studies have been conducted under Ethiopian water utilization practices, agricultural trends, water management systems, and hot climatic conditions (Fito et al. 2017). Therefore, this study evaluated the crop water requirement of sugarcane estate farms and the WF of sugar and bioethanol production in the Finchaa and Metehara sugarcane estate farms located in two different water basins. It is crucial to study the WF at the basin level, which is the basic unit in the hydrological cycle (Muratoglu 2019). In line with this, the Finchaa sugarcane estate farm and bioethanol distilleries are in the Blue Nile Basin, whereas the Metehara farm and distilleries are situated in the Awash Basin.

Materials and methods

Description of the study area

Ethiopia’s climate and fertile soil type are conducive to sugarcane production on extensive estate farms. Wonji Shoa, Metehara, and Finchaa sugarcane estate farms are among the largest and oldest sugarcane estate farms in the country. Metehara is the second largest irrigated sugarcane estate farm, located in the Awash Basin, whereas the Finchaa sugarcane estate farm is situated in the Blue Nile Basin as indicated in Fig. 1. The Metehara sugarcane estate farm was established in 1965 by an agreement between the Ethiopian government and the Dutch company Handelsvereniging Amsterdam. The farm’s sugar factory and molasses-based ethanol distillery are located at 940 m above sea level. The Metehara estate farm is found at the geographic coordinates of 8°54′0″ north and 39°55′0″ east in the East Shoa Zone of Oromia Regional State, which is about 200 km east of Addis Ababa, the capital of Ethiopia. It occupies a vast agricultural tract of 10,230 ha. The sugar factory and bioethanol distillery of Metehara have production capacities of 825,000 t/yr and 12,500 m3/yr, respectively. These industrial and farm areas have an average annual rainfall of 600 mm, relative humidity of 77.4%, sunshine duration of 8:46 h, and wind speed of 4.12 m/s. This area has semiarid climatic conditions; the rainiest period is between June and September (Fito et al. 2017).

Finchaa sugarcane estate farm is the largest farm in the Blue Nile Basin; it was established in 1995. This estate farm uses a large-scale pump, gravity, and sprinkler irrigation scheme. The sugarcane farmland is about 210,000 ha, which is larger than that of the Metehara estate farm. The annual industrial sugar production capacity of 270,000 t was set during Ethiopia’s industrial establishment period. Both the estate farm and sugar industries are located in Horro Guduru Wollega Zone in the Oromia Regional State in the western part of Ethiopia. The Finchaa area is situated at the geographical coordinates of 9°30′23′′–10°01′05′′ north and 37°30′30′′–38°51′59′′ east. Compared to the Metehara farm’s location, Finchaa is located at a higher altitude of 1350–2300 m above sea level. Finchaa has an average annual rainfall of 1280 mm, a maximum temperature of 30.6 °C, and a minimum temperature of 14.5 °C. The dominant soils in the area are luvisols and vertisols, which provide an environment conducive to sugarcane plantations.

2.2 Measurement of reference evapotranspiration (ETo)

Meteorological data, sugarcane estate farms information, and industrial data were used to determine bioethanol WFs. These data are maximum and minimum temperatures (°C), wind speed (m/s), rainfall (mm), sunshine duration (h), relative humidity (%), nitrogen fertilizer application rates (kg/ha), and sugarcane yield (t/ha). The sugarcane coefficient (Kc) was obtained from the Food and Agriculture Organization of the United Nations (FAO). Additionally, sugarcane factory data such as filter cake, molasses, bagasse, and amount of sugar yielded per ton of sugarcane were collected. The industry data were collected for the 12 years from 2008 to 2019. Data for the Metehara bioethanol distillery were collected after its establishment in 2011. Normally, ETo is the estimation of evapotranspiration of a hypothetical crop that covers an extensive surface with the green grass of a uniform height of 0.12 m. ETo was calculated using the CROPWAT 8 model program. The values of the ETo (mm/day) were determined using meteorological data such as the Kc, maximum and minimum local temperature (°C), relative humidity (%), wind speed (m/s), and sunshine duration (h). The ETo value was computed by the FAO Penman–Monteith method, as shown in Eq. 1:

where ETo is the reference evapotranspiration [mm/day], Rn is the net radiation at the crop surface [MJ/m2 day], G is the soil heat flux density [MJ/m2 day], T is the mean daily air temperature at 2 m height [°C], U2 is the wind speed at 2 m height [m/s], es is the saturation vapor pressure [kPa], ea is the actual vapor pressure [kPa], Δ is the slope vapor pressure curve [kPa/°C], and γ is the psychometric constant [kPa/°C] (Yang et al. 2021).

2.3 Computation of potential evapotranspiration (ETc)

Sugarcane evapotranspiration was computed in fundamentally the same way as crop water requirement. Crop water requirement refers to the amount of water needed to replace the evapotranspiration lost from the cropped field. Based on the relationship between Kc and ETo, crop water requirement was calculated using the CROPWAT 8 model. The crop water requirement is computed using Eq. 2. The model uses common modules such as effective rainfall, sugarcane growing season, crop module, and the climate-based value ETo.

where Kc is the sugarcane coefficient value that was taken from the FAO that fixes standards for sugarcane crops, ETc is the sugarcane water requirement (sugarcane evapotranspiration), and ETo is the reference crop evapotranspiration (Fito et al. 2017; Muratoglu 2019).

Effective rainfall (R eff) determination

For semiarid areas whose monthly rainfall amounts to less than 100 mm/month, the fixed percentage method of measuring Reff is highly recommended (Fito et al. 2017; Muratoglu 2019). Reff is the portion of total rainfall used by the crop effectively. Twelve years of rainfall data, 2008 to 2019, were used for the determination of Reff. The CROPWAT 8 model estimate was used to estimate the Reff using Eq. 3.

where R is the rainfall (mm/day) obtained from secondary data and Reff is the effective rainfall (mm/day) computed based on the secondary data (Muratoglu 2019).

Sugarcane water footprint

Computation of green water footprint (WFgreen)

The three components of WF are green, blue, and grey WF, which are rainwater, surface and/or groundwater, and polluted water, respectively. The common units of WF are volume of water per unit of mass (m3/t, L/kg), time (m3/month, m3/yr), and energy (m3/MJ, m3/GJ). WF can be evaluated through either the WF network approach or the life cycle assessment method, which are the most common approaches to assessing the environmental impact on water consumption and pollution burden (Hoekstra et al. 2011; Zhang et al. 2018; Forin et al. 2020). Initially, green evapotranspiration and the green component of sugarcane water requirements were determined. There are two options for computing ETgreen depending on whether Reff is greater than the sugarcane water requirement or ETgreen is less than the sugarcane water requirement. This study was conducted in semiarid regions where ETgreen was expected to be less than the total sugarcane water requirement. In such an approach, the green evapotranspiration calculation can be carried out through Eq. 4.

where ETgreen is the green evapotranspiration. Green sugarcane water used (SWU) is calculated using Eq. 5.

where SWU (m3/ha) is the sugarcane water requirement (use), lgp is the length of the growing period of the sugarcane in days, and the conversion factor of 10 was used to translate ETgreen into volume (0.1 mm/day is equal to 1 m3/ha/day). Finally, the green component of the sugarcane WF (WFgreen, m3/t) is calculated using Eq. 6.

where Y (t/ha) is the sugarcane yield of the study area (Fito et al. 2017).

Computation of blue water footprint (WFblue)

Blue WF is composed of blue evapotranspiration (ETblue) and the blue component of sugarcane water use (SWUblue, m3/ha). Blue evapotranspiration (ETblue), also known as the irrigation requirement, is the total amount of water required for irrigation. The crop water requirement is not fully met by Reff, and the calculation of ETblue was very important. The groundwater and surface water used for irrigation can be considered for the calculation of the ETblue. ETblue can be obtained by computing the difference between the ETc and Reff (Eq. 7).

Based on the value of the ETblue, blue sugarcane water use is calculated by summing the blue component of evapotranspiration over the length of the growing period of sugarcane, as indicated in Eq. 8.

where SWU is the sugarcane water requirement (use), lgp is the length of the growing period of the sugarcane in days. Finally, the sugarcane blue WF (WFblue) is computed using Eq. 9.

where WFblue (m3/t) refers to the blue water footprint, SWUblue is the sugarcane water use (m3/ha), and Y is the sugarcane yield (t/ha) (Hoekstra et al. 2011; El-Marsafawy and Mohamed 2021).

Computation of grey water footprint (WFgrey)

The discharge of wastes into water bodies due to farming and industrial processes and the hypothetical amount of water required for diluting the water bodies to the acceptable quality standards is the grey WF (WFgrey). The estimation of greywater is carried out according to Eq. 10. WFgrey (m3/t) is normally calculated using industrial wastes and agrochemicals such as fertilizers, pesticides, and herbicides.

where α is the leaching-runoff fraction in the agriculture field, AR is the chemical fertilizer applied rate in the sugarcane estate farm per hectare (kg/ha), Cmax is the maximum acceptable pollutant concentration solution (kg/m3), and Cnat is the pollutant concentration in water bodies under natural conditions (kg/m3) (Hoekstra et al. 2011). Finally, the total WF of the sugarcane is calculated using Eq. 11.

Computation of molasses WF

Sugarcane stalks are raw materials that can be processed in sugar factories to produce edible sugar. In Ethiopia, the sugar production process comprises the sugarcane grinding, juice extraction, clarification, evaporation, crystallization, and centrifugal and dry processes in the cane factory. Usually, lime is added to cane juice for clarification purposes and the impurities settle to the bottom of the clarifying vessel as a precipitate. In addition to sugar, the industrial by-products of the process, specifically bagasse (residue from sugarcane crushing), press mud (dirt mud residue from juice clarification), molasses (final residue from sugar crystallization), and wastewater, were considered in the determination of the WF. Most Ethiopian sugar industries are annexed to distilleries for bioethanol production. Molasses is the chief source of ethanol production by the enzymatic action of the yeast in distilleries. The major processes of ethanol production are fermentation and distillation. The stepwise accumulative method was used to determine the WF of molasses. The WF of the bioethanol in the distillery industry was assessed based on the WF of the sugar industry and sugarcane estate farm. This is calculated using Eq. 12.

where WFprod [p] (m3/t) refers to the WF of molasses, which is a by-product of the sugar industry; p, in this case, refers to the product of the sugar industry, i refers to the input of the sugar industry, WFproc (p) (m3/t) is the WF of the sugar industrial process, fp [p] is the molasses fraction (product), fv [p] is the molasses as the product with its value fraction, and WFprod (i) (m3/t) is the WF of molasses as the product of the sugar industry. Finally, the production fraction fp [p, i] and the value fraction of the output product molasses are calculated using Eq. 13. But the denominator in this equation was aggregated over the z output products of the sugar industry: molasses, filter cake, bagasse, and sugar.

where fp [p, i] is the unitless molasses fraction (the product), w(i) is the mass of input in the sugar industry (sugarcane in kg), w(p) is the mass of molasses in kg referring to the product, fv [p, i] is the value fraction of product which is the molasses, and price(p) refers to the market cost of product p, molasses (monetary unit/mass).

Determination of bioethanol WF

In this study, bioethanol was produced from sugarcane molasses in the sugar industry. Molasses is the input material in the distillery industry, whereas the spent wash is the by-product of the industry. Finally, the WF of the bioethanol is calculated using Eq. 14.

where WFprod [p] (m3/t) refers to the WF of the bioethanol that is the product of the bioethanol distillery; p, in this case, refers to the product of the bioethanol distillery; i is the input of the bioethanol distillery; WFproc (p) (m3/t) is the WF of the bioethanol distillery process; fp [p] is the bioethanol fraction of product (bioethanol); and fv [p] is the bioethanol as the product with its value fraction.

Results and discussion

Factors influencing sugarcane water requirement

Many weather conditions play significant roles in influencing evapotranspiration, which in turn affects crop water requirements. These factors are temperature, wind speed, relative humidity, and solar radiation. Increasing many of the factors injects energy, which removes water vapor from the crop and the surface of the soil. These conditions can aggravate the crop water requirement. Based on the 12 years of meteorological data from the two water catchments, the monthly maximum temperature values of 36.0 °C and 38.3 °C at Metehara and Finchaa estate farms, respectively, were recorded. The average temperature variation at Metehara sugarcane estate farm was 28 °C, whereas at Finchaa it was 21.7 °C. These differences indicate huge variations in temperature in both water basins, which raises crop water requirements for sugarcane estate farms. But the difference in temperature variation between the two basins was insignificant. The high temperature of crop farms is directly proportional to the amount of evapotranspiration and crop water requirement. Generally, high temperatures generate high energy, which can result in an enormous amount of evaporation and evapotranspiration. Temperature increases from 28–33 °C to 28–35 °C have been shown to raise transpiration by 20% and 30%, respectively (Allen 1999).

Wind speeds at the Metehara and Finchaa farms were 0.9–8.9 m/s and 0.1–1.2 m/s, respectively. Average solar radiation was 8.3 h at Metehara and 7.7 h at Finchaa. These values at Metehara are significant. Both wind speed and solar radiation have a direct relationship with the amount of evapotranspiration and the crop water requirement. The longer duration of sunshine and the higher wind speed observed in this study encouraged evapotranspiration in the Metehara area. Therefore, the Metehara estate farm can be expected to have a greater crop water requirement. The average minimum and maximum relative humidity of Metehara and Finchaa were found to be 24 and 77%, and 39 and 82.5%, respectively. The higher relative humidity recorded for the Finchaa water basin had a lowering effect on both evapotranspiration and crop water requirement; humid air is inversely related to evapotranspiration and crop water requirement. Generally, humid air suppresses evapotranspiration and crop water requirement. The relative humidity is a great contributor to sugarcane and bioethanol WFs. In all aspects, the studied weather parameters showed that evapotranspiration and crop water requirement are expected to be higher at Metehara compared to Finchaa.

Sugarcane reference evapotranspiration (ETo)

The meteorological weather data of monthly minimum and maximum temperatures, relative humidity, sunshine duration, and wind speed were used to determine the sugarcane ETo. Over the 12 years from 2008 to 2019, the mean annual ETo at Metehara was in the range 4.71–7.98 mm/day, whereas the mean annual ETo at Finchaa sugarcane estate farm was 3.22–4.70 mm/day. The average value of the ETo over the study period at Metehara was 6.17 mm/day and at Finchaa 4.01 mm/day. The wide ETo range observed in both water basins could be attributed to the hot and dry weather conditions that adversely impact both crop water requirement and water footprint. The ETo values at the Metehara sugarcane estate farm were higher than those at Finchaa. This difference implies that the crop water requirement demand was highly diversified during the sugarcane’s growing period. The details of the values of ETo over the years are indicated in Fig. 2. The ETo values at Metehara are higher than at Finchaa, in line with the differences between the two estate farms in temperature, relative humidity, solar radiation, and wind speed. These values are in line with the climatic condition of the semiarid area in which the Metehara farm is situated and the tropical area in which the Finchaa farm is located. The mean values for both Metehara and Finchaa were statistically significant (p < 0.05), but the difference between the two water basins was not statistically significant (p > 0.05). In another study conducted at Metehara from 2007 to 2016, a sugarcane means annual ETo value of 6.2 mm/day was reported (Fito et al. 2017). It was also reported that sugarcane ETo values of 3.66–6.42 mm/day were recorded, similar to those in this study (Karuppanan and Ramasamy 2014). A study conducted in China over the years 1956–to 2015 suggested that climate change has had adverse effects on ETo, which has shown an increasing trend (Fan et al. 2016). Findings from these studies indicated that the current ETo found in this study is within the global trend with respect to this value (Fig. 3).

Effective rainfall (R eff)

Estimating Reff is crucial to determining the appropriate SWR. The actual amount of rainfall and Reff results are presented in Fig. 4. Reff was calculated to identify the amount of water loss due to runoff or percolation from the actual rainfall. Over this study period, the Reff at Metehara was found to be in the range of 313.2–667 mm/yr, whereas at Finchaa it was in the range of 1050–1460.9 mm/yr. The maximum Reff at Finchaa was two times higher than at Metehara. But Reff variation at Metehara was high at 53%, whereas variation at Finchaa was 28%. These numbers imply that more SWR from irrigation is needed for the Metehara sugarcane estate farm. The amount of water required for irrigation may be higher than expected due to low water management and high reference evapotranspiration. Furthermore, a comparison by ANOVA of the mean annual rainfall over the study period for the two basins produced a statistically insignificant result at p > 0.05. The results indicate that the distribution of rainfall over the study period is very irregular, resulting in significant variations in SWRs in the basins. Moreover, the study findings of Reff showed that the SWR was not satisfied completely by the rainfalls observed in the two regions.

Sugarcane evapotranspiration (ETc)

Sugarcane ETc was investigated and the results are presented as ranges. Generally, the average ETc value found at Metehara was 3160 mm/growth period, whereas ETc at Finchaa was 2021.1 mm/growth period. There were huge ETc variations between Metehara and Finchaa. Additionally, the value of the ETo is highly influenced by Reff, crop module, critical depletion, crop development stage, yield response, crop height, plantation dates, and root system depth. The sugarcane growth stages dates of the initial 50, development 70, mid 220, and late stages of 140 were applied, and the corresponding Kc of initial 0.4, mid 0.25, and late-stage 0.75 were used. Moreover, the sugarcane growing period to the harvest of 16 months in both water basins was used. Maximum root depth, depletion factor, and seasonal yield response function factors of 1.2–2, 0.65 and 1.2 were observed, respectively. Even though the Kc value can vary based on the conditions of the climate and the crop stage, it is a very dominant value overall. It is a factor correlating atmosphere, crop physiology, and agricultural practices with ETc values. Variations in ETc values over the seasons were observed due to changes in climatic conditions. In addition, the study results indicated that more of the irrigation water requirement was consumed than the effective rainfall at both sugarcane estate farms. The values of SWR at these farms were higher than the global average value, but a value of 3459.2 mm/growth period, similar to that in this study, was reported in the Metehara area in another study (Fito et al. 2017). Generally, this study showed that interventions in water management and water irrigation are urgent. Finally, the ANOVA test done for means comparison between water basins found a statistically significant difference between means at p < 0.05. Normally, when the Reff > ETc the irrigation water requirement is zero. However, in this study, the finding that Reff < ETc implies that irrigation water is a must and the amount of the requirement should be obtained by calculating the difference between the ETc and Reff (Muratoglu 2019).

Sugarcane estate farm footprint

Data regarding sugarcane yield were gathered for the 12-year study period for both sugarcane estate farms. The sugarcane estate farm footprints with their components are illustrated in Fig. 5. Sugarcane yields at Metehara ranged from 118.4 to 193.4 t/ha and in Finchaa they ranged from 97 to 146.4 t/ha. The average yield at Metehara was 154.8 t/ha and at Finchaa 122.2 t/ha. High sugarcane yield is the major factor that suppressed the amount of sugarcane WF. The average Ethiopian sugarcane yield was 161.15 t/ha, which was much higher than many sugarcane-producing countries (Fito et al. 2017). The variations in sugarcane yield between Metehara and Finchaa were huge. The sugarcane yield of Metehara was higher than that of Finchaa by 36.8 t/ha. These values are extremely high compared to the values in other sugarcane producer countries. The average sugarcane yields in tons per hectare for many typical producers are lower: for Brazil, 75.2; China, 69.5; India, 63.4; USA, 75.7; Cuba, 39.9; Peru, 133.7; Thailand, 75.7; Pakistan, 56.5; Egypt 118.6; South Africa, 53.7; Mexico, 74.4; and Cuba, 31.4 t/ha (Scholten 2009; Jorrat et al. 2018). The high sugarcane yield in Ethiopia might be attributed to the tropical climatic conditions in addition to the fertile soil types that are conducive to sugarcane production. The high yield in Ethiopia plays a significant role in suppressing and reducing the WF for sugarcane and bioethanol. Low WF can have an adverse effect on water resources management for sugarcane plantations in the basins and cane industrial expansion. In Finchaa ETgreen of 824.3 mm/season, SWUgreen of 8243 m3/ha, and green WF of 67.45 m3/t were recorded, whereas, in Metehara ETgreen of 455.4 mm/season, SWUgreen of 4554 m3/ha, and green WF of 29 0.42 m3/t were obtained.

Finchaa WFgreen was 67.45 m3/t, whereas Metehara WFgreen was 29.42 m3/t. In the comparison of the two water basins, the WFgreen at Finchaa was more than twice Metehara’s. These figures indicate that the high WF of sugarcane in both industries and both sugarcane estate farms is attributed mainly to irrigation water requirements. The values of the green SWF were too small to have a significant influence on the total WF of the study areas. In another study conducted at Metehara, sugarcane water use of 4486 m3/ha and WFgreen components of 27.84 m3/ha were reported. These values are nearly the same as the findings of the current study (Fito et al. 2017).

From an irrigation perspective, the sugarcane water use at Finchaa was 13,860 m3/ha, whereas at Metehara it was 31,600 m3/ha. The irrigation water requirement at Metehara was nearly three times higher than at Finchaa. The blue WF of sugarcane at Finchaa was 113.42 m3/t, whereas Metehara’s WFblue was 204.13 m3/t. The value of WFblue was large in both factories, which shows that abundant water for SWR came from irrigation. In another study conducted on sugarcane WF at Metehara, the blue component was found to be 187.35 m3/t (Fito et al. 2017). For WFgrey determination, fertilizers, pesticides, nitrogen-leaching runoff fraction of 10%, acceptable nitrate concentration of 0.05 kg/m3, natural nitrate concentration of water bodies, and average fertilizer application rate of 207.8 kg/h were used. The purpose of measuring the greywater is to determine the amount of freshwater required to dilute hypothetically polluted water bodies.

Finchaa WFgrey was 7.14 m3/t, whereas Metehara sugarcane WFgrey was 5.56 m3/t. The WFgrey values for the two estate farms were nearly the same. The overall contribution of WFgrey to total WF was generally significant. Additionally, the influence of this element on the total WF of sugarcane for both farms was indeed minor. But from pollution and environmental protection point of view, due attention has to be given to mitigating the water pollution from the sugarcane estate farms and cane industrial processes. Normally, the contribution of the WFgrey to total WF is within the range of 4–11%. Both estate farms fall below this range; Finchaa’s WFgrey was 3.8% and Metehara’s was even less at 2.3%. The insignificant contribution of WFgrey is attributed to the types of fertilizers and pesticides considered in the analysis. Globally, WF evaluations of products do not include some nutrients, pesticides, and herbicides, indicating that this environmental tool has certain limitations. The experience developed so far was focused on nitrogen fertilizer. Generally, the varied values of WF are attributed to variations in climate, sugarcane yield, fertilizers, herbicides, and pesticides used in the analysis.

The WF of sugarcane at Finchaa was 188.01 m3/t and in Metehara 239.11 m3/t. The green, blue, and grey components of the sugarcane WF at Finchaa were 67.45 m3/t (35.9%), 113.42 m3/t (60.2%), and 7.14 m3/t (3.8%), respectively, whereas the corresponding values at Metehara were 29.42 m3/t (12.3%), 204.13 m3/t (85.4%), and 5.56 m3/t (2.3%). The average global sugarcane WF (1500 m3/t) is composed of green 45%, blue 49%, and grey 6% (Gerbens-Leenes and Hoekstra 2009). Significant sugarcane WF difference was observed between Metehara and Finchaa; Metehara was higher by 51.01 m3/t. In another study, nearly identical sugarcane WF (217.69 m3/t) was reported at Metehara (Fito et al. 2017). Sugarcane WF of many countries were varied in the range of 877–3340 m3/t. For instance, in Argentina 1318, in Australia 1492, in Brazil 1284, in China 1224, in Columbia 1018, in Cuba 3340, in Egypt 1003, in Ethiopia 975, in India 1571, in Indonesia 1475, in Morocco 1339, in Pakistan 2807, in Peru 877, in Philippines 1307, in South Africa 1879, in Thailand 1850, in Guatemala 1070, in USA, 1135, in Venezuela 1688, and in Vietnam 1707 m3/t, but the global average was 1500 m3/t (Gerbens-Leenes and Hoekstra 2009; Scholten 2009). However, in South Africa, the lowest WF of 160 m3/t was reported (Pahlow et al. 2015). Additionally, a study of sugarcane WF in Brazil’s Paranaiba Basin recorded a WF of 151 m3/t under rain feed and 142 m3/t under irrigated cultivation (Fachinelli and Pereira 2015). Even though ETo, ETc, and Reff were very high in the current study, a WF lower than the global average was observed. This low value might be attributed to extremely high sugarcane yield in both water basins.

WF evaluation for bioethanol

Molasses WF

In determining the WF of bioethanol, the investigation of molasses WF is essential. In this study, the product fractions and value fractions of the molasses produced in the sugar industrial process were determined using bagasse, filter cake, sugar, and molasses. Basically, molasses was a by-product of the sugar industry at the farms studied, whereas sugarcane was the input material in the cane factories. In the Finchaa sugar industry, processing 1 t of sugarcane generated on average of 108.5 kg sugar, 280.6 kg bagasse, 14.8 kg filter cake, and 36.5 kg molasses; at Metehara processing, the sugarcane resulted in 99 kg of sugar, 295.5 kg bagasse, 28.5 kg filter cake, and 32.78 kg molasses. The average amounts of sugarcane and molasses at Finchaa were 9,929,536.4 quintals and 362,821.5 quintals, respectively. Product and value fractions were based on fertilizer application of 430 kg/ha, price of 1350 birr/100 kg of fertilizer, molasses process water of 10 m3/t, and filter cake 14.8 t/ha (0.398 birr/kg). Processing 1 t bagasse generated 0.2 kWh of electricity (0.816 birr/kWh), which resulted in a product fraction of 0.036 and an estimated value fraction of 0.0585. Specifically, the amount of sugarcane used, bioethanol produced, process water consumed, and spent wash generated in the processing of 1 t of molasses are indicated in Table 1. Similarly, at Metehara the molasses production fraction of 0.033 and the estimated value fraction of 0.06 were obtained based on fertilizer application of 430 kg/ha, fertilizer price of 1350 birr/100 kg, molasses process water of 10 m3/t, 1 t of bagasse-based generation of 0.2 kWh of electricity (0.816 birr/kWh) and filter cake as fertilizer 28.5 t/ha (0.204 birr/kg). Finally, the molasses WFs of Finchaa and Metehara were 306.10 m3/t and 435.35 m3/t, respectively. The molasses WF of Metehara was higher than Finchaa’s WF by 129.25 m3/t. The current findings of molasses WF of Finchaa are lower than the global average (407 m3/t), but the WF of Metehara was a bit higher than the global average (Kongboon and Sampattagul 2012). In another study conducted in Metehara, a higher molasses WF of 553.6 m3/t was reported. This WF was composed of green 76.65 m3/t, blue 469.43 m3/t, and grey 7.3 m3/t (Fito et al. 2017). The findings indicated that the Metehara sugar industry contributes a tremendous amount to water appropriation and pollution in comparison with global scenarios. Hence, environmental and water management is recommended to minimize the burden on development.

Bioethanol WF

The determination of the WF of bioethanol was fundamentally based on the WFs of the sugar and molasses in the sugar industrial processes. The WFs of bioethanol and its components are presented in Fig. 6. In this study, the main product was bioethanol and the by-product was used in the WF assessment. The spent wash was used as a natural fertilizer, which can reduce the amount of artificial fertilizer consumed for the sugarcane estate farms and treated as such in calculating its economic value. Based on this, the use of the spent wash reduced the amount of fertilizer by about 25% per hectare. Currently, in Ethiopia, the estimated value of the fertilizer used for sugarcane cultivation per hectare is 2500 birr/ha. In Finchaa, the economic value of the spent wash was 625 birr/ha, which was equivalent to 35.57 birr/m3. Finally, the amount of spent wash was 17.57 m3/ha. The estimated average current price of bioethanol is 18 birr/L. Based on these values, the calculated product and value fractions of bioethanol in Finchaa were 0.12 and 0.97, respectively. Similarly, in Metehara, the bioethanol product fraction of 0.23 and value fraction of 0.96 were found, based on sugarcane yield of 154.8 t/ha, amount of the spent wash applied 22.45 m3/ha, and cost of spent wash consumed/hectare 27.84 birr/m3.

Generally, the WF of bioethanol in Finchaa was 2067.62 L/L, whereas the WF in Metehara (1441.54 L/L) showed a good value compared with that of Peru (1670 L/L) (Gerbens-Leenes and Hoekstra 2009). The WF of the bioethanol at Metehara was composed of green 177.01 L/L, blue 1231.08 L/L, and grey 33.16 L/L, whereas the WF bioethanol at Finchaa was composed of green 742.28 L/L, blue 1244.71 L/L, and grey 78.57 L/L. The sugarcane-based bioethanol in Peru has been reported at 1670 L/L; in Cuba, 6355 L/L; in Brazil, 2450 L/L; in India, 2995 L/L; and in the USA 2775 L/L; the global average is 2855 L/L (Gerbens-Leenes and Hoekstra 2009; Scholten 2009). The WF of sugarcane-based bioethanol can be varied based on the crop watering system. For instance, in Brazil, the WF of rainfed crops has been reported at 1646 L/L and the irrigated crops at 1229 L/L (Chico et al. 2015). The WF of molasses-based bioethanol can be influenced spatially. For instance, the WF of molasses-based bioethanol in Kanchanaburi provinces was 1104.5 m3/t, whereas in the Suphanburi it was 876 m3/t (Chooyok et al. 2013). The ultimate goal of WF studies and implementation of interventions based on their findings are to enhance water utility efficiency and differentiate hot spots of production along production chains [23].

Conclusions

Bioethanol production is highly promoted in Ethiopia to combat the impact of fossil fuels on the climate. Sugarcane estate farms and bioethanol production are increasing competition for freshwater. Determining the WFs of sugarcane estate farms is an essential tool for evaluating water consumption and pollution burden on water resources in the two water basins. The sugarcane water requirements of Finchaa and Metehara of 2021.1 and 3605.4 mm/growing period, respectively, were obtained in this study. The average sugarcane yields on both estate farms are much higher than the global average. These high cane yields have resulted in WF fluctuations, illustrated by the 188.01 m3/t WF of Finchaa and the 239.11 m3/t of Metehara. These values are within the global WF averages for sugarcane. But there is abundant room to improve the WF of the sugarcane crop in the two areas. Additionally, the average bioethanol WF of the Finchaa distillery was 2067.62 L/L (green 742.28 L/L, blue 1244.71 L/L, and grey 78.57 L/L), whereas the WF of the Metehara distillery was 1441.54 L/L (green 170.01 L/L, blue 1231.08 L/L, and grey 33.16 L/L). The WFs in both water basins were within the global range, but significant variations were observed between the two areas. Specifically, the study findings indicate a need to reduce the WFs of sugarcane and bioethanol production in the areas to achieve sustainable development and secure water sustainability. This information is essential for researchers who are interested in conducting further studies in the same thematic area in the two water basins.

Data availability

All data are fully available without restriction.

Abbreviations

- α :

-

Leaching-runoff fraction in the agricultural field

- AR:

-

Chemical fertilizer application rate

- C max :

-

Maximum acceptable pollutant concentration

- C nat :

-

Pollutant concentration in water bodies under natural conditions

- CWR:

-

Crop water requirement

- e s :

-

Saturation vapor pressure

- e a :

-

Actual vapor pressure

- Δ:

-

Slope vapor pressure curve

- γ :

-

Psychometric constant

- ETblue :

-

Blue evapotranspiration

- ETgreen :

-

Green evapotranspiration

- ETc :

-

Crop evapotranspiration

- ETo :

-

Reference evapotranspiration

- f p :

-

Product fraction

- f v :

-

Value fraction

- G :

-

Soil heat flux density

- K c :

-

Crop coefficient

- R eff :

-

Effective rainfall

- R n :

-

Net radiation at crop surface

- SWR:

-

Sugarcane water requirement

- SWU:

-

Sugarcane water used

- U 2 :

-

Wind speed at 2 m height

- Y :

-

Sugarcane yield

References

Allen LH (1999) Evapotranspiration responses of plants and crops to carbon dioxide and temperature. J Crop Prod 2:37–70. https://doi.org/10.1300/J144v02n02_02

Bellezoni RA, Sharma D, Arruda A et al (2018) Water-energy-food nexus of sugarcane ethanol production in the state of Goiás, Brazil: an analysis with regional input–output matrix. Biomass Bioenerg 115:108–119. https://doi.org/10.1016/j.biombioe.2018.04.017

Borsato E, Giubilato E, Zabeo A et al (2019) Comparison of water-focused life cycle assessment and water footprint assessment : the case of an Italian wine. Sci Total Environ 666:1220–1231. https://doi.org/10.1016/j.scitotenv.2019.02.331

Burek P, Satoh Y, Fischer G, et al (2016) Water futures and solution-FastTrack initiative (final report), International Institute for Applied Systems Analysis Schlossplatz 1, A-2361 IIASA working paper, Approved by: Bill Cosgrove, Acting Program Director Water, Laxenburg, Austria

Chico D, Santiago AD, Garrido A (2015) Increasing efficiency in ethanol production: water footprint and economic productivity of sugarcane ethanol under nine different water regimes in north-eastern Brazil. Span J Agric Res 13:1–10. https://doi.org/10.5424/sjar/2015132-6057

Chooyok P, Pumijumnog N, Ussawarujikulchai A (2013) The water footprint assessment of ethanol production from molasses in Kanchanaburi and Supanburi Province of Thailand. APCBEE Proc 5:283–287. https://doi.org/10.1016/j.apcbee.2013.05.049

Cui X (2021) Cyber-Physical System (CPS) architecture for real-time water sustainability management in manufacturig industry. In: Procedia CIRP. Elsevier, pp 622–628

Deepa R, Anandhi A, Alhashim R (2021) Volumetric and impact-oriented water footprint of agricultural crops: a review. Ecol Indic 130:108093. https://doi.org/10.1016/j.ecolind.2021.108093

del Jorrat M, Araujo PZ, Mele FD, (2018) Sugarcane water footprint in the province of Tucumán, Argentina. comparison between different management practices. J Clean Prod 188:521–529. https://doi.org/10.1016/j.jclepro.2018.03.242

Deressa A (2017) The impact of Fincha Sugar Factory plantation expansion on forest covers. MSc. thesis submitted to Addis Ababa University for partial Fulfillment of the Requirements for MSc. Degree, Addis Abba University, Ethiopia

El-Marsafawy SM, Mohamed AI (2021) Water footprint of Egyptian crops and its economics. Alex Eng J 60:4711–4721. https://doi.org/10.1016/j.aej.2021.03.019

Fachinelli NP, Pereira AO (2015) Impacts of sugarcane ethanol production in the Paranaiba basin water resources. Biomass Bioenerg 83:8–16. https://doi.org/10.1016/j.biombioe.2015.08.015

Fan J, Wu L, Zhang F et al (2016) Climate change effects on reference crop evapotranspiration across different climatic zones of China during 1956–2015. J Hydrol 542:923–937. https://doi.org/10.1016/j.jhydrol.2016.09.060

FAO (2015) Towards a water and food secure future: critical perspectives for policy-makers, Food and Agriculture Organization of the United Nations, Rome and World Water Council, Marseille

Fito J, Van Hulle SWH (2021) Wastewater reclamation and reuse potentials in agriculture: towards environmental sustainability. Environ Dev Sustain 23:2949–2972. https://doi.org/10.1007/s10668-020-00732-y

Fito J, Tefera N, Demeku S, Kloos H (2017) Water footprint as an emerging environmental tool for assessing sustainable water use of the bioethanol distillery at Metahara Sugarcane Farm, Oromiya Region, Ethiopia. Water Conserv Sci Eng 2:165–176

Fito J, Tefera N, Van Hulle SWH (2019) Sugarcane biorefineries wastewater: bioremediation technologies for environmental sustainability. Chem Biol Technol Agric 6:1–13. https://doi.org/10.1186/s40538-019-0144-5

Forin S, Mikosch N, Berger M, Finkbeiner M (2020) Organizational water footprint: a methodological guidance. Int J Life Cycle Assess 25:403–422. https://doi.org/10.1007/s11367-019-01670-2

Gerbens-Leenes PW (2018) green, blue and grey bioenergy water footprints, a comparison of feedstocks for bioenergy supply in 2040. Environ Process 5:167–180

Gerbens-Leenes PW, Hoekstra AY (2009) The water footprint of sweeteners and bio-ethanol from sugar cane, sugar beet and maize. Value of water: research report series No. 38, published by UNESCO-IHE Institute for Water Education in collaboration with University of Twente & Delft University

Ghani HU, Silalertruksa T, Gheewala SH (2019) Water-energy-food nexus of bioethanol in Pakistan: a life cycle approach evaluating footprint indicators and energy performance. Sci Total Environ 687:867–876. https://doi.org/10.1016/j.scitotenv.2019.05.465

Hoekstra AY, Chapagain AK, Aldaya MM, Mekonnen MM (2011) The water footprint assessment manual-setting the global standard. Earthscan Ltd, Dunstan House, 14a St Cross Street, London EC1N 8XA, UK and LLC, 1616 P Street, NW, Washington, DC 20036, USA Earthscan

Jefferies D, Muñoz I, Hodges J et al (2012) Water footprint and life cycle assessment as approaches to assess potential impacts of products on water consumption. Key learning points from pilot studies on tea and margarine. J Clean Prod 33:155–166. https://doi.org/10.1016/j.jclepro.2012.04.015

Kahil T, Albiac J, Fischer G et al (2019) A nexus modeling framework for assessing water scarcity solutions. Curr Opin Environ Sustain 40:72–80. https://doi.org/10.1016/j.cosust.2019.09.009

Karuppanan S, Ramasamy S (2014) Determination of water requirements of main crops in the tank irrigation command area using CROPWAT 8. 0. Int J Interdiscip Multidiscip Stud 1:266–272

Kongboon R, Sampattagul S (2012) Water footprint of bioethanol production from sugarcane. J Environ Earth Sci 2:61–68

Maryam B, Büyükgüngör H (2019) Wastewater reclamation and reuse trends in Turkey: opportunities and challenges. J Water Process Eng. https://doi.org/10.1016/j.jwpe.2017.10.001

Mekonnen MM, Gerbens-Leenes W (2020) The water footprint of global food production. Water 12:1–12. https://doi.org/10.3390/w12102696

Mota-lópez DR, Sánchez-ramírez C, Alor-hernández G et al (2019) Computers & industrial engineering evaluation of the impact of water supply disruptions in bioethanol production. Comput Ind Eng 127:1068–1088. https://doi.org/10.1016/j.cie.2018.11.041

Muratoglu A (2019) Water footprint assessment within a catchment: a case study for Upper Tigris River Basin. Ecol Indic 106:105467. https://doi.org/10.1016/j.ecolind.2019.105467

Pahlow M, Snowball J, Fraser G (2015) Water footprint assessment to inform water management and policy making in South Africa. Water SA 41:300–313. https://doi.org/10.4314/wsa.v41i3.02

Perry C (2014) Water footprints: path to enlightenment, or false trail? Agric Water Manag 134:119–125. https://doi.org/10.1016/j.agwat.2013.12.004

Scarpare F, Hernandes T, Ruiz-Correa S et al (2016) Sugarcane water footprint under different management practices in Brazil: Tiet^e/Jacar_e watershed assessment. J Clean Prod 112:4576–4584. https://doi.org/10.1016/j.jclepro.2015.05.107

Scholten W (2009) The water footprint of sugar and sugar-based ethanol. Thesis submitted to University of Twente, Enschede, The Netherlands

Shi X, Liao X, Li Y (2020) Quantification of fresh water consumption and scarcity footprints of hydrogen from water electrolysis: a methodology framework. Renew Energy 154:786–796. https://doi.org/10.1016/j.renene.2020.03.026

Sun S (2019) Water footprints in Beijing, Tianjin and Hebei: a perspective from comparisons between urban and rural consumptions in different regions. Sci Total Environ 647:507–515. https://doi.org/10.1016/j.scitotenv.2018.07.343

UN-Water (2019) Leaving no one behind, The United Nations World Water Development Report 2019, United Nations Educational, Scientific and Cultural Organization, 7, Place de Fontenoy, 75352 Paris 07 SP, France

UN-Water (2020) Water and climate change, the United Nations World Water Development Report 2020, the United Nations Educational, Scientific and Cultural Organization 7, Place de Fontenoy, 75352 Paris 07 SP, France

UN-Water (2021) Valuing water, The United Nations World Water Development Report 2021, the United Nations Educational, Scientific and Cultural Organization, 7, place de Fontenoy, 75352 Paris 07 SP, France

Xinchun C, Mengyang W, Xiangping G et al (2017) Assessing water scarcity in agricultural production system based on the generalized water resources and water footprint framework. Sci Total Environ 609:587–597. https://doi.org/10.1016/j.scitotenv.2017.07.191

Yang X, Jin X, Chu Q et al (2021) Impact of climate variation from 1965 to 2016 on cotton water requirements in North China Plain. Agric Water Manag 243:106502. https://doi.org/10.1016/j.agwat.2020.106502

Yu Y, Hubacek K, Feng K, Guan D (2010) Assessing regional and global water footprints for the UK. Ecol Econ 69:1140–1147. https://doi.org/10.1016/j.ecolecon.2009.12.008

Zhang G, Wang X, Zhang L et al (2018) Carbon and water footprints of major cereal crops production in China. J Clean Prod 194:613–623. https://doi.org/10.1016/j.jclepro.2018.05.024

Acknowledgements

We would like to thank the Ethiopian Road Authority (ERA) for the research fund and Addis Ababa Science and Technology University (AASTU), and the University of South Africa (UINSA) for other research support and Ann Byers for editing the manuscript.

Funding

This research work was supported by the Ethiopian Road Authority.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interests.

Additional information

Editorial responsibility: Jing Chen.

Rights and permissions

About this article

Cite this article

Fito, J., Ahmed, I., Nkambule, T.T.I. et al. Evaluation of water footprint in sugar industries and bioethanol distilleries in two different water basins toward water sustainability. Int. J. Environ. Sci. Technol. 20, 2427–2440 (2023). https://doi.org/10.1007/s13762-022-04182-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-022-04182-z