Abstract

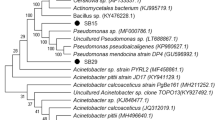

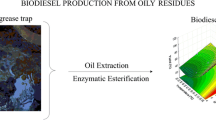

Change in the climatic conditions due to uncontrolled emission of carbon dioxide is continuously encouraging to search alternative renewable energy sources. Corn stover is one of the several feedstocks being considered as growth medium for oil producing bacteria. India ranks third in the production of corn in the world. The present study focused on biodiesel synthesis from microbial oil, chemical profiling and evaluation of physicochemical properties of produced biodiesel. The bacterium was isolated from food waste resources and identified as Bacillus amyloliquefaciens (MF510169) on the basis of morphological‚ biochemical characters and 16S rRNA sequencing. The bacterium B. amyloliquefaciens (MF510169) was grown on corn stover as an ideal agro-waste feedstock. The bacterium grown on corn stover peels revealed maximum lipid production after acid hydrolysis (0.25% HCl) over other feedstocks used under study. The bacterium produces 3.8% oil under operating parameters, i.e. inoculum size, density, carbon and nitrogen source, C/N ratio, temperature, pH, rotational speed and fermentation period. The oil was transesterified using sulphuric acid (0.12%) as a catalyst to form fatty acids methyl esters. Transesterification reaction was optimised at various parameters like catalyst type, catalyst loading, oil: methanol ratio, temperature and reaction time. The chemical profiling of FAMEs revealed hexadecanoic acid methyl ester, 9-1, 2 octadecanoic acid methyl ester, octadecanoic acid methyl ester and methyl stearate as characterised by using GC–MS, GC-FID, FTIR and NMR techniques. The physicochemical properties of transesterified biodiesel revealed 85% similarity with the ASTM International Standards. The produced biodiesel from Bacillus could be exploited at commercial level after successful engine trial tests.

Similar content being viewed by others

Abbreviations

- B. amyloliquefaciens :

-

Bacillus amyloliquefaciens

- MSM:

-

Mineral salt medium

- LB:

-

Luria–Bertani

- GC–MS:

-

Gas chromatography mass spectroscopy

- GC-FID:

-

Gas chromatography flame ionization detector

- FTIR:

-

Fourier transform infrared spectroscopy

- NMR:

-

Nuclear magnetic resonance

- ASTM:

-

American Standard Testing Material

- TLC:

-

Thin-layer chromatography

- FAME:

-

Fatty acid methyl ester

- BHT:

-

Butylated hydroxytoluene

- BHA:

-

Butylated hydroxyanisole

- PG:

-

Propyl gallate

- ANOVA:

-

Analysis of variance

- NCBI:

-

National Centre for Biotechnology Information

- µL:

-

Microlitre

- D/W:

-

Distilled water

- HCl:

-

Hydrochloric acid

- v/v:

-

Volume by volume

- W/V:

-

Weight by volume

- kPa:

-

Kilopascal

References

Abd-Elhalem BT, El-Sawy M, Gamal RF, Abou-Taleb KA (2015) Production of amylases from Bacillus amyloliquefaciens under submerged fermentation using some agro-industrial by-products. Ann Agric Sci 60(2):193–202

Agarwal M, Chauhan G, Chaurasia SP, Singh K (2012) Study of catalytic behavior of KOH as homogeneous and heterogeneous catalyst for biodiesel production. J Taiwan Inst Chem Eng 43:89–94

Anthony J, Rangamaran VR, Gopal D, Shivasankarasubbiah KT, Thilagam MLJ, Dhassiah MP, Thirunavukkarasu S (2015) Ultraviolet and 5′-Fluorodeoxyuridine induced random mutagenesis in Chlorella vulgaris and its impact on fatty acid profile: a new insight on lipid-metabolizing genes and structural characterization of related proteins. Mari Biotechnol 17(1):66–80

Apun K, Jong BC, Salleh MA (2000) Screening and isolation of a cellulolytic and amylolytic Bacillus from sago pith waste. J Gen Appl Microbiol 46(5):263–267

Bajwa K, Bishnoi NR, Toor M, Gupta S, Sharma P, Kirrolia A, Kumar SS, Sharma J, Selvan ST (2015) Isolation, screening, characterization of indigenous oleaginous bacteria: evaluation of various carbon and nitrogen sources as substrates for single celled oil producing bacteria. Asian J Biotechnol Bioresour Technol 3:1–12

Bligh EG, Dyer WJA (1959) Rapid method of total lipid extraction and purification. Can J Biochem Physiol 37(8):911–917

Breil C, Vian MA, Zemb T, Kunz W, Chemat F (2017) Bligh and Dyer and Folch methods for solid–liquid–Liquid extraction of lipids from microorganisms. Comprehension of solvation mechanisms and towards substitution with alternative solvents. Int J Mol Sci 18:708–729

Cherubini F (2010) The biorefinery concept: using biomass instead of oil for producing energy and chemicals. Energy Conver Manag 51(7):1412–1421

Claus D, Berkeley RCW (1986) Genus Bacillus Cohn 1872, 174AL. In: Sneath PHA, Mair NS, Sharpe ME, Holt JG (eds) Bergey’s manual of systematic bacteriology, vol 2. Williams & Wilkins, Baltimore

De Clercq D, Wen Z, Fan F (2017) Performance evaluation of restaurant food waste and biowaste to biogas pilot projects in China and implications for national policy. J Environ Manag 189:115–124

Economou CN, Aggelis G, Pavlou S, Vayenas DV (2011) Single cell oil production from rice hulls hydrolysate. Bioresour Technol 102(20):9737–9742

Escobar-Niño A, Luna C, Luna D, Marcos AT, Cánovas D, Mellado E (2014) Selection and characterization of biofuel-producing environmental bacteria isolated from vegetable oil-rich wastes. PLoS ONE 9(8):e104063

Fadhil AB, Ali LH (2013) Alkaline-catalyzed transesterification of Silurus triostegus Heckel fish oil: optimization of transesterification parameters. Renew Ene 60:481–488

Felizardo P, Correia MJN, Raposo I, Mendes JF, Berkemeier R, Bordado JM (2006) Production of biodiesel from waste frying oil. Waste Manag 26:487–494

Fnyees SMDAA, Hairuddin AA, Abdullah NMALC (2018) Recent trends in biodiesel production from commonly used animal fats. Int J Energy Res 42(3):885–902

García-Moreno PJ, Khanum M, Guadix A, Guadix EM (2014) Optimization of biodiesel production from waste fish oil. Renew Energy 68:618–624

Goswami L, Namboodiri MT, Kumar RV, Pakshirajan K, Pugazhenthi G (2017) Biodiesel production potential of oleaginous Rhodococcus opacus grown on biomass gasification wastewater. Renew Energy 105:400–406

Hartman TL (1940) The use of Sudan Black B as a bacterial fat stain. Stain Technol 15(1):23–28

Haska N, Ohta Y (1993) Effect of cellulase addition on hydrolysis of sago starch granules by raw starch digesting amylase from Penicillium brunneum No. 24. J Starch 45(7):237–241

Highina BK, Bugaje IM, Umar B (2011) Biodiesel production from Jatropha Caucus oil in a batch reactor using zinc oxide as catalyst. J Petrol Technol Alter Fuels 2(9):146–149

Huiru Z, Yunjun Y, Liberti F, Pietro B, Fantozzi F (2019) Technical and economic feasibility analysis of an anaerobic digestion plant fed with canteen food waste. Energy Conver Manag 180:938–948

Kalsi PS (2007) Spectroscopy of organic compounds. New Age International, New Delhi

Kamel DA, Farag HA, Amin NK, Foud YO (2016) Biodiesel synthesis from non edible oils by transesterification using the activated carbon as heterogeneous catalyst. Int J Environ Sci Technol 14(4):785–794

Knothe G (2007) Some aspects of biodiesel oxidative stability. Fuel Process Technol 88(7):669–677

Köpke M, Mihalcea C, Liew F, Tizard JH, Ali MS, Conolly JJ, Al-Sinawi B, Simpson SD (2011) 2,3-butanediol production by acetogenic bacteria, an alternative route to chemical synthesis using industrial waste gas. Appl Environ Microbiol 77(15):5467–5475

Kudre TG, Bhaskar N, Sakhare PZ (2017) Optimization and characterization of biodiesel production from rohu (Labeo rohita) processing waste. Renew Energy 113:1408–1418

Kurosawa K, Wewetzer SJ, Sinskey AJ (2014) Triacylglycerol production from corn stover using a xylose-fermenting Rhodococcus opacus strain for lignocellulosic biofuels. J Microb Biochem Technol 6(5):254–259

Kwolek-Mirek M, Zadrag-Tecza R (2014) Comparison of methods used for assessing the viability and vitality of yeast cells. FEMS Yeast Res 14(7):1068–1079

Leung YC, Wu X, Leung MKH (2010) A review on biodiesel production using catalyzed transesterification. Appl Energy 87:1083–1095

Ma YL (2006) Microbial oils and its research advance. Chin J Bioprocess Eng 4(4):7–11

Maghami M, Sadrameli SM, Ghobadian B (2015) Production of biodiesel from fishmeal plant waste oil using ultrasonic and conventional methods. Appl Thermal Eng 75:575–579

Mosier N, Wyman C, Dale B, Richard Elander YY, Lee MH, Ladisch M (2005) Fetures of promising technologies for pretreatment of lignocellulosic biomass. Bioresour Technol 96:673–686

Naureen R, Tariq M, Yusoff I, Chowdhury AJK, Ashraf MA (2015) Synthesis, spectroscopic and chromatographic studies of sunflower oil biodiesel using optimized base catalyzed methanolysis. Saudi J Biol Sci 22(3):332–339

Phalakornkule C, Tanasupawat S (2006) Characterization of lactic acid bacteria from traditional Thai sausages. J Cult Collect 5:46–57

Ranjith Kumar R, Hanumantha Rao P, Arumugam M (2015) Lipid extraction methods from microalgae: a comprehensive review. Front Energy Res 2:61

Richards MP, Hultin HO (2002) Contributions of blood and blood components to lipid oxidation in fish muscle. J Agric Food Chem 50(3):555–564

Shantha NC, Napolitano GE (1998) Lipid analysis using thin-layer chromatography and the Iatroscan. In: Hamilton RJ (ed) Lipid analysis in oils and fats. Springer, Boston, pp 1–33

Singh SP, Singh D (2010) Biodiesel production through the use of different sources and characterization of oils and their esters as the substitute of diesel: a review. Renew Sustain Energy Rev 14(1):200–216

Tariq M, Ali S, Ahmad F, Ahmad M, Zafar M, Khalid N, Khan MA (2011) Identification, FT-IR, NMR (1H and 13C) and GC/MS studies of fatty acid methyl esters in biodiesel from rocket seed oil. Fuel Process Technol 92(3):336–341

Torres-Rodrìguez DA, Romero-Ibarra IC, Ibarra IA, Pfeiffer H (2016) Biodiesel production from soybean and Jatropha oils using cesium impregnated sodium zirconate as a heterogeneous base catalyst. Renew Energy 93:323–331

Xing D, Wang H, Pan A, Wang J, Xue D (2012) Assimilation of corn fiber hydrolysates and lipid accumulation by Mortierella isabellina. Biomass Bioenerg 39:494–501

Yang T, Rao Z, Zhang X, Xu M, Xu Z, Yang ST (2013) Improved production of 2,3-butanediol in Bacillus amyloliquefaciens by over-expression of glyceraldehyde-3-phosphate dehydrogenase and 2,3-butanediol dehydrogenase. PLoS ONE 8(10):e76149

Ye M, Sun L, Yang R, Wang Z, Qi K (2017) The optimization of fermentation conditions for producing cellulase of Bacillus amyloliquefaciens and its application to goose feed. R Soc Open Sci 4(10):171012

Zhang Q, Li Y, Xia L (2014) An oleaginous endophyte Bacillus subtilis HB1310 isolated from thin-shelled walnut and its utilization of cotton stalk hydrolysate for lipid production. Biotechnol Biofuel 7(1):152

Zhao X, Peng F, Du W, Liu C, Liu D (2012) Effects of some inhibitors on the growth and lipid accumulation of oleaginous yeast Rhodosporidium toruloides and preparation of biodiesel by enzymatic transesterification of the lipid. Bioprocess Biosyst Eng 35(6):993–1004

Zheng Y, Yu X, Zeng J, Chen S (2012) Feasibility of filamentous fungi for biofuel production using hydrolysate from dilute sulfuric acid pretreatment of wheat straw. Biotechnol Biofuels 5(1):50

Acknowledgment

Authors are thankful to the SRTM University for providing the necessary research facilities.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Additional information

Editorial responsibility: Parveen Fatemeh Rupani.

Rights and permissions

About this article

Cite this article

Kanakdande, A.P., Khobragade, C.N. Biodiesel synthesis from non-edible oil using agro-waste and evaluation of its physicochemical properties. Int. J. Environ. Sci. Technol. 17, 3785–3800 (2020). https://doi.org/10.1007/s13762-020-02731-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-020-02731-y