Abstract

This study compared the dewatering properties of aerobic granular and activated sludge from full-scale wastewater treatment plants, and determined how polymer dose and type affect granular sludge dewatering efficiency. At the same dose, granular sludge filtration cake had about 4% lower humidity than activated sludge cake. Aerobic stabilization improved only activated sludge dewatering. The granular sludge reactor had over 1.5 times more extracellular polymeric substances (1.8 times more alginate) per reactor volume than the activated sludge reactor, but the high polymer content did not decrease granular sludge dewatering. Granular sludge dewatered best with FLOPAM EM 840MEB, due to its composition (n-alkanes, isoalkanes, cyclic/aromatic hydrocarbons). With this polymer, sludge cake moisture was lowest (84.7 ± 0.4%) at 1.6 g polymer/kg MLSS. With all tested polymers, the lowest dose (0.2 g/kg MLSS) ensured low cake humidities; this dose was far lower than typical doses for activated sludge dewatering. Upgrading from activated to granular sludge technology significantly facilitates excess sludge management.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Dewatering of excess sludge has attracted much attention because it substantially affects the final volume of sludge before storage and transportation, and it diminishes the amount of bulking agents that are added during composting or energy usage for drying or incineration of sludge. The low dewaterability of excess sludge means that capital and operating costs may account for up to 60% of the total costs of wastewater treatment (Wang et al. 2017).

The most commonly used type of biomass in sewage treatment systems is activated sludge (AS), but this is being gradually replaced with aerobic granular sludge (GS). Granules are dense and compact aggregates of microorganisms that are formed in GS batch reactors (GSBRs) as a result of spontaneous immobilization without the support of a carrier. GS is characterized by a spherical shape, an irregular or smooth surface (depending on the type of organisms in the granules), a layered structure ensuring simultaneous nutrient removal, and a high resistance to toxins. The specific gravity of the GS is higher than that of AS (0.997–1.010 kg/m3) and varies from 1010 to 1017 kg/m3 (Nancharaiah and Reddy 2018), which also translates into better settling properties. GS is also characterized by lower hydration (94–97%) than AS (> 99%) (Linlin et al. 2005).

Extracellular polymeric substances (EPS) secreted by bacteria play an important role in building the skeleton and ensuring the integrity of the granules (Adav et al. 2008), and determine sludge properties such as surface charge or hydrophobicity (Ruiz-Hernando et al. 2013). EPS in biomass can be separated into two main fractions: soluble EPS (SOL-EPS) and bound EPS (Yu et al. 2008). SOL-EPS can move freely between the flocs and the surrounding solution, while bound EPS form a separate layer coating the biomass. Bound EPS can be further divided into loosely bound (LB-EPS) and tightly bound (TB-EPS) EPS. The main components of EPS are polysaccharides, proteins and DNA (Sheng et al. 2010), and for sludge dewatering, the relative amounts of these components are more important than their total amount (Neyens and Baeyens 2003; Li and Yang 2007). EPS may entrap water, so a high content of EPS in the biomass may decrease sludge dewaterability (Liu and Fang 2003). Various factors have modified the effect of EPS on dewaterability. Inoculation of sterilized excess AS with spores of the filamentous fungus Talaromyces flavus S1 improved dewaterability, due to the degradation of slime and LB-EPS (Liu et al. 2017). Methane addition also improved sludge dewaterability by causing the release of interstitial and bound water (Xu et al. 2018). A high content of proteins in EPS in AS improved sludge dewaterability, whereas addition of proteolytic enzymes caused the sludge to disintegrate and worsened dewaterability. In contrast, the content of carbohydrates in EPS did not have an effect on dewatering (Higgins and Novak 1997; Liu and Fang 2003).

To change the properties of sludge for faster and more effective removal of water, sludge can be conditioned with high molecular weight synthetic chemicals (polymers/flocculants). These substances lower the electrokinetic potential of negatively charged colloids and accelerate the formation of macromolecules. The use of polymers reduces the forces that bind water to the sludge, improves deodorization in centrifuges or filter presses, and increases the dry mass of the sludge cake. However, the type and dose of polymer should be precisely chosen. The use of large amounts of chemicals as conditioners for sludge disposal is disadvantageous because they are costly, they may cause corrosion, they pose an ecological risk when applied to land and they can worsen the biological treatment of sludge (Wang et al. 2017).

Cationic polymers usually have a molecular weight of 104–107 Da (Daltons), whereas anionic polymers usually have a molecular weight of 104–105 Da. Cationic polymers are used more frequently because particles suspended in wastewater typically have a negative surface charge (Łomotowski and Szpindor 2002). The doses of polymers used for dewatering of excess AS can vary widely, from 1 to 12 g/kg MLSS (Bień and Wystalska 2011), but in field applications, they most commonly range from 4 to 12 g/kg MLSS (Project PURE 2012).

The effectiveness of polymer-supported dewatering of AS depends on the temperature, the pH of the polymers, the type of sludge (primary, excess, mixed), the type of sludge processing (raw, fermented, aerobically stabilized) and the polymer dose (Zhang et al. 2010; Zheng et al. 2013; Niu et al. 2013). Information on dewatering of GS and the effect of unit processes on dewatering of this kind of biomass are limited. Zhou et al. (2011) investigated how dewatering of GS from a lab-scale GSBR depended on their size. The granules were divided into fractions < 1.0 mm, 1.0–2.5 mm, 2.5–3.5 mm and 3.5–5.0 mm. Dewatering proceeded more quickly with granules than with AS, both with and without the addition of 1% polyacrylamide as a flocculant. In contrast to the granules studied in Zhou et al. (2011), those in GS from technical installations usually have diameters up to 1 mm (Yang et al. 2016; Świątczak and Cydzik-Kwiatkowska 2018), and they are not separated into separate size fractions before dewatering. Thus, further studies are needed to better understand GS dewatering in full-scale facilities.

Therefore, the aims of this work were to compare the dewatering properties of raw and aerobically stabilized GS and AS from full-scale batch reactors taking into consideration polymer content in both types of biomass and their morphology, and to determine how the dose and type of polymer affect the efficiency of GS dewatering. The study was conducted in 2018 in northeastern Poland. The results can serve as guidelines for designing systems for dewatering excess GS on a technical scale.

Materials and methods

Excess sludge

Samples of AS and aerobically stabilized AS were collected from the constantly aerated batch reactor and from the aerobic stabilization tank, respectively, of the municipal WWTP in Janowo (Poland). Samples of GS and aerobically stabilized GS were collected from the constantly aerated GSBR and the aerobic stabilization tank, respectively, of the municipal WWTP in Lubawa (Poland). Both WWTPs are operated at moderate loading, and the cycle lengths of the batch reactors are about 5 h, of which the decantation/reactor filling phase lasts for 45 min, and settling lasts for 25 min. The volumetric organic loading rates of the WWTP in Lubawa and Janowo are about 2.0 kg COD/(m3 day) and 1.5 kg COD/(m3 day), respectively.

Experimental procedure At first, the experiments comparing the efficiency of dewatering of AS and GS and aerobically stabilized AS and GS were conducted. In these experiments, FLOPAM EM 840 MEB (abbreviated as FLOP) polymer (Korona, Poland) was used. 1 mL of FLOP was diluted in 1 L of distilled water, and the flocculant solution was added to excess sludge at a dose of 1.6 g of polymer/kg MLSS. (The dose was chosen based on the results from the experiments described below.)

Next, the experiments on dewatering of aerobic GS were done using three different polymers at different doses. Polymers FLOP and PRAESTROL k 255 l (abbreviated as PRA) (Ashland Deutschland GmbH Environmental and Process Solutions) were diluted in distilled water at a ratio of 1 mL polymer to 1 L of water. In contrast, a stock solution of polymer FLOCCULANT F-290 (abbreviated as FLOC) (SNF Floerger, France) was prepared by completely dissolving 1 g of the powdered polymer in distilled water and then incubating the resulting solution for 24 h prior to use. The polymer solutions were added to excess GS at doses of 0, 0.2, 0.4, 0.8, 1.2, 1.6, 2.0 and 4 g of polymer/kg MLSS. The flasks were stirred for 1 min at 100 rpm. The properties of polymers are summarized in Table 1.

Analytical methods

The vacuum filtration method (VFM) was selected to measure the dewaterability of sludge. In VFM, sludge (25 mL) was poured into a standard Buchner funnel fitted with a pre-wetted filter paper (Whatman #1). To determine the specific resistance to filtration (SRF) of the sludge, a vacuum of 50 kPa was applied after 1 min of gravitational drainage. Both the filtrate volume and the filtration time were recorded until no additional water flowed out of the sludge. SRF was calculated using an Eq. 1 (Eckenfelder and William 1989):

where F is the filtration area; b is the slope of line showing the relationship between filtration time and filtrate volume; C is the weight of solids per unit volume of filtrate; P is the pressure of filtration; n is the viscosity of filtrate.

The dry mass of sludge and the water content of the sludge cake trapped by the filter paper were measured in accordance with standard methods (APHA 1998). Each dewatering was performed in duplicate, and mean values and standard deviations were calculated. Three fractions of EPS were isolated from the dewatered AS and GS as described in Pellicer-Nàcher et al. (2013). SOL-EPS was the fraction remaining in the supernatant after centrifugation (12,000 g, 15 min, 4 °C). Then, the pellet was resuspended by adding PBS buffer up to the initial volume, vortexed (4 min, 40 Hz) and centrifuged (12,000 g, 15 min, 4 °C), after which, the supernatant contained LB-EPS. Finally, TB-EPS was extracted according to Frølund et al. (1996) using a cation exchange resin. The concentrations of proteins and carbohydrates in the three fractions of EPS were measured according to Frølund et al. (1996) using Lowry and Anthrone methods. The total EPS in each fraction was expressed as the organic fraction after incineration at 500 °C (APHA 1998). Alginate in biomass was measured according to Lin et al. (2010) with slight modification. One gram of MLSS was homogenized using Ultra Turrax T25 basic IKA-WERKE for 4 min at 9.500 L/min, and then incubated for 1 h at 70 °C in 0.2 M Na2CO3. Biomass was then centrifuged at 12,000 rpm for 20 min. Reaction of the supernatant was adjusted to a pH of 2 using 0.1 M HCl. Supernatant was centrifuged at 12,000 rpm for 20 min, and the sludge was dissolved in 0.1 M NaOH. Alginate was precipitated using cold EtOH adjusting the solution to 80% (vol/vol).

The particle size of dewatered sludge was measured using the wet sieving method with a Retsch unit (AS 400) as described in Cydzik-Kwiatkowska et al. (2009).

Results and discussion

Comparison of dewatering of AS and GS

The basic difference between GS and AS is their morphology. GS is a consortium of microorganisms aggregated in compact spherical shapes, while AS consists of loosely connected clusters of bacteria. In this study, the analysis of the GS morphology showed that nearly 80% of granular biomass was made of granules with diameters of 90–354 μm; granules that were larger than this constituted about 10% of the biomass. In AS, over 80% of the biomass was composed of flocs with a diameter of 89 μm or less, and 95% of the biomass consisted of flocs with diameters up to 124 μm (Fig. 1). According to Christensen et al. (2015), AS with compact flocs without single cells and dissolved EPS demonstrated high dewaterability.

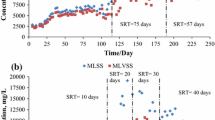

One of the most important aspects influencing sludge dewatering is its initial humidity. Lower initial humidity of raw and conditioned AS caused the effectiveness of dewatering of sludge to increase after addition of polymer (Jagoszewski and Świderska-Bróż 2000). In this study, the humidity of the raw GS was lower than that of the raw AS (about 99%), but the humidities of both aerobically stabilized sludges were similar—about 98% (Fig. 2a). Dewatering of raw and aerobically stabilized GS without polymer resulted in a cake with a moisture content of about 88%. Aerobically stabilized AS dewatered better than raw AS but the humidities of both sludge cakes were much higher than that of GS. During dewatering of raw AS, the SRF was an order of magnitude higher than during dewatering of raw GS although this difference was smaller with aerobically stabilized sludge.

Addition of polymer (1.6 g/kg MLSS) caused an immediate change in the structure of sludge, which was visible both to the naked eye and under a microscope (see Supplementary Materials). Addition of polymer decreased the humidities of sludge cake of raw GS and AS by 1.5 and 3%, respectively, in comparison with the humidities of unconditioned sludge, but it did not influence the dewatering of both aerobically stabilized sludges. At the same dose of polymer, the humidity of the stabilized GS sludge cake was 5.0% lower than the stabilized AS, which in practice, means that, after dewatering, a ton of GS will occupy over 13% less volume than a ton of dewatered AS. After addition of polymer, the SRF of raw and stabilized GS and of stabilized AS more than doubled (Fig. 2b), but the SRF of raw AS decreased.

After addition of polymer, humidity of sludge cake was higher for stabilized biomass although the overall SRF was lower for both types of sludge. Higher humidity may result from the fact that during aerobic stabilization content of EPS in sludge increases with time (Zhang et al. 2016) that causes water storage in EPS inside the flocs and granules. Lower SRF, on the other hand, resulted from better aggregation of biomass in larger structures due to increased hydrophobicity of cells under starvation conditions (Di Iaconi et al. 2006).

An EPS content in biomass over 35 mg/g MLSS reduces its dewaterability (Liu and Fang 2003). The average total content of individual fractions of EPS in AS and GS, as well as the content of polysaccharides and proteins in individual fractions of EPS, is presented in Table 3. Regardless of the type of the biomass, the EPS content increased with the degree of binding of EPS to biomass. SOL-EPS content in reactors with both types of biomass was similar. The total content of LB-EPS in aerobic granular sludge reactors was about 1.3 times higher than in activated sludge reactors, and the total content TB-EPS in GSBR was almost two times higher.

In both types of biomass, polysaccharide content was lowest in SOL-EPS, probably because polysaccharides are one of the most attractive substrates for microorganisms and are easily sorbed from the solution. TB-EPS contained over 3 times more polysaccharides in GS than in AS.

In all fractions of EPS, protein content was about 1.5–2.5 times higher in GS than in AS. Increased protein content in granules reduces sludge hydration, but it also leads to clogging of pores and loss of stability in granules (Corsino et al. 2016). The content of proteins in EPS may also decrease the dewaterability of sludge (Liu et al. 2016), as can a high proteins to polysaccharides (PN/PS) ratio (Yu et al. 2010). SOL-EPS in GS had a PN/PS ratio of about 6.0, whereas SOL-EPS in AS had PN/PS ratio of about 2.3. LB-EPS in both types of biomass had a PN/PS ratio of about 1.5. TB-EPS contained the majority of proteins and polysaccharides: 76% and 75% of all the polysaccharides and proteins in EPS in GS, and about 55% of these substances in EPS in AS. The PN/PS ratio in TB-EPS was about 2.3 and 3.3 in GS and AS, respectively. The fact that, in both AS and GS, over 70% of proteins were present in the biomass in TB-EPS, diminished the negative effect of proteins on dewatering. It was observed that sludge flocculation rate, settling capacity, compressibility and dewatering positively correlate with the LB-EPS content, but not will the TB-EPS content (Yang and Li 2009).

The amount of SOL-EPS and LB-EPS per unit of biomass was higher in activated sludge while the content of TB-EPS per unit of both GS and AS was similar (Table 2). Predomination of SOL-EPS and LB-EPS in activated sludge may decrease dewaterability of AS because SOL-EPS and LB-EPS are regarded as the EPS fractions that have the greatest effect on sludge dewatering (Li and Yang 2007; Yu et al. 2008). Removal of SOL- and LB-EPS decreased the CST by about 48.1% (Liu et al. 2017). Dai et al. (2018) indicate that the addition of modified phosphogypsum to AS releases LB-EPS to SOL-EPS, which results in better dewatering effects.

Alginates are a family of extracellular exopolysaccharides produced by algae and bacteria (Rehm 2009) that contribute to the gel-like structure of granules (Draget et al. 2000). In this study, the content of alginate per liter of excess AS was about 184 mg, whereas the amount of alginate in GS was over three times higher (Table 2). Amount of alginate per g of MLSS was over 2 times higher in GS (86.0 ± 11.2 mg/g MLSS) in comparison with AS (49.0 ± 9.0 mg/g MLSS). Although the content of alginate in GS was higher than in the AS, the overall dewatering properties of the granules were better. This indicates that it is not the content of alginate but rather the compact spherical structure of granules was the main factor affecting water removal from GS.

Impact of type and dose of polymer on GS dewatering

In this study, high molecular weight, strongly cationic polymers were used. Although flocculation is efficient with a low dose of higher molecular weight polymers, the strong electrostatic repulsion creates elastic flocs that contain a large amount of water, making dewatering more difficult. In contrast, higher doses of lower molecular weight polymers create less elastic sludge that can be more efficiently dewatered (Saveyn et al. 2005a).

In the present study, lower sludge cake humidity was not associated with higher polymer dose. Figure 3 shows the effect of the dose and the type of polymer on dewatering of aerobically stabilized GS. The humidity of the sludge before dewatering was 97.4%. FLOP ensured the best results of GS dewatering, and the humidity of the sludge cake was about 86–88%, except at a dose of 1.6 g/kg MLSS, when the humidity decreased to 84.7 ± 0.4%. The good performance of FLOP could be due to the fact that it contains aromatic hydrocarbons, isoalkanes, n-alkanes and ethoxylated isotridecanol (Safety data sheet FLOPAM EM 840 MEB). The presence of aromatic groups facilitates hydrophobic interactions between the polymer and the surface of the particle, which enhances the adsorption process. Furthermore, the structure of this polymer, which is more highly branched than the other polymers, enables it to adsorb more particles and form denser particle conformations (Mierczynska-Vasilev et al. 2013). Such properties turned out to be the most desirable for GS dewatering. FLOC decreased humidity to about 88%, except when it was added at a dose of 0.8 g/kg MLSS—at this dose the humidity of the sludge cake increased to over 92%. With PRA, humidity also exceeded 92% at doses of 0.8 and 1.2 g/kg MLSS, whereas the sludge was most effectively dewatered at the lowest dose of 0.2 g/kg MLSS.

FLOP enabled very good dewatering of GS to about 85% humidity even at the lowest dose of 0.2 g/kg MLSS. This dose is only 20% of the minimum dose that has been reported effective for AS dewatering (Table 3). Many experimental works show that polymer doses for efficient dewatering of AS need to be very high. Maliga et al. (2009) studied the effectiveness of dewatering of excess AS (96.9% humidity) using a laboratory gravity filter. They noted that the use of high molecular weight FLOERGER type 4650 cationic polymer at doses lower than 6 g/kg MLSS prevented the dewatering of the flocculated sludge via the filtering fabric. The optimal dose of polymer was 10 g/kg MLSS; at this dose, the sludge was dehydrated to 95% humidity after 10 s of dewatering. The highest doses of polymer, 15 g/kg MLSS and 20 g/kg MLSS, decreased the humidity to approximately 95.7%. In studies on dewatering of stabilized AS with the use of Zetag 7631 polymer, the optimal dose was 2.5 g/kg MLSS, and increasing the dose did not significantly improve the process (Korzekwa-Wojtal and Wolny 2008). Wolski et al. (2010) indicated that increasing the dose of Praestrol 658 BC and Praestrol 852 BC from 2.5 g/g MLSS to 3.5 g/kg MLSS increased the humidity of AS cake from 75.2 to 77.3% and from 75.2 to 78.3%, respectively. A similar phenomenon was observed in the present study when using PRA polymer for dewatering of GS. Increasing the polymer dose from 0.2 to 0.8 g/g MLSS increased sludge cake humidity to about 94%. The dose of polymer should ensure proper sorption of polymer on solid particles and effective formation of polymer bridges. Using too high a concentration of polymers in the dewatering process may lead to an undesirable phenomenon in which the sludge particles are completely covered by polymer chains, which can result in osmotic phenomena that cause particles of dewatered biomass to repel each other (Polowczyk 2016).

The fact that low polymer doses can enable effective dewatering of GS is very advantageous, not only because this reduces costs, but also because large amounts of polymer may cause problems during further management of dewatered sludge. The presence of polymers may hamper anaerobic stabilization or inhibits efficient compositing of sludge. For example, when a cationic polymer was present in excess AS, anaerobic digestion was slowed and methane yield was decreased. The decrease in methane yield was due to the fact that about 46% of the flocculant was degraded during anaerobic digestion, and the degradation products affected methane production (Wang et al. 2018).

In the present study, there was no clear dependence between the dose of polymer and the SRF value, as was observed in some studies on dewatering of AS. For example, Wolski et al. (2010) dewatered excess and fermented AS using weakly, moderately and strongly cationic polymers, and the SRF consistently decreased as the doses of the polymers were increased. In the present study, the SRF was lowest (4.09 × 1010 ± 1.15 × 1010 m/kg) with FLOC at a dose of 0.8 g/kg MLSS (Fig. 4). With FLOP, the SRF was lowest at the lowest dose of this polymer, and increasing the doses increased the SRF in a range from 14 × 1010 to 23 × 1010 m/kg. In the case of PRAESTROL k 225l, the filtration resistance decreased with increases in dose from 0.2 to 1.2 g/kg MLSS; however, the SRF increased sharply to 4.3 × 1011 ± 5.2·109 m/kg when a dose of 1.6 g/kg MLSS was used.

During GS dewatering, lower SRF values were not correlated with lower sludge cake humidity. With FLOCCULANT F-290 and PRAESTROL k 225l, humidity was highest at a dose of 0.8 g/kg MLSS, and at the same time, the SRF value was lowest. This can be explained by the fact that polymer addition causes the surfaces of flocs to have a positive charge, so that water is easily removed from between the sludge flocs, whereas inside the flock, sludge particles have a lesser chance of coming into contact with polymer molecules, so that the interior still has a negative charge, and water is less easily removed from this part of the floc (Saveyn et al. 2005b). As a result, during dewatering, pores between flocks are easily squeezed and the filtration resistance increases, but little water is removed from within the flocks. Thus, the sludge cakes had high moisture content despite low SRF values when this dose was used.

With all three polymers that were tested, the average SRF values of the GS were about 1 order of magnitude lower than the values reported for AS (Wolski 2016). Thus, our results indicate that GS is much more susceptible to dewatering than conventional AS.

Conclusion

GS dewatered better than AS, with SRF values around 10 times lower than those of AS. Aerobic stabilization did not affect GS dewatering, but improved AS dewatering. Although GS contained a large amount of EPS (particularly alginate), they were tightly bound in the granule structures, so GS was effectively dewatered with polymer doses much lower than those in reports of effective AS dewatering. GS dewatering was most effective with FLOP (containing aromatic hydrocarbons and isoalkanes); dewatering effectiveness did not correlate with polymer dose. SRF was affected by the type of polymer used; it was lowest with FLOC.

References

Adav SS, Lee D-J, Tay J-H (2008) Extracellular polymeric substances and structural stability of aerobic granule. Water Res 42:1644–1650. https://doi.org/10.1016/J.WATRES.2007.10.013

APHA (1998) Standard methods for the examination of water and wastewaters. American Public Health Association, Washington DC

Bień B, Bień JD (2014) Application of inorganic coagulants and polyelectrolytes on sonicated digested sewage sludge. J Ecol Eng 37:7–16. https://doi.org/10.12912/2081139X.13(in Polish)

Bień J, Wystalska K (2011) Osady ściekowe—teoria i praktyka. Wydawnictwo Politechniki Częstochowskiej, Częstochowa (in Polish)

Christensen ML, Keiding K, Nielsen PH, Jørgensen MK (2015) Dewatering in biological wastewater treatment: a review. Water Res 82:14–24. https://doi.org/10.1016/J.WATRES.2015.04.019

Corsino SF, Capodici M, Torregrossa M, Viviani G (2016) Fate of aerobic granular sludge in the long-term: the role of EPSs on the clogging of granular sludge porosity. J Environ Manage 183:541–550. https://doi.org/10.1016/J.JENVMAN.2016.09.004

Cydzik-Kwiatkowska A, Białowiec A, Wojnowska-Baryła I, Smoczyński L (2009) Characteristics of granulated activated sludge fed with glycerin fraction from biodiesel production. Arch Environ Prot 35:45–52

Dai Q, Ma L, Ren N et al (2018) Investigation on extracellular polymeric substances, sludge flocs morphology, bound water release and dewatering performance of sewage sludge under pretreatment with modified phosphogypsum. Water Res 142:337–346. https://doi.org/10.1016/J.WATRES.2018.06.009

Di Iaconi C, Ramadori R, Lopez A, Passino R (2006) Influence of hydrodynamics shear forces on properties of granular biomass in a sequencing batch biofilter reactor. Biochem Eng J 30:152–157. https://doi.org/10.1016/j.bej.2006.03.002

Draget KI, Strand B, Hartmann M et al (2000) Ionic and acid gel formation of epimerised alginates; the effect of AlgE4. Int J Biol Macromol 27:117–122. https://doi.org/10.1016/S0141-8130(00)00115-X

Eckenfelder WW, William W (1989) Industrial water pollution control. McGraw-Hill, New York

Frølund B, Palmgren R, Keiding K, Nielsen PH (1996) Extraction of extracellular polymers from activated sludge using a cation exchange resin. Water Res 30:1749–1758. https://doi.org/10.1016/0043-1354(95)00323-1

Guo B, Yu H, Gao B et al (2017) Novel cationic polyamidine: synthesis, characterization, and sludge dewatering performance. J Environ Sci 51:305–314. https://doi.org/10.1016/J.JES.2016.08.002

Higgins MJ, Novak JT (1997) Characterization of exocellular protein and its role in bioflocculation. J Environ Eng 123:479–485. https://doi.org/10.1061/(ASCE)0733-9372(1997)123:5(479)

Jagoszewski T, Świderska-Bróż M (2000) Wpływ polielektrolitów na zagęszczanie grawitacyjne osadów pokoagulacyjnych. Ochr Środowiska 1:7–10 (in Polish)

Jin L-Y, Zhang P-Y, Zhang G-M, Li J (2016) Study of sludge moisture distribution and dewatering characteristic after cationic polyacrylamide (C-PAM) conditioning. Desalin Water Treat 57:29377–29383. https://doi.org/10.1080/19443994.2016.1144085

Korzekwa-Wojtal A, Wolny L (2008) Wpływ dawki polielektrolitu na charakterystyki osadów ściekowych w procesie sedymentacji w małych oczyszczalniach ścieków. Proc ECOpole 2(2):445–448 (in Polish)

Li XY, Yang SF (2007) Influence of loosely bound extracellular polymeric substances (EPS) on the flocculation, sedimentation and dewaterability of activated sludge. Water Res 41:1022–1030. https://doi.org/10.1016/J.WATRES.2006.06.037

Lin Y, de Kreuk M, van Loosdrecht MCM, Adin A (2010) Characterization of alginate-like exopolysaccharides isolated from aerobic granular sludge in pilot-plant. Water Res 44:3355–3364. https://doi.org/10.1016/J.WATRES.2010.03.019

Linlin H, Jianlong W, Xianghua W, Yi Q (2005) The formation and characteristics of aerobic granules in sequencing batch reactor (SBR) by seeding anaerobic granules. Process Biochem 40:5–11. https://doi.org/10.1016/J.PROCBIO.2003.11.033

Liu Y, Fang HHP (2003) Influences of extracellular polymeric substances (EPS) on flocculation, settling, and dewatering of activated sludge. Crit Rev Environ Sci Technol 33:237–273. https://doi.org/10.1080/10643380390814479

Liu J, Wei Y, Li K et al (2016) Microwave-acid pretreatment: a potential process for enhancing sludge dewaterability. Water Res 90:225–234. https://doi.org/10.1016/J.WATRES.2015.12.012

Liu H, Shi J, Xu X et al (2017) Enhancement of sludge dewaterability with filamentous fungi Talaromyces flavus S1 by depletion of extracellular polymeric substances or mycelium entrapment. Bioresour Technol 245:977–983. https://doi.org/10.1016/J.BIORTECH.2017.08.185

Łomotowski J, Szpindor A (2002) Nowoczesne systemy oczyszczania ścieków. Arkady, Warszawa (in Polish)

Lu Y, Zheng G, Wu W et al (2017) Significances of deflocculated sludge flocs as well as extracellular polymeric substances in influencing the compression dewatering of chemically acidified sludge. Sep Purif Technol 176:243–251. https://doi.org/10.1016/J.SEPPUR.2016.12.016

Maliga G, Składzień J, Szymków J (2009) Ocena efektywności grawitacyjnego odwadniania osadów ściekowych na zagęszczaczach taśmowych. Inż Ap Chem 48:77–78 (in Polish)

Mierczynska-Vasilev A, Kor M, Addai-Mensah J, Beattie DA (2013) The influence of polymer chemistry on adsorption and flocculation of talc suspensions. Chem Eng J 220:375–382. https://doi.org/10.1016/J.CEJ.2012.12.080

Nancharaiah YV, Reddy GKK (2018) Aerobic granular sludge technology: mechanisms of granulation and biotechnological applications. Bioresour Technol 247:1128–1143. https://doi.org/10.1016/J.BIORTECH.2017.09.131

Neyens E, Baeyens J (2003) A review of thermal sludge pre-treatment processes to improve dewaterability. J Hazard Mater 98:51–67. https://doi.org/10.1016/S0304-3894(02)00320-5

Niu M, Zhang W, Wang D et al (2013) Correlation of physicochemical properties and sludge dewaterability under chemical conditioning using inorganic coagulants. Bioresour Technol 144:337–343. https://doi.org/10.1016/J.BIORTECH.2013.06.126

Pellicer-Nàcher C, Domingo-Félez C, Mutlu AG, Smets BF (2013) Critical assessment of extracellular polymeric substances extraction methods from mixed culture biomass. Water Res 47:5564–5574. https://doi.org/10.1016/J.WATRES.2013.06.026

Polowczyk I (2016) Flokulacja łupka miedzionośnego. In: Kowalczuk PB, Drzymała J (eds) Łupek miedzionośny II. WGGG PWr, Wrocław, pp 44–49 (in Polish)

Project PURE (Project on Urban Reduction of Eutrophication—Projekt redukcji eutrofizacji z obszarów zurbanizowanych) (2012) Dobre praktyki związane z gospodarką osadami ściekowymi. (in Polish)

Rehm BHA (2009) Alginate production: precursor biosynthesis, polymerization and secretion. Springer, Berlin, pp 55–71

Ruiz-Hernando M, Martinez-Elorza G, Labanda J, Llorens J (2013) Dewaterability of sewage sludge by ultrasonic, thermal and chemical treatments. Chem Eng J 230:102–110. https://doi.org/10.1016/J.CEJ.2013.06.046

Saveyn H, Meersseman S, Thas O, Van der Meeren P (2005a) Influence of polyelectrolyte characteristics on pressure-driven activated sludge dewatering. Colloids Surfaces A Physicochem Eng Asp 262:40–51. https://doi.org/10.1016/J.COLSURFA.2005.04.006

Saveyn H, Pauwels G, Timmerman R, Van der Meeren P (2005b) Effect of polyelectrolyte conditioning on the enhanced dewatering of activated sludge by application of an electric field during the expression phase. Water Res 39:3012–3020. https://doi.org/10.1016/J.WATRES.2005.05.002

Sheng G-P, Yu H-Q, Li X-Y (2010) Extracellular polymeric substances (EPS) of microbial aggregates in biological wastewater treatment systems: a review. Biotechnol Adv 28:882–894. https://doi.org/10.1016/J.BIOTECHADV.2010.08.001

Świątczak P, Cydzik-Kwiatkowska A (2018) Performance and microbial characteristics of biomass in a full-scale aerobic granular sludge wastewater treatment plant. Environ Sci Pollut Res 25:1655–1669. https://doi.org/10.1007/s11356-017-0615-9

Wang Q, Wei W, Gong Y et al (2017) Technologies for reducing sludge production in wastewater treatment plants: state of the art. Sci Total Environ 587–588:510–521. https://doi.org/10.1016/J.SCITOTENV.2017.02.203

Wang D, Liu X, Zeng G et al (2018) Understanding the impact of cationic polyacrylamide on anaerobic digestion of waste activated sludge. Water Res 130:281–290. https://doi.org/10.1016/J.WATRES.2017.12.007

Wolski P (2016) Wspomaganie końcowego zagęszczania i odwadniania osadów ściekowych. Annu Set Environ Prot 18:730–742 (in Polish)

Wolski P, Wolny L, Zawieja I (2010) Kondycjonowanie osadów nadmiernych poddanych stabilizacji a ich odwadnialność. Inżynieria i Ochr Środowiska T 13(1):67–77 (in Polish)

Xu Q, Wang Q, Zhang W et al (2018) Highly effective enhancement of waste activated sludge dewaterability by altering proteins properties using methanol solution coupled with inorganic coagulants. Water Res 138:181–191. https://doi.org/10.1016/J.WATRES.2018.03.038

Yang S, Li X (2009) Influences of extracellular polymeric substances (EPS) on the characteristics of activated sludge under non-steady-state conditions. Process Biochem 44:91–96. https://doi.org/10.1016/J.PROCBIO.2008.09.010

Yang HG, Li J, Liu J et al (2016) A case for aerobic sludge granulation: from pilot to full scale. J Water Reuse Desalin 6:188–194. https://doi.org/10.2166/wrd.2015.188

Yu G-H, He P-J, Shao L-M, He P-P (2008) Stratification structure of sludge flocs with implications to dewaterability. Environ Sci Technol 42:7944–7949. https://doi.org/10.1021/es8016717

Yu G-H, He P-J, Shao L-M (2010) Novel insights into sludge dewaterability by fluorescence excitation–emission matrix combined with parallel factor analysis. Water Res 44:797–806. https://doi.org/10.1016/J.WATRES.2009.10.021

Zhang W, Shang Y, Yuan B et al (2010) The flocculating properties of chitosan-graft-polyacrylamide flocculants (II)—test in pilot scale. J Appl Polym Sci 117:2016–2024. https://doi.org/10.1002/app.32143

Zhang Z, Zhou Y, Zhang J et al (2016) Effects of short-time aerobic digestion on extracellular polymeric substances and sludge features of waste activated sludge. Chem Eng J 299:177–183. https://doi.org/10.1016/J.CEJ.2016.04.047

Zheng H, Sun Y, Zhu C et al (2013) UV-initiated polymerization of hydrophobically associating cationic flocculants: synthesis, characterization, and dewatering properties. Chem Eng J 234:318–326. https://doi.org/10.1016/J.CEJ.2013.08.098

Zhou YN, Li J, Li J, Wei S (2011) Dewaterability of aerobic granular sludge. Appl Mech Mater 90–93:2944–2948. https://doi.org/10.4028/www.scientific.net/AMM.90-93.2944

Acknowledgements

This study was supported by the Polish National Science Center (Grant Number 2016/21/B/NZ9/03627).

Author information

Authors and Affiliations

Corresponding author

Additional information

Editorial responsibility: Parveen Fatemeh Rupani.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Cydzik-Kwiatkowska, A., Nosek, D., Wojnowska-Baryła, I. et al. Efficient dewatering of polymer-rich aerobic granular sludge with cationic polymer containing hydrocarbons. Int. J. Environ. Sci. Technol. 17, 361–370 (2020). https://doi.org/10.1007/s13762-019-02505-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-019-02505-1