Abstract

The aim of the research was to determine deposition of zinc on soybean plants sprayed in three development phases: 2, 4 and 6 specific leaves. The spraying involved the following parameters: speed was 0.86 m s−1, pressure: 0.20 and 0.28 MPa, standard nozzles: flat fan XR 110-02 and double flat fan DF 120-02. Soybean plants of Pollux variety were sprayed, with foliar fertilizer Mikrovit Zinc 112 and the preparation containing zinc nanoparticles. The dose of both preparations amounted 160 g Zn ha−1. After spraying, the plants were cut, dried, and mineralized. Zinc content in the samples was measured with atomic absorption spectrometer. The highest values of zinc deposition soybean plants were recorded DF 120-02 nozzle, regardless the spraying parameters, as well as soy development phase. The use of nanozinc and DF 120-02 nozzle in 4 leaves development phase caused higher values of zinc deposition 12.5% (0.20 MPa) and 15% (0.28 MPa), while in 6 leaves phase, the mentioned values increased by 13% (0.20 MPa) and 3.6% (0.28 MPa), as compared to the ones obtained for the foliar fertilizer. The highest values of nanozinc deposition using DF 120-02 nozzles were recorded at 0.20 MPa pressure: 179.1 mg kg−1 (2 leaves phase) and 178.0 mg kg−1 (6 leaves phase), as well as at 0.28 MPa pressure: 127.7 mg kg−1(4 leaves phase). In comparison with flat fan nozzle XR 110-02, the use of double flat fan nozzle DF 120-02 increased zinc deposition by 151, 110, and 90%, respectively. Statistical analysis of the test results showed a significant effect of the type of nozzle used for spraying on the value of zinc deposition on soybean plants.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In the recent years, the possibility of using nanomaterials in a number of areas of life like technology, industry, medicine, or agriculture has been observed. Nanomaterials enable detection of enzymes and are able to decompose organic contaminants. Nanoparticle biodetectors and photocatalysts provide monitoring, control, and the improvement in ecosystem conditions, and they are often used to clean sewage, as well as to degrade textile and food colouring (Gnanasekaran et al. 2017; Gupta et al. 2017; Manoj et al. 2018; Qin et al. 2017; Rajendran et al. 2016, 2018; Saravanan et al. 2013, 2018).

Accumulation of excessive amount of organic contaminants in the environment can result from, e.g. the use of fertilizers containing nutrients, whose remains flow to surface and ground Waters, therefore, being a threat to human and animal health, as well as to the whole ecosystem (Gupta and Ali 2013). Pesticides are one of the main sources of chiral contaminants in the environment (Basheer 2018). Even trace residues of these chemical compounds in crops and the Earth`s ecosystem penetrate tissues of human organism and can cause different diseases. Yet there do exist a number of precise analytical techniques which allow to detect contaminants (including ions) of very low concentrations. These methods were described in details in the works by Ali et al. (2009), as well as Ali and Aboul-Enein (2006).

Zinc is an element necessary for proper functioning of the human body. The daily demand for this element is, depending on age, from 3 to 19 mg/day. Zinc is supplied to the human body mainly with food (Gapys et al. 2014; Wołonciej et al. 2016). Deficiency of this microelement is associated with a wide range of physiological problems, including growth impedance, delayed puberty (Prasad 2014; Tian and Diaz 2012), impaired sense of smell and taste, cognitive impairment, and can even lead to autism (Gapys et al. 2014). Zinc deficiency also affects the increased susceptibility infectious diseases, reduced physical fitness and work efficiency, and poor birth results in pregnant women (Black et al. 2008; Cakmak and Kutman 2018; Gibson 2012; Krebs et al. 2014; Terrin et al. 2015).

Cakmak et al. (2010) observed that foliar application of zinc has significantly increased its concentration in wheat grains, compared to soil fertilization. The use of foliar fertilizers is a very easy and fast way to replenish the missing micronutrients in plants. However, excessive application of agrochemicals, whose residues bring about contamination of the whole ecosystem, still remains a considerable problem. Therefore, the main direction for modern and pro-ecological plant protection is finding the possibilities and ways of diminishing the hazards to the environment, especially to living organisms, as well as to surface and groundwater, caused by agrochemicals. It is essential to reduce the amount of agrochemicals and, at the same time, to achieve high efficiency of plant treatments. One of the factors providing the best quality, meaning the most efficient spraying treatments, is choice of an appropriate nozzle for particular treatments.

Therefore, the aim of the study was to determine the amount of zinc-deposited soybean plants in three development phases (2, 4, and 6 leaves), depending on the type of preparation used for their treatment and selected parameters of the spraying process (type of nozzle and pressure).

The research was carried out in 2017 in two stages. The first stage of the research was conducted at the Institute of Soil Science and Plant Cultivation, National Research Institute, Department of Weed Science and Tillage Systems in Wroclaw (Poland). The second stage of the research was done at the Food Research Laboratory, at the Faculty of Biotechnology and Food Sciences, at the University of Environmental and Life Sciences in Wroclaw.

Materials and methods

In the first stage of the investigation, a greenhouse experiment was established using a modified first-generation phytotest (Sekutowski 2011). Soybean plants of Pollux variety were used for the study. The experiment was divided into three series defining the development phases of the plant according to the Biologische Bundesanstalt, Bundessortenamt and CHemical industry (BBCH): 12 BBCH (2 leaves), 14 BBCH (4 leaves), 16 BBCH (6 leaves), three replicates in each series (meaning three different plants). Plants were sown in pots of 15 cm diameter. The peat–mineral mix (pH = 6.5) and sand (0.6–0.8 mm diameter) in the ratio 2:1 were the sowing surface. Plants were grown under greenhouse conditions. After 14 days, the soybean plants reached the first development phase 12 BBCH, after subsequent 13 days, the second phase (14 BBCH), and then, the next 14 days, the third phase (16 BBCH).

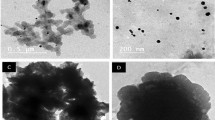

The spraying of plants was performed in the “Aporo1” spray chamber with constant spraying rate of 0.86 m s−1. Two standard nozzles were used for the treatment: flat fan nozzle XR 110-02 (Tee Jet) and double flat fan nozzle DF 120-02 (Lechler). The spraying was carried out at pressure of 0.20 and 0.28 MPa. The droplet size produced by the tested nozzles was determined in accordance with the ANSI/ASAE Standard 572.1 (2009). The research was carried out in the laboratory at the Industrial Institute of Agricultural Engineering in Poznan (Poland) using the “Spraytec” laser particle spectrum analyser (Malvern Instruments). Both nozzles were classified as fine at both pressures. The nozzle spray flow at the pressure of 0.20 MPa was equal 0.65 L min−1, while at the pressure of 0.28 MPa, it was 0.79 L min−1. The nozzles were set at the height of 0.5 m from the sprayed plants. The plants were sprayed with Mikrovit Zinc 112 foliar fertilizer and the preparation containing zinc oxide nanoparticles of < 50 nm size (Sigma Aldrich). The same dose of preparations 160 g Zn ha−1 was used. Creating preparations, 160 g of zinc, was mixed with 250 L of water per ha at pressure of 0.20 MPa and 300 L of water per ha at pressure of 0.28 MPa. The air temperature during the spraying of plants ranged 20 °C, and humidity was 60%.

In the second stage, laboratory tests were conducted, and in order to determine the deposition of zinc on the studied plants, the mineralization was performed by the microwave ‘wet’ dissolution technique using nitric acid HNO3 (Chemprum, 65%, pure p.a.). The sprayed plants were cut 24 h after the treatment, dried, ground, weighed, and then 5 ml of HNO3 acid was poured and sealed in XP 1500 Teflon dishes. The samples were mineralized in the Mars 5 microwave oven (CEM, USA). Then, due to the atomic absorption method, Zn content in mineralized plants was measured using (SpectrAA 240, Varina, Australia) spectrometer. The correctness of the determinations was verified with the reference material NCS ZC73031Carrot.

Statistical analysis

Statistical analysis was done according to the Statistica 12.5 program. In order to verify the applicability, the analysis of variance was conducted, with normality test (Shapiro–Wilk) and a homogeneity test of variance (Test Levene’a). Based on the obtained results, it was found that the data are not consistent with the normal distribution, and the variances are not homogeneous. Therefore, the nonparametric U Mann–Whitney test was performed in developmental phases (12, 14, 16 BBCH) in order to determine the effect of the tested factors (type of preparation, type of the nozzle and pressure) on zinc deposition on soybean plants. The analysis was performed at the significance level of p = 0.05.

Results and discussion

The highest values of zinc deposit on soybean plants were observed using double flat fan nozzle DF 120-02, irrespective of the parameters of the spraying process and the development phase of plants (Figs. 1, 2 and 3).

The use of the preparation containing nanozinc and double flat fan nozzle DF 120-02 for spraying resulted in higher values of zinc deposit on the soybean plants in the 14 and 16 BBCH development phase, regardless the pressure used for spraying, as compared to the values obtained for Mikrovit Zinc 112 foliar fertilizer (Figs. 2, 3). At the pressure of 0.20 MPa for the DF 120-02 nozzle, 13% higher (phase 16 BBCH) and 12.5% higher (phase 14 BBCH) zinc deposit in the nanoform were noted, in comparison with the values obtained during spraying with a Mikrovit Zinc 112 foliar fertilizer (Figs. 2, 3). However, when spraying plants with nanopreparation at a pressure of 0.28 MPa, increase in zinc deposit for the DF 120-02 nozzle occurred by 15% (phase 14 BBCH) and by 3.6% (phase 16 BBCH), compared to the values for the Mikrovit Zinc 112 foliar fertilizer (Figs. 2, 3).

The highest values of zinc deposit through the DF 120-02 nozzle, while spraying plants with nanopreparation, were at pressure of 0.20 MPa: 179.1 mg kg−1 (development phase BBCH 12) and 178.0 mg kg−1 (development phase BBCH 16). Compared to the zinc deposition in the nanopreparation at pressure of 0.20 MPa for the flat fan nozzle XR 110-02, the introduction of double flat fat nozzle DF 120-02 increased the deposit by 151% (BBCH 12) and by 110% (BBCH 16) (Figs. 1, 3). However, for the 14 BBCH development phase, the highest values of zinc deposit on the soybean plants were recorded during spraying with the preparation containing the nanocolloid particles at pressure of 0.28 MPa, and this value equalled 127.7 mg kg−1 (Zn deposit was greater by 90%, compared to the value of 67 mg kg−1 obtained by the flat fan nozzle XR 110-02) (Fig. 2).

As it can be seen in Fig. 1, in general, the higher zinc deposit on soybean plants in the 12 BBCH development phase was recorded for spraying with Mikrovit Zinc 112 foliar fertilizer, regardless the type of nozzle and pressure, in relation to the nanopreparation. The exception was noted when spraying soybean in the 12 BBCH phase with a nanopreparation, at the pressure of 0.20 MPa, where higher zinc deposit by 2% was obtained for double flat fan nozzle DF 120-02 compared to the values obtained for the Mikrovit Zinc 112 foliar fertilizer (Fig. 1).

The use of the flat fan nozzle XR 110-02 for the treatment resulted in higher zinc deposit on soybean plants during spraying with Mikrovit Zinc 112 foliar fertilizer, regardless the pressure and plant’s development phase, in comparison with the deposition of the product obtained during spraying with nanozinc (Figs. 1, 2 and 3). The spraying of soybean plants with Mikrovit Zinc 112 foliar fertilizer, at pressure of 0.20 MPa, with the XR 110-02 nozzle resulted in higher zinc deposit by 151%, as compared to the value obtained using preparation containing nanocolloid particles (12 BBCH) (Fig. 1). The exception was noted during soybean spraying in the 16 BBCH development phase at a pressure of 0.28 MPa, where higher zinc deposit on plants was obtained for the XR 110-02 nozzle by 3.6%, using nanozinc for spraying, compared to the values obtained for the Mikrovit Zinc 112 foliar fertilizer (Fig. 3).

The results of statistical analysis research carried out for soybean plants in three sprayed development phases are presented in Table 1. The influence of the selected factors (nozzle, type of preparation, pressure) on the values of dependent variable (deposit) was evaluated.

On the basis of the statistical analysis results, it was found that the type of a nozzle has a statistically substantial significance the value of zinc deposition at all development stages of soybean plants (Table 1). There was no statistically significant effect on the values of the dependent variable (deposit) of the type of preparation sprayed on plants and the magnitude of the pressure at which the convergence was performed. Both the type of the preparation and the pressure parameters had no significant statistical effect (at the significance level of p = 0.05) on zinc deposition in all three sprayed development phases of soybean plants (12, 14, 16 BBCH).

In order to determine the deposition of the spray liquid on the sprayed objects, the scientists use different metallic tracers, e.g. manganese sulphate (Costa et al. 2013), copper oxychloride (De Souza Christovam et al. 2010), copper oxide (Raetano and Bauer 2003), or zinc sulphate (Boonchuay et al. 2013; McBeath and McLaughlin 2014). The above-mentioned authors measured the concentration of the tested tracers using a spectrometer. In our research, two tracers based on the zinc element (foliar fertilizer Mikrovit zinc 112 and a nanozinc preparation containing particles of the < 50 nm size) were used. In the conducted studies, higher values of zinc deposit on soybean plants sprayed in the 14 and 16 BBCH development phase were obtained while using nanopreparation and DF 120-02 nozzle for spraying, regardless the pressure, compared to the value deposit obtained for the plant spraying with a Mikrovit Zinc 112 foliar fertilizer. But this founding was not confirmed by statistical analysis.

De Souza Christovam et al. 2010 determined the deposit of a copper tracer on the samples in the form of filter papers placed on soybean plants. Using the nozzle with an auxiliary air stream and standard XR 8002 flat fan nozzles and rotary LVO (low-volume oily) nozzles, they found that the speed of air produced by the fan not affect the amount of spray deposit on the leaf surfaces in the upper part of soybean plants. In this research, standard nozzles were used for spraying soybean: flat fan nozzle XR 110-02 and double flat fan nozzle DF 120-02. Higher values of zinc deposit on the plants using the DF 120-02 nozzle for spraying, irrespective of the plant’s development phase, pressure, or type of preparation were observed.

Cakmak et al. (2010) studied Zn concentration in various parts of wheat grain, using soil fertilization and foliar fertilization at various stages of plant development. They found that foliar deposition of zinc significantly increased its concentration in wheat grains. They also observed increased absorption of zinc by plants during fertilization with additional dose of nitrogen. Moreover, they observed that the use of foliar fertilizers containing Zn in the last phases of plant growth increased the absorption of zinc by wheat grains. Boonchuay et al. (2013), on the other hand, examined how the zinc concentration in rice grains can be increased by the application foliar fertilizer at different development phases of the plant. They stated the amount of zinc in rice grain can be effectively increased by spraying with foliar fertilizer after the flowering phase of the plant. In these studies, the authors did not take into account the conditions of the spraying process, nor did they analyse the most important parameters, such as the nozzle, preparation, or pressure. Our research has shown that not only the development phase, but above all the way of applying foliar fertilizers affects the content of the studied element in plants. It is unwise to assess the content of zinc in plants or grains, not taking into account the parameters of the spraying process, and especially, the type of the nozzle and the size of the drops produced by the nozzle.

Many researchers, during study conducted with the application of plant protection products and foliar fertilizers, forgot that the droplet size is one of the most important factors determining the effectiveness of spraying which covers the sprayed object. Therefore, one should choose the right type of nozzle adopted to technical and technological conditions prevailing during the spraying operation. Nuyttens et al. (2007) and Douzals (2012) in their research confirmed the fact that the size of droplets, and hence the quality of spraying, are the most important factors affecting the efficiency of spraying convergence and the amount of losses of plant protection products used. It should be remembered that one of the methods of obtaining a more precise distribution of the active substance on sprayed plants is proper selection of nozzles (Cunha et al. 2008). Nozzles are the most important elements of sprayers because their type depends on the spraying spectrum, the homogeneity of the spray pattern distribution, and the spray volume (Fernandes et al. 2007; Nuyttens et al. 2007). The statistical analysis of the presented research results showed that the type of nozzle has a significant impact on the deposition of zinc tracer on soybean plants in development phases.

Costa et al. (2013) examined the effect of the liquid dose and the angle of inclination of nozzles mounted on the beam on manganese deposit on soybean leaves. The TT8B centrifugal energy nozzle, nozzles that use hydraulic energy, and wide-angle flat nozzles TT11002 were used for spraying. These researchers found that modification of nozzle deviation from the beam increases the spray deposit on plants, but it also depends on the applied spray dose. In addition, they observed that flat fan nozzles are characterized by higher deposition of the analysed spray on soybean plants, compared to the rotary disc nozzles. The research results obtained by the authors prove that flat fan nozzles that produce two streams of liquid are characterized by higher amount of zinc applied to soybean plants than flat fan nozzles producing one stream of liquid.

Many researchers describe the deposition of a usable liquid on plants using samplers in the form of filter papers (Celen et al. 2009; De Souza Christovam et al. 2010; Sánchez-Hermosilla et al. 2012). The location of the samplers directly on the sprayed plants cause measurement errors resulting from deformation of the leaves loaded by the samplers placed on them. Therefore, to determine the value of zinc deposit on soybean plants sprayed in our experiments, a representative sample selected from the whole sprayed plant was tested. The highest values of zinc trace deposit and nanozinc were recorded the BBCH 12 development phase of soybean plants, and they amounted 176.0 (Zn) and 179.1 (Zn nano) mg kg−1 of dry matter, at pressure of 0.20 MPa for the nozzle DF 120-02. The lowest values of zinc tracer deposit were determined during soybean spraying in the BBCH 14 development phase, and they ranged from 70.0 to 110.7 mg Zn kg−1 of dry matter, while for nanozinc tracer, they ranged from 68.4 to 127.7 mg Zn kg−1 of dry mass. Total zinc content in soybean plants was the lowest in 14 BBCH phase, while the highest in 12 BBCH phase. Because the prevalence of Zn deficiency in human organisms is associated with low intake of zinc in foods and the consumption of plant products is common throughout the world, special attention should be paid to the need for using foliar fertilizers for plants. As the research by many scientists has shown, the use of foliar fertilizers is a very easy and fast form that supplements minerals in arable crops.

Conclusion

According to the change of plant development phase, soybean plants increase their surface expose to spraying. The research by the authors proved that the amount of zinc absorbed by soybean is very similar and only to a low degree depends on particular phases of plant development.

Statistical analysis of research results indicated significant effect of the type of nozzle used for spraying on the value of zinc deposit on soybean plants. The use of double flat fan nozzle DF 120-02 resulted in higher zinc deposit on soybean plants, regardless the type of preparation, pressure and plant development phase, compared to the values obtained for flat fan nozzle XR 120-02. The use of the preparation containing nanozinc and double flat fan nozzle DF 120-02 resulted in higher values of zinc deposition on soybean plants in the 14 and 16 BBCH development plants, irrespectively of the pressure used for spraying, compared to the values obtained for foliar fertilizer Mikrovit Zinc 112. The flat fan nozzle XR 110-02 enabled higher zinc deposit on soybean plants during spraying performed with Mikrovit Zinc 112 foliar fertilizer, regardless the pressure the treatment was carried out with and the development phase of plants, in relation plant, compared to the deposit values obtained while spraying plants with the preparation containing nanozinc.

The most considerable effect on zinc absorption by plants belonged to the type of a nozzle. In further research the authors are going to confirm the relation between the sizes of the sprayed plant surface in particular phase of plant development and the amount of zinc absorber by plants after spraying. In the future, the results of conducted research will enable reduction in the use of agrochemicals by farmers who will apply nanoelements, as well as appropriate types of nozzles. The obtained results can prove innovative approach involving making use of the size of the nozzle surface and spraying with nanoelements, which translates to the reduction in the amount of agrochemicals used by farmers. In that case the possibility of reducing the quantity of agrochemicals in the whole ecosystem would become a fact which would significantly improve the environmental conditions.

References

Ali I, Aboul-Enein HY (2006) Instrumental methods in metal ions speciation: chromatography, capillary electrophoresis and electrochemistry. Taylor & Francis Ltd., New York. ISBN 0-8493-3736-4

Ali I, Aboul-Enein HY, Gupta VK (2009) Nanochromatography and nanocapillary electrophoresis: pharmaceutical and environmental analyses. Wiley, Canada

ANSI/ASAE S572.1 (2009) Spray Nozzle Classification by Droplet Spectra. ASABE Standards. p 1-4. https://elibrary.asabe.org/abstract.asp?aid=44208&t=2&redir=&redirType=

Basheer A (2018) Chemical chiral pollution: impact on the society and science and need of the regulations in the 21st century. Chirality 30(4):402–406. https://doi.org/10.1002/chir.22808

Black RE, Lindsay HA, Bhutta ZA, Caulfield LE, de Onnis M, Ezzati M et al (2008) Maternal and child under nutrition: global and regional exposures and health consequences. Lancet 371:243–260

Boonchuay P, Cakmak I, Rerkasem B, Prom-u-thai C (2013) Effect of different foliar zinc application at different growth stages on seed zinc concentration and its impact on seedling vigor in rice. J Soil Sci Plant Nut 59:180–188. https://doi.org/10.1080/00380768.2013.763382

Cakmak I, Kutman UB (2018) Agronomic biofortification of cereals with zinc: a review. Eur J Soil Sci 69:172–180. https://doi.org/10.1111/ejss.12437

Cakmak I, Kalayci M, Kaya Y, Torun AA, Aydin N, Wang Y et al (2010) Biofortification and localization of zinc in wheat grain. J Agric Food Chem 58:9092–9102. https://doi.org/10.1021/jf101197h

Celen I, Durgut M, Avci G, Kilic E (2009) Effect of air assistance on deposition distribution on spraying by tunnel-type electrostatic sprayer. Afr J Agric Res 4:1392–1397

Costa LL, Da Costa Ferreira M, Rodrigues Peres, da Costa AC, De Souza Rolim G, Neves Campos HB (2013) Spraying deposit in soybean plants as influenced by application volume and the degree of inclination of centrifugal energy nozzles. Agric Sci Res J 3(11):343–351

Cunha JPAR, Moura EAC, Silva Júnior JL, Zago FA, Juliatti FC (2008) Efeitos de pontas de pulverização no controle químico da ferrugem da soja. Engenharia Agrícola 28:283–291

De Souza Christovam R, Raetano CG, Prado EP, Dal Pogetto MH, Júnior HO, Gimenes M, Serra ME (2010) Air-assistance and low volume application to control of asian rust on soybean crop. J Plant Prot Res 50:354–359. https://doi.org/10.2478/v10045-010-0060-y

Douzals JP (2012) Asymmetric classification of drift reducing nozzles considering frontal or lateral wind conditions. In: International conference agricultural engineers CIGR-AgEng. Spain, Valencia Conf. Centre, July 8–12, 4 pp

Fernandes AP, Parreira RS, Ferreira MC, Romani GN (2007) Caracterização do perfil de deposição e do diâmetro de gotas e otimização do espaçamento entre bico na barra de pulverização. Engenharia Agrícola 27:728–733

Gapys B, Raszeja-Specht A, Bielarczyk H (2014) Rola cynku w procesach fizjologicznych i patofizjologicznych organizmu. Diagn Lab 50:45–52

Gibson RS (2012) Zinc deficiency and human health: etiology, health consequences, and future solutions. Plant Soil 361:291–299

Gnanasekaran L, Hemamalini R, Saravanan R, Ravichandran K, Gracia F, Agarwal S, Gupta VK (2017) Synthesis and characterization of metal oxides (CeO2, CuO, NiO, Mn3O4, SnO2 and ZnO) nanoparticles as photo catalysts for degradation of textile dyes. J Photochem Photobiol B 173:43–49. https://doi.org/10.1016/j.jphotobiol.2017.05.027

Gupta VK, Ali I (2013) Environmental water: Advances in treatment, remediation and recycling. Elsevier, Amsterdam, pp 6–10

Gupta VK, Saravanan R, Agarwal S, Gracia F, Khan MM, Qin J, Mangalaraja RV (2017) Degradation of azo dyes under different wavelengths of UV light with chitosan-SnO2 nanocomposites. J Mol Liq 232:423–430. https://doi.org/10.1016/j.molliq.2017.02.095

Krebs NF, Miller LV, Hambridge KM (2014) Zinc deficiency in infants and children: a review of its complex and synergistic interactions. Paediatr Int Child Health 34:279–288. https://doi.org/10.1179/2046905514Y.0000000151

Manoj D, Saravanan R, Santhanalakshmi J, Agarwal S, Gupta VK, Boukherroub R (2018) Towards green synthesis of monodisperse Cu nanoparticles: an efficient and high sensitive electrochemical nitrite sensor. Sens Actuators B Chem 266:873–882. https://doi.org/10.1016/j.snb.2018.03.141

McBeath TM, McLaughlin MJ (2014) Efficacy of zinc oxides as fertilisers. Plant Soil 374:843–855. https://doi.org/10.1007/s11104-013-1919-2

Nuyttens D, Baetens K, De Schampheleire M, Sonck B (2007) Effect of nozzle type, size and pressure on spray droplet characteristics. Biosyst Eng 97:333–345. https://doi.org/10.1016/j.biosystemseng.2007.03.001

Prasad AS (2014) Impact of the discovery of human zinc deficiency on health. J Trace Elem Med Biol 28:357–363

Qin J, Yang C, Cao M, Zhang X, Rajendran S, Limpanart S, Ma M, Liu R (2017) Two-dimensional porous sheet-like carbon-doped ZnO/g-C3N4 nanocomposite with high visible-light photocatalytic performance. Mater Lett 189:156–159. https://doi.org/10.1016/j.matlet.2016.12.007

Raetano CG, Bauer FC (2003) Efect of the air speed in air-assisted sprayer on bean crop pesticide spray deposition. Bragatina 62:329–334. https://doi.org/10.1590/S0006-87052003000200019

Rajendran S, Khan MM, Gracia F, Qin J, Gupta VK, Arumainathan S (2016) Ce 3 + -ion-induced visible-light photocatalytic degradation and electrochemical activity of ZnO/CeO 2 nanocomposite. Sci Rep 6:31641. https://doi.org/10.1038/srep31641

Rajendran S, Hoang TK, Boukherroub R, Diaz-Droguett DE, Gracia F, Gracia-Pinilla MA, Akbari-Fakhrabadi A, Gupta VK (2018) Hydrogen adsorption properties of Ag decorated TiO2 nanomaterials. Int J Hydrog Energy 43(5):2861–2868. https://doi.org/10.1016/j.ijhydene.2017.12.080

Sánchez-Hermosilla J, Rincón VJ, Páez F, Fernández M (2012) Comparative spray deposits by manually pulled trolley sprayer and a spray gun in greenhouse tomato crops. Crop Prot 31:119–124. https://doi.org/10.1016/j.cropro.2011.10.007

Saravanan R, Karthikeyan S, Gupta VK, Sekaran G, Narayanan V, Stephen A (2013) Enhanced photocatalytic activity of ZnO/CuO nanocomposite for the degradation of textile dye on visible light illumination. Mater Sci Eng C 33(1):91–98. https://doi.org/10.1016/j.msec.2012.08.011

Saravanan R, Aviles J, Gracia F, Mosquera E, Gupta VK (2018) Crystallinity and lowering band gap induced visible light photocatalytic activity of TiO2/CS (Chitosan) nanocomposites. Int J Biol Macromol 109:1239–1245. https://doi.org/10.1016/j.ijbiomac.2017.11.125

Sekutowski T (2011) Application of bioassays in studies on phytotoxic herbicide residues in the soil environment. In: Kortekamp A (ed) Herbicides and Environment. InTech, Rijeka, pp 253–272

Terrin G, Canani RB, di Chiara M, Pietravalle A, Aleandri V, Conte F et al (2015) Zinc in early life: a key element in the fetus and preterm neonate. Nutrients 7:10427–10446. https://doi.org/10.3390/nu7125542

Tian X, Diaz FJ (2012) Zinc depletion causes multiple defects in ovarian function during the periovulatory period in mice. Endocrinology 153:873–886. https://doi.org/10.1210/en.2011-1599

Wołonciej M, Milewska E, Roszkowska-Jakimiec W (2016) Pierwiastki śladowe jako aktywatory enzymów antyoksydacyjnych. Postepy Hig Med Dosw 70(1483–1498):16. https://doi.org/10.5604/17322693.1229074

Acknowledgements

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Editorial responsibility: Shahid Hussain.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Dereń, K., Szewczyk, A. & Sekutowski, T.R. Effect of the type of preparation and spraying parameters on zinc deposition on soybean plants. Int. J. Environ. Sci. Technol. 16, 3447–3454 (2019). https://doi.org/10.1007/s13762-018-1988-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-018-1988-0