Abstract

From 5-amino pyrazole, azo disperse pyrazole dyes containing o-vanillin have been synthesized and characterized using elemental analyses and Spectroscopic techniques. All synthesized dyes have been effectively used on polyester fabrics as disperse dyes, and the performances of dyeing have been studied and evaluated. The dyes have good depth, brightness and good leveling properties. The fastness properties of the dyed samples have been thoroughly examined and assessed with regard to washing, perspiration, rubbing, and light fastness. Color representation, colorimetric data (L*, a*, b, C*, h, and K/S), and other multifunctional features have also been studied. The degree of exhaustion and fixation were attained. Additionally, the dyed fabrics were put through an ultraviolet protection factor test, with the findings demonstrating that these dyes provided superior UV protection. The synthetic dyes were tested in- vitro against different bacteria and fungi, all of the dyes shown a significant activity compared with the standard drug.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Polyethylene terephthalate (PET) has been utilized extensively in apparel, household textiles, and other characteristics because of its superior mechanical properties, high strength, wear resistance and other attributes [1, 2]. Disperse dyes of various types and with full chromatograms have traditionally held a significant role in the dye industry. Such dyes are frequently used to color hydrophobic textiles as polyester since their molecular structure only comprises a small number of polar groups and lacks water-soluble groups as sulfonate or carboxylate groups. After dyeing, certain dye particles may still be present on the surface of the fiber; these particles will have an impact on the fabric's brightness and wash ability and rubbing fastness [3, 4]. Due to their wide range of applications in chemical science and technology, azo dyes, a family of regularly occurring organic chemicals, are very interesting. Because of their characteristic properties of dyeing strength, ease of manufacture, wide color scales, and high-quality color fastness, azo dyes are the most widely used colorants among textile dyes [5,6,7,8,9]. Over 50% of commercial dyes contain azo dyes as colorants. Azo dyes have a wide range of uses, including inkjet printing, thermal transfer printing, photography, color additives, molecular recognition, light-controlled polymers, metallochromic indicators, electro-optic devices [10,11,12,13,14] in the liquid crystal industry, and solar cells [15]. Over 50% of commercial dyes contain azo dyes as colorants.

Additionally, azo dyes have recently become the interest of researchers in the field of biology and have been the topic of theoretical studies [16, 17], azo dyes are reported to have antibacterial properties [18, 19] as well as antifungal activity [20].

Nowadays, azo dyes with heterocyclic moieties display improved coloring properties, tinctorial strength, thermal stability, and more favourable solvatochromic behavior in comparison to dyes derived from a simple aromatic amine [21, 22]. In addition, the synthesis of heterocycle-containing azo dyes and their derivatives has attracted particular interest because of their potent bioactivities, which include antimicrobial, antifungal, antiviral activity, analgesic properties, chemosensing abilities, anti-inflammatory, anticonvulsant, antidiabetic, antitubercular, and anticancer DNA binding [23,24,25,26,27].

Pyrazole derivative among the dispersed azo dyestuffs which are the most frequently employed group in the dyeing of hydrophobic fibers, have recently gained a lot of popularity [28,29,30]. It is widely used for dyeing synthetic based fabrics for textile industry due to their wide and different color choices, Color and color fastness characteristics of synthetic fibers dyed with these dyes displayed satisfying results [30,31,32,33].

In recent years, amino pyrazole derivatives are becoming more and more popular in the textile and dyestuffs industry because they offer a wide range of colors, excellent dyeing properties and long-lasting fastness properties [34,35,36]. Amino pyrazole derivatives are important compounds have a variety of intriguing qualities, such as anticancer [37], anti-inflammatory [38], anti-bacterial [39], Antimalarial [40], insecticides, and anti-influenza agents [41], and Analgesic Activity [42].Ortho-vanillin Schiff bases are multipurpose ligands which are synthesized from the condensation of aldehydes with amines derivatives to creating a limitless number of possible compounds. Various applications used to search for potential efficacy of ortho-vanillin Schiff base ligands are including the anti-bacterial, antifungal, anticancer and Cytotoxicity evaluation, DNA infarction and cleavage, molecular docking, anti-oxidant studies, catalytic activity, formation of novel polymer and removing of metals from water, as well as many other potential applications [43,44,45,46,47]. As a part of our continuous interest on 5-amino pyrazole derivatives [48,49,50], the goal of this study is to synthesize some novel Schiff bases derived from azo amino pyrazole derivatives and study their applications as disperse dyes to polyester fabrics, Color representation, colorimetric data, UV protection and multifunctional features have also been studied. Also, the synthetic dyes were tested in- vitro against different bacteria and fungi.

Experimental section

Materials and instrumentation

All data of materials and instrumentations are available in the supplementary file.

Synthesis of 1-(2,4-dinitrophenyl)-3-phenyl-1H-pyrazol-5-amine (1)

2,4-Dinitrophenyl hydrazine (1.39 g, 7 mmol) was dissolved in ethyl alcohol (5 ml) and few drops of acetic acid, then added to 3-oxo-3-phenylpropanenitrile (0.986 g, 6.8

mmol). After 10 h of refluxing, the excess solvent was drawn off under reduced pressure. Compound 1 was created by crystallizing the crude product from ethanol.

Orange color (63%); m.p. 160–163 °C; IR (ν/cm−1): 3324 (NH2), 3092 (CH-Ar.), 1610 (C=N); 1H NMR (DMSO-d6): δ 5.87 (s, 2H, NH2 exchangeable with D2O), 5.59 (s, 1H, CH of pyrazole), 7.43–8.86 (m, 8H, Ar–H); 13C NMR (DMSO-d6): δ 87.22 (C4 of pyrazole), 144.32 (C3 of pyrazole), 144.38 (C5 of pyrazole), 124.29, 125.45, 126.11, 127.99, 129.65, 135.76, 139.27, 149.68 (Carom.); MS (EI) m/z [M +] calcd. For C15H11N5O4: 325.28, found: 325.96; Anal. Calcd. For C15H11N5O4 (325.28): C, 55.39; H, 3.41; N, 21.53; Found: C, 55.28; H, 3.51; N, 21.53.

Synthesis of 1-(2,4-dinitrophenyl)-3-phenyl-4-(substitutedphenyldiazenyl)-1H-pyrazol-5-amine (3a–d)

To a cooled solution of aromatic amines (13.7 mmol) in concentrated HCl, a solution of sodium nitrite (0.9 g, 12.7 mmol) in water was added dropwise. The diazonium salt was added with constant stirring to a cooled solution of compound 1 (2.76 g, 8.5 mmol) in ethanol (42 ml) containing sodium acetate (3.4 g).The mixture of the reaction was agitated for two h at 0 °C, then the product was filtered, and crystallized from ethanol to obtain (3a–d).

4-((2-chloro-5-(trifluoromethyl)phenyl)diazenyl)-1-(2,4-dinitrophenyl)-3-phenyl-1H-pyrazol-5-amine (3a)

Brown color (75%); m.p.132–134 °C, IR (ν/cm−1): 3259 (NH2), 3073 (CH–Ar), 1660 (C=N), 1597 (N=N); 1H NMR (DMSO-d6): δ 7.49 –8.81 (m, 11H, Ar–H), 9.98 (s, 2H,

NH2); 13C NMR (DMSO-d6): δ 125.49 (CF3), 129.69(C-CF3), 136.72 (C–Cl), 153.73 (C-NH2), 154.96 (C=N), 88.16, 115.94, 116.41, 118.85, 118.69, 121.38, 123.80, 127.55, 128.85, 132.13, 134.66, 145.42, 149.63, 150.47, 152.06 (C-Aromatic); MS (EI) m/z [M+] calcd for C22H13ClF3N7O4: 531.83, found: 532.40; Anal. Calcd. For C22H13ClF3N7O4 (531.83): C, 49.68; H, 2.46; Cl, 6.67; N, 18.44; Found: C, 49.53; H, 2.32; Cl, 6.71; N, 18.34.

4-((5-amino-1-(2,4-dinitrophenyl)-3-phenyl-1H-pyrazol-4-yl)diazenyl)-2,5-dimethoxybenzonitrile (3b).

Brown color (77%); m.p.155–157OC; IR (ν/cm−1): 3294 (NH2), 3073 (CH-Ar), 2949 (CH-Aliph), 1665 (C=N), 1578 (N=N); 1H NMR (DMSO-d6): δ 3.84 (s, 6H, 2OCH3), 7.30–8.81 (m, 11H, Ar–H), 10.05 (s, 2H, NH2); 13C NMR (DMSO-d6): δ 54.49 (OCH3), 57.01 (OCH3), 115.58 (CN), 149.63 (C-NH2), 150.00 (C=N), 88.17, 121.37, 123.80, 125.49, 128.01, 128.39, 129.23, 129.71, 132.13, 132.98, 134.66, 136.72, 140.46, 144.58, 145.41, 152.91, 157.49 (C-Aromatic); MS (EI) m/z [M +] calcd for C24H18N8O6: 514.45, found: 515.73; Anal. Calcd. For C24H18N8O6 (514.45): C, 56.03; H, 3.53; N, 21.78; Found: C, 56.11; H, 3.61; N, 21.69.

1-(2,4-dinitrophenyl)-4-((2-methyl-4-nitrophenyl)diazenyl)-3-phenyl-1H-pyrazol-5-amine (3c).

Brown color (70%); m.p.151–153°C; IR (ν/cm−1): 3278 (NH2), 3029 (CH-Ar), 2966 (CH-Aliph), 1656 (C=N), 1576 (N=N); 1H NMR (DMSO-d6): δ 2.05 (s, 3H, CH3), 7.32–8.77 (m, 11H, Ar–H), 9.92 (s, 2H, NH2); 13C NMR (DMSO-d6): δ 14.63 (CH3), 99.76, 115.57, 115.95, 121.75, 123.42, 124.65, 125.49, 128.39, 128.85, 129.70, 130.54, 132.13, 133.45, 134.66, 137.18, 144.58, 145.89 (C-Aromatic), 149.62 (C-NH2), 150.47 (C=N); MS (EI) m/z [M +] calcd for C22H16N8O6:488.41, found: 489.28; Anal.Calcd.for C22H16N8O6 (488.41): C, 54.10; H, 3.30; N, 22.94; Found: C, 54.99; H, 3.34; N, 22.88.

1-(2,4-dinitrophenyl)-4-((2-methoxy-4-(phenylamino)phenyl)diazenyl)-3-phenyl-1H-pyrazol-5-amine (3d)

Dark green color (74%); m.p.130–132 °C; IR (ν/cm−1): 3250 (NH2), 3165 (NH), 3055 (CH-Ar), 2922 (CH-Aliph), 1667 (C=N), 1571 (N=N); 1H NMR (DMSO-d6): δ 3.86 (s, 3H, OCH3), 7.07–8.92 (m, 16H, Ar–H), 9.20 (s, 2H, NH2), 10.10 (s, 1H, NH); 13C NMR (DMSO-d6): δ 58.22 (OCH3), 85.27, 94.34, 119.32, 120.54, 120.91, 122.22, 122.59, 124.28, 127.18, 129.25, 130.08, 130.92, 131.76, 132.59, 134.19, 140.93, 142.52, 145.42, 147.10, 148.79, 157.48 (C-Aromatic), 149.62 (CN), 150.84 (C-NH2), 160.00 (C=N); MS (EI) m/z [M +] calcd for C28H22N8O5: 550.52, found: 550.30; Anal. Calcd.for C28H22N8O5 (550.52): C, 61.09; H, 4.03; N, 20.35; Found: C, 61.13; H, 4.09; N, 20.40.

Synthesis of 4-((Z)-((1-(2,4-dinitrophenyl)-3-phenyl-4-((E)-substitutedphenyldiazenyl)-1H-pyrazol-5-yl)imino)methyl)-2-methoxyphenol (4a-d).

A mixture of o-Vanillin (0.05 mol, 7.60 g), appropriate amine derivatives (0.05 mol), 30 mL ethanol and few drops of acetic acid was refluxed for 6 h (TLC control). The product was formed with cooling then filtered and dried over anhydrous CaCI2 to give compounds 4a-d.

4-((Z)-((4-((E)-(2-chloro-5-(trifluoromethyl)phenyl)diazenyl)-1-(2,4-dinitrophenyl)-3-phenyl-1H-pyrazol-5-yl)imino)methyl)-2-methoxyphenol (4a)

Orange red color (81%); m.p. 247–249 °C; IR (ν/cm−1): 3410 (OH), 3055 (CH-Ar),

2936 (CH-Aliph), 1656 (C=N), 1589 (N=N), 1520 (C=N imine); 1H NMR (DMSO-d6): δ 3.83 (s, 3H, OCH3), 5.94 (s, 1H, OH), 6.83–8.53 (m, 14H, Ar–H), 8.81 (s, 1H, CH=N); 13C NMR (DMSO-d6): δ 56.17 (OCH3), 123.81 (CF3), 129.70 (C-CF3),137.94 (C–Cl),, 100.14, 110.15, 114.27, 115.94, 117.16, 118.48, 123.05, 125.49, 126.80, 130.55, 131.76, 134.19, 136.35, 136.73, 142.52, 143.83, 145.42, 147.58, 148.79, 150.00, 150.84, 152.91 (C-Aromatic), 155.43(C=N), 155.80 (CH=N); MS (EI) m/z [M+] calcd for C30H19ClF3N7O6: 665.96, found: 665.74; Anal. Calcd. For C30H19ClF3N7O6 (665.96): C, 54.11; H, 2.88; N, 14.72; Cl, 5.32; Found: C, 54.11; H, 2.91; N, 14.83; Cl, 5.12.

4-((E)-(1-(2,4-dinitrophenyl)-5-(((Z)-4-hydroxy-3-methoxybenzylidene)amino)-3-phenyl-1H-pyrazol-4-yl)diazenyl)-2,5-dimethoxybenzonitrile (4b)

Brown color (75%); m.p.254–256 °C; IR (ν/cm−1): 3424 (OH), 3099 (CH-Ar).), 2943 (CH-Aliph), 1664 (C=N), 1583 (N=N), 1517 (C=N imine); 1H NMR (DMSO-d6): δ 3.83 (s, 3H, OCH3), 5.95 (s, 1H, OH), 6.83–8.56 (m, 13H, Ar–H), 8.79 (s, 1H, CH=N); 13C NMR (DMSO-d6): δ 55.69 (OCH3), 56.18 (OCH3), 58.23 (OCH3), 116.42 (CN), 88.16,110.15, 113.05, 117.16, 118.48, 123.05, 123.81, 124.65, 125.96, 127.17, 129.22, 129.70, 130.91, 136.72, 137.94, 138.41, 142.15, 142.52, 145.04, 145.88, 148.78, 149.99, 150.83, 152.52 (C-Aromatic); 157.11 (CH=N), 155.80 (C=N); MS (EI) m/z [M +] calcd for C32H24N8O8: 648.58, found: 647.84; Anal. Calcd. For C32H24N8O8 (648.58): C, 59.26; H, 3.73; N, 17.28; Found: C, 59.18; H, 3.92; N, 17.19.

4-((Z)-((1-(2,4-dinitrophenyl)-4-((E)-(2-methyl-4-nitrophenyl)diazenyl)-3-phenyl-1H-pyrazol-5-yl)imino)methyl)-2-methoxyphenol (4c)

Orange red color (86%); m.p. 257–259 °C; IR (ν/cm−1): 3412 (OH), 3029 (CH–Ar),

2966 (CH-Aliph), 1656 (C=N), 1563 (N=N), 1527 (C=N imine); 1H NMR (DMSO-d6): δ 1.87 (s, 3H, CH3), 3.83 (s, 3H, OCH3), 5.99 (s, 1H, OH), 6.83–8.55 (m, 14H, Ar–H), 8.82 (s, 1H, CH=N); 13C NMR (DMSO-d6): δ 15.48 (CH3), 56.19 (OCH3), 110.15, 111.36, 113.42, 116.79, 117.16, 118.00, 118.48, 123.06, 123.82, 124.65, 125.50,129.70, 130.07, 131.29, 137.19, 137.94, 139.25, 145.04, 146.72, 147.94, 148.79, 150.47, 154.59, 156.26 (C-Aromatic), 157.11 (C=N), 157.49 (CH=N); MS (EI) m/z [M +] calcd for C30H22N8O8: 622.54, found: 623.39; Anal. Calcd. For C30H22N8O8 (622.54): C, 57.88; H, 3.56; N, 18.00; Found: C, 57.79; H, 3.50; N, 18.12.

4-((Z)-((1-(2,4-dinitrophenyl)-4-((E)-(2-methoxy-4-(phenylamino)phenyl)diazenyl)-3-phenyl-1H-pyrazol-5-yl)imino)methyl)-2-methoxyphenol (4d)

Dark green color (69%); m.p. 192–194 °C; IR (ν/cm−1): 3435 (OH), 3175 (NH), 3055 (CH-Ar), 2954 (CH-Aliph), 1667 (C=N), 1571 (N=N); 1H NMR (DMSO-d6): δ 3.80 (s, 6H, 2OCH3), 6.30 (s, 1H, OH), 6.83–8.80 (m, 19H, Ar–H), 9.78 (s,1H, CH=N), 10.10 (s,1H, NH); 13C NMR (DMSO-d6): δ 56.54 (OCH3), 57.01(OCH3), 108.09, 110.15, 111.37, 111.83, 114.27, 115.95, 117.17, 118.47, 120.16, 123.07, 123.43, 124.65, 128.02, 129.70, 130.08, 131.29, 133.82, 137.19, 139.62, 145.04, 146.73, 148.79, 150.84, 152.05, 154.58, 154.96, 155.80, 156.64 (C-Aromatic), 157.48 (C=N), 161.23 (CH=N); MS (EI) m/z [M +]calcd for C36H28N8O7:684.66, found:683.58; Anal.Calcd.for C36H28N8O7 (684.66): C, 63.15; H, 4.12; N, 16.37; Found: C, 63.21; H, 4.19; N, 16.41.

General procedure for dyeing of polyester fabric

The polyester fabrics were dyed using the synthetic dyes as reported [51,52,53]. Detailed information's about the procedure for dyeing of polyester fabric were reported in the supporting information (Section S1) (Fig. 1).

Measurement for the dyeing properties

Color fastness test

We evaluated the fastness performance of the synthetic dyes. Detailed procedures for the color fastness test are presented in the supporting information (Section S2).

Colorimetric analysis

Using a D65/108 source and barium sulphate as the standard blank, the L*, a*, and b* values as well as K/S values of the dyed fabric samples were calculated on a CE 7000A reflectance spectrophotometer (Gretag Macbeth, UK). With UV eliminated, the specular component included, and three average settings from repeated measurements. The color yield of colored fabrics was determined using dyed samples at the wavelength of maximum absorption. An average value was calculated after each sample was measured three times in various locations. On the basis of the Kubelka–Munk equation, the value of "K/S" was derived [54].

where K (adsorption coefficient), S (scattering coefficient), and R (dyed sample reflectance). The CIE 1976 Color Space technique was used to express the color values. The color values were determined through the following coordinates: L* for lightness, a* for greenness (negative value) and redness (positive value), b* for blueness (negative value) and yellowness (positive value), C* for chroma and h* for hue angle.

Exhaustion study

By taking samples from the dye bath both before and after dying, the absorbance of azo dispersed dyes by the polyester fabrics was determined.the dye concentration (g/L) of the dye bath, diluted with 25ml ethanol, the value of λmax was determined by using spectrophotometry. Using Eqs. 1 [55], the percentage of dye bath exhaustion (%E) was calculated. The rate of exhaustion of the dyestuffs on polyester fiber was measured on polyester fibers at 100° C. The rate of exhaustion was assessed by taking samples from the dyebath at different times during the dyeing process. The dye fixation ratio was then determined using Eq. (1) after measuring the optical density of the dye bath samples spectrophotometrically at (λmax) of each dye:

where A0 and A1 are the absorbance of the dye bath before and after dyeing, respectively.

Fixation study

Refluxing the dyed samples in 50% aqueous DMF (20:1) for 15 min to extract the unfixed dye allowed to determine the percentage of the exhausted dye that was chemically bound on the fiber ( dye fixation) (% F) [56]. Until the extract was clear, this process was repeated. The concentration of the extract was then measured spectrophotometrically at (ʎmax) of each dye and the dye fixation ratio was calculated using Eq. (2):

where A0 and A1 are the absorbance of the dye bath before and after dyeing, respectively. A2 is the absorbance of the soaping solution.

Ultraviolet protective factor (UPF)

The UV Protection Factor measures how well textile materials protect the human skin from ultraviolet rays. It is measured as the ratio of the extent of time needed under continuous sunlight exposure with and without protection for the skin to become red (erythema) [57]. Equation (3) is used in the calculation of the UPF.

where, after 22 ± 2 h of continuous exposure, the minimum erythemal dose (MED) is the amount of radiant energy required to cause the first observable reddening of skin. The various ratings of UPF are mentioned in Table 1.

Biological evaluation

Antimicrobial activity of the dyes against different clinical bacterial isolates

Detailed methodology of the antimicrobial screening is mentioned in the supporting information (Section S3) and reported by Williams [58].

Results and discussions

Chemistry

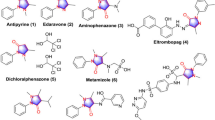

We report here the synthesis of a series of monoazo dyes based 1-(2,4-dinitrophenyl)-3-phenyl-1H-pyrazol-5-amine (1) by coupling with a variety of aromatic diazonium salts to give the corresponding 1-(2,4-dinitrophenyl)-3-phenyl-4-(substituteddiazenyl)-1H-pyrazol-5-amine (3a–d) in good yield (Scheme 1). UV–Vis, FT-IR, 1H-NMR, 13C-NMR, mass spectrometry and elemental analyses were used to confirm the structures of dyes 3a–d. the IR Spectra of all the dyes 3a-d showed absorption band in the range 3250–3294 cm−1 indicates the presence of NH2 of the pyrazole moiety, absorption band at 1656–1667 cm−1 is due to the C=N group. A strong band at 1571–1597 cm−1 is due to the N=N group. Furthermore the 1H-NMR spectra of dyes 3a–d showed the presence of a singlet signal at δ 9.20–10.05 ppm corresponding to amino (NH2) proton, which is exchangeable by D2O, and multiplet at δ 7.07–8.92 ppm corresponding to heteroaromatic moieties. 13C NMR spectrum of compound 3a–d displayed three singlet signals at δ 150.00–160.00, 149.62–153.73, due to C=N of pyrazole ring, C5 of pyrazole ring, respectively. Reaction between aldehyde group (vanillin) and primary amine (1-(2,4-dinitrophenyl)-3-phenyl-4-(substituteddiazenyl)-1H-pyrazol-5-amine) 3a-d giving Schiff base dyes with molar ratio (aldehyde and primary aromatic group) 1:1 (Scheme 2). Different spectroscopic methods and elemental analyses, were used to confirm the structures of compounds 4a–d. the IR Spectra of compounds 4a–d showed absorption band in the range 1517–1527 cm−1 indicates the presence of azomethine group (CH=N). The presence of absorption band at 1656–16,679 cm−1 is due to C=N of the pyrazole moiety. A strong band at 1563–1589 cm−1 is due to the stretching vibration of the N=N group. Furthermore the 1H-NMR spectra of dyes 4a–d showed the presence of a singlet signal at δ 8.79–9.78 ppm corresponding to azomethine (CH=N) protons, and multiplet at 6.83–8.80 ppm corresponding to heteroaromatic moieties. 13C NMR spectrum of compound 5a-d displayed singlet signals at δ 155.43–157.84, 155.80–161.32, due to C=N of pyrazole ring, CH=N group, respectively. The use of mass spectra, which consistently displayed the molecular ion peaks, further validated the structures of the synthesized dyes 4a-d and 5a-d (see experimental section).

Visible absorption spectroscopic properties of dyes 3a–d and 4a–d

At room temperature, the electronic absorption spectra of compounds 3a–d and 4a–d were determined in the polar protic solvents (ethanol), dipolar aprotic solvent (DMF), and non-polar solvent (toluene). The molar absorptivity (ε) and maximum absorption wavelength (λmax) are listed in (Table 2). Generally, changes in the nature of the substituents on amine derivatives cause variation in color of dyes. The synthesized dyes spectra revealed absorption bands in the range of λmax = 334–409 nm. This is because various overlapping π–π* and n−π* transitions of pyrazolone, aryl, and azo groups (Table 2) (Figs. 2, 3, 4 and 5).

Solvent effect on the absorption spectra

Table 2 demonstrates that the trend of the polarity sensitivity in polar aprotic solvent higher than polar aprotic solvent higher than non-polar solvent for all synthetic heterocyclic reactive dispersion dyes. The strong hydrogen bonds formed by the ethanol's hydrogen with the nitrogen, oxygen, chlorine, and fluorine centers can be blamed for the polar protic solvent ethanol's negligible contribution to the transition energy. Therefore, hydrogen bonds account for a large portion of the solute–solvent interaction. The interaction of the solute and solvent in the case of DMF as a polar aprotic solvent is primarily caused by the polar and alkaline characteristics of DMF (Figs. 2, 3, 4 and 5).

Substituent effects

All synthetic heterocyclic dyes contain π electrons that can be excited by the absorption of visible or ultraviolet light to detect the electron shell state. The electron delocalization of the conjugated system, which will impact the dyes' absorption spectrum and λmax, is significantly influenced by the substituents. Here their UV–Vis spectra were determined by the UV-2600 spectrophotometer at a concentration of 3 × 10–5 for all dyes in ethanol (polar protic solvent), DMF (dipolar aprotic solvent), and toluene (non-polar solvent) respectively. The λmax of synthesized dyes was 362–408, 358–387 and 363–380 nm, respectively. Evident bathochromic shift dyes were caused by the number and type of electron withdrawing groups contained in amine derivatives. It is clear that the electron oscillation and the presence of substituents are what cause the color variation seen for each dye. This shift's magnitude is most likely explained by the dyes' nucleus' structural modifications.

Dyeing properties of the dyes on polyester fabrics

Assessment of fastness properties

The synthesized dyes 3a–d and 4a–d was applied to polyester fabrics at 2% owf by the high-temperature pressure technique (130 °C) [59]. All of the synthesized compounds 3a–d and 4a–d shown good levelling, uniformity of coloration, and dye liquor exhaustion. These good results could be attributed to the dye particles dispersing through the polyester fabric pores and then adhering to the surface by various forces, such as hydrogen bonds, dipole–dipole forces, and van der Waals forces [60]. Additionally, it was discovered that the dyes had great washing and rubbing resistance (wet, dry). This stability could be attributed to the dyes' electron-withdrawing groups, which produced strong van der Waals forces and enabled hydrogen bonding between the dye and the fabric [59].The results obtained show that the fastness to acid and alkaline perspiration could be very good to excellent (5, 4–5); such results indicate the relative stability of the dyes in acid and alkaline medium. Most of the dyes have a very good (4, 4–5) to excellent (5) sublimation fastness due to high molecular weight of dyes which prevent the decomposition of dyes at high temperature. Most of the PET samples dyed with azo dyes were found to have very good to excellent light fastness because the presence of electron-withdrawing groups increased the ability of the azo group (–N=N–) to form intramolecular hydrogen bonds with the adjacent N=CH group, which stabilized the dye against UV light degradation [61] as shown in (Table 5). Designing disperse dyes with a vaniline Schiff base moiety would be an alternative strategy to creating universal dyes. El-Borai and coworkers synthesized a series of 5-amino pyrazole disperse dyes derivatives, and investigated their dyeing and fastness properties on PET fibers, the results show that these dyes exhibited good washing, perspiration, sublimation and rubbing fastness properties and moderate to very good light fastness properties [36, 50]. In this study, dyeing and fastness properties of a 5-amino pyrazole disperse azo dyes containing a vaniline Schiff base group on PET revealed that the newly designed dyes with vaniline moiety showed very good to excellent washing, perspiration, sublimation and rubbing fastness properties. Moreover, most of the samples azo dyes were found to have very good to excellent light fastness. Due to the ability of the azo group (–N=N–) to form intramolecular hydrogen bonds with the adjacent N=CH group which led to the strong dye–dye and dye–fiber interaction energy which prevents the dye molecule from transferring to the fiber surface and increase the affinity of dyes to fiber (Tables 3, 4, 5).

Color assessment

On PET fabrics, the dyestuff colors were expressed in terms of CIELAB values (Table 6). The reflectance spectrometer measured the following CIELAB coordinates: L* values represent color lightness; Chroma (C*) values represent color purity; hue angle (h) values, which vary from 0° to 360°, specify the color related to the principle colors; a* values represent the degree of redness (positive) and greenness (negative); and b* values represent the degree of yellowness (positive) and blueness (negative) [60]. The dyes have an excellent affinity for polyester fabrics with good levelness, brightness, and color depth, according to the color coordinates. Comparing the values of L* allows one to determine the degree of blackness or lightness of the dye on polyester fabrics. The L* values given in Table 6 show that the color lightness value (L*) of the dyes 3a–d and 4a-d vary from (38.91–67.11). Dyes 3a–d are lighter compared with 4a–d dyes. The positive values of a* (red–green axis) and the positive values of b* (yellow–blue axis) indicate that the color hues of dyes 3a–d and 4a–d on polyester fabric are along the yellow and red axis in the CIE color space. Each dye on polyester fabric is measured by comparing the chromaticity difference C* where most of dyes are brighter. The value of K/S of the dyes that applied to polyester fabrics depend on the nature of the substituent that founded on aryl group of amines (Fig. 6).

Exhaustion and fixation study

The absorbance measurements of the initial dye bath and the exhausted dye solution were used to explore the exhaustion and fixing of dyes. Table 6 displays the values for exhaustion and fixation. Exhaustion is concerned with the dye relocation from the dye bath to the fiber and is typically represented as a percentage of the dye that was first added to the dye bath. Fixation of a dye refers to the quantity of dye that has been transferred to fabric from dye that has been exhausted on fiber. Exhaustion is caused by the concentration of dye in the two phases, whereas fixation is caused by interactions between physical and chemical forces. For all dyes, the percentages of exhaustion and fixation at 2% dyeing on polyester ranged from 72 to 80% and 70 to 80%, respectively. Since the dye molecules diffuse quickly through the fabric, the rate of diffusion is high, and the dyes were strongly attracted and soluble with the fabric, good exhaustion and fixation values were observed for all dyes. Additionally, this shows that the have good compatibility with the fabrics (Fig. 7).

Ultraviolet protection factor (UPF)

It is well recognized that sun exposure is associated with various types of skin cancer, accelerated skin ageing, cataracts, and other eye disorders. There is evidence that UV light decreases the immune system's efficiency. Utilizing protective clothing in addition to avoiding the sun is considered sun protection. Reduced sun exposure, sunscreen use, and wearing protective clothing are the three main defenses against the harmful effects of UV radiation. In addition to sunscreen creams, a major portion of UV protection is provided by textiles and accessories made of textiles. Ultraviolet protection factor (UPF). It is defined as a ratio of average effective UV irradiance calculated for unprotected skin to the average UV irradiance for skin protected by the test fabric [53, 62,63,64]. Tables 7 provide the polyester fabric's UV protection factor results for all synthetic dyes. The UPF rating for dyed polyester is excellent, with a value in the range of 67.23–39.39. This means that the transmittance percentage in the UV-B region of 290–315 nm is 0.01–0.07, and the UV-A range of 315–400 nm is 0.01–0.09, respectively (blocking 100%) of the UV light. As a result, all synthesized dyes provide the textile material with excellent ultraviolet Protection. The reason that UPF values are higher on polyester fabric may be explained by the larger percentage of dye exhaustion and compact structure of polyester fabric (Fig. 8).

Antimicrobial activity

The majority of pathogenic microorganisms consistently show signs of antibiotic resistance. Therefore, extending newer sorts of antibacterial drugs is a crucial responsibility in the fight against this serious medical issue [65]. Dietary flavoring compound vanillin (4-hydroxy-3-methoxybenzaldehyde) has been shown to have antimicrobial properties when tested against a wide range of chemical and physical agents [66, 67]. The antibacterial activity of vanillin and similar derivatives was discovered to be dependent on the time of exposure, concentration, and the target organism. The synthesized compounds 3a–d and 4a–d were tested for their in vitro antibacterial activities against a panel of two-gram positive bacteria (Staphylococcus aurous, Bacillus subtilis), and two Gram-negative bacteria (Escherichia coli, Pseudomonas aeuroginosa). Also, they were examined for their antifungal activity against (Candida albicans, Aspergillus flavus). The diameter of inhibition zones (IZ) of the newly synthesized compounds were compared with the reference drugs Ampicillin and Clotrimazole. The obtained results are presented in (Table 8, Fig. 9) and showed moderate activity against tested strains, while in the same cases, some compounds exhibited very good activity to some strains only. In general, compounds 4a and 4b displayed very good activity against E. coli, P. aeruginosa, S. aureus, and B. subtilis. Moreover, compound 4c gave moderate activity against all strains of bacteria. While, compound 4d showed low antibacterial activity and compound 3d showed no antibacterial activity against tested strains.

With respect to antifungal activity, compounds 3a, 3b and 3c exhibited very good to excellent activity against C. Albicans and A. flavus. Moreover, compound 4a and 4b gave moderate activity against all strains of fungi. While, compound 4d showed low antifungal activity and compound 3d showed no antifungal activity against tested strains. They demonstrated that the change in the structure of the tested compounds strongly affected on the antimicrobial activity.

Conclusions

Furthermore, their remarkable degree of evenness indicates their good diffusion, penetration and fabric affinity. The newly synthesized dyes also exhibited antibacterial properties, which render them promising as safe disperse dyes for fabrics with antibacterial effect. Considering that the synthesis of these dyes is simple and inexpensive and that they show dyeing qualities comparable to those of commercial dyes, this study provides access to a new group of dyes to satisfy the growing demand for dyes in the textile industry. Additionally, their remarkable level of evenness demonstrates good fabric affinity, diffusion, and penetration. The newly synthesized dyes showed antibacterial activity which render them promising as safe disperse dyes for fabrics with antibacterial effect. This work offers access to a new category of dyes to meet the expanding demand for dyes in the textile industry because the synthesis of these dyes is easy and inexpensive and they exhibit dyeing properties equivalent to those of commercial dyes.

References

J. Oh, S.S. Kim, K.H. Kim, J. Lee, C. Kang, J. Supercrit. Fluid. 170, 105 (2021)

S. Yu, H. Zhang, L. Pei, S. Liang, A. Dong, J. Wang, Fibers. Polym. 23, 443 (2022)

L. Jin, T. Qian, T. Zhu, R.L. Wang, W.G. Chen, H. Jiang, Z.H. Cui, Fibers Polym. 23, 1040 (2022)

J. Koh, Dyes Pigm. 64, 17 (2005)

V.G. Vidya, V. Sadasivan, Asian. J. Chem. 30, 2049 (2018)

H. Yousefi, A. Yahyazadeh, E.M. Rufchahi, M. Rassa, J. Mol. Liq. 180, 51 (2013)

H.F. Rizk, S.A. Ibrahim, M.A. El-Borai, Dyes Pigm. 112, 86 (2015)

A. Demirçalı, F. Karcı, O. Avinc, A.U. Kahrıman, G. Gedik, E. Bakan, J. Mol. Struct. 1181, 8 (2019)

A.Z. Sayed, M.S. Aboul-Fetouh, H.S. Nassar, J. Mol. Struct. 1010, 146 (2012)

S. Benkhaya, S. M’rabet, A. El Harfi, Heliyon 6(1), e03271 (2020)

I.J. Al-Busaidi, A. Haque, N.K. Al Rasbi, M.S. Khan, Synth. Met. 257, 116 (2019)

O.A. Adegoke, T.E. Adesuji, O.E. Thomas, Spectrochim. Acta. A. Mol. Biomol. Spectrosc. 128, 147 (2014)

M. Luka, T. Nikola, T. Nemanja, L. Jelena, V. Vesna, V. Željko, G. Branimir, M. Dušan, Turk. J. Chem. 43, 1183 (2019)

M. Poddar, R. Misra, Coord. Chem. Rev. 421, 213462 (2020)

J.A. Mikroyannidis, D.V. Tsagkournos, P. Balraju, G.D. Sharma, J. Power. Sour. 196, 4152 (2011)

A.Y. Al-Ahmad, Q.M. Hassan, H.A. Badran, K.A. Hussain, Opt. Laser. Technol. 44(5), 1450 (2012)

M. Erfantalab, H. Khanmohammadi, Spectrochim. Acta. A. Mol. Biomo.l Spectrosc. 125, 345 (2014)

F. Yıldırım, A. Demirçalı, F. Karcı, A. Bayrakdar, P.T. Taşlı, H.H. Kart, J Mol. Liq. 223, 557 (2016)

M.R. Yazdanbakhsh, H. Yousefi, M. Mamaghani, E.O. Moradi, M. Rassa, H. Pouramir, M. Bagheri, J. Mol. Liq. 169, 21 (2012)

G.K. Weldegebrieal, Inorg. Chem. Commun. 120, 108140 (2020)

B.N. Ravi, J. Keshavayya, V. Kumar, S. Kandgal, J. Mol. Struct. 1204, 127493 (2020)

B. Manjunatha, Y.D. Bodke, J. Mol. Struct. 1244, 130933 (2021)

K. Singh, R. Pal, S.A. Khan, B. Kumar, M.J. Akhtar, J. Mol. Struct. 1237, 30369 (2021)

A.L. Alanzy, D.A. Bakhotm, R.M. Abdel-Rahman, Int. J. Org. Chem. 10(02), 39 (2020)

H.F. Rizk, A.A. Noser, S.A. Ibrahim, A.K. Fares, J. Heterocycl. Chem. 59, 2190 (2022)

A.A. Noser, I.A. Shehadi, A.H. Abdelmonsef, M.M. Salem, ACS Omega 7(29), 25265–25277 (2022)

A.A. Noser, A.H. Abdelmonsef, M.M. Salem, Bioorg. Chem. 131, 106299 (2023)

A. Demirçalı, J. Mol. Struct. 1231, 129960 (2021)

K. Karrouchi, S. Radi, Y. Ramli, J. Taoufik, Y.N. Mabkhot, F.A. Al-aizari, Molecules 23(1), 134 (2018)

A. Saeed, M.A. Nasher, E. Abdel-Latif, E.M. Keshk, A.M. Khalil, H.M. Metwally, Optik 196, 163036 (2019)

V.R. Mishra, C.W. Ghanavatkar, N.N. Sekar, Spectrochim. Acta A Mol. Biomol. 223, 117353 (2019)

M. Lusardi, A. Spallarossa, C. Brullo, Int. J. Mol. Sci. 24(9), 7834 (2023)

E. Bakan, F. Karcı, J. Eng. Sci. 5(2), 78–94 (2022)

A.M. Al-Etaibi, M.A. El-Apasery, Polymers 14, 1703 (2022)

S. Nitu, M.S. Mile, B. Sorina, G. Mosoarca, A.D. Zamfir, S. Popa, S. Funar Timofei, Materials 15(16), 5507 (2022)

H.F. Rizk, S.A. Ibrahim, M.A. El-Borai, Arab. J. Chem. 10(2), S3303 (2017)

Z. Zhai, Y. Ren, C. Shu, D. Chen, X. Liu, Y. Liang, A. Li, J. Zhou, Cell Death Discov. 8, 169 (2022)

K.R.A. Abdellatif, E.K.A. Abdellal, P.F. Lamie, M.B. Labib, E.S. El-Nahaas, M.M. Abdelhakeem, Bioorg. Chem. 95, 103540 (2019)

P. Modi, S. Patel, M. Chhabria, Mol. Divers. 2022.

M. Verma, R.K. Gupta, R.K. Nema, U. Misra, Int. J. Chem. Sci. 6, 179 (2008)

A.M.S. Hebishy, H.T. Salama, G.H. Elgemeie, ACS Omega 5, 25104 (2020)

G. Singh, P. Chandra, N. Sachan, Int. J. Pharm. Sci. Rev. Res. 65(1), 201–214 (2020)

A.M. Hassan, A. Osman Said, B.H. Heakal, A. Younis, M.A. Abdelmoaz, M.M. Abdrabou, Adv. J. Chem. 3, 621 (2020)

H. Bahron, S.S. Khaidir, A.M. Tajuddin, K. Ramasamy, B.M. Yamin, Polyhedron 161, 84 (2019)

D. Majumdar, D.K. Singh, D.K. Pandey, D. Parai, K. Bankura, D. Mishra, J. Mol. Struct. 1209, 127936 (2020)

N. Turan, K. Buldurun, Y. Alan, A. Savci, N. Çolak, A. Mantarcı, Res. Chem. Intermed. 45, 3525 (2019)

S. Gao, Z. Cheng, X. Zhou, Y. Liu, J. Wang, C. Wang, D. Zhang, Chem. Eng. J. 394, 124896 (2020)

H.F. Rizk, M.A. EI-Badawi, S.A. Ibrahim, M.A. El-Borai, Chin. J. Chem. 29, 1451 (2011)

H.F. Rizk, M.A. EI-Badawi, S.A. Ibrahim, M.A. El-Borai, J. Korean. Chem. Soc. 154, 737 (2010)

H.F. Rizk, M.A. Ei-Badawi, S.A. Ibrahim, M.A. El-Borai, Arabian. J. Chem. 4, 37 (2011)

M.A. Metwally, E. Abdel-Latif, F.A. Amer, G. Kaupp, Dyes Pigm. 60, 249 (2004)

M.N. El-Nahass, E.A. Bakr, M.M. El-Gamil, S.A. Ibrahim, Appl. Organomet. Chem. 36, 665 (2022)

S.A. Ibrahim, H.F. Rizk, Text. Res. J. 92, 2849 (2022)

F.W. Billmeyer, M. Saltzman, J. Wiley and S. Principles of color technology. Inc, New York. 1981.

J. Cai, H. Jiang, W. Chen, Z. Cui, Dyes Pigm. 179, 108385 (2020)

W. Ma, S. Du, S. Yan, X. Yu, Z.Z.S. Zhang, Polymja. 12, 462 (2020)

V.R. Mishra, C.W.S.N. Ghanavatkar, Spectrochim. Acta. Part. A. Mol. Biomol. Spectrosc. 223, 117353 (2019)

W. Brand-Williams, M.E. Cuvelier, C.L. Berset, L.W.T. Food, Sci. Technol. 28, 25 (1995)

Y.A. Youssef, M.M. Kamel, M.S. Taher, J. Saudi. Chem. Soc. 18, 220 (2014)

K. Asnake, W. Amare, J. Chem. (2020). https://doi.org/10.1155/2020/6628404

T. Abou Elmaaty, F. El-Taweel, S. Abdeldayem, A. Abou, J. Heterocycl. Chem. 56, 922 (2019)

W.S. Hamama, M.E. Ibrahim, A.A. Gooda, H.H. Zoorob, J. Heterocycl. Chem. 5, 2623 (2018)

E. Louris, E. Sfiroera, G. Priniotakis, R. Makris, H. Siemos, C. Efthymiou, M.N. Assimakopoulos, Mater. Sci. Eng. 459, 012051 (2019)

A.I. Seham, F.R. Hala, S.A. Dina, R. Ahmed, Dyes Pigm. 193, 109504 (2021)

Y. Rakesh, S. Dharamvir, Y. Divya, Turk. J. Pharm. Sci. 15(1), 57 (2018)

M. Leeb, Nature 431, 892 (2004)

M.B. Hocking, J. Chem. Educ. 74, 1055 (1997)

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Contributions

AAN: contributed to Conceptualization; data curation; formal analysis; funding acquisition; investigation; methodology; resources; writing—review and editing. SE: contributed to Conceptualization; data curation; formal analysis; funding acquisition; investigation; methodology; resources; writing—review and editing. HAAES: contributed to data curation, investigation, methodology, and writing—original draft. NMAE-E: data curation, investigation, methodology. HSAM: Data curation; formal analysis; investigation; methodology; resources; validation.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Noser, A.A., Ibrahim, S.A., Abd El Salam, H.A. et al. Pyrazole-vaniline Schiff base disperse azo dyes for UV protective clothing: synthesis, characterization, comparative study of UPF, dyeing properties and potent antimicrobial activity. J IRAN CHEM SOC 20, 2963–2976 (2023). https://doi.org/10.1007/s13738-023-02891-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13738-023-02891-x