Abstract

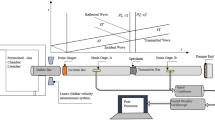

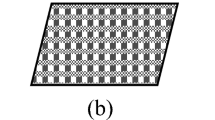

The emerging needs for lightweight structural materials with high performance eagerly await the hybridization of materials with high stiffness and toughness. Kevlar polymer composites protect against ballistic impacts and sharp objects but suffer from poor compressive strength and stiffness. This work attempts to hybridize Kevlar and carbon yarns in the fabrics used to fabricate the composite and evaluate the effects of carbon fiber hybridization on the mechanical performance of hybrid fabric composites. Intraply hybridized carbon–Kevlar (C–K) composite laminates are manufactured through a vacuum-assisted resin transfer molding process. Performance parameters, such as strength and failure limits, of the composites are experimentally evaluated under tensile, compressive, flexural, and low-velocity impact loading. Warp and weft, both directions, are considered for load application under each testing category, enabling the performance evaluation in longitudinal and transverse directions. Scanning electron microscopy is used to identify the breaking patterns and failure mechanisms of fibers, matrix, and overall laminates. The mechanical test results indicate that the hybridization pattern and direction of carbon yarn in the carbon–Kevlar hybrid fabric significantly affect the modulus and strength. The tabulated test data claim that elastic modulus increases by 30% equal to 10.18 GPa under tensile loading, flexural modulus by 29% equal to 36.9 GPa under three-point bend loading and the compressive strength by 57% equal to 166 MPa under compression loading geometry for C–K composites having carbon yarns in load direction when compared with the monolithic Kevlar composites. The results may indicate the suitability of C–K hybrid composites in structural applications that require high strength and optimal protection against ballistic impacts in defense and aviation sectors.

Graphical abstract

Similar content being viewed by others

Data Availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Chawla KK (2012) Composite materials: science and engineering, 3rd edn. Springer, New York

Jensen EM, Leonhardt DA, Fertig RS (2015) Effects of thickness and fiber volume fraction variations on strain field inhomogeneity. Compos A 69:178–185

Priyanka P, Dixit A, Mali HS (2017) High-strength hybrid textile composites with carbon, Kevlar, and E-glass fibers for impact-resistant structures. Review Mech Compos Mater 53:685–704

Sun Z, Hu X, Chen H (2014) Effects of aramid-fibre toughening on interfacial fracture toughness of epoxy adhesive joint between carbon-fibre face sheet and aluminum substrate. Int J Adhes Adhes 48:288–294

Dixit A, Mali HS, Misra RK (2015) Investigation of the thermomechanical behavior of a 2 × 2 twill weave fabric advanced textile composite. Mech Compos Mater 51:253–264

Horrocks AR (2011) Flame retardant challenges for textiles and fibres: new chemistry versus innovatory solutions. Polym Degrad Stab 96:377–392

Bandaru AK, Chavan V, Ahmad S, Alagirusamy R, Bhatnagar N (2016) Ballistic impact response of Kevlar® reinforced thermoplastic composite armors. Int J Impact Eng 89:1–13

Priyanka P, Dixit A, Mali HS (2019) High strength Kevlar fiber reinforced advanced textile composites. Iran Polym J 28:621–638

Abounaim M, Diestel O, Hoffmann G, Cherif C (2011) High performance thermoplastic composite from flat knitted multi-layer textile preform using hybrid yarn. Compos Sci Technol 71:511–519

Yahaya R, Sapuan SM, Jawaid M, Leman Z, Zainudin ES (2016) Effect of fibre orientations on the mechanical properties of kenaf-aramid hybrid composites for spall-liner application. Def Technol 12:52–58

Fidan S, Sinmazcelik T, Avcu E, Bora MO, Coban O (2012) Detecting impact damages in an aramid/glass fiber reinforced hybrid composite with micro tomography. J Adv Mater Res 445:9–14

Xing J, Hsiao GC, Chou TW (1981) A dynamic explanation of the hybrid effect. J Compos Mater 15:443–461

Kretsis G (1987) A review of the tensile, compressive, flexural and shear properties of hybrid fibre-reinforced plastics. Composites 18:13–23

Bulut M, Erklig A, Eyup Y (2015) Experimental investigation on influence of Kevlar fiber hybridization on tensile and damping response of Kevlar/glass/epoxy resin composite laminates. J Compos Mater 50:1–12

da Silva AAX, Scazzosi R, Manes A, Amico SC (2021) High-velocity impact behavior of aramid/S2-glass interply hybrid laminates. Appl Compos Mater 28:1899–1917

Swolfs Y, Gorbatikh L, Verpoest I (2014) Fibre hybridization in polymer composites: a review. Compos A 67:181–200

Song JH (2015) Pairing effect and tensile properties of laminated high-performance hybrid composites prepared using carbon/glass and carbon/aramid fibers. Compos B 79:61–66

Abd El-baky MA (2018) Impact performance of hybrid laminated composites with statistical analysis. Iran Polym J 27:445–459

Zafar HMN, Nair F (2022) Comparison of static/dynamic loading and tensile behavior of interply and intraply hybridized carbon/basalt epoxy composites. Appl Compos Mater 29:451–472

Yeung KKH, Rao KP (2012) Mechanical properties of Kevlar-49 fibre reinforced thermoplastic composites. Polym Polym Compos 20:411–424

Chen Q, Zhao Y, Zhou Z, Rahman A, Wu XF, Wu W, Xu T, Fong H (2013) Fabrication and mechanical properties of hybrid multi-scale epoxy composites reinforced with conventional carbon fiber fabrics surface-attached with electrospun carbon nanofiber mats. Compos B 44:1–7

Aronhime J, Harel H, Gilbert A, Marom G (1992) The rate-dependence of flexural shear fatigue and uniaxial compression of carbon- and aramid-fibre composites and hybrids. Compos Sci Technol 43:105–116

Bejan L, Taranu N, Sîrbu A (2013) Effect of hybridization on stiffness properties of woven textile composites. Appl Compos Mater 20:185–194

Valenҫa SL, Griza S, De Oliveira VG, Sussuchi EM, Cunha FGC (2015) Evaluation of the mechanical behavior of epoxy composite reinforced with Kevlar plain fabric and glass/Kevlar hybrid fabric. Compos B 70:1–8

Behera BK, Dash BP (2015) Mechanical behavior of 3D woven composites. Mater Des 67:261–271

Masoumi M, Mansoori H, Dastan T, Sheikhzadeh M (2021) Intralayer hybridization of triaxially braided composite lamina using carbon and basalt fibers: experimental and numerical study. Compos Struct 267:113896

Masoumi M, Mansoori H, Dastan T, Sheikhzadeh M (2022) An experimental investigation into flexural properties of hybrid carbon-basalt triaxially braided composite lamina. Compos Struct 284:115231

Shekarchizadeh N, Jafari NR, Dastan T, Hasani H (2021) Experimental and numerical study on stiffness and damage of glass/epoxy biaxial weft-knitted reinforced composites. J Reinf Plast Compos 40:70–83

Hufenbach W, Böhm R, Kroll L, Langkamp A (2004) Theoretical and experimental investigation of anisotropic damage in textile-reinforced composite structures. Mech Compos Mater 40:519–532

Guermazi N, Haddar N, Elleuch K, Ayedi HF (2014) Investigations on the fabrication and the characterization of glass/epoxy, carbon/epoxy and hybrid composites used in the reinforcement and the repair of aeronautic structures. Mater Des 56:714–724

Cao S, Chen Q, Wang Y, Xuan S, Jiang W, Gong X (2017) High strain-rate dynamic mechanical properties of Kevlar fabrics impregnated with shear thickening fluid. Compos A 100:161–169

Hossain MM, Khan MA, Khan RA, Siddiquee MAB, Islam T (2015) Carbon/Kevlar reinforced hybrid composite: impact of matrix variation. In: Proc, Int Conf Mech Eng Renew Energy, Chittagong, Bangladesh. ICMERE2015-PI-216, pp 26–29. https://www.researchgate.net/publication/303825766_CARBONKEVLAR_REINFORCED_HYBRID_COMPOSITE_IMPACT_OF_MATRIX_VARIATION. Accessed 2 Feb 2023

Moezzi M, Ghane M, Nicoletto G, Nedoushan RJ (2014) Analysis of the mechanical response of a woven polymeric fabric with locally induced damage. Mater Des 54:279–290

Dickson AN, Barry JN, McDonnell KA, Dowling DP (2017) Fabrication of continuous carbon, glass and Kevlar fibre reinforced polymer composites using additive manufacturing. Addit Manuf 16:146–152

Bulut M, Erkliğ A (2018) The investigation of quasi-static indentation effect on laminated hybrid composite plates. Mech Mater 117:225–234

Bandaru AK, Mittal VK, Ahmad S, Bhatnagar N (2017) Influence of hybridization on in-plane shear properties of 2D & 3D thermoplastic composites reinforced with kevlar/basalt fabrics. Polym Test 61:396–403

Grimsley BW, Hubert P, Song X, Langley N (2001) Flow and Compaction During the Vacuum. NASA Langley Research Center, Hampton, VA, United States

Priyanka P, Mali HS, Dixit A (2020) Dynamic mechanical behaviour of Kevlar and carbon-Kevlar hybrid fibre reinforced polymer composites. J Mech Eng Sci 235:4181–4193

Hannibal P (2015) Compressibility Measurement and Modeling to Optimize Flow Simulation of Vacuum Infusion Processing for Composite Materials. Brigham Young University, Provo. Theses and Dissertations 4433

Pincheira G, Canales C, Medina C, Ferna’ndez E, Flores P (2015) Influence of aramid fibers on the mechanical behavior of a hybrid carbon/aramid-reinforced epoxy composite. J Mater Des Appl 232:58–66

Zhang J, Chaisombat K, He S, Wang CH (2012) Hybrid composite laminates reinforced with glass/carbon woven fabrics for lightweight load bearing structures. Mater Des 36:75–80

Zahid B, Chen X (2012) Properties of 5-layer angle-interlock Kevlar-based composite structure manufactured from vacuum bagging. J Compos Mater 47:3227–3234

Guled FD, Chittappa HC (2020) Effect of inter-ply hybridization on flexural and dynamic mechanical properties of carbon-Kevlar/epoxy hybrid composites. AIP Conf Proc 2274:30023

Wan YZ, Chen GC, Huang Y, Li QY, Zhou FG, Xin JY, Wang YL (2005) Characterization of three-dimensional braided carbon/Kevlar hybrid composites for orthopedic usage. Mater Sci Eng A 398:227–232

Delavari K, Safavi A (2022) The effect of stacking sequence on high-velocity impact resistance of hybrid woven reinforced composites: experimental study and numerical simulation. Fibers Polym 23:184–195

Leopold C, Schütt M, Liebig WV, Philipkowski T, Kürten J, Schulte K, Fiedler B (2017) Compression fracture of CFRP laminates containing stress intensifications. Materials 10:1039

Acknowledgements

The research work has been financially supported by the Defense Research and Development Organization-ARMREB, Govt. of India under Grant No: ARMREB/MAA/2019/213.

Author information

Authors and Affiliations

Contributions

PP: conceptualization, methodology, investigation, visualization, writing—original draft preparation; HSM: supervision, visualization, writing—reviewing and editing; AD: visualization, writing—reviewing and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no competing interests to declare that are relevant to the content of this article. The authors declare no conflict of interest concerning the research, authorship, and/or publication of this article.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Priyanka, P., Mali, H.S. & Dixit, A. Carbon–Kevlar intraply hybrid fabric polymer composites: mechanical performance. Iran Polym J 32, 633–645 (2023). https://doi.org/10.1007/s13726-023-01150-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-023-01150-3