Abstract

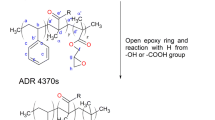

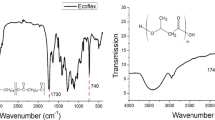

The effects of different processing parameters of an internal mixer connected to a torque rheometer were studied on a blend containing 70% (by wt) poly(butylene succinate) (PBS) and 30% (by wt) poly(butylene adipate-co-terephthalate) (PBAT). Different conditions were evaluated for various processing parameters, such as temperature (120, 135, and 150 °C), mixing time (3, 4.5, and 6 min), and screw rotation (50, 75, and 100 rpm). The developed blends' rheological, structural and thermomechanical properties were analyzed through tensile strength, Fourier transform infrared spectroscopy (FTIR), parallel plate rheometry, differential scanning calorimetry (DSC) and dynamic mechanical thermal analysis (DMTA). The response graphics for the analysis of tensile strength tests suggested that lower temperature and screw rotation would favor transesterification. The rheological results showed higher storage modulus (G') and complex viscosity (ƞ*) values for the blend processed at a lower temperature (120 °C), screw rotation (50 rpm), and extended mixing time (6 min), corroborating with previous tensile strength test results. An increase in the carbonyl groups interaction was observed by FTIR spectrum, indicating that transesterification occurred. Blends’ crystallinity presented no significant change by DSC analysis. The improved thermomechanical properties suggested that transesterification occurred due to specific processing parameters. The increase in compatibility between the polymers led to improved thermomechanical and rheological properties without any significant changes in blends’ crystallinity.

Graphical abstract

Similar content being viewed by others

Data availability

All the data that supports the findings of our work are available in a private and online repository. The authors confirm that all relevant data are included in the article, but the link for sharing and accessing the files can be provided under request.

References

Ravati S, Favis B (2013) Tunable morphologies for ternary blends with poly(butylene succinate): partial and complete wetting phenomena. Polymer 54:3271–3281

Threepopnatkul P, Charoendee N, Wiriyamontree N, Phodaeng A (2022) Effect of essential oil on properties of PBAT/PBS for bio-packaging films. J Phys: Conf Ser, IOP Publishing

Nobile M, Crocitti A, Malinconico M, Santagata G, Cerruti P (2018) Preparation and characterization of polybutylene succinate (PBS) and polybutylene adipate-terephthalate (PBAT) biodegradable blends. AIP Conf Proc, AIP LLC

Su S (2022) Compatibilization, processing and characterization of poly(butylene adipate terephthalate)/polylactide (PBAT/PLA) blends. Mater Res Exp 9:025308

Lopes H, Oliveira G, Talabi S, Lucas A (2021) Production of thermoplastic starch and poly(butylene adipate-co-terephthalate) films assisted by solid-state shear pulverization. Carbohydr Polym 258:117732

Fourati Y, Tarrés Q, Mutjé P, Boufi S (2018) PBAT/thermoplastic starch blends: effect of compatibilizers on the rheological, mechanical and morphological properties. Carbohydr Polym 199:51–57

Siracusa V, Lotti N, Munari A, Dalla Rosa M (2015) Poly(butylene succinate) and poly(butylene succinate-co-adipate) for food packaging applications: gas barrier properties after stressed treatments. Polym Degrad Stabil 119:35–45

Ayu R, Khalina A, Harmaen A, Zaman K, Jawaid M, Lee C (2018) Effect of modified tapioca starch on mechanical, thermal, and morphological properties of PBS blends for food packaging. Polymers 10:1187

Oliveira G, Maia T, Talabi S, Canto L, Lucas A (2021) Characterization of cellulose nano/microfibril reinforced polypropylene composites processed via solid-state shear pulverization. Polym Compos 42:1371–1382

Kim YJ, Park OO (1999) Miscibility and biodegradability of poly(butylene succinate)/poly(butylene terephthalate) blends. J Environ Polym Degrad 7:53–66

Kim HS, Lee BH, Choi SW, Kim S, Kim HJ (2007) The effect of types of maleic anhydride-grafted polypropylene (MAPP) on the interfacial adhesion properties of bio-flour-filled polypropylene composites. Compos Part A: Appl Sci Manuf 38:1473–1482

John J, Mani R, Bhattacharya M (2002) Evaluation of compatibility and properties of biodegradable polyester blends. J Polym Sci Part A: Polym Chem 40:2003–2014

Jayakannan M, Anilkumar P (2004) Mechanistic aspects of ester–carbonate exchange in polycarbonate/cycloaliphatic polyester with model reactions. J Polym Sci Part A: Polym Chem 42:3996–4008

Muthuraj R, Misra M, Mohanty A (2014) Biodegradable poly(butylene succinate) and poly(butylene adipate-co-terephthalate) blends: reactive extrusion and performance evaluation. J Polym Environ 22:336–349

Cai Y, Lv J, Feng J (2013) Spectral characterization of four kinds of biodegradable plastics: poly(lactic acid), poly(butylenes adipate-co-terephthalate), poly(hydroxybutyrate-co-hydroxyvalerate) and poly(butylenes succinate) with FTIR and Raman spectroscopy. J Polym Environ 21:108–114

Peng Y, Nair S, Chen H, Yan N, Cao J (2018) Effects of lignin content on mechanical and thermal properties of polypropylene composites reinforced with micro particles of spray dried cellulose nanofibrils. ACS Sustain Chem Eng 6:11078–11086

Zaverl M, Valerio O, Misra M, Mohanty A (2015) Study of the effect of processing conditions on the co-injection of PBS/PBAT and PTT/PBT blends for parts with increased bio-content. J Appl Polym Sci 132:2

Canevarolo S (2019) Polymer science: a textbook for engineers and technologists: Carl Hanser Verlag GmbH Co KG

Wu F, Misra M, Mohanty A (2019) Novel tunable super-tough materials from biodegradable polymer blends: nano-structuring through reactive extrusion. RSC Adv 9:2836–2847

Wu F, Misra M, Mohanty A (2019) Super toughened poly(lactic acid)-based ternary blends via enhancing interfacial compatibility. ACS Omega 4:1955–1968

Wu F, Misra M, Mohanty A (2020) Tailoring the toughness of sustainable polymer blends from biodegradable plastics via morphology transition observed by atomic force microscopy. Polym Degrad Stabil 173:109066

Wu F, Misra M, Mohanty A (2020) Sustainable green composites from biodegradable plastics blend and natural fibre with balanced performance: synergy of nano-structured blend and reactive extrusion. Compos Sci Technol 200:108369

de Matos CA, Crocitti A, Hecker de Carvalho L, Carroccio SC, Cerruti P, Santagata G (2020) Properties of biodegradable films based on poly(butylene succinate) (PBS) and poly(butylene adipate-co-terephthalate) (PBAT) blends. Polymers 12:2317

Boonprasertpoh A, Pentrakoon D, Junkasem J (2017) Investigating rheological, morphological and mechanical properties of PBS/PBAT blends. J Metal Mater Miner 27:2

Boonprasertpoh A, Pentrakoon D, Junkasem J (2020) Effect of PBAT on physical, morphological, and mechanical properties of PBS/PBAT foam. Cell Polym 39:31–41

Acknowledgements

This work was supported by Coordenação de Aperfeiçoamento de Pessoal de Nível Superior, Brasil (Capes), Finance Code 001.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lopes, H.S.M., de Oliveira, G.H.M., Maia, T.H.S. et al. Transesterification of poly(butylene adipate-co-terephthalate) (PBAT) and poly(butylene succinate) (PBS) blends: variations in some processing parameters. Iran Polym J 32, 313–324 (2023). https://doi.org/10.1007/s13726-022-01133-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-022-01133-w