Abstract

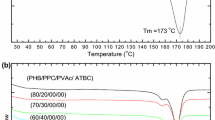

Polyhydroxybutyrate (PHB) is a biodegradable polymer, and preparation of a blend with another biodegradable polymer, polybutylene adipate terephthalate or Ecoflex® (ECO) is described. Some works in the previous literature show the possibility of preparing blends involving both. The techniques normally used previously described normally an extrusion process or even mixers that require high investment such as HAAKE Rheomix, for example. The main contribution is use of an original and simple technique, especially with low cost in relation to the earlier works described elsewhere. Obtaining solutions of both polymers and studies of miscible mixtures is the basis of the blending preparation process. The mass percentage ratios used to prepare the blends were 5, 10 and 20% ECO in PHB. Fourier transform infrared spectroscopy, scanning electron microscopy (SEM) and dynamic-mechanical thermal analysis (DMA) were used for characterization of blends. It was observed an increase in the flexibility of blends when compared to PHB as pointed out in the recent literature. By using SEM, it was concluded that there is interaction between the phases present in the blend and this interaction benefits miscibility. The results obtained by the DMA analyses in flexion modulus and by the differential scanning calorimetry (DSC) curves showed miscibility is dependent on ECO concentration as expected.

Similar content being viewed by others

References

Coutinho BC, Miranda GB, Sampaio GR, et al (2007) Importance and advantages of polyhydroxybutyrate (biodegradable plastic). HOLOS 3:76. https://doi.org/10.15628/holos.2004.49

Botaro VR, Novack KM, Siqueira ÉJ (2012) Dynamic mechanical behavior of vinylester matrix composites reinforced by Luffa cylindrica modified fibers. J Appl Polym Sci 124:1967–1975. https://doi.org/10.1002/app.35019

Landim APM, Bernardo CO, Martins IBA et al (2016) Sustainability concerning food packaging in Brazil. Polimeros 26:82–92. https://doi.org/10.1590/0104-1428.1897

Carmo KP, Paiva JMF (2015) Biodegradable films and starch compositions with other materials. Rev Virtual Quim 7:2377–2386. https://doi.org/10.5935/1984-6835.20150141

Baran A, Vrábel P, Olčák D, Chodák I (2018) Solid state 13 C-NMR study of a plasticized PLA/PHB polymer blend. J Appl Polym Sci 135:46296. https://doi.org/10.1002/app.46296

Sadi RK, Fechine GJM, Demarquette NR (2013) Effect of prior photodegradation on the biodegradation of polypropylene/poly(3-hydroxybutyrate) blends. Polym Eng Sci. https://doi.org/10.1002/pen.23471

Lai S-M, Sun W-W, Don T-M (2015) Preparation and characterization of biodegradable polymer blends from poly(3-hydroxybutyrate)/poly(vinyl acetate)-modified corn starch. Polym Eng Sci 55:1321–1329. https://doi.org/10.1002/pen.24071

de Mesquita PJP, Araújo RdeJ, de Carvalho LH et al (2016) Thermal evaluation of PHB/PP- g -MA blends and PHB/PP-g-MA/vermiculite bionanocomposites after biodegradation test. Polym Eng Sci 56:555–560. https://doi.org/10.1002/pen.24279

El-Taweel SH, Al-Ahmadi AO (2020) Thermal behavior and soil biodegradation for blends of poly(hydroxybutyrate)/ethylene vinyl acetate copolymer (EVA 60) with 1 mass% NH4Cl. Polym Bull. https://doi.org/10.1007/s00289-020-03129-z

Seoane IT, Cerrutti P, Vazquez A et al (2019) Ternary nanocomposites based on plasticized poly(3-hydroxybutyrate) and nanocellulose. Polym Bull 76:967–988. https://doi.org/10.1007/s00289-018-2421-z

Fonseca FMC, Oréfice RL, De Oliveira Patricio PS (2014) Effect of the incorporation of TiO2 nanoparticles on the behavior of polypropylene-poly(hydroxybutyrate) blends submitted to accelerated aging tests. Polimeros 24:395–401. https://doi.org/10.4322/polimeros.2014.022

De Freitas RRM, Botaro VR (2018) Biodegradation behavior of cellulose acetate with ds 2. 5 in simulated soil. Int J Chem Mol Eng 12:347–351

Casarin SA, Agnelli JAM, Malmonge SM, Rosário F (2013) Biodegradable PHB/copolyester blends—biodegradation in soil. Polimeros 23:115–122. https://doi.org/10.1590/S0104-14282013005000003

Rosa DS, Franco BLM, Calil MR (2001) Biodegradability and mechanical properties of polymeric mixtures. Polímeros 11:82–88. https://doi.org/10.1590/s0104-14282001000200010

Roy N, Saha N, Kitano T, Saha P (2012) Biodegradation of PVP-CMC hydrogel film: a useful food packaging material. Carbohydr Polym 89:346–353. https://doi.org/10.1016/j.carbpol.2012.03.008

Milošević M, Krkobabić A, Radoičić M et al (2017) Biodegradation of cotton and cotton/polyester fabrics impregnated with Ag/TiO2 nanoparticles in soil. Carbohydr Polym 158:77–84. https://doi.org/10.1016/j.carbpol.2016.12.006

Ikejima T, Inoue Y (2000) Crystallization behavior and environmental biodegradability of the blend films of poly(3-hydroxybutyric acid) with chitin and chitosan. Carbohydr Polym 41:351–356. https://doi.org/10.1016/S0144-8617(99)00105-8

Marlina D, Sato H, Hoshina H, Ozaki Y (2018) Intermolecular interactions of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (P(HB-co-HV)) with PHB-type crystal structure and PHV-type crystal structure studied by low-frequency Raman and terahertz spectroscopy. Polymer (Guildf) 135:331–337. https://doi.org/10.1016/j.polymer.2017.12.030

Gonzalez A, Irusta L, Fernández-Berridi MJ et al (2004) Miscibility behaviour of amorphous poly(3-hydroxybutyrate) (a-PHB)/styrene-vinyl phenol copolymer (STY-co-VPH) blends applying an association model. Polymer (Guildf) 45:1477–1483. https://doi.org/10.1016/j.polymer.2003.12.053

El-Hadi AM (2011) Effect of processing conditions on the development of morphological features of banded or nonbanded spherulites of poly(3-hydroxybutyrate) (PHB) and polylactic acid (PLLA) blends. Polym Eng Sci 51:2191–2202. https://doi.org/10.1002/pen.21991

Souza D, Sánchez Rodríguez RJ, Gomes da Silva M et al (2016) Compatibilization of cellulose acetate/poly(3-hydroxybutyrate) blends by grafting copolymer. Polym Eng Sci 56:689–696. https://doi.org/10.1002/pen.24295

Don T-M, Chung C-Y, Lai S-M, Chiu H-J (2010) Preparation and properties of blends from poly(3-hydroxybutyrate) with poly(vinyl acetate)-modified starch. Polym Eng Sci 50:709–718. https://doi.org/10.1002/pen.21575

De Faria AU, Martins-Franchetti SM (2010) Biodegradation of polypropylene (PP), Poly(3-hydroxybutyrate) (PHB) films and PP/PHB blend by microorganisms from Atibaia river. Polimeros 20:141–147. https://doi.org/10.1590/S0104-14282010005000024

Moraes MFV de (2005) Produção e caracterização da blenda polimérica biodegrável poli(hidroxibutirato)[PHB]/Co-poliéster alifático aromático [ecoflex] para aplicações em embalagens. Dissertation, Universidade Federal de Ouro Preto

Morro A, Catalina F, Corrales T et al (2016) New blends of ethylene-butyl acrylate copolymers with thermoplastic starch. Characterization and bacterial biodegradation. Carbohydr Polym 149:68–76. https://doi.org/10.1016/j.carbpol.2016.04.075

Garcia-Garcia D, Ferri JM, Boronat T et al (2016) Processing and characterization of binary poly(hydroxybutyrate) (PHB) and poly(caprolactone) (PCL) blends with improved impact properties. Polym Bull 73:3333–3350. https://doi.org/10.1007/s00289-016-1659-6

Garcia-Campo MJ, Quiles-Carrillo L, Sanchez-Nacher L et al (2019) High toughness poly(lactic acid) (PLA) formulations obtained by ternary blends with poly(3-hydroxybutyrate) (PHB) and flexible polyesters from succinic acid. Polym Bull 76:1839–1859. https://doi.org/10.1007/s00289-018-2475-y

Hazer B, Akyol E, Şanal T et al (2019) Synthesis of novel biodegradable elastomers based on poly[3-hydroxy butyrate] and poly[3-hydroxy octanoate] via transamidation reaction. Polym Bull 76:919–932. https://doi.org/10.1007/s00289-018-2410-2

Werlang MM, de Araújo MA, Nunes SP, Yoshida IVP (1998) Miscibilidade de Blendas de Poliestireno com Polímeros de Silício. Polímeros 8:77–81. https://doi.org/10.1590/s0104-14281998000400011

Arrieta MP, Fortunati E, Dominici F et al (2015) Bionanocomposite films based on plasticized PLA-PHB/cellulose nanocrystal blends. Carbohydr Polym 121:265–275. https://doi.org/10.1016/j.carbpol.2014.12.056

Ma P, Xu P, Chen M et al (2014) Structure-property relationships of reactively compatibilized PHB/EVA/starch blends. Carbohydr Polym 108:299–306. https://doi.org/10.1016/j.carbpol.2014.02.058

Sousa FM, Costa ARM, Reul LTA et al (2019) Rheological and thermal characterization of PCL/PBAT blends. Polym Bull 76:1573–1593. https://doi.org/10.1007/s00289-018-2428-5

Pachekoski WM, Dalmolin C, Agnelli JAM (2014) Biodegradable polymeric blends of PHB and PLA for film production. Polimeros 24:501–507. https://doi.org/10.1590/0104-1428.1489

Chen J, Wang Y, Yin Z et al (2017) Morphology and mechanical properties of poly(β-hydroxybutyrate)/poly(ε-caprolactone) blends controlled with cellulosic particles. Carbohydr Polym 174:217–225. https://doi.org/10.1016/j.carbpol.2017.06.053

Barud HS, Souza JL, Santos DB et al (2011) Bacterial cellulose/poly(3-hydroxybutyrate) composite membranes. Carbohydr Polym 83:1279–1284. https://doi.org/10.1016/j.carbpol.2010.09.049

Witt U, Einig T, Yamamoto M et al (2001) Biodegradation of aliphatic-aromatic copolyesters: evaluation of the final biodegradability and ecotoxicological impact of degradation intermediates. Chemosphere 44:289–299. https://doi.org/10.1016/S0045-6535(00)00162-4

Nozirov F, Fojud Z, Klinowski J, Jurga S (2002) High-resolution solid-state 13C NMR studies of poly[(R)-3-hydroxybutyric] acid. Solid State Nucl Magn Reson 21:197–203. https://doi.org/10.1006/snmr.2002.0060

Nozirov F, Fojud Z, Szcześniak E, Jurga S (2000) Molecular dynamics in poly[(R)-3-hydroxybutyric acid] biopolymer as studied by NMR. Appl Magn Reson 18:37–45. https://doi.org/10.1007/BF03162097

Yamamoto M, Witt U, Skupin G et al (2005) Biodegradable aliphatic-aromatic polyesters: “Ecoflex ®”. In: Steinbüchel A, Doi Y (eds) Biopolymers online. Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim

Armentano I, Fortunati E, Burgos N et al (2015) Bio-based PLA_PHB plasticized blend films. Part I: processing and structural characterization. LWT: Food Sci Technol 64:980–988. https://doi.org/10.1016/j.lwt.2015.06.032

Arrieta MP, Fortunati E, Dominici F et al (2014) Multifunctional PLA—PHB/cellulose nanocrystal films : processing, structural and thermal properties. Carbohydr Polym 107:16–24. https://doi.org/10.1016/j.carbpol.2014.02.044

Weinmann S, Bonten C (2019) Thermal and rheological properties of modified polyhydroxybutyrate (PHB). Polym Eng Sci 59:1057–1064. https://doi.org/10.1002/pen.25075

Canevarolo SVJ (2007) Técnicas de caracterização de polímeros, 1st edn. Artliber Editora Ltda, São Paulo

Silverstein RM, Robert M, Webster FX, Kiemle DJ (2005) Spectrometric identification of organic compounds. Wiley, New York

Casarin SA, Malmonge SM, Agnelli JAM (2005) Characterization of Blend PHB / ECOFLEXTM modified with powder-of-wood. In: 8o Congresso Brasileiro de Polímeros. pp 1053–1055

Coelho NS, Ferreira FGD, Almeida YMB, Vinhas GM (2007) Investigation of the proprieties of the PHB, PHB-HV and their blends with anphoteric starch. In: 9o Congresso Brasileiro de Polímeros

Esposito AR, Duek EAR, Lucchesi C et al (2010) Citocompatibilidade de blendas de poli(p-dioxanona)/poli(hidroxi butirato) (PPD/PHB) para aplicações em engenharia de tecido cartilaginoso. Polimeros 20:383–388. https://doi.org/10.1590/S0104-14282010005000062

Corradini E, Marconcini JM, Agnelli JAM, Mattoso LHC (2011) Thermoplastic blends of corn gluten meal/starch (CGM/Starch) and corn gluten meal/polyvinyl alcohol and corn gluten meal/poly (hydroxybutyrate-co- hydroxyvalerate) (CGM/PHB-V). Carbohydr Polym 83:959–965. https://doi.org/10.1016/j.carbpol.2010.09.004

Hutníkova M, Fricova O (2016) Solid-State NMR study of poly(3-Hydroxybutyrate) and ecoflex® blends. Acta Phys Pol A 129:388–393. https://doi.org/10.12693/APhysPolA.129.388

Pellicano M (2008) Desenvolvimento e Caracterização de Blendas PHBV/ECOFLEX ® e suas Modificações com Amidos. Universidade Federal de São Carlos

Acknowledgements

JP Project 2008-00835 FAPESP, CNPq and Capes.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Botaro, V.R., de Freitas, R.R.M., do Carmo, K.P. et al. A simple and efficient technique to prepare aromatic polyhydroxibutirate/polybutylene adipate terephthalate blends. Polym. Bull. 78, 6029–6045 (2021). https://doi.org/10.1007/s00289-020-03378-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-020-03378-y