Abstract

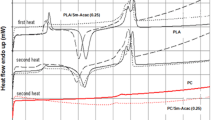

Poly(lactic acid)/polycarbonate (PLA/PC) blends are often explored for use in durable applications such as mobile phones, laptops, and automotive parts. With the use of this blend, while reducing the dependence on the petroleum-based polymers, environmental pollution can be prevented. However, PLA/PC blend is immiscible and needs to be compatibilized. To encourage compatibilization and improve of the performance of the PLA/PC blend, TiO2 and CeO2 were incorporated into the blend. The effects of catalysts type and amount on the structural (Fourier transform infrared analysis-FTIR), morphological (scanning electron microscopy-SEM), rheological, mechanical, and thermal properties (thermogravimetric analysis-TGA, differential scanning calorimeter-DSC) of the PLA/PC blends were evaluated in this study. FTIR results revealed that the catalysts promoted the reaction between PLA and PC. The modulus of the blend increased with the addition of catalyst. The CeO2 containing blends exhibited brittle behavior which was also supported by SEM micrographs. The added catalysts acted as a lubricant, lowered the complex viscosity of the blend, and made processing easier. With the addition of fillers at all amounts, thermal decomposition temperature decreased while the residual weight at 800 °C increased with the inclusion of 3 wt% CeO2. Mechanical results revealed that the highest tensile strength and elongation values were obtained for 0.5 wt% CeO2 and 0.5 wt% TiO2, respectively. It was observed that the loading level and type of catalyst significantly affected the PLA/PC blends mechanical and thermal properties.

Graphical abstract

Similar content being viewed by others

References

Nagarajan V, Mohanty AK, Misra M (2016) Perspective on polylactic acid (PLA) based sustainable materials for durable applications: focus on toughness and heat resistance. ACS Sustain Chem Eng 4:2899–2916

Ucpinar Durmaz B, Aytac A (2022) Investigation of the mechanical, thermal, morphological and rheological properties of bio-based polyamide11/poly(lactic acid) blend reinforced with short carbon fiber. Mater Today Commun 30:103030

Yemisci F, Aytac A (2017) Compatibilization of poly(lactic acid)/polycarbonate blends by different coupling agents. Fibers Polym 18:1445–1451

Ebrahimi H, Sharif F, Ramazani SAA (2022) Effects of modified titanium dioxide nanoparticles on the thermal and mechanical properties of poly(l-lactide)-b-poly(ε-caprolactone). Iran Polym J 31:893–904. https://doi.org/10.1007/s13726-022-01039-7

Hazer S, Coban M, Aytac A (2018) A study on carbon fiber reinforced poly(lactic acid)/polycarbonate composites. J Appl Polym Sci 135:46881

Lin L, Deng C, Wang YZ (2015) Improving the impact property and heat-resistance of PLA/PC blends through coupling molecular chains at the interface. Polym Adv Technol 26:1247–1258

Penco M, Rahman MA, Verstichel S, DeWilde BL, Cinelli P, Lazzeri A (2011) Biodegradable PLA/PC copolymers for automotive applications. Bioplastics 6:20–21

Hedayati F, Moshiri-Gomchi N, Assaran-Ghomi M, Sabahi S, Bahri-Laleh N, Mehdipour-Ataei S, Mokhtari-Aliabad J, Mirmohammadi SA (2020) Preparation and properties of enhanced nanocomposites based on PLA/PC blends reinforced with silica nanoparticles. Polym Adv Technol 31:566–573

Wang B, Zheng Q, Li M, Wang S, Xiao S, Li X, Liu H (2022) Enhancing interfacial interactions of cocontinuous poly(lactic acid)/polyethylene blends using vinylsilane grafted carbon nanotubes as generic reactive compatibilizers. Express Polym Lett 16:524–539

Rajan KP, Gopanna A, Abdelghani EAM, Thomas SP (2021) Halloysite nanotubes (HNT) as reinforcement for compatibilized blends of polypropylene (PP) and polylactic acid (PLA). J Polym Res 28:374

Khosravi A, Fereidoon A, Khorasani MM, Saeb MR (2022) Experimental and theoretical mechanical behavior of compatibilized polylactic acid/polyolefin elastomer blends for potential packaging applications. Iran Polym J 31:651–663

Phuong VT, Gigante V, Aliotta L, Coltelli MB, Cinelli P, Lazzeri A (2017) Reactively extruded ecocomposites based on poly(lactic acid)/bisphenol A polycarbonate blends reinforced with regenerated cellulose microfibers. Compos Sci Technol 139:127–137

Chen Y, Peng Y, Liu WY, Zeng GS, Yang JH, Yan XH (2013) The effect of various catalyzers on transesterification in reactive blending PC/PLA blends. Adv Mater Res 741:24–27

Yiga VA, Lubwama M, Olupot PW (2022) Thermal and alkali modification of kaolin for potential utilization as filler material in fiber-reinforced polylactic acid composites. J Therm Anal Calorim 147:11077–11091. https://doi.org/10.1007/s10973-022-11379-4

Xia X, Liu W, Zhou L, Hua Z, Liu H, He S (2016) Modification of flax fiber surface and its compatibilization in polylactic acid/flax composites. Iran Polym J 25:25–35

Karsli NG, Aytac A (2014) Properties of alkali treated short flax fiber reinforced poly(lactic acid)/polycarbonate composites. Fibers Polym 15:2607–2612

Chelghoum N, Guessoum M, Fois M, Haddaoui N (2018) Contribution of catalytic transesterification reactions to the compatibilization of poly(lactic acid)/polycarbonate blends: thermal, morphological and viscoelastic characterization. J Polym Environ 26:342–354

Liang J, Ding C, Wei Z, Sang L, Song P, Chen G, Chang Y, Xu J, Zhang W (2015) Mechanical, morphology, and thermal properties of carbon fiber reinforced poly(butylene succinate) composites. Polym Compos 36:1335–1345

Liu C, Lin S, Zhou C, Yu W (2013) Influence of catalyst on transesterification between poly(lactic acid) and polycarbonate under flow field. Polymer (Guildf) 54:310–319

Phuong VT, Coltelli MB, Cinelli P, Cifelli M, Verstichel S, Lazzeri A (2014) Compatibilization and property enhancement of poly(lactic acid)/polycarbonate blends through triacetin-mediated interchange reactions in the melt. Polym (Guildf) 55:4498–4513

Ganguly A, Channe P, Jha R, Mitra S, Saha S (2021) Review on transesterification in polycarbonate–poly(butylene terephthalate) blend. Polym Eng Sci 61:650–661

Zhou L, Zhao G, Jiang W (2016) Effects of catalytic transesterification and Composition on the toughness of poly(lactic acid)/poly(propylene carbonate) blends. Ind Eng Chem Res 55:5565–5573

Pilati F, Marianucci E, Berti C (1985) Study of the reactions occurring during melt mixing of poly(ethylene terephthalate) and polycarbonate. J Appl Polym Sci 30:1267–1275

Nicolino MVB, de Alimeida LA, Branciforti MC (2020) Reactive extrusion of poly (butylene succinate-co-adipate) and poly (ε-caprolactone) biodegradable blends through titanium-based transesterification catalyst. Polym Degrad Stab 181:109320

Reddy KR, Hassan M, Gomes VG (2015) Hybrid nanostructures based on titanium dioxide for enhanced photocatalysis. Appl Catal A Gen 489:1–16

Daghrir R, Drogui P, Robert D (2013) Modified TiO2 for environmental photocatalytic applications: a review. Ind Eng Chem Res 52:3581–3599

Mohamed H, Deutou JGN, Kaze CR, Beleuk à Moungam LM, Kamseu E, Chinje Melo U, Leonelli C (2020) Mechanical and microstructural properties of geopolymer mortars from meta-halloysite: effect of titanium dioxide TiO2 (anatase and rutile) content. SN Appl Sci 2:1573

Wacharawichanant S, Thongyai S, Siripattanasak T, Tipsri T (2009) Effect of mixing conditions and particle sizes of titanium dioxide on mechanical and morphological properties of polypropylene/titanium dioxide composites. Iran Polym J 18:607–616

Cai L, Qi Z, Xu J, Guo B, Huang Z (2019) Study on the photodegradation stability of poly(butylene succinate-co-butylene adipate)/TiO2 nanocomposites. J Chem 1:5036019

Liu HY, Chen L, Li W, Wang KW (2019) Effect of halloysite nanotube loading on structure, mechanical and thermal properties of poly (l-lactic acid)/poly-(butylene succinate) blend. IOP Conf Ser Mater Sci Eng 634:012012

Deori K, Kalita C, Deka S (2015) (100) surface-exposed CeO2 nanocubes as an efficient heterogeneous catalyst in the tandem oxidation of benzyl alcohol, para-chlorobenzyl alcohol and toluene to the corresponding aldehydes selectively. J Mater Chem A 3:6909–6920

Larosa C, Saldābola R, Zicāns J, Merijs Meri R, Eggenhöffner R, Converti A (2021) Prediction of thermal behavior of polycarbonate/cerium oxide composite films. Chem Eng Technol 44:1534–1540

Cai G, Lu H, Zhou Y, Hao J, Wilkie CA (2012) Fire retardancy of emulsion polymerized poly (methyl methacrylate)/cerium(IV) dioxide and polystyrene/cerium(IV) dioxide nanocomposites. Thermochim Acta 549:124–131

Parlar Karakoc O, Kibar ME, Akin AN, Yildiz M (2019) Nickel-based catalysts for hydrogen production by steam reforming of glycerol. Int J Environ Sci Technol 16:5117–5124

Wang X, Huang Z, Wei M, Lu T, Nong D, Zhao J, Gao X, Teng L (2019) Catalytic effect of nanosized ZnO and TiO2 on thermal degradation of poly(lactic acid) and isoconversional kinetic analysis. Thermochim Acta 672:14–24

Joshi M, Butola BS, Simon G, Kukaleva N (2006) Rheological and viscoelastic behavior of HDPE/Octamethyl-POSS nanocomposites. Macromolecules 39:1839–1849

Luo YB, Da LW, Wang XL, Xu DY, Wang YZ (2009) Preparation and properties of nanocomposites based on poly(lactic acid) and functionalized TiO2. Acta Mater 57:3182–3191

Sangroniz L, Ruiz JL, Sangroniz A, Fernández M, Etxeberria A, Müller AJ, Santamaria A (2019) Polyethylene terephthalate/low density polyethylene/titanium dioxide blend nanocomposites: morphology, crystallinity, rheology, and transport properties. J Appl Polym Sci 136:46986

Xie X-L, Liu Q-X, Li RK-Y, Zhou X-P, Zhang Q-X, Yu Z-Z, Mai Y-W (2004) Rheological and mechanical properties of PVC/CaCO3 nanocomposites prepared by in situ polymerization. Polymer (Guildf) 45:6665–6673

Wang Z, Zhang M, Liu Z, Zhang S, Cao Z, Yang W, Yang M (2018) Compatibilization of the poly(lactic acid)/poly(propylene carbonate) blends through in situ formation of poly(lactic acid)-b-poly(propylene carbonate) copolymer. J Appl Polym Sci 135:46009

Nguyen VG, Thai H, Mai DH, Tran HT, Tran DL, Vu MT (2013) Effect of titanium dioxide on the properties of polyethylene/TiO2 nanocomposites. Compos Part B Eng 45:1192–1198

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zengin, E., Ucpinar Durmaz, B., Yıldız, M. et al. Effects of different catalysts on the mechanical, thermal, and rheological properties of poly(lactic acid)/polycarbonate blend. Iran Polym J 32, 103–114 (2023). https://doi.org/10.1007/s13726-022-01106-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-022-01106-z