Abstract

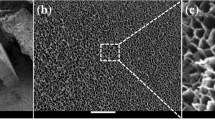

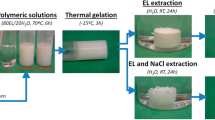

Peroxide salts are the in-situ oxygen generating components and can resolve the oxygen deficiency of the tissue engineering constructs. The type and properties of the polymeric carriers affect the release rate of the oxygen and peroxide reaction byproducts. In the present study, the composites including calcium peroxide (CPO) and different polyesters, i.e., PGA, PLA, and PCL were modeled with molecular dynamics (MD) simulation. The results of the simulation corroborated that diffusion coefficient of the molecules in PLA/CPO were intermediate between those of PGA/CPO and PCL/CPO composites. Therefore, PLA/CPO composite was fabricated with the combination of electrospinning and aminolysis methods for the experimental phase. The elemental analysis corroborated the uniform distribution of the CPO in microparticles and TGA results implied that composite microparticles were achieved with loading content and encapsulation efficiency of 2.92 and 73%, respectively. The evaluation of aminolysis time and PLA concentration implied that the aminolysis for 150 min produced microparticles with uniform shape. Moreover, the increase of PLA concentration from 6.5 to 13% (w/w) increased the average diameter and length of microparticles by 55 and 136%, respectively. The oxygen release measurement proved that microparticles with 13% PLA had the slowest release rate oxygen and the lowest burst release of it.

Graphical abstract

Similar content being viewed by others

References

Erdem A, Haghniaz R, Ertas YN, Sangabathuni SK, Nasr AS, Swieszkowski W, Ashammakhi N (2022) Methods for fabricating oxygen releasing biomaterials. J Drug Target 30:188–199

Farris AL, Lambrechts D, Zhou Y, Zhang NZ, Sarkar N, Moorer MC, Rindone AN, Nyberg EL, Perdomo-Pantoja A, Burris SJ, Free K, Witham TF, Riddle RC, Grayson WL (2022) 3D-printed oxygen-releasing scaffolds improve bone regeneration in mice. Biomaterials 280:121318. https://doi.org/10.1016/j.biomaterials.2021.121318

Lim JO, Huh JS, Abdi SIH, Ng SM, Yoo JJ (2015) Functionalized biomaterials - oxygen releasing scaffolds. J Biotechnol Biomater 5:843–848. https://doi.org/10.4172/2155-952X.1000182

Farris AL, Rindone AN, Grayson WL (2016) Oxygen delivering biomaterials for tissue engineering. J Mater Chem B 4:3422–3432. https://doi.org/10.1039/C5TB02635K

Camci-Unal G, Alemdar N, Annabi N, Khademhosseini A (2013) Oxygen-releasing biomaterials for tissue engineering. Polym Int 62:843–848. https://doi.org/10.1002/pi.4502

Seyyed Nasrollah SA, Karimi-Soflou R, Karkhaneh A (2021) PEG-coated magnesium peroxide nanosheets with tunable microstructure: effect of microstructure on concurrent oxygen and magnesium ion release. Mater Lett 291:129550. https://doi.org/10.1016/j.matlet.2021.129550

Akhavan-Kharazian N, Izadi-Vasafi H (2019) Preparation and characterization of chitosan/gelatin/nanocrystalline cellulose/calcium peroxide films for potential wound dressing applications. Int J Biol Macromol 133:881–891. https://doi.org/10.1016/j.ijbiomac.2019.04.159

Khorshidi S, Karkhaneh A, Bonakdar S (2020) Oxygen-releasing nanofibers for breathable bone tissue engineering application. J Biomater Appl 35:72–82. https://doi.org/10.1177/0885328220913051

Khorshidi S, Karkhaneh A, Bonakdar S (2020) Fabrication of amine-decorated nonspherical microparticles with calcium peroxide cargo for controlled release of oxygen. J Biomed Mater Res A 108:136–147. https://doi.org/10.1002/jbm.a.36799

Khorshidi S, Karkhaneh A (2021) A hydrogel/particle composite with gradient in oxygen releasing microparticle for oxygenation of the cartilage-to-bone interface: modeling and experimental viewpoints. Mater Sci Eng C 118:111522. https://doi.org/10.1016/j.msec.2020.111522

Montazeri L, Hojjati-Emami S, Bonakdar S, Tahamtani Y, Hajizadeh-Saffar E, Noori-Keshtkar M, Najar-Asl M, Ashtiani MK, Baharvand H (2016) Improvement of islet engrafts by enhanced angiogenesis and microparticle-mediated oxygenation. Biomaterials 89:157–165. https://doi.org/10.1016/j.biomaterials.2016.02.043

Steg H, Buizer AT, Woudstra W, Veldhuizen AG, Bulstra SK, Grijpma DW, Kuijer R (2017) Oxygen-releasing poly(trimethylene carbonate) microspheres for tissue engineering applications. Polym Adv Technol 28:1252–1257. https://doi.org/10.1002/pat.3919

Forget A, Staehly C, Ninan N, Harding FJ, Vasilev K, Voelcker NH, Blencowe A (2017) Oxygen-releasing coatings for improved tissue preservation. ACS Biomater Sci Eng 3:2384–2390. https://doi.org/10.1021/acsbiomaterials.7b00297

Mohseni-Vadeghani E, Karimi-Soflou R, Khorshidi S, Karkhaneh A (2021) Fabrication of oxygen and calcium releasing microcarriers with different internal structures for bone tissue engineering: solid filled versus hollow microparticles. Colloids Surf B Biointerfaces 197:111376. https://doi.org/10.1016/j.colsurfb.2020.111376

McQuilling JP, Sittadjody S, Pendergraft S, Farney AC, Opara EC (2017) Applications of particulate oxygen-generating substances (POGS) in the bioartificial pancreas. Biomater Sci 5:2437–2447. https://doi.org/10.1039/C7BM00790F

Gavezzotti A, Lo Presti L, Rizza S (2022) Molecular dynamics simulation of organic materials: structure, potentials and the MiCMoS computer platform. CrystEngComm 24:922–930

Smith A, Dong X, Raghavan V (2022) An Overview of molecular dynamics simulation for food products and processes. Processes 10:119. https://doi.org/10.3390/pr10010119

Anderson RL, Yang Q, Ediger AM (2018) Comparing gas transport in three polymers via molecular dynamics simulation. Phys Chem Chem Phys 20:22123–22133. https://doi.org/10.1039/C8CP02829J

Sun D, Zhou J (2012) Effect of water content on microstructures and oxygen permeation in PSiMA-IPN-PMPC hydrogel: a molecular simulation study. Chem Eng Sci 78:236–245. https://doi.org/10.1016/j.ces.2011.11.020

Wang Y, Wei Q, Wang S, Chai W, Zhang Y (2017) Structural and water diffusion of poly(acryl amide)/poly(vinyl alcohol) blend films: experiment and molecular dynamics simulations. J Mol Graph Model 71:40–49. https://doi.org/10.1016/j.jmgm.2016.11.001

Vasconcelos A, Gomes AC, Cavaco-Paulo A (2012) Novel silk fibroin/elastin wound dressings. Acta Biomater 8:3049–3060. https://doi.org/10.1016/j.actbio.2012.04.035

Zhang H-P, Gandhi NS, Gu Y, Zhang Y, Tang Y (2020) Chitosan/graphene complex membrane for polymer electrolyte membrane fuel cell: a molecular dynamics simulation study. Int J Hydrog Energy 45:25960–25969. https://doi.org/10.1016/j.ijhydene.2020.03.124

Hansen CM (2007) Hansen solubility parameters: A user’s handbook, 2nd edn. CRC Press, USA

Shariatinia Z, Mazloom-Jalali A (2019) Chitosan nanocomposite drug delivery systems designed for the ifosfamide anticancer drug using molecular dynamics simulations. J Mol Liq 273:346–367. https://doi.org/10.1016/j.molliq.2018.10.047

Yu R, Wang Q, Wang W, Xiao Y, Wang Z, Zhou X, Zhang X, Zhu X, Fang C (2021) Polyurethane/graphene oxide nanocomposite and its modified asphalt binder: Preparation, properties and molecular dynamics simulation. Mater Des 209:109994. https://doi.org/10.1016/j.matdes.2021.109994

Sun D, Zhou J (2013) Molecular simulation of oxygen sorption and diffusion in the poly (lactic acid). Chin J Chem Eng 21:301–309. https://doi.org/10.1016/S1004-9541(13)60472-7

Sahebi Jouibari I, Haddadi-Asl V, Mirhosseini MM (2019) A novel investigation on micro-phase separation of thermoplastic polyurethanes: simulation, theoretical, and experimental approaches. Iran Polym J 28:237–250. https://doi.org/10.1007/s13726-019-00695-6

Karlsson GE, Gedde UW, Hedenqvist MS (2004) Molecular dynamics simulation of oxygen diffusion in dry and water-containing poly (vinyl alcohol). Polymer (Guildf) 45:3893–3900. https://doi.org/10.1016/j.polymer.2003.12.082

Mohabatpour F, Karkhaneh A, Sharifi AM (2016) A hydrogel/fiber composite scaffold for chondrocyte encapsulation in cartilage tissue regeneration. RSC Adv 6:83135–83145. https://doi.org/10.1039/C6RA15592H

Waite AJ, Bonner J, Autenrieth RL (1999) Kinetics and stoichiometry of oxygen release from solid peroxides. Environ Eng Sci 16:187–199. https://doi.org/10.1089/ees

Acknowledgements

The authors would like to express their gratitude to Iran’s National Elites Foundation (INEF) for supporting this research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Khorshidi, S., Karkhaneh, A. Cylindrical polyester/calcium peroxide oxygen-releasing microparticles: molecular dynamics simulation and experimental analyses. Iran Polym J 32, 45–58 (2023). https://doi.org/10.1007/s13726-022-01098-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-022-01098-w