Abstract

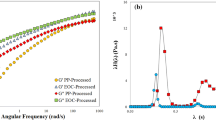

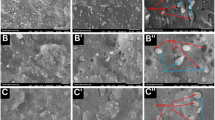

In this work, morphology and rheology of the blends of cyclic olefin copolymer (COC) with two types of crystalline polyolefins were investigated through a wide range of compositions. The used polyolefins had various plasticity, elasticity and viscoelastic behavior. Their molecular structures were similar but their molecular architectures were different in terms of comonomer content and composition distribution (i.e., a linear low-density polyethylene with 4 mol% of 1-butene comonomer (LLDPEB labeled as LLB) and nonuniform composition distribution and a polyolefin elastomer (POE) with 33 mol% of 1-butene comonomer and uniform composition distribution). Morphology of the COC/POE blends was droplet-matrix at low concentrations of the dispersed phase which was changed to co-continuous morphology at intermediate concentrations. Good compatibility and adhesion between phases were also observed. In COC/LLB blends, droplet-matrix morphology and good compatibility were observed between the two phases, except for compositions of 70/30 and 50/50, which exhibited continuous morphology and phase separation. The results of morphology and rheological data such as Cole–Cole plots and variations of viscosity versus composition revealed that these blends were immiscible. The interfacial interaction of the blend phases was investigated using rheological diagrams of variations of their complex viscosities, storage modulus versus frequency, relaxation time spectra and tan δ versus frequency. In addition, the interfacial tension was calculated using emulsion models. It was found that in the intermediate concentrations and COC-rich compounds, the interfacial interaction of the phases and form relaxation time of the dispersed particles of the COC/POE blends were higher than those of the COC/LLB blends, resulting in a further increase in elasticity. In blends with low COC content, the interfacial interaction of the phases and form relaxation time of the dispersed particles of the COC/LLB blends were higher than those of the COC/POE blends.

Similar content being viewed by others

Notes

\(\left( {\log G_{{\text{M}}}^{^{\prime}} = \varphi \log G_{{\text{A}}}^{^{\prime}} + \left( {1 - \varphi } \right)\log G_{{\text{B}}}^{^{\prime}} } \right)\)

References

Lacroix C, Bousmina M, Carreau PJ, Favis BD, Michel A (1996) Properties of PETG/EVA blends: 1. Viscoelastic, morphological and interfacial properties. Polymer 37:2939–2947

Hsu YC, Truss RW, Laycock B, Weir MP, Nicholson TM, Garvey CJ, Halley PJ (2017) The effect of comonomer concentration and distribution on the photo-oxidative degradation of linear low density polyethylene films. Polymer 119:66–75

Adhikari R, Godehardt R, Lebek W, Frangov S, Michler GH, Radusch J, Baltá Calleja FJ (2005) Morphology and micromechanical properties of ethylene/1-octene copolymers and their blends with high density polyethylene. Polym Adv Technol 16:156–166

Liu MO, Lin H-F, Yang M-C, Lai M-J, Chang CC, Shiao P-L, Chen I-M, Chen J-Y (2007) Thermal, dynamic mechanical and rheological properties of metallocene-catalyzed cycloolefin copolymers (mCOCs) with high glass transition temperature. Mater Lett 61:457–462

Durmus A, Alanalp MB, Aydin I (2018) Investigation of morphological, rheological, and mechanical properties of cyclic olefin copolymer/poly(ethylene-co-vinyl acetate) blend films. J Plast Film Sheet 34:140–159

Chen Y, Zou H, Cao Y, Liang M (2014) Melt miscibility of HDPE/UHMWPE, LDPE/UHMWPE, and LLDPE/UHMWPE blends detected by dynamic rheometer. Polym Sci Series A 56:630–639

Dorigato A, Pegoretti A, Fambri L, Lonardi C, Šlouf M, Kolařik J (2011) Linear low density polyethylene/cycloolefin copolymer blends. Express Polym Lett 5:23–33

Malpass DB (2010) Introduction to industrial polyethylene: properties, catalysts, and processes. Scrivener Publishing LLC

Lamnawar K, Vion-Loisel F, Maazouz A (2010) Rheological, morphological, and heat seal properties of linear low density polyethylene and cyclo olefine copolymer (LLDPE/COC) blends. J Appl Polym Sci 116:2015–2022

Ostafinska A, Vackova T, Slouf M (2018) Strong synergistic improvement of mechanical properties in HDPE/COC blends with fibrillar morphology. Polym Eng Sci 58:1955–1964

Adhikari R, Godehardt R, Lebek W, Michler GH (2007) Blends of high density polyethylene and ethylene/1-octene copolymers: Structure and properties. J Appl Polym Sci 103:1887–1893

Kim J, Kwon H, Choi Y, Lee K, Song E, Hong D, Kim W, Kim S (2015) Ethylene/1-hexene or ethylene/1-butene copolymer having excellent processibility and environmetal stress crack resistance. US Patent 9732172B2

Morshedian J, Moballegh L, Azizi H, Degheh H (2020) Effects of Nano-SiC on silane grafting and curing of polyolefin elastomer: mixing order, physical, and mechanical properties. J Vinyl Addit Technol 26:244–252

Mileva D, Radusch HJ, Betchev C (2007) Study on the phase behavior of high density polyethylene - ethylene octene copolymer blends. Macromol Mater Eng 292:319–328

Khonakdar HA, Jafari SH, Hesabi MN (2015) Miscibility analysis, viscoelastic properties and morphology of cyclic olefin copolymer/polyolefin elastomer (COC/POE) blends. Compos Part B Eng 69:111–119

Doshev P, Tomova D, Wutzler A, Radusch HJ (2005) Morphology and mechanical properties of reactive and non-reactive COC/EOC blends. J Polym Eng 25:375–392

Jafari SH, Khonakdar HA, Tarameshlou M, Saeb MR (2016) Comparative study on tensile properties and microstructure development in elastomer-modified cyclic olefin copolymer. J Vinyl Addit Technol 22:222–230

Hussein IA (2005) Melt miscibility and mechanical properties of metallocene linear low-density polyethylene blends with high-density polyethylene: influence of comonomer type. Polym Int 54:1330–1336

Guimarães MJOC, Coutinho FMB, Rocha MCG, Farahe M, Bretase RES (2003) Effect of molecular weight and long chain branching of metallocene elastomers on the properties of high density polyethylene blends. Polym Test 22:843–847

Kontopoulou M, Wang W, Gopakumar TG, Cheung C (2003) Effect of composition and comonomer type on the rheology, morphology and properties of ethylene-α-olefin copolymer/polypropylene blends. Polymer 44:7495–7504

Simpson DM, Vaughan GA (2001) Ethylene polymers, LLDPE. In: Encyclopedia of polymer science and technology. Wiley https://doi.org/10.1002/0471440264.pst122

Hussein IA (2003) Influence of composition distribution and branch content on the miscibility of m-LLDPE and HDPE blends: rheological investigation. Macromolecules 36:2024–2031

Hussein IA (2004) Implications of melt compatibility/incompatibility on thermal and mechanical properties of metallocene and Ziegler-Natta linear low density polyethylene (LLDPE) blends with high density polyethylene (HDPE): influence of composition distribution and branch. Polym Int 53:1327–1335

Salehiyan R, Ray SS, Stadler FJ, Ojijo V (2018) Rheology-microstructure relationships in melt-processed polylactide/poly(vinylidene fluoride) blends. Materials (Basel) 11:2450. https://doi.org/10.3390/ma11122450

Cui L, Zhou Z, Zhang Y, Zhang X, Zhou W (2007) Rheological behavior of polypropylene/novolac blends. J Appl Polym Sci 106:811–816

Pimbert S (2003) Evaluation of the fractionated crystallization of isotactic polypropylene and high density polyethylenes in their blends with cycloolefin copolymers. Macromol Symp 203:277–284

Lee JK, Han CD (1999) Evolution of polymer blend morphology during compounding in an internal mixer. Polymer 40:6277–6296

Jafari SH, Hesabi MN, Khonakdar HA, Asl-Rahimi M (2011) Correlation of rheology and morphology and estimation of interfacial tension of immiscible COC/EVA blends. J Polym Res 18:821–831

Shahbazi K, Razavi Aghjeh MK, Abbasi F, Partovi Meran M, Mehrabi Mazidi M (2012) Rheology, morphology and tensile properties of reactive compatibilized polyethylene/polystyrene blends via Friedel-Crafts alkylation reaction. Polym Bull 69:241–259

Utracki LA, Kanial MR (1982) Melt rheology of polymer blends. Polym Eng Sci 22:96–114

Stahl PO, Sederel WL (1996) Polymer blends. Wiley-Inter Science

Moly KA, Oommen Z, Bhagawan SS, Groeninckx G, Thomas S (2002) Melt rheology and morphology of LLDPE/EVA blends: effect of blend ratio, compatibilization, and dynamic crosslinking. J Appl Polym Sci 86:3210–3225

Isayev A, Palsule S (2011) Encyclopedia of polymer blends, vol. 2: processing. Wiely-VCH Verlag CmbH

Grizzuti N, Buonocore G, Iorio G (2000) Viscous behavior and mixing rules for an immiscible model polymer blend. J Rheol 44:149–164

Graebling D, Muller R, Palierne JF (1993) Linear viscoelastic behavior of some incompatible polymer blends in the melt. Interpretation of data with a model of emulsion of viscoelastic liquids. Macromolecules 26:320–329

Lacroix C, Grmela M, Carreau PJ (1998) Relationships between rheology and morphology for immiscible molten blends of polypropylene and ethylene copolymers under shear flow. J Rheol 42:41–62

Jozaghkar MR, Jahani Y, Arabi H, Ziaee F (2018) Preparation and assessment of phase morphology, rheological properties, and thermal behavior of low-density polyethylene/polyhexene-1 blends. Polym Plast Technol Eng 57:757–765

Palierne JF (1990) Linear rheology of viscoelastic emulsions with interfacial tension. Rheol Acta 29:204–214

Galloway JA, Macosko CW (2004) Comparison of methods for the detection of cocontinuity in poly(ethylene oxide)/polystyrene blends. Polym Eng Sci 44:714–727

Hernández-Alamilla M, Valadez-Gonzalez A (2016) The effect of two commercial melt strength enhancer additives on the thermal, rheological and morphological properties of polylactide. J Polym Eng 36:31–41

Mehrabi Mazidi M, Razavi Aghjeh MK (2015) Effects of blend composition and compatibilization on the melt rheology and phase morphology of binary and ternary PP/PA6/EPDM blends. Polym Bull 72:1975–2000

Bonilla-Blancas AE, Romero-Ibarra IC, Vazquez-Arenas J, Sanchez-Solis A, Manero O, Alvarez-Ramirez J (2019) Molecular interactions arising in polyethylene-bentonite nanocomposites. J Appl Polym Sci 136:1–9

Li R, Yu W, Zhou C (2006) Phase behavior and its viscoelastic responses of poly(methyl methacrylate) and poly(styrene-co-maleic anhydride) blend systems. Polym Bull 56:455–466

Madbouly SA, Ougizawa T (2002) Binary miscible blends of poly(methyl methacrylate)/poly(α-methyl styrene-co-acrylonitrile): I. Rheological behavior. J Macromol Sci Phys 41B:255–269

Yang Z, Peng H, Wang W, Liu T (2010) Crystallization behavior of poly(ε-caprolactone)/layered double hydroxide nanocomposites. J Appl Polym Sci 116:2658–2667

Hussein IA, Williams MC (2004) Rheological study of the influence of branch content on the miscibility of octene m-LLDPE and ZN-LLDPE in LDPE. Polym Eng Sci 44:660–672

Nandan B, Kandpal LD, Mathur GN (2004) Poly(ether ether ketone)/poly(aryl ether sulfone) blends: melt rheological behavior. J Polym Sci B Polym Phys 42:1548–1563

Hsieh TT, Tiu C, Hsieh KH, Simon GP (2000) Characterization of thermotropic liquid crystalline polyester/polycarbonate blends: miscibility, rheology, and free volume behavior. J Appl Polym Sci 77:2319–2330

Calvão PS, Yee M, Demarquette NR (2005) Effect of composition on the linear viscoelastic behavior and morphology of PMMA/PS and PMMA/PP blends. Polymer 46:2610–2620

Souza AMC, Demarquette NR (2002) Influence of composition on the linear viscoelastic behavior and morphology of PP/HDPE blends. Polymer 43:1313–1321

Ajji A, Choplin L, Prud’Homme RE (1991) Rheology of polystyrene/poly(vinyl methyl ether)blends near the phase transition. J Polym Sci B Polym Phys 29:1573–1578

Codou A, Anstey A, Misra M, Mohanty AK (2018) Novel compatibilized nylon-based ternary blends with polypropylene and poly(lactic acid): morphology evolution and rheological behaviour. RSC Adv 8:15709–15724

Chen Y, Zou H, Liang M, Liu P (2013) Rheological, thermal, and morphological properties of low-density polyethylene/ultra-high-molecular-weight polyethylene and linear low-density polyethylene/ultra-high-molecular-weight polyethylene blends. J Appl Polym Sci 129:945–953

Chopra D, Kontopoulou M, Vlassopoulos D, Hatzikiriakos SG (2002) Effect of maleic anhydride content on the rheology and phase behavior of poly(styrene-co-maleic anhydride)/poly(methyl methacrylate) blends. Rheol Acta 41:10–24

Chen ZK, Huang HX, Xu LQ (2012) Effects of component viscosities and dispersed phase volume fraction on relaxation behavior for polymer blends, 70th Ann Tech Conf Soci Plast Eng, Orlando, Florida, USA, 2–4 April. ANTEC Proc 1:39–43

Lacroix C, Aressy M, Carreau PJ (1997) Linear viscoelastic behavior of molten polymer blends: a comparative study of the Palierne and Lee and Park models. Rheol Acta 36:416–428

Mortazavi S, Ghasemi I, Oromiehie A (2014) Morphological and rheological properties of (low-density polyethylene)/thermoplastic starch blend: investigation of the role of high elastic network. J Vinyl Addit Technol 20:250–259

Bousmina M (1999) Rheology of polymer blends: linear model for viscoelastic emulsions. Rheol Acta 38:73–83

Sengers WGF, Sengupta P, Noordermeer JWM, Picken SJ, Gotsis AD (2004) Linear viscoelastic properties of olefinic thermoplastic elastomer blends: melt state properties. Polymer 45:8881–8891

Shi D, Hu GH, Ke Z, Li RKY, Yin J (2006) Relaxation behavior of polymer blends with complex morphologies: palierne emulsion model for uncompatibilized and compatibilized PP/PA6 blends. Polymer 47:4659–4666

Van Hemelrijck E, Van Puyvelde P, Velankar S, Macosko CW, Moldenaers P (2004) Interfacial elasticity and coalescence suppression in compatibilized polymer blends. J Rheol 48:143–158

Sarathchandran C (2020). In: Thomas S, Sarathchandran C, Chandran N (eds) Rheology of polymer blends and nanocomposites: theory, modelling and applications. Elsevier

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shamsoddini-Zarch, F., Karrabi, M. & Jahani, Y. Effects of different molecular architectures in terms of comonomer content and composition distribution on the miscibility of cyclic olefin copolymer/polyolefin (COC/POE and COC/LLDPEB) blends. Iran Polym J 30, 593–612 (2021). https://doi.org/10.1007/s13726-021-00914-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-021-00914-z