Abstract

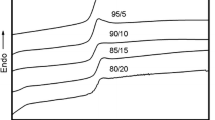

Structure–property relationship in typical polypropylene/polycarbonate/poly[styrene-b-(ethylene-co-butylene)-b-styrene] (PP/PC/SEBS) ternary blends containing maleated SEBS (SEBS-g-MAH) was investigated. Three grades of PC with different melt viscosities were used, and changes in blend morphology from PC/SEBS core–shell particles partially surrounded by SEBS-g-MAH to inverse SEBS/PC core–shell particles in PP matrix were observed upon varying the viscosity ratio of PC to SEBS. It was found that the viscosity ratio completely controls the size of the core–shell droplets and governs the type, population, and shape of the dispersed domains, as evidenced by rheological, mechanical, and thermomechanical behavioral assessments. Dynamic mechanical analysis of samples with common (PC–SEBS) and inverse (SEBS–PC) core–shell particles revealed that they show completely different behaviors: blends containing PC–SEBS presented a higher storage and loss modulus, while blends containing SEBS–PC exhibited a lower β-transition temperature. Moreover, ternary blends with PC cores showed the highest Young’s modulus values and the lowest impact strength, due to the different fracture modes of the blends containing PC–SEBS and SEPS–PC core–shell droplets, which present debonding and shell-fracture mechanisms, respectively. Morphological observations of blends with high-molecular-weight PC demonstrated the presence of detached droplets and rods of PC in the PP matrix, along with composite core–shell and rod-like particles. Micrographs of the fracture surfaces confirmed the proposed mechanisms, given the presence of stretched (debonded) PC (SEBS) cores encapsulated by SEBS (PC), which require more (less) energy to achieve fracture. The correlation between the mechanical and morphological properties proves that decreasing core diameter and shell thickness has positive effects on the impact strength but decreases the Young’s modulus.

Similar content being viewed by others

References

Sionkowska A (2011) Prog Polym Sci 36:1254

Yu L, Dean K, Li L (2006) Progr Polym Sci 31:576

Manson JA, Sperling LH (1976) Polymer blends and composites. Plenum, New York

Robeson LM (1984) Polym Eng Sci 24:587

Barlow JW, Paul DR (1981) Polym Eng Sci 21:985

Paul DR, Newman S (1978) Polymer blends, volume 1. Academic, New York

Hemmati F, Garmabi H, Modarress H (2013) Exp Polym Lett 7:996

Brannock GR, Paul DR (1990) Macromolecules 23:5240

Mester Z, Lynd NA, Fredrickson GH (2013) Soft Matter 9:11288

Khalili R, Jafari SH, Saeb MR, Khonakdar HA, Wagenknecht U, Heinrich G (2014) Macro Mater Eng 299:1197

Moini Jazani O, Arefazar A, Jafari SH, Peymanfar MR, Saeb MR, Talaei A (2013) Polym Plast Tech Eng 52:206

Favis BD (1990) J Appl Polym Sci 39:285–300

Li J, Ma PL, Favis BD (2002) Macromolecules 35:2005

Liang H, Favis BD, Yu YS, Eisenberg A (1999) Macromolecules 32:1637

Hong X, Nie G, Lin Z, Rong J (2012) Polym Plast Tech Eng 51:971

Mazidi MM, Razavi Aghjeh MK, Khonakdar HA, Reuter U (2016) RSC Adv 6:1508

Mekhilef N, Favis BD, Carreau PJ (1997) J Appl Polym Sci 35:293

Moini Jazani O, Arefazar A, Saeb MR, Ghaemi A (2010) J Appl Polym Sci 116:2312

Saeb MR, Khonakdar HA, Razban M, Jafari SH, Garmabi H, Wagenknecht U (2012) Macro Chem Phys 213:1791

Moini Jazani O, Arefazar A, Jafari SH, Saeb MR (2011) J Polym Eng 31:237

Sarvestani MRY, Arefazar A, Moini Jazani O, Saeb MR (2014) J Vinyl Add Tech 21:245

Moini Jazani O, Arefazar A, Peymanfar MR, Saeb MR, Talaei A (2013) Polym Plast Tech Eng 52:1295

Sarazin P, Li G, Orts WJ, Favis BD (2008) Polymer 49:599

Rastin H, Jafari SH, Saeb MR, Khonakdar HA, Wagenknecht U, Heinrich G (2014) J Polym Res 21:352

Saeb MR, Khonakdar HA, Moghri M, Razban M, Moini Jazani O, Alorizi AE (2014) Polym Plast Tech Eng 53:1142

Rastin H, Jafari SH, Saeb MR, Khonakdar HA, Wagenknecht U, Heinrich G (2014) Eur Polym J 53:1

Virgilio N, Desjardins P, L’Espérance G, Favis BD (2009) Macromolecules 42:7518

Ravati S, Favis BD (2010) Polymer 51:4547

Saeb MR, Khonakdar HA, Jafari SH, Rastin H, Wagenknechtd U, Heinrich G (2015) Polym Plast Tech Eng 54:223

Rastin H, Saeb MR, Jafari SH, Khonakdar HA, Kritzschmar B, Wagenknecht U (2014) Macro Mater Eng 300:86

Reignier J, Favis BD, Heuzey MC (2003) Polymer 44:49

Dou R, Shen C, Yin B, Yang M, Xie B (2015) RSC Adv 5:14592

Shen C, Zhou Y, Dou R, Wang W, Yin B, Yang M (2015) Polymer 56:395

Tchomakov KP, Favis BD, Huneault MA, Champagne MF, Tofan F (2004) Polym Eng Sci 44:749–759

Zhang J, Ravati S, Virgilio N, Favis BD (2007) Macromolecules 40:8817

Reignier J, Favis BD (2003) Polymer 44:5061

Tchomakov KP, Favis BD, Huneault MA, Champagne MF, Tofan F (2005) Cana J Chem Eng 83:300

Freitas CA, Valera TS, Souza AMC, Demarquette NR (2007) Macro Symp 247:260

Zhou Y, Yin B, Li L, Yang M, Feng J (2012) Polym Plast Tech Eng 51:983

Sathe SN, Devi S, Srinivas GS, Rao K, Rao V (1996) J Appl Polym Sci 61:97

Landry JT, Yang H, Machell JS (1991) Polymer 32:44

Luzinov I, Pagnoulle C, Jérôme R (2000) Polymer 41:7099

Dou R, Li S, Shao Y, Yin B, Yang M (2016) RSC Adv 6:439

Reignier J, Favis BD (2000) Macromolecules 33:6998

Krache R, Benachour D, Pötschke P (2004) J Appl Polym Sci 94:1976

Sabetzadeh M, Bagheri R, Masoomi M (2015) Carbohy Polym 119:126

Mittal V, Akhtar T, Luckachan G, Matsko N (2015) Coll Polym Sci 293:573

Mazidi MM, Razavi Aghjeh MK (2015) RSC Adv 5:47183

Horiuchi S, Matchariyakul N, Yase K, Kitano T (1997) Polymer 38:59

Wilkinson AN, Clemens ML, Harding VM (2004) Polymer 45:5239

Azizi A, Arefazar A, Moini Jazani O (2013) Polym Plast Tech Eng 52:1595

Luzinov I, Xi K, Pagnoulle C, Huynh-Ba G, Jérôme R (1999) Polymer 40:2511

Hemmati M, Nazokdast H, Panahi HS (2001) J Appl Polym Sci 82:1129

Horiuchi S, Matchariyakul N, Yase K, Kitano T (1996) Polymer 37:3065

Horiuchi S, Matchariyakul N, Yase K, Kitano T (1997) Macromolecules 30:3664

Horiuchi S, Matchariyakul N, Yase K, Kitano T (1997) Polymer 38:6317

Garhwal A, Maiti SN (2015) Polym Bull 25:1

Qiao X, Lu X, Gong X, Yang T, Sun K, Chen X (2015) Polym Test 47:51

Chen F, Shangguan Y, Jiang Y, Qiu B, Luo G, Zheng Q (2015) Polymer 65:81

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Jazani, O.M., Goodarzi, V., Hemmati, F. et al. Structure–property relationships in ternary polymer blends with core–shell inclusions: revisiting the critical role of the viscosity ratio. J Polym Res 23, 231 (2016). https://doi.org/10.1007/s10965-016-1116-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-016-1116-0