Abstract

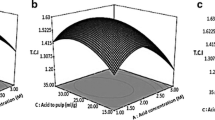

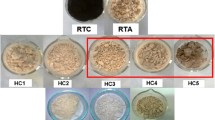

The effect of cellulose nanofibers (CNFs) and poly [methyl methacrylate (MMA)]-grafted cellulose nanofibers (CNF-g-PMMA) on mechanical properties and degradability of a 75/25 low density polyethylene/thermoplastic starch (LDPE/TPS) blend was investigated. Graft copolymerization on CNFs was performed in an aqueous suspension by free radical polymerization using MMA as an acrylic monomer. In addition, a LDPE/TPS blend was reinforced by different amounts of CNFs (1–5 wt%) and CNF-g-PMMA (1–7 wt%) using a twin-screw extruder. A 61% grafting of PMMA on the surface of CNFs was demonstrated by gravimetric analysis. Moreover, after modification the X-ray photoelectron spectroscopy analysis showed a 20% increase of carbon atoms on the surface of CNFs and a 22.6% decrease in the oxygen content of its surface. The mechanical properties of the CNFs-modified composites were significantly improved compared to the unmodified nanocomposites. The highest tensile strength and Young’s modulus were obtained for the composites reinforced by 3 and 7 wt% CNF-g-PMMA, respectively. The degradability of cellulose nanocomposites was studied by water absorption and soil burial tests. Surface modification of CNFs lowered water absorption, and soil burial test of the LDPE/TPS blend showed improvement in biodegradability by addition of CNF-g-PMMA.

Similar content being viewed by others

References

Kim M (2003) Evaluation of degradability of hydroxypropylated potato starch/polyethylene blend films. Carbohyd Polym 54:173–181

Prachayawarakorn J, Sangnitidej P, Boonpasith P (2010) Properties of thermoplastic rice starch composites reinforced by cotton fiber or low-density polyethylene. Carbohyd Polym 81:425–433

Nawang R, Danjaji ID, Ishiaku US, Ismail H, Mohd Ishak ZA (2001) Mechanical properties of sago starch-filled linear low density polyethylene (LLDPE) composites. Polym Test 20:167–172

Lu DR, Xiao CM, Xu SJ (2009) Starch-based completely biodegradable polymer materials. eXPRESS Polym Lett 3:366–375

Mortazavi S, Ghasemi I, Oromiehie A (2013) Effect of phase inversion on the physical and mechanical properties of low density polyethylene/thermoplastic starch. Polym Test 32:482–491

Abdul Khalil HPS, Bhat AH, Ireana Yusra AF (2012) Green composites from sustainable cellulose nanofibrils: a review. Carbohyd Polym 87:963–979

Hu W, Chen S, Yang J, Li Z, Wang H (2014) Functionalized bacterial cellulose derivatives and nanocomposites. Carbohyd Polym 101:1043–1060

Siqueira G, Bras J, Dufresne A (2010) Cellulosic bionanocomposites: a review of preparation, properties and applications. Polymers 2:728–765

Kumar AP, Singh RP (2008) Biocomposites of cellulose reinforced starch: improvement of properties by photo-induced crosslinking. Biorersour Technol 99:8803–8809

Oksman K, Niska KO, Sain M (2006) Cellulose nanocomposites: processing, characterization, and properties. ASC Meeting, Cellulose Division, London

Islam MT, Alam MM, Zoccola M (2013) Review on modification of nanocellulose for application in composites. Inte J Innov Res Sci Eng Techol 2:5444–5451

Alidadi-Shamsabadi M, Behzad T, Bagheri R, Nari-Nasrabadi B (2015) Preparation and characterization of low-density polyethylene/thermoplastic starch composites reinforced by cellulose nanofibers. Polym Compos 36:2309–2316

Abdul Khalil HPS, Davoudpour Y, Islam MN, Mustapha A, Sudesh K, Dungani R, Jawaid M (2014) Production and modification of nanofibrillated cellulose using various mechanical processes: a review. Carbohyd Polym 99:649–665

Sato A, Kabusaki D, Okumura H, Nakatani T, Nakatsubo F, Yano H (2016) Surface modification of cellulose nanofibers with alkenyl succinic anhydride for high-density polyethylene reinforcement. Compos Part A Appl S 83:72–79

Menezes AJ, Longo E, Leite FL, Dufresne A (2014) Characterization of cellulose nanocrystals grafted with organic acid chloride of different sizes. J Renew Mater 2:306–313

de Menezes AJ, Siqueira G, Curvelo AA, Dufresne A (2009) Extrusion and characterisation of functionalised cellulose whiskers reinforced polyethylene nanocomposites. Polymer 50:4552–4563

Tan C, Peng J, Lin W, Xing Y, Xu K, Wu J, Chen M (2015) Role of surface modification and mechanical orientation on property enhancement of cellulose nanocrystals/polymer nanocomposites. Euro Polym J 62:186–197

Alemdar A, Sain M (2008) Isolation and characterization of nanofibers from agricultural residues—wheat straw and soy hulls. Bioresour Technol 99:1664–1671

Segal LG, Creely JJ, Martin AE Jr, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29:786–794

Lacerda PS, Barros-Timmons AM, Freire CS, Silvestre AJ, Neto CP (2013) Nanostructured composites obtained by ATRP sleeving of bacterial cellulose nanofibers with acrylate polymers. Biomacromol 14:2063–2073

Pavia D, Lampman G, Kriz G, Vyvyan J (2008) Introduction to spectroscopy. Cengage Learning, Boston

Habibi Y, Goffin AL, Schiltz N, Duquesne E, Dubois P, Dufresne A (2008) Bionanocomposites based on poly (ε-caprolactone)-grafted cellulose nanocrystals by ring-opening polymerization. J Mater Chem 18:5002–5010

Tian C, Fu S, Habibi Y, Lucia LA (2014) Polymerization topochemistry of cellulose nanocrystals: a function of surface dehydration control. Langmuir 30:14670–14679

Ifuku S, Nogi M, Abe K, Handa K, Nakatsubo F, Yano H (2007) Surface modification of bacterial cellulose nanofibers for property enhancement of optically transparent composites: dependence on acetyl-Group DS. Biomacromol 8:1973–1978

Jonoobi M, Harun J, Mathew AP, Hussein MZ, Oksman K (2010) Preparation of cellulose nanofibers with hydrophobic surface characteristics. Cellulose 17:299–307

Jonoobi M, Mathew AP, Abdi MM, Makinejad MD, Oksman K (2012) A comparison of modified and unmodified cellulose nanofiber reinforced polylactic acid (PLA) prepared by twin screw extrusion. J Polym Environ 20:991–997

Siqueira G, Bras J, Dufresne A (2009) New process of chemical grafting of cellulose nanoparticles with a long chain isocyanate. Langmuir 26:402–411

Hu W, Chen S, Xu Q, Wang H (2011) Solvent-free acetylation of bacterial cellulose under moderate conditions. Carbohyd Polym 83:1575–1581

Ashori A, Babaee M, Jonoobi M, Hamzeh Y (2014) Solvent-free acetylation of cellulose nanofibers for improving compatibility and dispersion. Carbohyd Polym 102:369–375

Yang Z, Xu S, Ma X, Wang S (2008) Characterization and acetylation behavior of bamboo pulp. Wood Sci Technol 42:621–632

Li S, Xiao M, Zheng A, Xiao H (2011) Cellulose microfibrils grafted with PBA via surface-initiated atom transfer radical polymerization for biocomposite reinforcement. Biomacromol 12:3305–3312

Avérous L, Fringant C, Moro L (2001) Plasticized starch–cellulose interactions in polysaccharide composites. Polymer 42:6565–6572

Dufresn A, Thomas S, Pothan LA, Grossman RF, Nwabunma D (2013) Biopolymer nanocomposites: processing, properties, and applications. Wiley, New Jersey

Sarifuddin N, Ismail H, Ahmad Z (2013) Studies of properties and characteristics of low-density polyethylene/thermoplastic sago starch-reinforced kenaf core fiber composites. J Thermoplast Compos Mater 28:445–460

Arvanitoyannis I, Biliaderis CG, Ogawa H, Kawasaki N (1998) Biodegradable films made from low-density polyethylene (LDPE), rice starch and potato starch for food packaging applications: part 1. Carbohyd Polym 36:89–104

Vieyra H, Aguilar-Méndez MA, San Martín-Martínez E (2013) Study of biodegradation evolution during composting of polyethylene–starch blends using scanning electron microscopy. J Appl Polym Sci 127:845–853

Acknowledgements

The authors would like to thank Professor Mohini M Sain from Center for Biocomposites and Biomaterials Processing, University of Toronto for his scientific assistance.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ahmadi, M., Behzad, T. & Bagheri, R. Reinforcement effect of poly (methyl methacrylate)-g-cellulose nanofibers on LDPE/thermoplastic starch composites: preparation and characterization. Iran Polym J 26, 733–742 (2017). https://doi.org/10.1007/s13726-017-0558-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-017-0558-5