Abstract

The generation of chemically engineered essential oils (CEEOs) prepared from bi-heteroatomic reactions using ammonium thiocyanate as a source of bioactive compounds is described. The impact of the reaction on the chemical composition of the mixtures was qualitatively demonstrated through GC–MS, utilizing univariate and multivariate analysis. The reaction transformed most of the components in the natural mixtures, thereby expanding the chemical diversity of the mixtures. Changes in inhibition properties between natural and CEEOs were demonstrated through acetylcholinesterase TLC autography, resulting in a threefold increase in the number of positive events due to the modification process. The chemically engineered Origanum vulgare L. essential oil was subjected to bioguided fractionation, leading to the discovery of four new active compounds with similar or higher potency than eserine against the enzyme. The results suggest that the directed chemical transformation of essential oils can be a valuable strategy for discovering new acetylcholinesterase (AChE) inhibitors.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

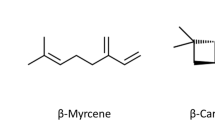

Natural products (NPs) arise through the evolution of biosynthetic pathways, driven by their functional benefits to the host organism [1]. Consequently, NPs have become a prolific source of active compounds and primary chemical structures for discovering new drugs [2, 3]. Essential oils (EOs) are complex blends that may contain over 300 different natural volatile compounds [4, 5]. Generally, EOs consist of low molecular weight lipophilic hydrocarbons (both aromatic and aliphatic) and their oxygenated derivatives. EOs primarily serve vital functions in plant chemoecology [6] and also hold potential as a novel source of interesting lead structures for drug discovery [7].

The success of drug discovery is closely linked to the accessibility to libraries containing molecules with interesting biomolecular properties. Leveraging the fact that NPs have evolved to efficiently bind to biological macromolecules, various techniques have been proposed as approaches to enhance their chemical diversity [3, 8, 9], leading to the discovery of active compounds [10,11,12,13,14]. Nearly two decades after its appearance, the chemical diversification of extracts has become a complementary strategy in the search for bioactive molecules [15]. This methodology aims to transform as many components of natural extracts as possible through simple chemical reactions. Modifying a substantial number of components within an inactive natural extract could potentially generate one or more active compounds. To increase the chances of creating new compounds during the modification, it is beneficial to introduce functional groups that are uncommon or rarely found in nature [16].

Various reactions have been developed to produce chemically engineered extracts (CEEs) enriched with specific elements [17] such as nitrogen [15, 18], sulfur [19,20,21], bromine [22, 23], or fluorine [24]. All these reactions so far are referred to as mono-heteratomic, as they primarily increase the proportion of functionalities based on a single element of interest. These mono-heteratomic transformations have led to the discovery to products with increased biological activity [16, 18, 20, 21, 25,26,27,28,29,30,31,32,33,34,35,36,37,38,39,40,41,42,43]. These remarkable outcomes suggest a vast potential to further explore this strategy [44].

A comparison of heteroatom content in and NPs drugs has revealed that drugs contain significantly more sulfur and nitrogen that NPs [2, 45]. The frequency of NPs with functionalities based on both heteroatoms is very rare [46, 47].

Thiocyanate is a versatile synthon which has been used extensively in synthetic organic chemistry and contains many biological features that are useful in various sectors, such as medicine, pesticides, and materials [48, 49]. Organic chemists have concentrated their efforts into exploring thiocyanation reactions and applications, which mostly involve nucleophilic substitution favored by oxidants [48]. As an alternative, thiocyanate salts in combination with different oxidants have been used as the thiocyanate source. Among the thiocyanate salts, NH4SCN is one of the most reactive nucleophilic reagents available and is safe, nontoxic, inexpensive, stable, and easy to handle [50]. This salt is generally directly used to access alkyl thiocyanates, while their combination with an oxidant is required for the preparation of aromatic counterparts via electrophilic reactions or cross-coupling reactions [51, 52].

This salt can introduce the thiocyanate synthon by reaction with ketones possessing α-hydrogens [49] and (hetero)aromatic C-H bonds [50]. The carbonyl and aromatic groups are among the most common functional groups found in NPs [46, 47]. Therefore, the use of reactions that transform both of them may result attractive to alter the composition of natural extracts in a significant way. To explore the value of CEEs as a source of bioactive compounds, we present a method to modify EOs using NH4SCN as a derivatizing reagent. Unlike previous approaches, this reaction is the first capable of introducing sulfur and nitrogen in a single step. In this work, we use various tools to analyze how this reaction affects the chemical composition and certain biomolecular properties of the mixtures to a significant extent.

2 Results and discussion

2.1 Ammonium thiocyanate as the reagent and chemical impact evaluation

Most conventional chemical reactions frequently employ considerable quantities of volatile and toxic organic solvents, which give rise to substantial concerns regarding worker health and safety, as well as environmental pollution [53, 54]. Thus, the development of green, sustainable, efficient reactions in the absence of hazardous organic solvents is a desirable step and the design of solvent-free procedures to generate CEEOs. Taking advantage of the liquid nature of EOs, eleven commercial mixtures were modified by solvent-free reaction conditions using NH4SCN (derivative reagent) and iodine (oxidant) [55, 56].

The key to success with CEEs is producing a high number of compounds to maximize the chance of finding a bioactive one. In view of the extensive chemical diversity of NPs, it is imperative to employ analytical methodologies capable of detecting most of the components present in these mixtures. GC–MS is a widely used technique for the analysis of complex mixtures of natural origin, demonstrating its reliability in creating EOs fingerprints [6] and identifying hundreds of metabolites within these mixtures [57].

Given the complexity of the chromatograms of the series of EOs and CEEOs, the GC–MS data were compared using Compass DataAnalysis (DA) and Mass Hunter (MH) software with the aim of finding peaks that were either present in both chromatograms (from EO and CEEO) or found exclusively in one of them. This analysis led to three pools of peaks with a unique combination of m/z and elution time values: (1) peaks found in both chromatograms, likely representing compounds that do not fully react under the applied reaction conditions, (2) peaks exclusively present in the starting EO chromatograms, possibly indicating compounds reacting with NH4SCN, and (3) peaks exclusively found in the CEEOs, likely denoting reaction products. Data comparison using DA involved a signal-to-noise ratio (S/N) of five. The average number of peaks per chromatogram at this S/N threshold was similar for EOs and CEEOs (49 and 48, respectively, Fig. 1a). Remarkably, the percentages of peaks that disappeared and appeared were also very similar (Fig. 1b). When comparing GC–MS data with the MH, a filter was applied for peaks with an area equal to or greater than 5% of the main peak (MP). In this case, the average number of peaks per chromatogram was two times higher for CEEOs as compared to the EOs (28 and 14 respectively, Fig. 1a). Nevertheless, the percentages of disappearing and appearing peaks closely mirrored those obtained with the S/N filter in DA. Both analyses revealed that at least 86% of the peaks observed in the EOs chromatograms were consumed during the diversification process, giving rise to products that represented a minimum of 90% of the peaks exclusive to the CEEOs chromatograms (Fig. 1b).

Box and whiskers plot for a number of peaks from EOs with DA and MH (red and blue respectively) and CEEOs with DA and MH (green and black respectively) detected in the GC–MS chromatograms, b percentage of peaks that disappeared with DA and MH (red and blue respectively) and that appeared with DA and MH (green and black respectively) and c Score plot of PCA of GC–MS data for EOs (green X) and CEEOs (blue circles). The mean value is represented with a +

The GC–MS data were also analyzed using the non-supervised method, Principal Component Analysis (PCA). The score plot showed discrimination between two groups by PC1 and PC2. The EOs exhibited positive values for PC2 and negative (or nearly zero) for PC1 placing them in the top left quadrant of the score plot (green x, Fig. 1c) while the CEEOs are distributed in the other quadrants (blue circles, Fig. 1c).

2.2 Alteration of biological properties

The impact of the reaction on the biomolecular properties of the mixtures was evaluated by comparing the AChE inhibitory properties of the CEEOs and EOs. There has been a significant effort to find compounds that could act as AChE inhibitors. This is primarily because there is evidence suggesting that AChE inhibition can be advantageous for Alzheimer’s disease (AD) patients. In AD, the impairment of the cholinergic system plays a role in the decline of cognitive function associated with the disease [58, 59]. Which is why, some reversible inhibitors of this enzyme are the primary class of drugs currently utilized for the symptomatic relief of AD [60].

The AChE inhibition properties of the mixtures were surveyed by thin layer chromatography (TLC) autography [61], a technique particularly well-suited for the analysis of mixtures [62]. This methodology allows the qualitative evaluation of the inhibitory properties of a sample spotted onto a TLC plate which is then covered with a gel containing enzyme, substrate, and a revealing reagent for the product. When comparing the bioactivity profiles of each CEEO/EO pair, it was observed that the number of inhibition halos increased 3 times because of the modification process (Fig. 2). The alteration of the biomolecular properties of the mixtures from their modification is attractive given that, in addition to expanding the overall number of active mixtures, CEEOs with inhibitory properties against AChE can be generated from previously inactive mixtures (four active CEEOs since eight inactive EOs, Table S1).

2.3 Identification and biological characterization of inhibitors from the CEEO of O. vulgare

One of the most interesting findings was in the case of CEEO from OV where the two more intense inhibition zones were detected, at Rf values 0.2 and 0.4, while its parent EO showed no activity (Fig. 3b and a). To differentiate between genuine AChE inhibitors and non-real inhibitors, a comparison was made between a control and the enzymatic assay [61]. Notably, none of the halos detected for the CEEO of OV produced false-positive inhibition spots (Fig. 3c).

An autography-guided chromatography column of the CEEO of OV led to the isolation of four active fractions: F0.2A and F0.2B, which contained the inhibition spot with Rf = 0.2, and F0.4A and F0.4b that contained the inhibition spot with Rf = 0.4. GC–MS analysis revealed that each fraction contained one major compound with the following m/z values: 207.1 in F0.2A, 330.2 in F0.2B, 414.2 in F0.4A, and 446.1 in F0.4B. The identity of the main component of each fraction was established by HRMS and NMR (1H and 13C) as follows: 5-isopropyl-2-methyl-4-thiocyanatophenol (1) in F0.2A, 4,4′-thiobis(5-isopropyl-2-methylphenol) (2) in F0.2B, 4-((5-(4-hydroxy-2-isopropyl-5-methylphenyl)-1,2,4-thiadiazol-2-yl)thio)-5-isopropyl-2-methylphenol (3) in F0.4A, and 4,4′-((1,2,4- reactions thiadiazole-2,5-diyl)bis(sulfanediyl))bis(5-isopropyl-2-methylphenol) (4) in F0.4B. Hence, each inhibition halo detected in the autography of the fractions was generated by two compounds.

The four isolated bioactive compounds shared common chemical features suggesting that their natural precursor could be carvacrol (5, Scheme 1). Carvacrol (Fig S5a), along with its isomer thymol, is a primary constituent of OV EO [63]. Indeed, the EO chromatographic profile obtained by GC–MS supported this observation (Fig S5b). Furthermore, carvacrol was found in significantly lower proportions in the CEEO (Fig S5c). To substantiate this hypothesis, a reaction was carried out using carvacrol under the same reaction conditions that were employed to obtain the CEEO previously. Interestingly, the TLC-AChE inhibition profile of the carvacrol reaction closely resembled that of the CEEO. Subsequently, the four compounds were purified from this mixture and their identities were confirmed through various spectroscopic analyses.

Synthesis of 5-isopropyl-2-methyl-4-thiocyanatophenol (1), 4,4′-thiobis(5-isopropyl-2-methylphenol) (2), 4-((5-(4-hydroxy-2-isopropyl-5-methylphenyl)-1,2,4-thiadiazol-3-yl)thio)-5-isopropyl-2-methylphenol (3), and 4,4′-((1,2,4-thiadiazole-3,5-diyl)bis(sulfanediyl))bis(5-isopropyl-2-methylphenol) (4)

Compounds 1, 3, and 4 contain one or two SCN units from the used derivatizing reagent. On the other hand, compound 2 is a thioether. Although the reaction was initially developed to produce thiocyanates or isothiocyanates, recent reports have indicated that reactions with thiocyanate salts can lead to the formation of thioethers [64]. Thioether compounds have become one of the main areas of interest in drug discovery [65]. Besides, in recent years, they acquired more importance in the plant protection field because of their broad spectrum of agricultural activities [66]. This result is interesting since this observed side reaction serves the purpose of diversification of NPs mixtures.

Microplate assays utilizing Ellman’s reagent were performed to quantitatively assess the inhibitory activity of the isolated compounds against AChE [67]. The half maximal inhibitory concentration (IC50) values were 4.086 ± 0.035 µM, 0.158 ± 0.059 µM, 0.056 ± 0.025 µM and 0.034 ± 0.016 µM for compounds 1–4, respectively.

While compound 1 demonstrated a reduced inhibitory potency when compared to the reference inhibitor eserine (IC50 0.224 ± 0.017 µM), compounds 2–4 exhibited similar or even greater inhibitory activity. Notably, carvacrol was determined to be inactive against this enzyme. This underscores the significance of the reaction in the generating diversity and converting inactive precursors into active compounds that effectively target this biological target.

All the bioactive isolated compounds (1–4) could be produced by an initial attachment of thiocyanate on the para position of the phenol group of carvacrol. The reaction most likely proceeds via the formation of active thiocyanogen and (SCN)2 from I2 and NH4SCN [57, 68]. The para-substitution in compound 1 agrees with that observed in aryl thiocyanates obtained by mechanochemical [69], ultrasound [70], K2S2O8 [71], and CeBr3/H2O2 [72] promoted thiocyanation of C-2 substituted phenols as well as by I2 promoted thiocyanation of aromatic amines [55]. The sulfur atom in compound 1 could suffer the nucleophilic attack of an aryl moiety [73,74,75,76], here a second carvacrol molecule, leading to the formation of 2 with the release of the cyanide group (Scheme 2a).

1,2,4-thiadiazoles of the type of compounds 3 and 4 have been conveniently prepared from thioamides or analogous substrates by oxidative heterocyclization [77,78,79,80]. Therefore, compound 3 could be achieved by the reaction of 1 with a thioamide such as 6 (Scheme 2a), generated in situ by the reaction of carvacrol with thiocyanate (Scheme 2b) [81]. Similarly, compound 4 could result from an analogous reaction between 1 and dithiocarbamate 7, generated in situ by the reaction of 1 with thiocyanate (Scheme 2c).

3 Conclusions

In summary, this study presents a new approach to create CEEOs through bi-heteroatomic reactions, which, for the first time, utilize a reaction with NH4SCN/I2 under solvent-free conditions. This methodology offers the opportunity to introduce sulfur and nitrogen atoms into natural compounds in a single step. The robustness of this technique is evident from the changes in the composition of the mixtures, as observed through GC–MS analysis, where most of the EOs components were transformed, expanding the chemical diversity of the mixtures. These modifications in the chemical composition were associated with changes in the inhibition properties against the enzyme AChE. A comparison of the bioactivity profiles of each pair of CEEO/EO revealed a threefold increase in the number of inhibition spots. Notably, in the case of the CEEO of O. vulgare, the generation of three active compounds with a similar o higher potency than eserine against enzyme was observed. These results highlight the feasibility of using this reaction as a means to enhance chemical diversity, potentially leading to alterations in biomolecular properties, offering new possibilities for developing new bioactive compounds.

4 Experimental

4.1 Chemicals and materials

Ammonium thiocyanate, sodium thiosulfate pentahydrate, anhydrous sodium sulfate and iodine were purchased from Cicarelli Laboratorios (San Lorenzo, Santa Fe). AChE from Electrophorus electricus EC 3.1.1.7, Fast blue salt B (FBB), α-naphthol, α-naphthyl acetate (α-NAc), and CDCl3, were purchased from Sigma-Aldrich (St. Louis, MO, USA). Acetonitrile (LCMS grade) was acquired from Carlo Erba Reagents (Val de Reuil, France) and formic acid from Merck. Aluminium TLC sheets coated with Silica gel 60 F were purchased from Merck (Darmstadt, Germany). Agar was purchased from Britania (Bs. As., Argentina).

The essential oils (EOs) were purchased from EUMA (Bs. As., Argentina): Pimenta racemosa (Mill.) J. W. Moore. (PR), Thuya occidentalis L. (TO), Coriandrum sativum L. (COS), Foeniculum vulgare Mill (FV), Lavandula angustifolia Mill. (LA), Cymbopogon citratus Spreng (CyC), Litsea cubeba (Lour.) Pers. (LC), Mentha arvensis L. (MA), Origanum vulgare L. (OV), Pogostemon cablin Benth. (PC), and Salvia officinalis L. (SO).

Gas chromatography mass spectrometry (GCMS) analysis was performed on an Agilent 7890B Gas Chromatograph coupled to Agilent model 5977A Mass Spectrometer. Column: HP-5MS UI, 30 m × 0.25 mm, 0.25 μm film thick. High-resolution mass spectra (HRMS) were recorded on a Q-Exactive (Thermo Fisher Scientific) using a reported method [82].

Nuclear magnetic resonance spectra were recorded on a Bruker Avance II in CDCl3 in the presence of TMS (0.00 ppm) as the internal standard (1H at 300 MHz and 13C at 75 MHz). The assignments were made on the basis of chemical shifts (1H and 13C), 1H multiplicities and using 2D spectrums (COSY 1H-1H, HSQC and HMBC).

4.2 Preparation of chemically engineered essential oils (CEEOs)

Since the detailed exact composition of the EOs used as starting material is unknown, some average properties of EOs components were used to estimate the appropriate amounts of reagents to be used. The number of moles of reacting molecules was estimated considering 150, as the average molecular weight of EOs components, and one, as the average number of reacting groups per molecule. Finally, two mol of SCNNH4 and 0.5 mol of I2 per “estimated” mol of EO components were used in the reaction.

A suspension of EO (500 mg), SCNNH4 (507.5 mg), and I2 (423.1 mg) was stirred during 16 h at ambient temperature. Following, a solution of 15% sodium thiosulfate pentahydrate (60 mL) was added, and the reaction mixture stirred for 5 min. The organic material was then extracted with ethyl acetate (2 × 60 mL), and the organic phase dried over anhydrous sodium sulfate and the ethyl acetate from the joined fractions was removed under reduced pressure. Chemically engineered essential oil yields: PR = 92.5%, TO = 95.0%, COS = 103.9%, FV = 106.9%, LA = 104.0%, CyC = 82.7%, LC = 84.7%, MA = 89.2%, OV = 121.6%, PC = 97.9%, and SO = 92.9%.

4.3 AChE TLC and false positive autographic assays

The AChE inhibition properties of the mixtures were surveyed by TLC autography using reported protocols (Ramallo et al., 2015). Briefly, a Silica gel-TLC plate (80 cm2) was sprayed with the α-NAc: FBB (4:1) solution. Then the plate was dried under air current at room temperature. 140 mg of agar was dissolved at 80 °C in 16 mL Tris–HCl buffer (50 mM, pH 8.0), and the solution was allowed to cool down (50 °C) and 136 μL of AChE solution (132 U/mL) were added, the obtained solution was mixed by inversion and distributed over the TLC plate. After cooling and solidification, the plate was incubated at 37 °C (20 min) in the dark (in a closed and humid Petri dish).

For the AChE false positive autographic assay, a Silica gel-TLC plate (80 cm2) was sprayed with the α-NAc: FBB (4:1) solution. Then the plate was dried under air current at room temperature. 140 mg of agar was dissolved at 80 °C in 16 mL Tris–HCl buffer (50 mM, pH 8.0), then 600 of ethanolic α-naphthol solution (1.7 mg/mL) were added, the obtained solution was mixed by inversion and finally the agar-α-naphthol solution was distributed over it. The autography was analyzed immediately after it was gelled.

4.4 Fractionation of CEEO of OV

The CEEO of OV (600 mg) was fractionated by column chromatography on Silica gel with hexane: EtOAc gradient: 95:5 (5 dead volumes), 90:10 (2.5 dead volumes), 80:20 (2.5 dead volumes), 70:30 (2.5 dead volumes), 50:50 (2.5 dead volumes), 30:70) (2.5 dead volumes), and pure EtOAc (2.5 dead volumes), giving twenty two fractions. TLC-autography analysis of those fractions detected inhibition halos in four fractions: F0.2A, F0.2B, F0.4A and F0.4B.

GC–MS analysis revealed that each fraction contained one major compound each with the following m/z values: 207.1 in F0.2A, 330.2 in F0.2B, 414.2 in F0.4A, and 446.1 in F0.4B (Fig. S1–S4). The identities of these compounds were established by HRMS and NMR (1H and 13C) analyses as 5-isopropyl-2-methyl-4-thiocyanatophenol (1), 4,4′-thiobis(5-isopropyl-2-methylphenol) (2), 4-((5-(4-hydroxy-2-isopropyl-5-methylphenyl)-1,2,4-thiadiazol-3-yl)thio)-5-isopropyl-2-methylphenol (3), and 4,4′-((1,2,4-thiadiazole-3,5-diyl)bis(sulfanediyl))bis(5-isopropyl-2-methylphenol (4), respectively. The assignments for 1–4 are shown below.

4.5 Synthesis of carvarol derivatives

Standard procedure A suspension of carvacrol (250 mg), SCNNH4 (253.5 mg), and I2 (211.1 mg) was stirred during 16 h at 20 °C. Following, a solution of 15% of sodium thiosulfate pentahydrate (30 mL) was added, and the reaction mixture stirred for 5 min. The organic material was then extracted with ethyl acetate (2 × 30 mL), and the organic phase dried over anhydrous sodium sulfate. Next, ethyl acetate was removed by rotary evaporation, and the crude product was purified by column chromatography over silica gel using hexane: EtOAc gradient: 95:5 (5 dead volumes), 90:10 (2.5 dead volumes), 80:20 (2.5 dead volumes), 70:30 (2.5 dead volumes), 50:50 (2.5 dead volumes), 30:70) (2.5 dead volumes), and pure EtOAc (2.5 dead volumes).

1. Yield: 25%; 1H NMR (300 MHz, CDCl3) δ = 1.24 (6H, d, J = 6.7 Hz, CH(CH3)2), 2.22 (3H, s, Ar-CH3), 3.41 (1H, m, CH(CH3)2), 5.24 (1H, s, OH), 6.77 (1H, s, Ar), 7.41 (1H, s,Ar); 13C NMR (75 MHz, CDCl3) δ = 15.30 (CH3, Ar-CH3), 23.40 (2 CH3, CH(CH3)2), 31.34 (CH, CH(CH3)2), 111.02 (C, Ar), 112.84 (C, Ar), 113.80 (CH, Ar), 124.29 (C, SCN), 137.16 (CH, Ar), 150.64 (C, Ar), 157.18 (C, Ar); HRMS: found m/z = 206.0642, calculated m/z for C11H12OSN [M-H]− 206.0634 (0.8 mDa error).

2. Yield: 20%; 1H NMR (300 MHz, CDCl3) δ = 1.20 (12H, d, J = 6.8 Hz, 2 CH(CH3)2), 2.14 (6H, s, 2 Ar-CH3), 3.46 (1H, m, 2 CH(CH3)2), 4.67 (1H, s, 2 OH), 6.76 (1H, s, 2 Ar), 6.87 (1H, s, 2 Ar); 13CNMR (75 MHz, CDCl3) δ = 15.36 (2 CH3, Ar-CH3), 23.65 (4 CH3, CH(CH3)2), 30.42 (2 CH, CH(CH3)2), 112.70 (2 CH, Ar), 122.13 (2 C, Ar), 125.36 (2 C, Ar), 134.64 (2 CH, Ar), 148.64 (2 C, Ar), 153.56 (2 C, Ar); HRMS: found m/z = 329.1581, calculated m/z for C20H25O2S [M-H]− 329.1570 (1.1 mDa error).

3. Yield: 3%; 1H NMR (300 MHz, CDCl3) δ = 1.19 (6H, d, J = 6.7 Hz, CH(CH3)2), 1.20 (6H, d, J = 6.7 Hz, CH(CH3)2), 2.24 (3H, s, Ar-CH3), 2.26 (3H, s, Ar-CH3), 3.57 (2H, m, 2 CH(CH3)2), 4.98 (1H, s, OH), 5.14 (1H, s, OH), 6.84 (1H, s, Ar), 6.85 (1H, s, Ar), 7.49 (1H, s, Ar), 7.52 (1H, s, Ar); 13CNMR (75 MHz, CDCl3) δ = 15.08 (CH3, Ar-CH3), 15.22 (CH3, Ar-CH3), 23.76 (2 CH3, CH(CH3)2), 23.79 (2 CH3, CH(CH3)2), 29.30 (CH, CH(CH3)2), 31.06 (CH, CH(CH3)2), 112.87 (CH, Ar), 113.15 (CH, Ar), 118.12 (C, Ar), 121.32 (C, Ar), 121.81 (C, Ar), 122.36 (C, Ar), 133.21 (CH, Ar), 139.69 (CH, Ar), 147.83 (C, Ar), 152.36 (C, Ar), 155.95 (C, Ar), 156.64 (C, Ar), 172.16 (C, Ar), 187.96 (C, Ar); HRMS: found m/z = 413.1364, calculated m/z for C22H25O2N2S2 [M-H]− 413.1352 (1.2 mDa error).

4. Yield: 5%; 1H NMR (300 MHz, CDCl3) δ = 1.16 (6H, d, J = 6.7 Hz, CH(CH3)2), 1.18 (6H, d, J = 6.7 Hz, CH(CH3)2), 2.19 (3H, s, Ar-CH3), 2.22 (3H, s, Ar-CH3), 3.44 (2H, m, 2 CH(CH3)2), 5.07 (1H, s, OH), 5.33 (1H, s, OH), 6.80 (1H, s, Ar), 6.83 (1H, s, Ar), 7.42 (1H, s, Ar), 7.43 (1H, s, Ar); 13CNMR (75 MHz, CDCl3) δ = 15.15 (CH3, Ar-CH3), 15.23 (CH3, Ar-CH3), 23.75 (2 CH3, CH(CH3)2), 23.89 (2 CH3, CH(CH3)2), 31.04 (2 CH, CH(CH3)2), 113.26 (CH, Ar), 113.86 (CH, Ar), 116.99 (C, Ar), 117.49 (C, Ar), 122.39 (C, Ar), 123.77 (C, Ar), 139.38 (CH, Ar), 139.52 (CH, Ar), 152.45 (C, Ar), 152.60 (C, Ar), 156.02 (C, Ar), 157.25 (C, Ar), 172.37 (C, Ar), 194.06 (C, Ar); HRMS: found m/z = 445.1086, calculated m/z for C22H25O2N2S3 [M-H]− 445.1073 (1.3 mDa error).

4.6 Microplate assays

Inhibition percentage determinations were carried out using the method applied by Osella et al. [83]. Wells were filled in triplicate with AChE solution (in 0.1 M phosphate buffer, pH 7.5, and 13.7 µU/mL end concentration per well), Ellman’s reagent (DTNB, 5,5dithio-bis-(2-nitrobenzoic acid)), the same buffer solution (0.31 mM end concentration per well) and 10 µL of test compound in DMSO solution (0.05 µM end concentration per well). Wells containing the corresponding volume of DMSO without an inhibitor were used as references of maximum enzymatic rates, and standard drug eserine was used as the control for enzyme inhibition. The enzymatic reaction was initiated by addition of acetylthiocholine iodide (0.46 mM end concentration per well). The final volume per well was 270 µL. The plate was shaken for 2 s and the increase in absorbance at 405 nm was monitored at 37 °C for 15 min. For IC50 determination, ten serial dilutions of the compounds were prepared in DMSO, following equally spaced points on a neperian logarithm scale, starting at 2.16 mM and finishing at 0.00023 mM (end concentration per well: 80.00 to 0.00839 µM). IC50 calculated using Prism V5.01 (GraphPad Software Inc., La Jolla, CA, USA) applying a non linear regression curve fit for a log[inhibitor] vs. normalized answer model with variable slope.

Data availability

The data supporting the results of this study can be obtained from the corresponding authors upon reasonable request.

Abbreviations

- CEEOs:

-

Chemically engineered essential oils

- CEEs:

-

Chemically engineered extracts

- EOs:

-

Essential oils

- GCMS:

-

Gas chromatography mass spectrometry

- HRMS:

-

High resolution mass spectrometry

- IC50 :

-

Half maximal inhibitory concentration

- NPs:

-

Natural products

- NMR:

-

Nuclear magnetic resonance spectroscopy

- OV:

-

Origanum vulgare

References

Karageorgis G, Warriner S, Nelson A. Efficient discovery of bioactive scaffolds by activity-directed synthesis. Nat Chem. 2014;6:872–6. https://doi.org/10.1038/nchem.2034.

Young RJ, Flitsch SL, Grigalunas M, Leeson PD, Quinn RJ, Turner NJ, Waldmann H. The time and place for nature in drug discovery. JACS Au. 2022;2:2400–16. https://doi.org/10.1021/jacsau.2c00415.

Jalota K, Sharma V, Agarwal C, Jindal S. Eco-friendly approaches to phytochemical production: elicitation and beyond. Nat Prod Bioprospect. 2024;14:5. https://doi.org/10.1007/s13659-023-00419-7.

Raut JS, Karuppayil SM. A status review on the medicinal properties of essential oils. Ind Crops Prod. 2014;62:250–64. https://doi.org/10.1016/J.INDCROP.2014.05.055.

Sell CS. The Chemistry of Fragrance. In Perfumer to Consumer. 2nd ed. The Royal Society of Chemistry; Cambridge, UK. 2006, p. 329.

Liu Z, Wang M, Wu M, Li X, Liu H, Li S, Chen L. Volatile organic compounds (VOCs) from plants: from release to detection. Trends Anal Chem. 2023;158: 116872. https://doi.org/10.1016/j.trac.2022.116872.

Maffei ME, Gertsch J, Appendino G. Plant volatiles: production, function and pharmacology. Nat Prod Rep. 2011;28:1359–80. https://doi.org/10.1039/C1NP00021G.

Li G, Lou H-X. Strategies to diversify natural products for drug discovery. Med Res Rev. 2018;38:1255–94. https://doi.org/10.1002/med.21474.

Yao H, Liu J, Xu S, Zhu Z, Xu J. The structural modification of natural products for novel drug discovery. Expert Opin Drug Discov. 2017;12:121–40. https://doi.org/10.1080/17460441.2016.1272757.

Atanasov AG, Zotchev SB, Dirsch VM, the International Natural Product Sciences Taskforce, Supuran CT. Natural products in drug discovery: advances and opportunities. Nat Rev Drug Discov. 2021;20:200–16. https://doi.org/10.1038/s41573-020-00114-z.

Mahal A, Wu P, Jiang Z-H, Wei X. Synthesis and cytotoxic activity of novel tetrahydrocurcumin derivatives bearing pyrazole moiety. Nat Prod Bioprospect. 2017;7:461–9. https://doi.org/10.1007/s13659-017-0143-9.

Bankeu JJK, Sattar H, Fongang YSF, Muhammadi SW, Simoben CV, Ntie-Kang F, Feuya GRT, Tchuenmogne MAT, Lateef M, Lenta BN, Ali MS, Ngouela AS. Synthesis, urease inhibition and molecular modelling studies of novel derivatives of the naturally occurring β-Amyrenone. Nat Prod Bioprospect. 2021;9:49–59. https://doi.org/10.1007/s13659-018-0193-7.

Wang Y, Zhang M, Zhou X, Xu C, Zhu C, Yuan Y, Chen N, Yang Y, Guo Q, Shi J. Insight into medicinal chemistry behind traditional Chinese Medicines: p-Hydroxybenzyl alcohol-derived dimers and trimers from Gastrodia elata. Nat Prod Bioprospect. 2021;11:31–50. https://doi.org/10.1007/s13659-020-00258-w.

Deng X, Huang S-L, Ren J, Pan Z-H, Shen Y, Zhou H-F, Zuo Z-L, Leng Y, Zhao Q-S. Development and structure–activity relationships of tanshinones as selective 11ß-hydroxysteroid dehydrogenase 1 inhibitors. Nat Prod Bioprospect. 2022;12:36. https://doi.org/10.1007/s13659-022-00358-9.

Lopez SN, Ramallo IA, Gonzalez Sierra M, Zacchino SA, Furlan RLE. Chemically engineered extracts as an alternative source of bioactive natural product-like compounds. Proc Natl Acad Sci USA. 2007;104:441–4. https://doi.org/10.1073/pnas.0608438104.

Ramallo IA, Salazar MO, García P, Furlan RLE. Chemical Diversification of Natural Product Extracts, In Studies in Natural Products Chemistry, Vol. 60; Atta-ur-Rahman, Ed. Elsevier: Amsterdam, 2018, Chapter 10.

Ramallo IA, Salazar MO, Mendez L, Furlan RLE. Chemically engineered extracts: source of bioactive compounds. Acc Chem Res. 2011;44:241–50. https://doi.org/10.1021/ar100106n.

Solís CM, Salazar MO, Ramallo IA, García P, Furlan RLE. A tyrosinase inhibitor from a nitrogen-enriched chemically engineered extract. ACS Comb Sci. 2019;21:622–7. https://doi.org/10.1021/acscombsci.9b00064.

Salazar MO, Ramallo IA, Micheloni O, Gonzalez Sierra M, Furlan RLE. Chemically engineered extracts: bioactivity alteration through sulfonylation. Bioorg Med Chem Lett. 2009;19:5067–70. https://doi.org/10.1016/j.bmcl.2009.07.038.

Salazar MO, Micheloni O, Escalante AM, Furlán RLE. Discovery of a β-glucosidase inhibitor from a chemically engineered extract prepared through sulfonylation. Mol Divers. 2011;15:713–9. https://doi.org/10.1007/s11030-010-9301-2.

Salazar MO, Osella MI, Arcusin DEJ, Lescano LE, Furlán RLE. New α-glucosidase inhibitors from a chemically engineered essential oil of Origanum vulgare L. Ind Crops Prod. 2020;156: 112855. https://doi.org/10.1016/j.indcrop.2020.112855.

Mendez L, Salazar MO, Ramallo IA, Furlan RLE. Brominated extracts as source of bioactive compounds. ACS Comb Sci. 2011;13:200–4. https://doi.org/10.1021/co100073k.

García P, Ramallo IA, Salazar MO, Furlan RLE. Chemical diversification of essential oils, evaluation of complex mixtures and identification of a xanthine oxidase inhibitor. RSC Adv. 2016;6:57245–52. https://doi.org/10.1039/C6RA05373D.

García P, Salazar MO, Ramallo IA, Furlan RLE. A new fluorinated tyrosinase inhibitor from a chemically engineered essential oil. ACS Comb Sci. 2016;18:283–6. https://doi.org/10.1021/acscombsci.6b00004.

Adessi TG, Ana Y, Stempin CC, García MC, Bisogno FR, Nicotra VE, García ME. Psilostachyins as trypanocidal compounds: bioguided fractionation of Ambrosia tenuifolia chemically modified extract. Phytochem. 2022;194: 113014. https://doi.org/10.1016/j.phytochem.2021.113014.

Du Y, Sun J, Gong Q, Wang Y, Fu P, Zhu W. New α-pyridones with quorum-sensing inhibitory activity from diversity-enhanced extracts of a Streptomyces sp. derived from marine algae. J Agric Food Chem. 2018;66:1807–12. https://doi.org/10.1021/acs.jafc.7b05330.

Guo Q, Chen J, Ren Y, Yin Z, Zhang J, Yang B, Wang X, Yin W, Zhang W, Ding G, Chen L. Hydrazine-containing heterocycle cytochalasan derivatives from hydrazinolysis of extracts of a desert soil-derived fungus Chaetomium madrasense 375. Front Chem. 2021;9: 620589. https://doi.org/10.3389/fchem.2021.620589.

He W, Xu Y, Wu D, Wang D, Gao H, Wang L, Zhu W. New alkaloids from the diversity-enhanced extracts of an endophytic fungus Aspergillus flavus GZWMJZ-288. Bioorg Chem. 2021;107: 104623. https://doi.org/10.1016/j.bioorg.2020.104623.

Kamauchi H, Noji M, Kinoshita K, Takanami T, Koyama K. Coumarins with an unprecedented tetracyclic skeleton and coumarin dimers from chemically engineered extracts of a marine-derived fungus. Tetrahedron. 2018;74:2846-e2856. https://doi.org/10.1016/j.tet.2018.04.033.

Kikuchi H, Kawai K, Nakashiro Y, Yonezawa T, Kawaji K, Kodama EN, Oshima Y. Construction of a meroterpenoid-like compounds library based on diversity-enhanced extracts. Chem Eur J. 2019;25:1106–12. https://doi.org/10.1002/chem.201805417.

Lin Z, Ma X, Wei H, Li D, Gu Q, Zhu T. Spicarins A-D from acetylated extract of fungus Spicaria elegans KLA03. RSC Adv. 2015;5:35262–6. https://doi.org/10.1039/C5RA01923K.

Nalli Y, Mir KB, Amin T, Gennedi V, Jameel E, Goswami A, Ali A. Divergent synthesis of fractionated Cannabis sativa extract led to multiple cannabinoids C-&O-glycosides with antiproliferative/anti-metastatic properties. Bioorg Chem. 2024;143: 107030. https://doi.org/10.1016/j.bioorg.2023.107030.

Navarro Del Hierro J, Casado-Hidalgo G, Reglero G, Martin D. The hydrolysis of saponin-rich extracts from fenugreek and quinoa improves their pancreatic lipase inhibitory activity and hypocholesterolemic effect. Food Chem. 2021;338: 128113. https://doi.org/10.1016/j.foodchem.2020.128113.

Ortega CA, Favier LS, Cifuente DA. Chemical derivatization of natural extracts obtained from Larrea divaricata Cav. increase in the antioxidant activity and protein precipitating capacity. AJSR. 2017;5:197–202. https://doi.org/10.15413/ajsr.2017.0412.

Ramallo IA, Alonso VL, Rua F, Serra E, Furlan RLE. A bioactive Trypanosoma cruzi bromodomain inhibitor from chemically engineered extracts. ACS Comb Sci. 2018;20:220–8. https://doi.org/10.1021/acscombsci.7b00172.

Ray B, Ali I, Jana S, Mukherjee M, Pal S, Ray S, Schütz M, Marschall M. Antiviral strategies using natural source-derived sulfated polysaccharides in the light of the COVID-19 pandemic and major human pathogenic viruses. Viruses. 2022;14:35. https://doi.org/10.3390/v14010035.

Righi D, Marcourt L, Koval A, Ducret V, Pellissier L, Mainetti A, Katanaev VL, Perron K, Wolfender J-L, Ferreira QE. Chemo-diversification of plant extracts using a generic bromination reaction and monitoring by metabolite profiling. ACS Comb Sci. 2019;21:171–82. https://doi.org/10.1021/acscombsci.8b00132.

Salazar MO, Osella MI, Ramallo IA, Furlan RLE. Nα-arylsulfonyl histamines as selective β-glucosidase inhibitors. RSC Adv. 2018;8:36209–18. https://doi.org/10.1039/C8RA06625F.

Sulistyowaty MI, Uyen NH, Suganuma K, Chitama B-YA, Yahata K, Kaneko O, Sugimoto S, Yamano Y, Kawakami S, Otsuka H, Matsunami K. Six new phenylpropanoid derivatives from chemically converted extract of Alpinia galanga (L.) and their antiparasitic activities. Molecules. 2021;26:1756. https://doi.org/10.3390/molecules26061756.

Tan Y, Sun X, Dong F, Tian H, Jiang R. Enhancing the structural diversity and bioactivity of natural products by combinatorial modification exemplified by total tanshinones. Chin J Chem. 2015;33:1084–8. https://doi.org/10.1002/cjoc.201500276.

Tomohara K, Ohashi N, Uchida T, Nose T. Enhancing the structural diversity and bioactivity of natural products by combinatorial modification exemplified by total tanshinones. Sci Rep. 2022;12:15568. https://doi.org/10.1038/s41598-022-19579-6.

Zhang J-L, Xu W, Zhou Z-R, Li J, Jiang L-L, Zhang X-X, Jiang R-W. Antineoplastic constituents from the chemical diversified extract of Radix puerariae. Chem Biodiversity. 2019;16: e1800408. https://doi.org/10.1002/cbdv.201800408.

Suzuki Y, Ichinohe K, Sugawara A, Kida S, Zhang J, Yamada O, Hattori T, Oshima Y, Murase S, Kikuchi H. Development of indole alkaloid-type dual immune checkpoint inhibitors against CTLA-4 and PD-L1 based on diversity-enhanced extracts. Front Chem. 2021;9: 766107. https://doi.org/10.3389/fchem.2021.766107.

Beato A, Haudecoeur R, Boucherle B, Peuchmaur M. Expanding chemical frontiers: approaches for generating diverse and bioactive natural product-like compounds libraries from extracts. Chem Eur J. 2024;30: e202304166. https://doi.org/10.1002/chem.202304166.

Henkel T, Brune RM, Müller H, Reichel F. Statistical investigation into the structural complementarity of natural products in comparison with synthetic compounds. Angew Chem Int Ed Engl. 1999;38:643–7. https://doi.org/10.1002/(SICI)1521-3773(19990301)38:5%3c643::AID-ANIE643%3e3.0.CO;2-G.

Ertl P, Schuhmann T. A systematic cheminformatics analysis of functional groups occurring in natural products. J Nat Prod. 2019;82:1258–63. https://doi.org/10.1021/acs.jnatprod.8b01022.

Petkowski JJ, Bains W, Seager S. Natural products containing a nitrogen-sulfur bond. J Nat Prod. 2018;81:423–46. https://doi.org/10.1021/acs.jnatprod.7b00921.

Karmaker PG, Alam MdA, Huo F. Recent advances in photochemical and electrochemically induced thiocyanation: a greener approach for SCN-containing compound formation. RSC Adv. 2022;12:6214–33. https://doi.org/10.1039/d1ra09060g.

Vekariya RH, Patel HD. α-thiocyanation of carbonyl compounds: a review. Synth Commun. 2017;47:87–104. https://doi.org/10.1080/00397911.2016.1255973.

Majedi S, Sreerama L, Vessally E, Behmagham F. Metal-free regioselective thiocyanation of (hetero) aromatic CH bonds using ammonium thiocyanate: an overview. J Chem Lett. 2020;1:25–31. https://doi.org/10.22034/JCHEMLETT.2020.107760.

Castanheiro T, Suffert J, Donnard M, Gulea M. Recent advances in the chemistry of organic thiocyanates. Chem Soc Rev. 2016;45:494–505. https://doi.org/10.1039/c5cs00532a.

Gulea M, Donnard M. Sustainable synthetic approaches involving thiocyanation and sulfur-cyanation: an update. Curr Green Chem. 2020;7:201–16. https://doi.org/10.2174/2213346107999200616105745.

Sarkar A, Santra S, Kundu SK, Hajra A, Zyryanov GV, Chupakhin ON, Charushin VN, Majee A. A decade update on solvent and catalyst-free neat organic reactions: a step forward towards sustainability. Green Chem. 2016;18:4475–525. https://doi.org/10.1039/c6gc01279e.

Zangade S, Patil P. A review on solvent-free methods in organic synthesis. Curr Org Chem. 2019;23:2295–318. https://doi.org/10.2174/1385272823666191016165532.

Yadav JS, Subba Reddy BV, Shubashree S, Sadashiv K. Iodine/MeOH: a novel and efficient reagent system for thiocyanation of aromatics and heteroaromatics. Tetrahedron Lett. 2004;45:2951–4. https://doi.org/10.1016/j.tetlet.2004.02.073.

Yadav JS, Subba Reddy BV, Subba Reddy UV, Krishna AD. Iodine/MeOH as a novel and versatile reagent system for the synthesis of a-ketothiocyanates. Tetrahedron Lett. 2007;48:5243–6. https://doi.org/10.1016/j.tetlet.2007.05.143.

Kharbach M, Marmouzi I, El Jemli M, Bouklouze A, Heyden YV. Recent advances in untargeted and targeted approaches applied in herbal-extracts and essential-oils fingerprinting - a review. J Pharm Biomed Anal. 2020;177: 112849. https://doi.org/10.1016/j.jpba.2019.112849.

Tan ECK, Johnell K, Garcia-Ptacek S, Haaksma ML, Fastbom J, Bell JS, Eriksdotter M. Acetylcholinesterase inhibitors and risk of stroke and death in people with dementia. Alzheimer’s & Dementia. 2018;14:944–51. https://doi.org/10.1016/j.jalz.2018.02.0111552-5260.

Karunakaran KB, Thiyagaraj A, Santhakumar K. Novel insights on acetylcholinesterase inhibition by Convolvulus pluricaulis, scopolamine and their combination in zebraish. Nat Prod Bioprospect. 2022;12:6. https://doi.org/10.1007/s13659-022-00332-5.

dos Santos TC, Gomes TM, Serra Pinto BA, Camara AL, de Andrade Paes AM. Naturally occurring acetylcholinesterase inhibitors and their potential use for Alzheimer’s disease therapy. Front Pharmacol. 2018;9:1192. https://doi.org/10.3389/fphar.2018.01192.

Ramallo IA, Salazar MO, Furlan RLE. Thin layer chromatography-autography-high resolution mass spectrometry analysis: accelerating the identification of acetylcholinesterase inhibitors. Phytochem Anal. 2015;26:404–12. https://doi.org/10.1002/pca.2574.

Cabezudo I, Salazar MO, Ramallo IA, Furlán RLE. Effect-directed analysis in food by thin-layer chromatography assays. Food Chem. 2022;390: 132937. https://doi.org/10.1016/j.foodchem.2022.132937.

Pezzani R, Vitalini S, Iriti M. Bioactivities of Origanum vulgare L.: an update. Phytochem Rev. 2017;16:1253–68. https://doi.org/10.14500/aro.10085.

Lin Q, Yang W, Yao Y, Chen S, Tan Y, Chen D, Yang D. Copper-catalyzed diastereoselective 1,2-difunctionalization of oxabenzonorbornadienes leading to β-thiocyanato thioethers. Org Lett. 2019;21:7244–7. https://doi.org/10.1021/acs.orglett.9b02452.

Chen H, Jiang W, Zeng Q. Recent advances in synthesis of chiral thioethers. J Chem Rec. 2020;20:1–29. https://doi.org/10.1002/tcr.202000084.

Li P, Yang Y, Wang X, Wu X. Recent achievements on the agricultural applications of thioether derivatives: a 2010–2020 decade in review. J Heterocyclic Chem. 2021;58:1225–51. https://doi.org/10.1002/jhet.4234.

Ellman GL, Courtney D, Andres V Jr, Featherstone RM. A new and rapid colorimetric determination of acetylcholinesterase activity. Biochem Pharmacol. 1961;7:88–95.

Kelly TR, Kim MH, Curtis ADM. Structure correction and synthesis of the naturally occurring benzothiazinone BMY 40662. J Org Chem. 1993;58:5855–7. https://doi.org/10.1021/jo00073a057.

de Oliveira Lima Filho E, Malvestiti I. Mechanochemical thiocyanation of aryl compounds via C-H functionalization. ACS Omega. 2020;5:33329–39. https://doi.org/10.1021/acsomega.0c05131.

Wang Z, Wang L, Chen Q, He M. Rapid and efficient thiocyanation of phenols, indoles, and anilines in 1,1,1,3,3,3-hexafluoro-2-propanol under ultrasound irradiation. Synth Commun. 2018;48:76–84. https://doi.org/10.1080/00397911.2017.1390139.

Mete TB, Khopade TM, Bhat RG. Transition-metal-free regioselective thiocyanation of phenols, anilines and heterocycles. Tetrahedron Lett. 2017;58:415–8. https://doi.org/10.1016/j.tetlet.2016.12.043.

Weng Z, Wang H, Wang L. Efficient thiocyanation of phenols and anilines in the CeBr 3 / H2O2 system. Mendeleev Commun. 2023;33:118–20. https://doi.org/10.1016/j.mencom.2023.01.037.

Dey A, Hajra A. Metal-free synthesis of 2-arylbenzothiazoles from aldehydes, amines, and thiocyanate. Org Lett. 2019;21:1686–9. https://doi.org/10.1021/acs.orglett.9b0245.

US5294724. 4-hydroxytetrahydropyran-2-ones and the corresponding dihydroxycarboxylic acid derivatives, salts and esters and a process for their preparation. 03/15/1994.

Dwivedi V, Rajesh M, Kumar R, Kant R, Sridhar RM. A stereoselective thiocyanate conjugate addition to electron deficient alkynes and concomitant cyclization to N, S-heterocycles. Chem Commun. 2017;53:11060–3. https://doi.org/10.1039/c7cc06081e.

Wang C, Geng X, Zhao P, Zhou Y, Wu Y-D, Cui Y-F, Wu A-X. I2/CuCl2-promoted one-pot three-component synthesis of aliphatic or aromatic substituted 1,2,3-thiadiazoles. Chem Commun. 2019;55:8134–7. https://doi.org/10.1039/c9cc04254g.

Kurzer F. 1,2,4-thiadiazoles. Adv Heterocycl Chem. 1982;32:285–398. https://doi.org/10.1016/S0065-2725(08)60656-X.

Kihara Y, Kabashima S, Uno K, Okawara T, Yamasaki T, Furukawa M. Oxidative heterocyclization using diethyl azodicarboxylate. Synthesis. 1990;11:1020–3. https://doi.org/10.1055/s-1990-27081.

Chen M, Lin S, Li L, Zhu C, Wang X, Wang Y, Jiang B, Li Y, Wang S, Yuhuan L, Jiaoliang J, Shi J. Enantiomers of an indole alkaloid containing unusual dihydrothiopyran and 1,2,4-thiadiazole rings from the root of Isatis indigotica. Org Lett. 2012;14:5668–71. https://doi.org/10.1021/ol302660t.

Anstis DG, Davison EK, Sperry J. 1,2,4-Thiadiazole alkaloids – isolation, biological activity and synthesis. Tetrahedron. 2024;150: 133767. https://doi.org/10.1016/j.tet.2023.133767.

Aki S, Fujioka T, Ishigami M, Minamikawa J. A practical synthesis of 3,4-diethoxybenzthioamide based on friedel-crafts reaction with potassium thiocyanate in methanesulfonic acid. Bioorg Med Chem Lett. 2002;12:2317–20. https://doi.org/10.1016/s0960-894x(02)00398-0.

Solís CM, Salazar MO, Ramallo IA, García P, Furlan RLE. Cyclocondensation versus cyclocondensation plus dehydroxylation during the reaction of flavones and hydrazine. Eur J Org Chem. 2022. https://doi.org/10.1002/ejoc.202200455.

Osella MI, Salazar MO, Gamarra MD, Moreno DM, Lambertucci F, Frances DE, Furlan RLE. Arylsulfonyl histamine derivatives as powerful and selective α-glucosidase inhibitors. RSC Med Chem. 2020;11:518–27. https://doi.org/10.1039/c9md00559e.

Acknowledgements

The authors thank the Instituto de Química de Rosario (IQUIR, CONICET-UNR) for providing access to NMR equipment. Mario O. Salazar and Ricardo L. E. Furlan are CONICET researchers.

Funding

Ricardo L. E. Furlan and Mario O. Salazar would like to acknowledge for provided financial support by Universidad Nacional de Rosario (80020180300114UR and 80020180100128UR), CONICET (PIP Nº 11220200102423) and FONCYT (PICT2015-3574 and PICT2018-01554) for the development of this work.

Author information

Authors and Affiliations

Contributions

Liz E. Lescano: Investigation. Mario O. Salazar: Conceptualization; data curation; formal analysis; funding acquisition; investigation; methodology; project administration; supervision; validation; writing—original draft; and writing—review and editing. Ricardo L.E. Furlan: Conceptualization; methodology; writing—review and editing; supervision; project administration; and funding acquisition.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Lescano, L.E., Salazar, M.O. & Furlan, R.L.E. Chemically engineered essential oils prepared through thiocyanation under solvent-free conditions: chemical and bioactivity alteration. Nat. Prod. Bioprospect. 14, 35 (2024). https://doi.org/10.1007/s13659-024-00456-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13659-024-00456-w