Abstract

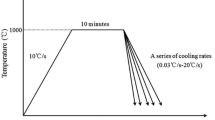

The high-nitrogen martensitic stainless steel (HNMS) was subjected to three different austenitizing cycles of 1050, 1075, and 1100 °C followed by sub-zero treatment at − 70 °C. The fraction of retained austenite has been reduced after sub-zero treatment as revealed by microstructural evolution. The material was subsequently tempered at different temperatures ranging from 180 to 650 °C and the change in micro-structure, hardness, tensile strength, and toughness were investigated after each heat treatment cycle. Optical microscopy, electron microscopy with EDS, and x-ray diffraction techniques were used to characterize the material. This has showed the constituents of microstructure were lath martensite, precipitated metal carbides of type M23C6, M7C6, and carbonitrides. Hardness, tensile testing, and Charpy impact testing were carried out to evaluate mechanical properties after the heat treatment which has showed the better mechanical properties for the samples solutionized at 1075 °C. Secondary hardening has been observed on tempering above 450 °C which can be attributed to the precipitation of secondary phase intermetallic compounds. Hardness attains a peak value at a peculiar temperature range after which it decreases on further tempering which is most likely because of the loss of coherency of the precipitates with the metal matrix. This has been further confirmed by the XRD of the specimens before and after tempering. The study establishes the structure-property correlation of HNMS for different heat treatment cycles. The results indicate that a good combination of hardness and strength can be achieved after solutionizing at 1075 °C followed by double tempering (DT) at 525 °C.

Similar content being viewed by others

References

A.N. Isfahany, H. Saghafian, G. Borhani, The effect of heat treatment on mechanical properties and corrosion behavior of AISI420 martensitic stainless steel. J. Alloy. Compd. 509(9), 3931–3936 (2011)

B. Pant, R. Sundar, H. Kumar, R. Kaul, A. Pavan, K. Ranganathan et al., Studies towards development of laser peening technology for martensitic stainless steel and titanium alloys for steam turbine applications. Mater. Sci. Eng. A. 587, 352–358 (2013)

D. Girodin, L . Manes, J. Moraux, J. De Monicault. Characterisation of the XD15N high nitrogen martensitic stainless steel for aerospace bearings. in Proceedings de 4th International Conference on Launcher Technology” Space Launcher Liquid Propulsion; 2002

R. Fan, M. Gao, Y. Ma, X. Zha, X. Hao, K. Liu, Effects of heat treatment and nitrogen on microstructure and mechanical properties of 1Cr12NiMo martensitic stainless steel. J. Mater. Sci. Technol. 28(11), 1059–1066 (2012)

D. Kesavan, S.N. Murty et al., Bearings for aerospace applications. Tribol. Int. 81, 108312 (2023)

A.B. Gingell, H.H. Bhadeshia, D. Jones, K.A. Mawella, Carbide precipitation in some secondary hardened steels. J. Mater. Sci. 32(18), 4815–4820 (1997)

I. Hucklenbroich, G. Stein, H. Chin, W. Trojahn, E. Streit. High nitrogen martensitic steel for critical components in aviation. in Materials Science Forum. vol. 318. (Trans Tech Publ, 1999). p. 161-6

T. Nykiel, T. Hryniewicz, Transformations of carbides during tempering of D3 tool steel. J. Mater. Eng. Perform. 23(6), 2050–2054 (2014)

V.G. Gavriljuk, H. Berns, High Nitrogen Steels: Structure, Properties, Manufacture, Applications (Springer Science & Business Media, 1999)

J. Rawers, Characterization of Fe–C–N alloys’ mechanical properties. Mater. Sci. Eng. A. 276(1–2), 91–98 (2000)

N. Akdut, J. Foct, Microstructure and deformation behavior of high nitrogen duplex stainless steels. ISIJ Int. 36(7), 883–892 (1996)

H. Berns, R. Ehrhardt. Carbon or nitrogen alloyed quenched and tempered stainless steels-a comparative study. Steel Res. (Duesseldorf) 67 (1996)

J. Agren, A thermodynamic analysis of the Fe-C and Fe-N phase diagrams. Metallurg. Trans. A. 10, 1847–1852 (1979)

W. Kaluba, T. Kaluba, R. Taillard, The austenitizing behaviour of high-nitrogen martensitic stainless steels. Scripta Mater. 41(12), 1289–1293 (1999)

M. Ojima, M. Ohnuma, J. Suzuki, S. Ueta, S. Narita, T. Shimizu et al., Origin of the enhanced hardness of a tempered high-nitrogen martensitic steel. Scripta Mater. 59(3), 313–316 (2008)

W.C. Jiao, H.B. Li, J. Dai, H. Feng, Z.H. Jiang, T. Zhang et al., Effect of partial replacement of carbon by nitrogen on intergranular corrosion behavior of high nitrogen martensitic stainless steels. J. Mater. Sci. Technol. 35(10), 2357–2364 (2019)

H. Feng, H.B. Li, Z.H. Jiang, T. Zhang, N. Dong, S.C. Zhang et al., Designing for high corrosion- resistant high nitrogen martensitic stainless steel based on DFT calculation and pressurized metallurgy method. Corros. Sci. 158, 108081 (2019)

A. Toro, W.Z. Misiolek, A.P. Tschiptschin, Correlations between microstructure and surface properties in a high nitrogen martensitic stainless steel. Acta Mater. 51(12), 3363–3374 (2003)

F. Vanderschaeve, R. Taillard, J. Foct, Effect of heat treatment on the microstructure of a high nitrogen 12% chromium martensitic steel. Steel Res. 64(4), 221–227 (1993)

K. Irvine, J. Murray, F. Pickering, The Effect of heat-treatment and microstructure on the high-temperature ductility of 18%Cr–12%Ni-1%Nb-steels. J. Iron Steel Instit. 10, 166–179 (1960)

I. Kj, High-strength austenitic stainless steels. J. Iron Steel Inst. 199, 153–175 (1961)

C.Y. Chen, F.Y. Hung, T.S. Lui, L.H. Chen, Microstructures and mechanical properties of austempering SUS440 steel thin plates. Metals. 6(2), 35 (2016)

M. Byrnes, M. Grujicic, W. Owen, Nitrogen strengthening of a stable austenitic stainless steel. Acta Metall. 35(7), 1853–1862 (1987)

M.O. Speidel, R.M. Pedrazzoli, High nitrogen stainless steels in chloride solutions. Mater. Perform. 31(9), 59–61 (1992)

G. Krauss, A. Marder, The morphology of martensite in iron alloys. Metallurg. Trans. 2(9), 2343–2357 (1971)

H. Bhadeshia, Martensite and bainite in steels: transformation mechanism & mechanical properties. Le J. Phys. IV. 7(C5), C5-367 (1997)

S.C. Krishna, N.K. Gangwar, A.K. Jha, B. Pant, K.M. George, Effect of heat treatment on the microstructure and hardness of 17Cr–0.17N–0.43C–1.7Mo martensitic stainless steel. J. Mater. Eng. Perform. 24(4), 1656–1662 (2015)

N. Zhu, Q. Wu, Y. He, X. Lu, L. Li, P. Hu, Effect of Ni on the stability of retained austenite and mechanical properties for TRIP steels containing vanadium. Steel Res. Int. 85(2), 143–154 (2014)

T. Ohmura, T. Hara, K. Tsuzaki, H. Nakatsu, Y. Tamura, Mechanical characterization of secondary- hardening martensitic steel using nanoindentation. J. Mater. Res. 19(1), 79–84 (2004)

L. Lim, M. Lai, J. Ma, D. Northwood, B. Miao, Tempering of AISI403 stainless steel. Mater. Sci. Eng. A. 171(1–2), 13–19 (1993)

L.D. Barlow, M. Du Toit, Effect of austenitizing heat treatment on the microstructure and hardness of martensitic stainless steel AISI 420. J. Mater. Eng. Perform. 21, 1327–1336 (2012)

S. Chenna Krishna, J. Srinath, A.K. Jha, B. Pant, S. Sharma, K.M. George, Effect of heat treatment on microstructure and mechanical properties of 12Cr–10Ni–0.25Ti–0.7 Mo stainless steel. Metallogr. Microstruct. Anal. 2, 234–241 (2013)

S.J. Lee, Y.M. Park, Y.K. Lee, Reverse transformation mechanism of martensite to austenite in a metastable austenitic alloy. Mater. Sci. Eng. A. 515(1–2), 32–37 (2009)

Acknowledgements

HSD expresses gratitude to his colleagues at Aerospace Materials Laboratory (AML), LPSC/ISRO, for their valuable assistance in characterization. The support provided by IIST, VSSC, and LPSC is sincerely acknowledged.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dhami, H.S., Kumar, N.D., Tharian, T. et al. Microstructure and Mechanical Properties of Heat-Treated High-Nitrogen Martensitic Stainless Steel. Metallogr. Microstruct. Anal. 13, 96–105 (2024). https://doi.org/10.1007/s13632-024-01041-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-024-01041-w