Abstract

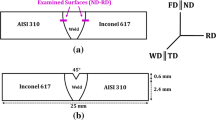

During this research work, the impact toughness and tensile strength of the electron beam-welded AISI409 plates were evaluated as a function of varied heat input (low 0.96 kJ/mm and high 1.10 kJ/mm) and after imparting post-weld heat treatment. Ferritic stainless steels are prone to enlargement in grain structure and degradation of mechanical properties on exposure to heating and cooling cycles during welding which results in deterioration in their performance. Results revealed that the base metal possessed coarse ferrite grains which got transferred into columnar and axial grains due to faster cooling rate of electron beam welding. The impact toughness of the specimens extracted from the top region of weld zone, when welded using high heat input, reduced by 46% as compared to the base metal. However, the specimens extracted from the bottom section possessed 83% higher impact toughness as compared to the top section. Further, the post-weld heat treatment resulted in refined microstructure, which increased the impact toughness by 35% and 24% for high heat input and low heat input welded joints, respectively. However, the tensile strength of the specimens extracted from the bottom section improved by 26% as compared to the base metal.

Graphical abstract

Similar content being viewed by others

References

M.B. Cortie, History and development of ferritic stainless steels. J. South. Afr. Inst. Min. Metall. 93(7), 165–176 (1993)

D.J. Kotecki, T.A. Siewert, WRC-1992 constitution diagram for stainless steel weld metals: a modification of the WRC-1988 diagram. Weld. Res. Suppl. 71(5), 171–178 (1992)

E. Taban, A. Dhooge, E. Kaluc, Plasma arc welding of modified 12% Cr stainless steel. Mater. Manuf. Process. 24(6), 649–656 (2009). https://doi.org/10.1080/10426910902769152

C. Köse, C. Topal, Laser welding of AISI 410S ferritic stainless steel. Mater. Res. Express 6(8), 1–14 (2019). https://doi.org/10.1088/2053-1591/ab26c0

S.K. Gupta, A.R. Raja, M. Vashista, M.Z.K. Yusufzai, Effect of heat input on microstructure and mechanical properties in gas metal arc welding of ferritic stainless steel. Mater. Res. Express 6(3), 1–46 (2018)

R.S. Vidyarthy, D.K. Dwivedi, M. Vasudevan, Influence of M-TIG and A-TIG Welding Process on Microstructure and Mechanical Behavior of 409 Ferritic Stainless Steel. J. Mater. Eng. Perform. 26(3), 1391–1403 (2017). https://doi.org/10.1007/s11665-017-2538-5

C.J. Van Niekerk, M. Du Toit, M.W. Erwee, Sensitization of AISI 409 ferritic stainless steel during low heat input arc welding. Weld. World 56, 55–64 (2012)

M. Du Toit, C.J. Van Niekerk, Sensitization behaviour of 11–12% Cr AISI 409 stainless steel during low heat input welding. J. South. African Inst. Min. Metall. 111(4), 243–256 (2011)

A. Doomra, S.S. Sandhu, B. Singh, Weldability studies of 18 mm thick AISI409 ferritic stainless steel plate using electron beam welding process. Int. J. Eng. 18(3), 23–28 (2020)

J. C. Lippold and D. J. Kotecki, Welding Metallurgy and Weldability of Stainless Steel, vol. 21, No. 2, Wiley, 2006

A.C.T.M. Van Zwieten, J.H. Bulloch, Some considerations on the toughness properties of ferritic stainless steels-A brief review. Int. J. Press. Vessel. Pip. 56(1), 1–31 (1993). https://doi.org/10.1016/0308-0161(93)90114-9

M.O.H. Amuda, S. Mridha, An overview of sensitization dynamics in ferritic stainless steel welds. Int. J. Corros. 1–9, 2011 (2011). https://doi.org/10.1155/2011/305793

C. Grobler, Weldability Studies on 12% and 14% Chromium Steels, No. September, 1987

E. Deleu, A. Dhooge, E. Taban, E. Kaluc, Possibilities and limitations to improve the weldability of low carbon 12Cr Ferritic stainless steel for expanded industrial applications. Weld. World 53(9–10), 198–208 (2009). https://doi.org/10.1007/BF03321131

M.A. Khattak et al., Effect of welding phenomenon on the microstructure and mechanical properties of ferritic stainless steel—a review Akademia Baru. J. Adv. Res. Mater. Sci. 1(1), 13–31 (2017)

A. Kumar, G. Sharma, D.K. Dwivedi, TIG spot weld bonding of 409 L ferritic stainless steel. Int. J. Adhes. Adhes. 84, 350–359 (2018). https://doi.org/10.1016/j.ijadhadh.2018.04.012

A. Doomra, S. S. Sandhu, and B. Singh, Effect of post weld heat treatment on metallurgical and mechanical properties of electron beam welded AISI 409 ferritic steel, 2020

J.A. Delgado, R.R. Ambriz, R. Cuenca-Álvarez, N. Alatorre, F.F. Curiel, Heat input effect on the microstructural transformation and mechanical properties in GTAW welds of a409L ferritic stainless steel. Rev. Metal. (2016). https://doi.org/10.3989/revmetalm.068

S.S. Sandhu, A.S. Shahi, Metallurgical, wear and fatigue performance of Inconel 625 weld claddings. J. Mater. Process. Technol. 233, 1–8 (2016). https://doi.org/10.1016/j.jmatprotec.2016.02.010

H. Schultz, Electron Beam Technologies, Vol. 1e. compact knowledge DVS media Gmbh, Dusseldorf, 2012

J. Singh, A.S. Shahi, Metallurgical, impact and fatigue performance of electron beam welded duplex stainless steel joints. J. Mater. Process. Technol. 272, 137–148 (2019). https://doi.org/10.1016/j.jmatprotec.2019.05.010

A. Kumar, S.S. Sandhu, B. Singh, Effect of thermal aging on impact toughness of electron beam-welded AISI 316 stainless steel. Miner. Met. Mater. Ser. (2020). https://doi.org/10.1007/978-3-030-36628-5_16

A. Kumar, B. Singh, S.S. Sandhu, Effect of thermal aging on metallurgical, tensile and impact toughness performance of electron beam welded AISI 316 SS joints. Fusion Eng. Des. 159(March), 111949 (2020). https://doi.org/10.1016/j.fusengdes.2020.111949

C.L.M. Cottrell, Electron beam welding review —a critical. Mater. Des. 6, 285–291 (1985)

M.S. Węglowski, S. Błacha, A. Phillips, Electron beam welding—Techniques and trends—review. Vacuum 130, 72–92 (2016). https://doi.org/10.1016/J.VACUUM.2016.05.004

M. S. Węglowski, J. Dworak, and S. Błacha, Electron Beam Welding – Characteristics, no. 3, 2014

A.K. Lakshminarayanan, V. Balasubramanian, Comparison of Electron Beam and Friction Stir Weldments of Modified 12 wt.% Ferritic Stainless Steel. Mater. Manuf. Process. 26(6), 37–41 (2011). https://doi.org/10.1080/10426914.2010.515643

M. Tullmin, F.P.A. Robinson, C.A.O. Henningt, A. Strausst, J. Le Grange, Properties of laser-welded and electron-beam-welded ferritic stainless steel. J. South Afr. Inst. Min. Metall. 89(8), 243–249 (1989)

V. Thomas Paul, S. Saroja, S.K. Albert, T. Jayakumar, E. Rajendra Kumar, Microstructural characterization of weld joints of 9Cr reduced activation ferritic martensitic steel fabricated by different joining methods. Mater. Charact. (2014). https://doi.org/10.1016/j.matchar.2014.08.013

P. Havlík, P. Šohaj, J. Kouril, R. Foret, I. Dlouhý, EBW of Stainless Steels and ODS Ferritic Steel. Methods 4, 5–6 (2014)

M.O.H. Amuda, E. Akinlabi, S. Mridha, Ferritic stainless steels: metallurgy, application and weldability. Ref. Modul. Mater. Sci. Mater. Eng. (2016). https://doi.org/10.1016/b978-0-12-803581-8.04010-8

M. Keskitalo, J. Sundqvist, K. Mäntyjärvi, J. Powell, A.F.H. Kaplan, The Influence of shielding gas and heat input on the mechanical properties of laser welds in ferritic stainless steel. Phys. Procedia 78(August), 222–229 (2015). https://doi.org/10.1016/j.phpro.2015.11.032

M.S. Rajadurai, S. Naveen, M. Afnas, T. Arun, N. Kumar, S. Surendhar, Methods to avoid material sensitization during welding for developing corrosion resistant exhaust system. Int. J. Recent Dev. Eng. Technol. 4(7), 23–36 (2015)

S. Anttila, P. Karjalainen, S. Lantto, Mechanical properties of ferritic stainless steel welds in using type 409 and 430 filler metals. Weld. World 57(3), 335–347 (2013). https://doi.org/10.1007/s40194-013-0033-7

E. Taban, E. Deleu, A. Dhooge, E. Kaluc, Laser welding of modified 12% Cr stainless steel: Strength, fatigue, toughness, microstructure and corrosion properties. Mater. Des. 30(4), 1193–1200 (2009). https://doi.org/10.1016/j.matdes.2008.06.030

ASTM Standard E8, Standard Test Methods for Tension Testing of Metallic Materials. ASTM Int. (2013). https://doi.org/10.1520/e0008_e0008m-13a

ASTM standard E 23-12c, Standard Test Methods for Notched Bar Impact Testing of Metallic Materials. ASTM Int. (2013). https://doi.org/10.1520/e0023-12c.2

ASTM standard E3-11, Standard Practice for Preparation of Metallographic Specimens. ASTM Int. 82(C), 1–15 (2016). https://doi.org/10.1520/d0638-14.1

ASTM Standard E407-99, E407-99: Standard Practice for Microetching Metals and Alloys, ASTM Int., pp. 1–21, 2012

M.V. Venkatesan, N. Murugan, S. Sam, S.K. Albert, Effect of heat input on macro, micro and tensile properties of flux cored arc welded ferritic stainless steel joints. Trans. Indian Inst. Met. 67(3), 375–383 (2014). https://doi.org/10.1007/s12666-013-0358-3

J. C. Lippold and W. F. Savage, Solidification of Austenitic Stainless Steel Weldments : Part I—A Proposed Mechanism The distribution and morphology of delta ferrite is dependent, Weld. Res. Suppl. No. December, pp. 362 s–374 s, 1979

A.K. Lakshminarayanan, V. Balasubramanian, G.M. Reddy, Microstructure and mechanical properties of electron beam-welded AISI 409 M-grade ferritic stainless steel. Int. J. Adv. Manuf. Technol. 1, 153–162 (2011). https://doi.org/10.1007/s00170-010-3044-1

G.M. Reddy, K.S. Rao, Microstructure and mechanical properties of similar and dissimilar stainless steel electron beam and friction welds. Int. J. Adv. Manuf. Technol. (2009). https://doi.org/10.1007/s00170-009-2019-6

H. Zheng, X. Ye, L. Jiang, B. Wang, Z. Liu, G. Wang, Study on microstructure of low carbon 12% chromium stainless steel in high temperature heat-affected zone. Mater. Des. 31(10), 4836–4841 (2010). https://doi.org/10.1016/j.matdes.2010.05.054

D.A. Carrizo, J.I. Besoky, M. Luppo, C. Danon, C.P. Ramos, Characterization of an ASTM A335 P91 ferritic-martensitic steel after continuous cooling cycles at moderate rates. J. Mater. Res. Technol. 8(1), 923–934 (2019). https://doi.org/10.1016/j.jmrt.2018.07.004

M C Balmforth and J C Lippold, A New Ferritic-Martensitic Stainless Steel Constitution Diagram, Weld. Res. Suppl. No. December, pp. 339–345, 2000

J. Pekkarinen, V. Kujanpää, The effects of laser welding parameters on the microstructure of ferritic and duplex stainless steels welds. Phys. Procedia 5(PART 1), 517–523 (2010). https://doi.org/10.1016/j.phpro.2010.08.175

V.L. Manugula, K.V. Rajulapati, G.M. Reddy, K.B.S. Rao, Role of evolving microstructure on the mechanical properties of electron beam welded ferritic-martensitic steel in the as-welded and post weld heat-treated states. Mater. Sci. Eng., A 698, 36–45 (2017). https://doi.org/10.1016/j.msea.2017.05.036

A.K. Lakshminarayanan, V. Balasubramanian, Influences of welding processes on microstructure and mechanical properties of modified 12 wt.% Cr ferritic stainless steel. Int. J. Manuf. Res. 7(4), 331–353 (2012). https://doi.org/10.1504/IJMR.2012.050100

Acknowledgements

The authors acknowledge the support and guidance provided by Mechanical Engineering Department, IK Gujral Punjab Technical University, Kapurthala.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Doomra, A., Singh, B. & Sandhu, S.S. Influence of Input Parameters and Post-weld Heat Treatment on the Metallurgical and Mechanical Properties of Electron Beam-Welded Thick AISI 409 Ferritic Stainless Steel. Metallogr. Microstruct. Anal. 10, 219–235 (2021). https://doi.org/10.1007/s13632-021-00735-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-021-00735-9