Abstract

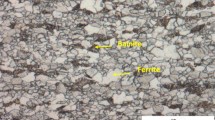

In this work, an instrumented indentation technique with a nearly flat tip indenter was used to measure the yield strength of API-X80 line pipe weld. Using this technique, the yield strength can be estimated directly from the indentation load–displacement response. The yield strength of the weld metal was measured in the transverse (hoop) and longitudinal (long) directions of the weld, and the results indicated that the weld metal exhibits anisotropy in terms of the yield strength by as much as 100 MPa, which could lead to a non-conservative estimate when strength mismatch is considered. Conventional tensile testing obtained strength values to within 4.6% of the indentation measurements and confirmed the results. Hardness maps also show a 20 HV0.5 difference in the two directions of the weld, which supports anisotropy of yield strength. The microstructure analysis using SEM reveals a slight difference in the grain size, which partially explains the differences in properties.

Similar content being viewed by others

References

M.D. Herynk, S. Kyriakides, A. Onoufriou, H.D. Yun, Effects of the UOE/UOC pipe manufacturing processes on pipe collapse pressure. Int. J. Mech. Sci. 49(5), 533–553 (2007)

M.S. Joo, D.W. Suh, H.K.D.H. Bhadeshia, Mechanical Anisotropy in Steels for Pipelines. ISIJ Int. 53(8), 1305–1314 (2013)

A.M. Sage, Physical metallurgy of high strength, low alloy line pipe and pipe fitting steels. Met. Technol. 10(1), 224–233 (1983)

O. Hilgert, S. Höhler, “Anisotropic hfi welded steel pipes for strain based design,” pp. 1–9, 2016.

W. T., D. H. J.T. Bowker, J.A. Gianetto, G. Shen, “Ipc2006-10400 Strain-Based Designed Pipelines,” in IPC, 2006, vol. 6, pp. 1–12.

Z.L. Zhang, M. Hauge, C. Thaulow, J. Odegard, A notched cross weld tensile testing method for determining true stress-strain curves for weldments. Eng. Fract. Mech. 69(3), 353–366 (2002)

W.D. Lockwood, B. Tomaz, A.P. Reynolds, Mechanical response of friction stir welded AA2024: experiment and modeling. Mater. Sci. Eng. A 323, 348–353 (2002)

J. Yan, M. A. Sutton, A. P. Reynolds, S. Adeeb, D. Horsley, Characterization of heterogeneous response of pipeline steel weld using digital image correlation, no. October 2015, 2006.

K.M. Saranath, A. Sharma, M. Ramji, Zone wise local characterization of welds using digital image correlation technique. Opt. Lasers Eng. 63, 30–42 (2014)

G. Xiao et al., Determination of power hardening elastoplastic constitutive relation of metals through indentation tests with plural indenters. Mech. Mater. 138, 103173 (2019)

X. Hernot, O. Bartier, G. Mauvoisin, J.M. Collin, A universal formulation for indentation whatever the indenter geometry. Mech. Mater. 81, 101–109 (2015)

W.C. Oliver, G.M. Pharr, Measurement of hardness and elastic modulus by instrumented indentation Advances in understanding and refinements to methodology. Mater. Res. Soc. 19(1), 3–20 (2004)

B. Taljat, T. Zachari, F. Kosel, New analytical procedure to determine stress strain curve from spherical indentation data. Int. J. Solids Struct. 35(33), 4411–4426 (1998)

O. Bartier, X. Hernot, G. Mauvoisin, Theoretical and experimental analysis of contact radius for spherical indentation. Mech. Mater. 42(6), 640–656 (2010)

E.G. Herbert, G.M. Pharr, W.C. Oliver, B.N. Lucas, J.L. Hay, On the measurement of stress-strain curves by spherical indentation. Thin Solid Films 398, 331–335 (2001)

F.M. Haggag, In-situ nondestructive measurements of key mechanical properties of oil and gas pipelines. ASME-PUBLICATIONS-PVP 429(November), 99–104 (2001)

F.Y.M. Haggag, G.E. Lucas, Determination of luders strains and flow properties in steels from hardness/microhardness tests. Metall. Trans. A 14(August), 1607–1613 (1983)

R.V. Prakash, S.S. Chow, An evaluation of stress-strain property prediction by Automated Ball Indentation (ABI) testing”. J. Test. Eval. 35(3), 221–232 (2007)

V. Karthik et al., Finite element analysis of spherical indentation to study pile-up/sink-in phenomena in steels and experimental validation. Int. J. Mech. Sci. 54(1), 74–83 (2012)

J.E. Campbell, R.P. Thompson, J. Dean, T.W. Clyne, Experimental and computational issues for automated extraction of plasticity parameters from spherical indentation. Mech. Mater. 124(March), 118–131 (2018)

M. Bocciarelli, G. Bolzon, G. Maier, Parameter identification in anisotropic elastoplasticity by indentation and imprint mapping. Mech. Mater. 37(8), 855–868 (2005)

P. Haušild, A. Materna, J. Nohava, Characterization of anisotropy in hardness and indentation modulus by nanoindentation. Metallogr. Microstruct. Anal. 3(1), 5–10 (2014)

A. Yonezu, K. Yoneda, H. Hirakata, M. Sakihara, K. Minoshima, A simple method to evaluate anisotropic plastic properties based on dimensionless function of single spherical indentation—application to SiC whisker-reinforced aluminum alloy. Mater. Sci. Eng. A 527(29–30), 7646–7657 (2010)

B. Riccardi, R. Montanari, Indentation of metals by a flat-ended cylindrical punch. Mater. Sci. Eng. A 381(1–2), 281–291 (2004)

Y.C. Lu, S.N.V.R.K. Kurapati, F. Yang, Finite element analysis of cylindrical indentation for determining plastic properties of materials in small volumes. J. Phys. D Appl. Phys. 41(11), 115415 (2008)

Z. Hu, K. Lynne, F. Delfanian, Characterization of materials’ elasticity and yield strength through micro-/nano-indentation testing with a cylindrical flat-tip indenter. J. Mater. Res. 30(4), 578–591 (2015)

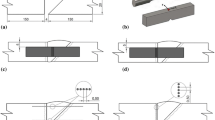

A.R.H. Midawi, C.H.M. Simha, M.A. Gesing, A.P. Gerlich, Elastic-plastic property evaluation using a nearly flat instrumented indenter. Int. J. Solids Struct. 104, 81–91 (2016)

A.R.H. Midawi, C.H.M. Simha, A.P. Gerlich, Novel techniques for estimating yield strength from loads measured using nearly-flat instrumented indenters. Mater. Sci. Eng. A 675, 449–453 (2016)

Det Norske Veritas, Submarine Pipeline Systems, no. F101. DNV, 2010

R. Hill, The mathematical theory of plasticity, vol. 11 (Oxford University Press, Oxford, 1998)

P. Reynolds, F. Duvall, Digital image correlation for determination of weld and base metal constitutive behavior. Welding Journal-New York 78(10), 355–360 (1999)

A.P. Institute, API 1104. standard for welding pipelings and related facilities. Api 552, 79 (2005)

J. Lu, O. Omotoso, J.B. Wiskel, D.G. Ivey, H. Henein, Strengthening mechanisms and their relative contributions to the yield strength of microalloyed steels. Metall. Mater. Trans. A 43(9), 3043–3061 (2012)

A.R.H. Midawi, E.B.F. Santos, N. Huda, A.K. Sinha, R. Lazor, A.P. Gerlich, Microstructures and mechanical properties in two X80 weld metals produced using similar heat input. J. Mater. Process. Tech. 226, 272–279 (2015)

ASTM, “ASTM E112-13: Standard test methods for determining average grain size,” ASTM Int., pp. 1–28, 2013

J. Lu, Quantitative Microstructural Characterization of Microalloyed Steels, University of Alberta, 2009.

Acknowledgment

The authors would like to acknowledge TransCanada Corp and the Natural Sciences and Engineering Research Council of Canada (NSERC) for their financial support. The authors also would like to acknowledge Mr. Jim Gianetto from CanmetMATERIALS and Natural Resources Canada for his help in performing the SEM analysis.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Midawi, A.R.H., Huda, N., Simha, C.H.M. et al. Characterization of Anisotropy of Strength in API-X80 Line Pipe Welds Through Instrumented Indentation. Metallogr. Microstruct. Anal. 9, 884–894 (2020). https://doi.org/10.1007/s13632-020-00693-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-020-00693-8