Abstract

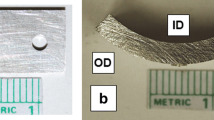

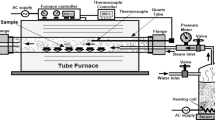

Surface modifications offer promising solutions to increase the lifetime and performance of superheaters in industrial applications. The surface and internal structure of the steamside of austenitic superheater tubes of TP347H austenitic stainless steel was modified by shot peening and the thermal stability of the microstructure at the surface was followed in-situ and ex-situ during subsequent isothermal annealing. At various industrially relevant temperatures, the kinetics of microstructure evolution near the surface was investigated by applying complementary methods of microscopy and diffraction analysis. The beneficial effect of shot peening on reducing steamside oxidation was confirmed both on laboratory scale mimicking the real industrial conditions and after long-term exposure to steam oxidation conditions in a thermal power plant. Both the effect of the grain size in austenite and the role of shot peening on steam oxidation are discussed.

Similar content being viewed by others

References

S. Osgerby, A.T. Fry, Steam Oxidation Resistance of Selected Austenitic Steels. Mater. Sci. Forum 461–464, 1023–1030 (2004)

A.N. Hansson, K. Pantleon, F.B. Grumsen, M.A.J. Somers, Microstructure Evolution During Steam Oxidation of a Nb Stabilized Austenitic Stainless Steel. Oxid. Met. 73, 289–309 (2010)

J.C. Rosser, M.I. Bass, C. Cooper, T. Lant, P.D. Brown, B.J. Connolly, H.E. Evans, Steam Oxidation od Super 304H and Shot-Peened Super 304H. Mater. High Temp. 29, 95–106 (2012)

T. Dudziak, M. Łukaszewicz, N. Simms, J. Nicholls, Analysis of High Temperature Steam Oxidation of Superheater Steels Used in Coal Fired Boilers. Oxid. Met. 85, 171–187 (2016)

I.G. Wright, R.B. Dooley, Morphology of Oxide Growth and Exfoliation in Superheater and Reheater Tubing of Steam Boilers. Mater. High Temp. 28, 40–57 (2011)

R. Viswanathan, W. Bakker, Materials for Ultrasupercritical Coal Power Plants—Boiler Materials: Part 1. J. Mater. Eng. Perform. 10, 81–95 (2001)

H., Matsuo, Y. Nishiyama, and Y. Yamadera, Steam oxidation property of fine-grain steels, in Proceedings from the Fourth International Conference on Advances in Materials Technology for Fossile Power Plants, EPRI Report Number 1011381, pp. 441–450 (2005)

K. Yoshikawa, H. Teranishi, K. Tokimasa, H. Fujikawa, M. Miura, K. Kubota, Fabrication and Properties of Corrosion Resistant TP347H Stainless Steel. J. Mater. Eng. 10, 69–83 (1988)

M. Montgomery, O. Hede Larsen, S. Aakjær Jensen, O. Biede, Field Investigation of Steamside Oxidation for TP347H. Mater. Sci. Forum 461–464, 1007–1014 (2004)

Y. Nishiyama, A. Iseda, M. Yoshizawa, S. Matsumoto, and M. Igarashi, Effect of grain size on steam oxidation for shot-peened stainless steels, in Advances in Materials Technology for Fossil Power Plants: Proceedings from the sixth International Conference, pp. 185–197 (2011)

S. Wang, Y. Li, M. Yao, R. Wang, Compressive Residual Stress Introduced by Shot Peening. J. Mater. Process. Technol. 73, 64–73 (1998)

S. Bagherifard, S. Slawik, I. Fernández-Pariente, C. Pauly, F. Mücklich, M. Guaglianoa, Nanoscale Surface Modification of AISI 316L Stainless Steel by Severe Shot Peening. Mater. Des. 102, 68–77 (2016)

G. Fargas, J.J. Roa, A. Mateo, Effect of Shot Peening on Metastable Austenitic Stainless Steels. Mater. Sci. Eng., A 641, 290–296 (2015)

S. Pour-Ali, A.R. Kiani-Rashid, A. Babakhani, S. Virtanen, Thermal Stability of Nanocrystalline Surface Layer of AISI 321 Stainless Steel. Vacuum 146, 297–303 (2017)

H. Yinsheng, Y. Keun-Bong, M. Houyu, S. Keesam, Study of the Austenitic Stainless Steel with Gradient Structured Surface Fabricated Via Shot Peening. Mater. Lett. 215, 187–190 (2018)

N.R. Tao, M.L. Suib, J. Lud, K. Lua, Surface Nanocrystallization of Iron Induced by Ultrasonic Shot Peening. Nanostruct. Mater. 11, 433–440 (1999)

J.L. Liu, M. Umemoto, Y. Todaka, K. Tsuchiya, Formation of a Nanocrystalline Surface Layer on Steels by Air Blast Shot Peening. J. Mater. Sci. 42, 7716–7720 (2007)

W.B. Liu, C. Zhang, Z.X. Xia, Z.G. Yang, P.H. Wang, J.M. Chen, Strain Induced Refinement and Thermal Stability of a Nanocrystalline Steel Produced by Surface Mechanical Attrition Treatment. Mater. Sci. Eng., A 568, 176–183 (2013)

W. Liu, C. Zhang, Z. Yang, Z. Xia, Microstructure and Thermal Stability of Bulk Nanocrystalline Alloys Produced by Surface Mechanical Attrition Treatment. Appl. Surf. Sci. 292, 556–562 (2014)

Y. Todaka, M. Umemoto, Y. Watanabe, K. Tsuchiya, Formation of Nanocrystalline Structure by Shot Peening. Mater. Sci. Forum 503–504, 669–674 (2006)

T. Wang, J. Yu, B. Dong, Surface Nanocrystallization Induced by Shot Peening and Its Effect on Corrosion Resistance of 1Cr18Ni9Ti Stainless Steel. Surf. Coat. Technol. 200, 4777–4781 (2006)

R.U. Husemann, Materials and Their Service Properties for Superheater and Reheater Tubing in Power Stations with Advanced Steam Parameters: Part 2: Influence of Oxidation and Cold Deformation, Conclusions and Recommendations. VGB PowerTech 79, 84–87 (1999)

J.I. Langford, A Rapid Method for Analysing the Breadths of Diffraction and Spectral Lines Using the Voigt Function. J. Appl. Cryst. 11, 10–14 (1978)

T.H. De Keijser, J.I. Langford, E.J. Mittemeijer, A.B.P. Vogels, Use of the Voigt Function in a Single-Line Method for the Analysis of X-ray Diffraction Line Broadening. J. Appl. Cryst. 15, 308–314 (1982)

G.K. Williamson, W.H. Hall, X-ray Line Broadening from Filed Aluminum and Wolfram. Acta Metall. 1, 22–31 (1953)

F.J. Humphreys, M. Hatherly, Recrystallization and Related Annealing Phenomena (Pergamon, New York, 1996)

W. Xuanpei, Q. Zeyou, Z. Zhiling, Z. Hongcheng, W. Weijie, W. Yanfei, Surface Grain Refinement of 304L Stainless Steel by Combined Severe Shot Peening and Reversion Annealing Treatment. Coatings 10, 470–477 (2020)

Acknowledgements

The authors are grateful to Richard Kemsies and Sunday Chukwudi Okoro, who carried out some of the experimental work. Furthermore, Alice Bastos Fanta and Hossein Alimadadi are kindly acknowledge for valuable discussions and support with EBSD.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pantleon, K., Lampert, F. & Montgomery, M. Annealing of Shot Peened Austenitic Superheater Tubes and Its Consequences for Steamside Oxidation. Metallogr. Microstruct. Anal. 9, 603–614 (2020). https://doi.org/10.1007/s13632-020-00666-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-020-00666-x