Abstract

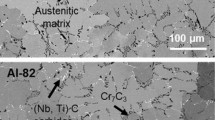

The oxidation behaviour of TP 347H FG in mixtures of water, oxygen, and hydrogen was investigated at 500, 600, and 700 °C for a fixed oxidation time of 336 h. The samples were characterised using X-ray diffraction, reflective light and electron microscopy methods. Thin discontinuous double-layered oxide scales developed during oxidation at 500 °C, whereas continuous double-layered oxide scales covered the entire sample surface after oxidation at 600 and 700 °C. The major part of the inner oxide layer developed within the former alloy grains, whereas a Fe–Cr spinel formed along the former alloy grain boundaries. Transmission electron microscopy and electron energy loss spectroscopy investigations revealed that the part of the scale that grows into the alloy grains consists of particles of Fe–Cr spinel embedded in a metallic Fe–Ni matrix, which indicates that this part of the scale grows by an internal oxidation mechanism. The thickness of the inner oxide zone at high humidity (46%) is not significantly affected by the type of carrier gas used, whereas this thickness at low humidity (8% H2O) is sensitive for the carrier gas and increases in the following order: air < Ar+7% H2 < Ar, indicating that the presence of oxygen or hydrogen in addition to a relatively low content of water vapour counteracts the effect of water vapour on the development of the inner oxide zone.

Similar content being viewed by others

Notes

Diffraction spots not included in the fcc and spinel patterns indicated in Fig. 9a, b are attributed to double diffraction.

Note that the sample has drifted slightly during the measurements.

It is noted that the results in Table 8 can be influenced by overlap of phases on analysis.

304L: 0.027 wt% C, 0.55 wt% Si, 1.41 wt% Mn, 18.5 wt% Cr, 0.49 wt% Mo, 10.2 wt% Ni, 0.075 wt% N, balc. Fe.

Esshete 1250: 0.09 wt% C, 0.6 wt% Si, 6.2 wt% Mn, 15.3 wt% Cr, 1.1 wt% Mo, 9.9 wt% Ni, 0.075 wt% N, balc. Fe.

Note that hydrostatic stresses relax in the depth direction towards the surface. Actually, hydrostatic compressive stresses should yield a lattice parameter that is smaller than for unconstrained spinel as measured in PB-XRD. The presence of the surface leads to (local) relaxation of stresses in the direction perpendicular to the surface and a stress state that is effectively biaxial compressive in the analyzed depth range. Consequently, a lattice parameter larger than for the unconstrained spinel is observed.

References

H. Asteman, J.-E. Svensson, and L.-G. Johansson, Oxidation of Metals 52, 95 (1999).

H. Asteman, J.-E. Svensson, and L.-G. Johansson, Oxidation of Metals 57, 193 (2002).

J. P. T. Vossen, P. Gawenda, K. Rahts, M. Röhrig, M. Schorr, and M. Schutze, Materials at High Temperatures 14, 387 (1997).

N. Otsuka, Y. Shida, and H. Fujikawa, Oxidation of Metals 32, 13 (1989).

T. Ericsson, Oxidation of Metals 2, 173 (1970).

T. Ericsson, Oxidation of Metals 2, 401 (1970).

A. F. Smith, M. O. Tucker, and R. Hales, Oxidation of Metal 17, 329 (1982).

M. Schütze, M. Schorr, D. P. Renusch, A. Donchev, and J. P. T. Vossen, Materials Research 7, 111 (2004).

M. Schütze, D. Renusch, and M. Schorr, Materials at High Temperatures 39, 157 (2004).

J. Ehlers, D. J. Young, E. J. Smaardijk, A. K. Tyagi, H. J. Penkalla, L. Singheiser, and W. J. Quadakkers, Corrosion Science 48, 3428 (2006).

C. T. Fujii and R. A. Meussner, Journal of Electrochemical Society 111, 1215 (1964).

D. Wallinder, E. Hörnlund, and G. Hultquist, Journal of Electrochemical Society 149, B393 (2002).

K. Nakagawa, Y. Matsunaga, and T. Yanagisawa, Materials at High Temperatures 20, 63 (2003).

M. Nakai, K. Nagai, Y. Murata, M. Morinaga, S. Matsuda, and M. Kanno, ISIJ International 45, 1066 (2005).

H. Nickel, Y. Wouters, M. Thiele, and W. J. Quadakkers, Fresenius’ Journal of Analytical Chemistry 361, 540 (1998).

S. Henry, A. Galerie, and L. Antoni, Materials Science Forum 369–372, 353 (2001).

E. Essuman, G. H. Meier, J. Zurek, M. Hänsel, L. Singheiser, and W. J. Quadakkers, Scripta Materialia 57, 845 (2007).

N. Otsuka and H. Fujikawa, Corrosion 47, 240 (1991).

W. E. Ruther and S. Greenberg, Journal of Electrochemical Society 111, 1116 (1964).

M. Warzee, J. Hennaut, M. Maurice, C. Sonnen, J. Waty, and P. Berge, Journal of Electrochemical Society 112, 670 (1965).

S. Janson, W. Hübner, G. Östberg, and M. dePaubaix, British Corrosion Journal 4, 21 (1969).

Thermo-Calc Software, Stockholm, Sweden. http://www.thermocalc.com/.

S. Osgerby and A. T. Fry, Material Science Forum 461–464, 1023 (2004).

B. J. Kooi, M. A. J. Somers, R. Jutte, and E. J. Mittemeijer, Oxidation of Metals 48, 111 (1997).

H. E. Evans, International Materials Reviews 40, 1 (1995).

B. B. Ebbinghaus, Combustion and Flames 93, 119 (1993).

B. A. Pint, paper no. 04530, Corrosion 2004, NACE International.

Acknowledgements

The authors wish to acknowledge Dong Energy and Vattenfall for partnership in this PSO funded project (ENERGINET.dk project no. 5293). The project is part of the European COST 536 ACCEPT action and the Swedish CROx project. The Centre for Electron Nanoscopy (DTU.CEN) and Risø DTU, both at the Technical University of Denmark, are acknowledged for providing FIB and TEM facilities, respectively. Dr. Melanie Montgomery (Vattenfall) is gratefully acknowledged for discussions on the characterization of oxidation and corrosion in power plant applications. Dr. Hilmar K. Danielsen’s (DTU) involvement in the interpretation of the electron diffraction results is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hansson, A.N., Pantleon, K., Grumsen, F.B. et al. Microstructure Evolution During Steam Oxidation of a Nb Stabilized Austenitic Stainless Steel. Oxid Met 73, 289–309 (2010). https://doi.org/10.1007/s11085-009-9182-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-009-9182-x