Abstract

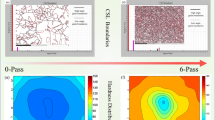

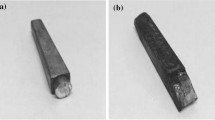

Various severe plastic deformation methods have been considered by numerous researchers with the purpose of making fine-grained parts with a high strength-to-weight ratio by applying severe mechanical deformations without changing the chemical composition of the material. The die of equal channel multiangular pressing (ECMAP) process was used here to exert repetitive severe plastic deformation on Al-3%Mg strip-type samples. In this work, the ECMAP die was made considering optimal geometric values that had been obtained in the previous studies by the grey optimization method, and then the microstructural evolution of output parts were studied carefully. Grain size distribution in various channels and channels curvature was extracted. The results showed that the average grain size obtained after the initial annealing operation is 39.48 μm, after passing through the first channel; the value reduces to 19.57 μm, and after passing through the second and third channels, the average grain size decreases to 9.74 and 6.66 μm, respectively.

Similar content being viewed by others

References

López-Chipres E, García-Sanchez E, Ortiz-Cuellar E, Hernandez-Rodriguez M, Colás R (2010) Optimization of the severe plastic deformation processes for the grain refinement of al6060 alloy using 3d fem analysis. Journal of Materials Engineering and Performance:1-7

H-j Hu, D-f Zhang, F-s Pan, Die structure optimization of equal channel angular extrusion for AZ31 magnesium alloy based on finite element method. Trans. Nonferrous Metals Soc. China 20(2), 259–266 (2010)

S. Xu, G. Zhao, X. Ma, G. Ren, Finite element analysis and optimization of equal channel angular pressing for producing ultra-fine grained materials. J. Mater. Process. Technol. 184(1–3), 209–216 (2007)

P. Keshtiban, R. Behnagh, V. Alimirzaloo, Routes Investigation in Equal Channel Multi-angular Pressing Process of UFG Al—3% Mg Alloy Strips. Trans. Indian Inst. Met. 71(3), 659–664 (2018)

T. Suo, Y. Li, Q. Deng, Y. Liu, Optimal pressing route for continued equal channel angular pressing by finite element analysis. Mater. Sci. Eng. A 466(1–2), 166–171 (2007)

W. Kim, C. Chung, D. Ma, S. Hong, H. Kim, Optimization of strength and ductility of 2024 Al by equal channel angular pressing (ECAP) and post-ECAP aging. Scripta Mater. 49(4), 333–338 (2003)

G. Purcek, H. Yanar, M. Demirtas, Y. Alemdag, D. Shangina, S. Dobatkin, Optimization of strength, ductility and electrical conductivity of Cu–Cr–Zr alloy by combining multi-route ECAP and aging. Mater. Sci. Eng. A 649, 114–122 (2016)

A. Nagasekhar, Y. Tick-Hon, Optimal tool angles for equal channel angular extrusion of strain hardening materials by finite element analysis. Comput. Mater. Sci. 30(3), 489–495 (2004)

V.M. Segal, Engineering and commercialization of equal channel angular extrusion (ECAE). Mater. Sci. Eng. A 386(1), 269–276 (2004)

S. Xu, G. Zhao, G. Ren, X. Ma, Numerical simulation and experimental investigation of pure copper deformation behavior for equal channel angular pressing/extrusion process. Comput. Mater. Sci. 44(2), 247–252 (2008)

B. Aour, F. Zaïri, M. Naït-Abdelaziz, J.-M. Gloaguen, O. Rahmani, J.-M. Lefebvre, A computational study of die geometry and processing conditions effects on equal channel angular extrusion of a polymer. Int. J. Mech. Sci. 50(3), 589–602 (2008)

S.I. J-y, G. Fan, J. Zhang, Finite element analysis of die geometry and process conditions effects on equal channel angular extrusion for β-Titanium alloy. J. Iron. Steel Res. Int. 19(10), 54–58 (2012)

C. Wang, F. Li, H. Lu, Z. Yuan, B. Chen, Optimization of structural parameters for elliptical cross-section spiral equal-channel extrusion dies based on grey theory. Chin. J. Aeronaut. 26(1), 209–216 (2013)

P.M. Keshtiban, M. Zadshakouyan, G. Faraji, Optimization of ECMAP parameters in production of ultra-fine grained Al1050 strips using grey relational analysis. J. Adv. Mater. Process. 3(4), 33–48 (2015)

P. Mashhadi Keshtiban, M. Zadshakouyan, G. Faraji, Optimization of geometrical parameters of equal channel multi angular pressing process. Modares Mech. Eng. 16(2), 275–282 (2016)

P. Keshtiban, F. Bashirzadeh, Die and process parameters effects on ECAP process of sheet-type samples. Metallography Microstruct. Anal. 6(6), 463–469 (2017)

P. Keshtiban, M. Zadshakouyan, G. Faraji, Friction study in equal channel multi angular pressing: load curve and ring compression tests. Trans. Indian Inst. Met. 69(9), 1793–1800 (2016)

P. Keshtiban, F. Bashirzadeh, Experimental investigation of multi-pass ECMAP process. Trans. Indian Inst. Met. 72(1), 239–244 (2019)

Q. Pei, B. Hu, C. Lu, Y. Wang, A finite element study of the temperature rise during equal channel angular pressing. Scripta Mater. 49(4), 303–308 (2003)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Keshtiban, P.M. Microstructural Evolutions During the ECMAP Process Using the Die with Optimum Geometrical Parameters. Metallogr. Microstruct. Anal. 9, 596–602 (2020). https://doi.org/10.1007/s13632-020-00664-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-020-00664-z