Abstract

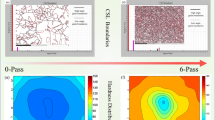

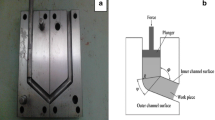

Severe plastic deformation processes (SPDs) have been developed over the past decades to produce bulky parts with proper mechanical and microstructural properties. Equal-channel angular pressing (ECAP) is a method in which a metal is subjected to severe plastic straining through simple shear. The combined extrusion-equal channel angular pressing (C-Ex-ECAP) is proposed in this paper as a new method of SPD. This process is a combination of extrusion and ECAP processes. The new process contains two shear zones which can lead to UFG structure in fewer passes compared with ECAP. In the proposed method, there is the capability of fabricating longer specimens because of the presence of the extrusion process. This investigation has been performed up to six passes, and the microstructural, mechanical, and electrical properties have been studied in the deformed workpieces. The samples produced in six passes of this process showed a 480% increase in yield strength compared to the annealed sample, and a decrease in grain size from 18 μm to 820 nm, as well as an increase in hardness from 41.8 to 125 HV. The electrical conductivity study also showed that the six-pass specimens had a 5% reduction in electrical conductivity compared to the annealed specimens.

Similar content being viewed by others

Data Availability

Not applicable.

Notes

The International Annealed Copper Standard (IACS)

References

Babaei A, Mashhadi M (2014) Tubular pure copper grain refining by tube cyclic extrusion–compression (TCEC) as a severe plastic deformation technique. Prog Nat Sci Mater Int 24(6):623–630. https://doi.org/10.1016/j.pnsc.2014.10.009

Xiong L, Shuai J, Liu K, Hou Z, Zhu L, Li W (2019) Enhanced mechanical and electrical properties of super-aligned carbon nanotubes reinforced copper by severe plastic deformation. Compos Eng 315-320:315–320. https://doi.org/10.1016/j.compositesb.2018.10.023

Segal V (1995) Materials processing by simple shear. Mater Sci Eng 197(2):157–164. https://doi.org/10.1016/0921-5093(95)09705-8

Wang C, Li F, Li Q, Li J, Wang L, Dong J (2013) A novel severe plastic deformation method for fabricating ultrafine grained pure copper. Mater Des 43:492–498. https://doi.org/10.1016/j.matdes.2012.07.047

Ebrahimi M, Djavanroodi F (2014) Experimental and numerical analyses of pure copper during ECFE process as a novel severe plastic deformation method. Prog Nat Sci Mater Int 24(1):68–74. https://doi.org/10.1016/j.pnsc.2014.01.013

Hohenwarter A (2015) Incremental high pressure torsion as a novel severe plastic deformation process: processing features and application to copper. Mater Sci Eng 626:80–85. https://doi.org/10.1016/j.msea.2014.12.041

Ivanisenko Y, Kulagin R, Fedorov V, Mazilkin A, Scherer T, Baretzky B, Hahn H (2016) High pressure torsion extrusion as a new severe plastic deformation process. Mater Sci Eng 664:247–256. https://doi.org/10.1016/j.msea.2016.04.008

Zhilyaev AP, Shakhova I, Belyakov A, Kaibyshev R, Langdon TG (2013) Wear resistance and electro conductivity in copper processed by severe plastic deformation. Wear 305:89–99. https://doi.org/10.1016/j.wear.2013.06.001

Straska J, Janecek M, Cizek J, Strasky J, Hadzima B (2014) Microstructure stability of ultra-fine grained magnesium alloy AZ31 processed by extrusion and equal-channel angular pressing (EX–ECAP). Mater Charact 94:69–79. https://doi.org/10.1016/j.matchar.2014.05.013

Afsari A, Ranaei MA (2014) Equal channel angular pressing to produce ultrafine pure copper with excellent electrical and mechanical properties. Int Nanosci Nanotechnol 10(4):215–222

Damavandi E, Nouroouzi S, Rabiee SM, Jamaati R (2019) Effect of ECAP on microstructure and tensile properties of A390 aluminum alloy. Trans Nonferrous Metals Soc China 29:931–940. https://doi.org/10.1016/S1003-6326(19)65002-8

Djavanroodi F, Ebrahimi M (2010) Effect of die parameters and material properties in ECAP with parallel channels. Mater Sci Eng 527(29-30):7593–7599. https://doi.org/10.1016/j.msea.2010.08.022

IbrahimAbd EL AAL M (2017) 3D FEM simulation and experimental validation of plastic deformation of pure-alumimum deformed by ECAP and combination of ECAP and direct extrusion. Trans Nonferrous Metals Soc Chin 27:1338–1352. https://doi.org/10.1016/S1003-6326(17)60155-9

Akbarzadeh B, Gorji H, Bakhshi-Jooybari M, Jamaati R, Mirnia MJ (2020) Development of a new process for the severe plastic deformation of AA 1050 to improve the mechanical properties. Iran J Manag Eng 7(4):19–29 (in Persian)

ASTM E8 / E8M-16ae1 (2016) Standard test methods for tension testing of metallic materials. ASTM International, West Conshohocken. https://doi.org/10.1520/E0008_E0008M-16AE01

Wang C, Li F, Li Q, Wang L (2012) Numerical and experimental studies of pure copper processed by a new severe plastic deformation method, Severely deformed copper by equal channel angular pressing. Mater Sci Eng 548:19–26. https://doi.org/10.1016/j.msea.2012.03.055

ASTM E92-17 (2017) Standard test methods for vickers hardness and knoop hardness of metallic materials. ASTM International, West Conshohocken. https://doi.org/10.1520/E0092-17

ASTM E1004-17 (2017) Standard test method for determining electrical conductivity using the electromagnetic (Eddy Current) method. ASTM International, West Conshohocken. https://doi.org/10.1520/E1004-17

Faraji G, Babaei A, Mashhadi MM, Abrinia K (2012) Parallel tubular channel angular pressing (PTCAP) as a new severe plastic deformation method for cylindrical tubes. Mater Lett 77:82–85. https://doi.org/10.1016/j.matlet.2012.03.007

Ebrahimi M, Gode C (2017) Severely deformed copper by equal channel angular pressing. Prog Nat Sci Mater Int 27:244–250. https://doi.org/10.1016/j.pnsc.2017.03.002

Iwahashi Y, Wang J, Horita Z, Nemoto M, Langdon TG (1996) Principle of equal-channel angular pressing for the processing of ultra-fine grained materials. Scr Mater 35(2):143–146. https://doi.org/10.1016/1359-6462(96)00107-8

Riazat M, Faraji G (2015) Size effect in equal channel angular pressing (ECAP) process. J Adv Mater Process 3(3):3–12

Habibi A, Ketabchi M, Eskandarzadeh M (2011) Nano-grained pure copper with high-strength and high-conductivity produced by equal channel angular rolling process. Mater Process Technol 211(6):1085–1090. https://doi.org/10.1016/j.jmatprotec.2011.01.009

Kommel L, Hussainova I, Volobueva O (2007) Microstructure and properties development of copper during severe plastic deformation. Mater Des 28(7):2121–2128. https://doi.org/10.1016/j.matdes.2006.05.021

Wei W, Wei K, Fan G (2008) A new constitutive equation for strain hardening and softening of fcc metals during severe plastic deformation. Acta Mater 56(17):4771–4779. https://doi.org/10.1016/j.actamat.2008.05.025

Ferrasse S, Segal VM, Hartwig KT, Goforth R (1997) Microstructure and properties of copper and aluminum alloy 3003 heavily worked by equal channel angular extrusion. Metall Mater Trans A 28(A):1047–1057. https://doi.org/10.1007/s11661-997-0234-z

Li BL, Shigeiri N, Tsuji N, Minamino Y (2006) Microstructural evolution in pure copper severely deformed by the ARB process. Mater Sci Forum 503(504):615–620. https://doi.org/10.4028/www.scientific.net/MSF.503-504.615

Wang YM, Ma E (2004) Three strategies to achieve uniform tensile deformation in a nanostructured metal. Acta Mater 52:1699–1709. https://doi.org/10.1016/j.actamat.2003.12.022

Mishra A, Kad BK, Gregori F, Meyers MA (2007) Microstructural evolution in copper subjected to severe plastic deformation: experiments and analysis. Acta Mater 55:13–28. https://doi.org/10.1016/j.actamat.2006.07.008

Xu J, Jianwei L, Shan D, Guo B (2016) Microstructural evolution and micro/meso-deformation behavior in pure copper processed by equal-channel angular pressing. Mater Sci Eng 664:114–125. https://doi.org/10.1016/j.msea.2016.03.016

Zhu CF, Du FP, Jiao QY, Wang XM, Chen AY, Liu F, Pan D (2013) Microstructure and strength of pure Cu with large grains processed by equal channel angular pressing. Mater Des 52:23–29. https://doi.org/10.1016/j.matdes.2013.05.029

Hansen N (2004) Hall–Petch relation and boundary strengthening. Scr Mater 51:801–806. https://doi.org/10.1016/j.scriptamat.2004.06.002

Valiev RZ, Alexandrov IV, Zhu YT, Lowe TC (2002) Paradox of strength and ductility in metals processed by severe plastic deformation. Mater Res 17:5–8. https://doi.org/10.1557/JMR.2002.0002

Dao M, Lu L, Asaro RJ, De Hosson JTM, Ma E (2007) Toward a quantitative understanding of mechanical behavior of nanocrystalline metals. Acta Mater 55:4041–4065. https://doi.org/10.1016/j.actamat.2007.01.038

Fata A, Faraji G, Mashhadi MM, Tavakoli V (2017) Hot deformation behavior of Mg-Zn Al alloy tube processed by severe plastic deformation. Arch Metall Mater 62:159–166. https://doi.org/10.1515/amm-2017-0022

Fang DR, Duan QQ, Zhao NQ, Li JJ, Wu SD, Zhang ZF (2007) Tensile properties and fracture mechanism of Al–Mg alloy subjected to equal channel angular pressing. Mater Sci Eng 459:137–144. https://doi.org/10.1016/j.msea.2007.01.062

Ko YG, Shin DH, Park KT, Lee CS (2006) An analysis of the strain hardening behavior of ultra-fine grain pure titanium. Scr Mater 54:1785–1789. https://doi.org/10.1016/j.scriptamat.2006.01.034

Vinogradov A, Ishida T, Kitagawa K, Kopylov V (2005) Effect of strain path on structure and mechanical behavior of ultra-fine grain Cu–Cr alloy produ ced by equal-channel angular pressing. Acta Mater 53:2181–2192. https://doi.org/10.1016/j.actamat.2005.01.046

Lipinska M, Olejnik L, Lewandowska M (2018) The influence of an ECAP-based deformation process on the microstructure and properties of electrolytic tough pitch copper. Mater Sci 53:3862–3875. https://doi.org/10.1007/s10853-017-1814-y

Code availability

Not applicable.

Author information

Authors and Affiliations

Contributions

All authors contributed equally to this work.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Akbarzadeh, B., Gorji, H., Bakhshi-Jooybari, M. et al. Investigation of mechanical and microstructural properties of pure copper processed by combined extrusion-equal channel angular pressing (C-Ex-ECAP). Int J Adv Manuf Technol 113, 2175–2191 (2021). https://doi.org/10.1007/s00170-021-06692-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-06692-5