Abstract

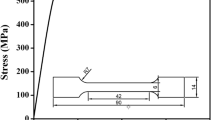

In the present study, the effect of post-weld heat treatment (PWHT) on the microstructure and mechanical properties of the friction stir welded Cu–Cr–Zr–Ti alloy was studied with the aid of optical and transmission electron microscopy, tensile testing, and microhardness measurement. In the as-welded condition, the stir zone was characterized with fine recrystallized grains and thermo-mechanically affected zone showed a necklace structure. The microstructure of heat-affected zone and base metal showed equiaxed grains with annealing twins. Welded samples were subjected to three different PWHT: (a) direct aging, (b) solution treatment, and (c) solution treatment and aging. PWHT showed the effect on the microstructure of the weld with changes in the grain size and formation of precipitates. The microhardness across the weld was highest for the direct aged samples, whereas solution treated samples showed minimum hardness. The yield strength and elongation in as-welded condition were 158 MPa and 18%, respectively. Direct aging of the welded samples resulted in an improvement in the yield strength (171 MPa) with a decrease in ductility (13%). Significant softening of weld was observed after solution treatment, and yield strength was lower than that of base metal. Solution treatment and aging yielded an increase in elongation with a minor decrease in the yield strength. The increase in yield strength of the weld after aging is attributed to the formation of fine chromium precipitates.

Similar content being viewed by others

References

G. Li, B.G. Thomas, J.F. Stubbins, Modeling creep and fatigue of copper alloys. Metall. Mater. Trans. A 31, 2491–2502 (2000)

H.C. Groh, D.L. Ellis, W.S. Loewenthal, Comparison of GRCop-84 to other cu alloys with high thermal conductivities. J. Mater. Eng. Perform. 17, 594–606 (2007)

G.J. Butterworth, C.B.A. Forty, Review article: a survey of the properties reactor materials of copper alloys for use as fusion. J. Nucl. Mater. 189, 237–276 (1992)

S.C. Krishna, G.S. Rao, A.K. Jha, B. Pant, K.M. George, Analysis of phases and their role in strengthening of Cu–Cr–Zr–Ti alloy. J. Mater. Eng. Perform. 24, 2341–2345 (2015)

P.K.C. Kanigalpula, A. Chatterjee, D.K. Pratihar, M.N. Jha, J. Derose, Effects of electron beam welding on microstructure, microhardness, and electrical conductivity of Cu–Cr–Zr alloy plates. J. Mater. Eng. Perform. 24, 4681–4690 (2015)

A. Durocher, D. Ayrault, C. Chagnot, M. Lipa, W. Saikaly, CuCrZr alloy hot cracking during electron beam welding. J. Nucl. Mater. 367–370B, 1208–1212 (2007)

A. Durocher, M. Lipa, P. Chappuis, J. Schlosser, T. Huber, B. Schedler, TORE SUPRA experience of copper chromium zirconium electron beam welding. J. Nucl. Mater. 307–311, 1554–1557 (2002)

J.M. Drezet, D. Ayrault, J. Wisniewski, P. Pilvin, D. Carron, F. Primaux, Experimental and numerical analysis of the hot tearing susceptibility of a CuCrZr alloy, in Mathematical Modelling of Weld Phenomena, ed, by H. Cerjak, N. Enzinger 9 (TU-Graz, 2010), pp. 997–1010

G. Çam, S. Mistikoglu, M. Pakdil, Microstructural and mechanical characterization of friction stir butt joint welded 63% Cu–37% Zn brass plate. Weld. J. 88, 225s–232s (2009)

C. Meran, The joint properties of brass plates by friction stir welding. Mater. Des. 27, 719–726 (2006)

M.S. Moghaddam, R. Parvizi, M. Haddad-Sabzevar, A. Davoodi, Microstructural and mechanical properties of friction stir welded Cu–30Zn brass alloy at various feed speeds: influence of stir bands. Mater. Des. 32, 2749–2755 (2011)

A. Heidarzadeh, T. Saeid, A comparative study of microstructure and mechanical properties between friction stir welded single and double phase brass alloys. Mater. Sci. Eng. A 649, 349–358 (2016)

W.-B. Lee, S.-B. Jung, The joint properties of copper by friction stir welding. Mater. Lett. 58, 1041–1046 (2004)

A. Heidarzadeh, T. Saeid, Prediction of mechanical properties in friction stir welds of pure copper. Mater. Des. 52, 1077–1087 (2013)

J.J. Shen, H.J. Liu, F. Cui, Effect of welding speed on microstructure and mechanical properties of friction stir welded copper. Mater. Des. 31, 3937–3942 (2010)

Y.M. Hwang, P.L. Fan, C.H. Lin, Experimental study on friction stir welding of copper metals. J. Mater. Process. Technol. 210, 1667–1672 (2010)

D.Q. He, R.L. Lai, S.H. Xu, K.Y. Yang, S.Y. Ye, J. Wang, J.M. Zhu, B. Su, Microstructure and mechanical properties of Cu–Cr–Zr alloy by friction stir welding. Adv. Mater. Res. 602, 608–611 (2013). (Trans Tech Publ)

R. Lai, D. He, G. He, J. Lin, Y. Sun, Study of the microstructure evolution and properties response of a friction-stir-welded copper–chromium–zirconium alloy. Metals (Basel) 7, 381 (2017)

K. Jha, S. Kumar, K. Nachiket, K. Bhanumurthy, G.K. Dey, Friction stir welding (FSW) of aged CuCrZr alloy plates. Metall. Mater. Trans. A 49(1), 223–234 (2018)

K.N. Krishnan, The effect of post weld heat treatment on the properties of 6061 friction stir welded joints. J. Mater. Sci. 37, 473–480 (2002)

K. Elangovan, V. Balasubramanian, Influences of post-weld heat treatment on tensile properties of friction stir-welded AA6061 aluminum alloy joints. Mater. Charact. 59, 1168–1177 (2008)

Y.N. Zhang, X. Cao, S. Larose, P. Wanjara, Review of tools for friction stir welding and processing. Can. Metall. Q. 51, 250–261 (2012)

V.V. Patel, V. Badheka, A. Kumar, Friction stir processing as a novel technique to achieve superplasticity in aluminum alloys: process variables, variants, and applications. Metallogr. Microstruct. Anal. 5, 278–293 (2016)

M.-K. Besharati-Givi, P. Asadi, Advances in Friction-Stir Welding and Processing (Elsevier, Amsterdam, 2014)

H. Pashazadeh, J. Teimournezhad, A. Masoumi, Numerical investigation on the mechanical, thermal, metallurgical and material flow characteristics in friction stir welding of copper sheets with experimental verification. Mater. Des. 55, 619–632 (2014)

I.S. Batra, G.K. Dey, U.D. Kulkarni, S. Banerjee, Precipitation in a Cu–Cr–Zr alloy. Mater. Sci. Eng. A 356, 32–36 (2003)

G.C. Weatherly, P. Humble, D. Borland, Precipitation in a Cu–0.55wt.%Cr alloy. Acta Mater. 27, 1815–1828 (1979)

T. Weinberger, B. Fuhrer, S. Khosa, N. Enzinger, H. Cerjak, Evolution of microstructure and properties for friction stir welded martensitic precipitation-hardening steels, in Proceedings of the 8th International Conference (2009), pp. 398–402

S.C. Krishna, G.S. Rao, A.K. Jha, B. Pant, P.V. Venkitakrishnan, Strengthening in high strength Cu–Cr–Zr–Ti alloy plates produced by hot rolling. Mater. Sci. Eng. A 674, 164–170 (2016)

T. Gladman, Precipitation hardening in metals. Mater. Sci. Technol. 15, 30–36 (1999)

Acknowledgements

The authors would like to thank their colleagues at Material Characterization Division of Materials and Metallurgy Group for the support rendered in characterization of the samples. The authors would like to express sincere gratitude to Director, VSSC, for his kind permission to publish this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Krishna, S.C., Karthick, N.K., Karthik, G.M. et al. Effect of Post-Weld Heat Treatment on the Microstructure and Mechanical Properties of Friction Stir Welds of Cu–Cr–Zr–Ti Alloy. Metallogr. Microstruct. Anal. 7, 703–710 (2018). https://doi.org/10.1007/s13632-018-0479-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-018-0479-5