Abstract

• Key message

This paper investigates the juvenility limit and structure–property relationship in secondary quality beech ( Fagus sylvatica L.) and oak ( Quercus petraea (Matt.) Liebl.). The juvenile wood occupies a very small area near the pith. The stabilization of the different parameters varies over time. Adding the microfibril angle (MFA) and the grain angle to the MOE prediction model significantly improves the quality of the model, despite little variation in both parameters.

• Context

Using secondary qualities and small logs of hardwoods such as beech and oak for engineered wood products is an increasingly important issue due to the technological challenges of processing smaller logs and denser woods. Secondary quality hardwoods are expected to have less variation in mechanical properties compared to softwoods with high juvenile wood content.

• Aims

The first objective of this study was to investigate the radial variation in wood properties of suppressed growth beech and oak trees obtained from thinning operations. The second objective was to develop a model to predict the mechanical properties of these hardwood species based on their structural parameters.

• Methods

The microfibril angle, ring wood density, and ring width from the pith to the bark were determined using an X-ray densitometer. The modulus of elasticity and modulus of rupture were evaluated on the small clear specimen using a three-point bending test. The wood density, grain angle, and microfibril angle of this small clear specimen were also measured.

• Results

The results show that the juvenile wood in oak has a wider ring and higher microfibril angle, whereas it has wider latewood and higher microfibril angle in beech. For both species, the juvenile wood occupies a very small area, less than 5 cm from the pith. The mechanical properties of oak and beech wood from suppressed growth trees are comparable to properties reported in the literature for dominant trees. The modulus of elasticity of oak was best predicted using wood density, grain angle, and microfibril angle. The modulus of rupture of oak is better predicted with wood density and grain angle, whereas it is best predicted with wood density alone for beech.

• Conclusion

Juvenile wood found in the suppressed growth trees of both hardwoods can be used in place of mature wood. It is important to take structural parameters into account when predicting the mechanical properties of hardwood species.

Similar content being viewed by others

1 Introduction

Beech (Fagus sylvatica L.) and oak (Quercus petraea (Matt.) Liebl.) are the two most important hardwood species in Europe and particularly in France, where the forest resource is dominated by hardwood (IGN 2016). Due to climatic risk mitigation and to the market demand in industrial wood products and fuelwood, there has been a move toward harvesting trees much younger than in the past, as well as an increase in the utilization of small trees that are removed during thinning operations (Fox et al. 2004; Paukkunen 2014; Davis et al. 2018). That means that the wood quality of these trees is expected to be lower according to trading standards, i.e., log grades based on diameter, straightness, and visual defects (Koutsianitis and Voulgaridis 2015). Wood properties vary within the ring, from pith to bark and along the tree stem (Burdon et al. 2004; Longuetaud et al. 2017; Vega et al. 2020). The wood quality of small logs is also usually reduced by the variability of mechanical properties associated with juvenile wood, which are linked to changes in several, generally not visible parameters (e.g., wood density or microfibril angle (MFA)), a phenomenon well known in fast-growing softwoods (Maeglin 1987; Burdon et al. 2004; Zobel and Sprague 2012) and less studied in a diversity of species including hardwoods (Woodcock and Shier 2002). Previous research has shown that engineered wood products such as oriented strand board (OSB) and laminated veneer lumber (LVL) have poorer performance results when made from logs with a high content of juvenile wood (Cloutier et al. 2007; Girardon et al. 2016). Juvenile wood is produced near the pith and in the upper parts of the tree by young cambium, and the transition to more mature wood is characterized by a large gradient of wood properties. Whether this variation is the result of ontogeny or tree adaptive response to the environmental conditions is still a matter of debate (Cutter et al. 2007; Downes and Drew 2008; Lachenbruch et al. 2011; Moore and Cown 2017).

Because wood is a complex biological composite, several non-visible quantifiable parameters impact the mechanical properties of clear wood (defined as a specimen of small size without any visual defects). Variations in the mechanical properties of clear wood such as MOE (modulus of elasticity) or MOR (modulus of rupture) are generally associated with variations in wood density linked to latewood percentage, fiber, or tracheid wall thickness, whereas in hardwoods, they are linked to vessel number and size, or the proportion of fiber tissue. Furthermore, independently to wood density, variations in these properties are linked to spiral grain and MFA (Burdon et al. 2004). Mechanistic approaches derived from composite mechanics (Gibson and Ashby 1999) have demonstrated the causal link between MOE or MOR and these parameters (Hofstetter and Gamstedt 2009), beyond statistical empirical observations.

In temperate species, these parameters vary inside the tree ring (from early to latewood) with typical patterns that make the tree ring width an integrative visual parameter, correlated with mechanical properties (Nepveu 1990; Leban and Haines 2007). Oak is a ring-porous species with a pronounced difference between early and latewood, i.e., the larger the ring is, the higher the proportion of latewood and the higher the wood density will be (Nepveu 1990; Zhang et al. 1993, 1994; Guilley et al. 2004). In contrast, beech, as a diffuse-porous species, shows a negative correlation between wood density and ring width but with very little variation (Bouriaud et al. 2004).

The grain angle is a misalignment between the tracheid of fiber direction and the stem axis of the timber. Wood stiffness (MOE) or strength (MOR) depends strongly on the angle between the applied load and the fiber/tracheid orientation (Bodig and Jayne 1982). Therefore, variations in grain angle can significantly impact the mechanical properties (Tsehaye and Walker 1995). Low variations in grain angle are expected in beech and oak (1°–3°) compared to that in some other species (Birot et al. 1980; Guilley et al. 1999).

Among all of the cited parameters, the MFA of crystalline cellulose in the S2 layer of the fiber wall has been less studied as it is less easily measurable (Barnett and Bonham 2004; Donaldson 2008). However, since crystalline cellulose is responsible for cell wall stiffness and strength, its variations can significantly change the value of MOE and MOR (Yang and Evans 2003; Alteyrac et al. 2007; Yin et al. 2011). As for the transition from juvenile to mature wood, many studies have shown that the MFA decreases from pith to bark in both softwood and hardwood species (Cave and Walker 1994; Evans et al. 2000), even if studies are less numerous in hardwoods where MFA is more difficult to measure (Ruelle et al. 2007). The value and variation of MFA in softwoods such as spruce (Picea abies (L.) H. Karst.) and pine (Pinus sylvestris L.) are commonly higher than those in the hardwood species (Lindström et al. 1998; Lichtenegger et al. 1999; Lestander et al. 2008). Beech and oak have a very low radial variation of MFA and present a high value only in the position close to the pith (Lichtenegger et al. 1999).

This study aims at characterizing radial variations of mechanical properties of clear wood of secondary quality oak and beech logs recovered from thinned trees. Quite low radial variations are expected compared to conifers or fast growth poplar. If this result is confirmed, it is a positive aspect in favor of the development of timber engineering of these hardwoods that are very common in France but that have been poorly developed for building uses up until now. We will then design and fit a predictive model of these variations on the basis of the wood structural parameters such as wood density, grain angle, and MFA. It is expected that such a model, which is based on physical causality, will fit well even if variations in mechanical properties (MOE and MOR) are low.

2 Material and methods

2.1 Wood material

The wood material used for this study was beech and oak from a mixed forest stand in Lorraine (48.893622 N, 6.741478 E), Grand-Est region, France. The round wood samples were gathered from trees that were removed during a thinning operation. Five trees were selected for each species and two round woods were extracted from each selected tree. As a result, selected round wood material consisted of 20 logs, 200-cm long, with large end diameters of between 21 and 30 cm. Log grading using a visual method based on EN 1316–1 (2012) was used to classify the round woods into grades C and D based on log diameter and knot presence. C and D grades are differentiated by the presence of unsound knots. Each round wood was extracted from the upper part of the stem (600 and 800 cm above the ground) and typically contained knots, as described in Fig. 1. Oak cambial ages ranged between 61 and 90 years old, while beech cambial ages ranged between 57 and 84 years. Individual cambial ages were determined by the ring number. These round woods represent the wood resources that are not commonly used as raw material for timber construction and engineered wood products (EWP).

2.2 Measurement of the radial growth component using an X-ray densitometer

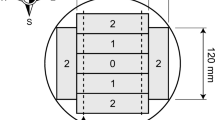

A disc approximately 10-cm thick was extracted from the central part of each log, as described in Fig. 1. A randomly oriented radial strip (2.5 cm × 5 cm, tangential (T) × longitudinal (L)) was cut in a defect-free zone and conditioned for 1 month at 12% relative humidity at ambient temperature. A radial slice (1 cm × 0.2 cm, T × L) was then cut for X-ray microdensitometry measurements, as described in Fig. 2. Using CERD (i.e., “Cernes sur Eprouvettes Radiographiées en Densité”), an image analysis software (Mothe et al. 1998a), the limit between two adjacent rings was manually assigned, as described in Fig. 2. Each ring was divided into 20 intervals of equal length, with each representing 5% of the ring’s width. The mean wood density was calculated for each interval. The separation of the earlywood from the latewood was automatically set by calculating the tree ring wood density threshold as defined in Mothe et al. (1998b).

The remaining part of the radial strip was then cut into sections of 1 cm in length from pith to bark, as described in Fig. 2. A 2-mm-thick strip was extracted from each section. The MFA was measured on this 2-mm-thick strip using an X-ray diffractometer (XRD) from Oxford Diffraction. The X-ray generator operating at 50 keV/0.8 mA with a beam diameter of around 300 µm generates CuK_α radiation. To reach the optimum noise, the exposure time was set at 60 s. The T parameter was used to calculate the MFA, according to Cave’s equation (Yamamoto 1993).

2.3 Measurement of mechanical properties and their related structural properties

For the characterization of mechanical properties, defect-free wood specimens with dimensions of 24 cm × 1 cm × 1 cm were prepared. The wood density was calculated by dividing their mass by their volume in the air-dry state or at 12% moisture content (MC). The wood mechanical properties were measured using a three-point bending method with a universal testing machine where annual rings were orientated horizontally with respect to the load (Instron 5969). The span length used was 150 mm and the loading speed was set at 3 mm min−1. The wood deformation caused by the loading was measured by a video extensometer. The static MOE and MOR were then determined for each wood specimen.

The grain angle was evaluated by scanning specimens used for the destructive test with a high-resolution flatbed scanner at 800 dpi. The images taken were then analyzed using ImageJ software in order to manually measure the grain angle on the surface of the rupture zone. The grain angle was determined as the angle between the direction of the sample and the direction of the grain, as described in Fig. 3. In addition, the measurement of MFA was also carried out on a 2-mm-thick sample extracted from the rupture zone.

2.4 Data analysis

Descriptive analyses such as mean value and standard error were calculated for each measured property, including the structural and mechanical properties. Analyses of exploratory data showed that both dependent and independent variables were normally distributed based on the D’Agostino-Pearson normality test. Furthermore, the co-linearity of independent variables was also tested. Patterns and outliers were analyzed using the residual plots. All data analyses were performed using the R-software, version 3.6.0.

The mean value and standard error of the measured wood properties from the pith to the bark of all trees were graphically presented. Radial variation of measured properties from pith to bark was fitted to a model described in Fig. 4 and Eq. 1, which is suitable for modeling the transition between juvenile and mature wood (Grzeskowiak 1997; Fajriani et al. 2013). The radial patterns of both suppressed growth beech and oak from the thinning operation decrease from the pith and then tend to stabilize; therefore, the model proposed by Grzeskowiak (1997) was used in this study.

Modeling the transition between juvenile and mature wood (Grzeskowiak 1997). Ym, the final value of the variation curve before the constant value is achieved; Yi, the value of the first ring; T, t − 1, where t is the ring number from the pith; τ, the time characteristic of the kinetics of the transition from juvenile to mature wood

Using this model, it is assumed that 95% of the variation in measured properties due to age is taken into consideration.

As a result, T = 3τ, and the demarcation point calculated in this study is therefore t = 3τ + 1. The model was calculated based on the data covering up to 40 years, and assuming that juvenile transition was finished and that the variation in properties we observed was not related to ontogenetic transition but to climate and/or changes in environmental conditions. The modeling efficiency (EF) was used to compare the predicted and measured values, and is expressed in Eq. 3:

where S = the predicted value and O = the measured value over the course of the simulation (i = time). The best model has an EF close to 1. In addition, the root mean square error (RMSE) of the model was also calculated.

Furthermore, the Pearson coefficient of correlation was analyzed in order to evaluate the relationship among the measured parameters of structural properties and mechanical properties. Various multiple linear regression models were developed for the MOE and MOR, as presented in Eq. 4. The independent variables used were wood density, grain angle, and MFA.

where u is the standard error:

where ei = yi – ŷ.

In order to select the most appropriate regression model, the adjusted coefficient of determination (R2) and the Akaike Information Criteria (AIC) were also calculated for each model. Analysis of relative importance (RI) was performed in order to calculate the contribution of each parameter of wood properties to the mechanical properties. This analysis was performed using the R package relaimpo (Grömping 2006).

3 Results

3.1 Radial variation of wood properties

Figure 5 shows the radial variation of ring width, ring wood density, and MFA from pith to bark. Mean values for all samples are displayed together with the standard error. It can be seen that the ring wood density, ring width, and MFA were higher near the pith for both species. A nonlinear decrease in the measured wood properties can be seen from the pith to the bark. The average oak earlywood density started at 696 kg m−3 and tended to stabilize at 570 kg m−3. Oak ring width near the pith was 1.4 mm and tended to stabilize at 0.5 mm. The average MFA for oak wood near the pith was 12.6° and reached a relatively constant value of 7.6°. The other measured properties of oak wood continued to decrease towards the bark. On the other hand, beech latewood ring width was higher near the pith, with average values of 0.65 mm, and reached a relatively constant value at 0.31 mm. The average MFA for beech near the pith was 11.9° and tended to stabilize at 8.5°. Other measured wood properties tended to decrease nonlinearly from the pith to the bark.

Radial variation of radial growth component, wood density component, and MFA from the pith to the bark as a function of the cambial age of a oak and b beech. The solid line and the light color area around each solid line represent the mean value and the standard error measured on each ring from all measured trees. Rw, ring width; EWw, earlywood width; LWw, latewood width; Rd, ring wood density; EWd, earlywood density; LWd, latewood density

Table 1 presents the demarcation point or limit of juvenile wood calculated using the ring properties and MFA. There are some predictors without results in the table. This happened because some predictors showed the demarcation point beyond age 40, which was the maximum age of data entry used for the model. Therefore, this model is not well suited for these properties. In the case of beech, ring width, as well as ring wood density, did not show any clear transition in the juvenile region. The best predictor of the juvenile transition seemed to be the MFA. For oak, the best predictor of juvenile wood was the earlywood width, followed by earlywood density, MFA, and latewood width.

3.2 Structural and mechanical properties

The mean value and standard error of wood density, grain angle, MOE, and MOR measured on beech and oak are presented in Table 2. Based on the standard error, both species showed relatively low wood density variation on the measured specimen. Despite this low standard error on wood density, the MOE and MOR values were quite varied. The grain angle on the specimen extracted from the secondary quality resources was found to be fairly low and close to 0. The oak used in this study demonstrated a higher variation of wood properties compared to beech. Beech showed slightly higher MOE and MOR than oak.

To understand the influence of wood structural properties on wood mechanical properties, all measured parameters were cross-correlated and presented in Table 3. For both species, the MOE and MOR increased with the wood density. The MOE and MOR decreased following the increase in MFA and grain angle. Nonetheless, the influence of MFA and grain angle was only statistically significant on the MOE. The correlation between MOE and MOR is highly significant for both hardwood species.

Table 4 gives the adjustment results of MOE and MOR regression models, whereas Table 5 shows the selected model whose AIC is the lowest and R2 the highest for which the independent variables are significant. For oak, the adjusted R2 of the MOE model showed a better result when using wood density (RI = 62%), grain angle (RI = 20%), and MFA (RI = 18%) as the independent variables. However, the MOR of oak was better predicted using wood density (RI = 77%) and grain angle (RI = 33%). For beech MOE, the best model was the one that used wood density (RI = 84%) and MFA (RI = 16%), while the MOR of beech was better predicted with wood density alone without adding grain angle or MFA. The MOE prediction for both species was slightly more accurate than the MOR prediction.

4 Discussion

The area with a high gradient of wood properties is called juvenile wood. This area of juvenile wood is less than 5 cm from the pith. For both species, the ring wood density was slightly higher near the pith. These results are similar to those reported by Bouriaud et al. (2004) and Longuetaud et al. (2017) concerning oak. Previous studies have shown that the wood density of juvenile beech wood could be higher or lower compared to mature wood (Nepveu 1981). Oak, however, demonstrated a decrease in wood density with higher ring numbers by producing narrower rings while maintaining the same earlywood width. Higher wood density on juvenile wood is often associated with understory and late-successional species, which produce dense wood at the beginning of growth in order to increase resistance to biotic damage (Woodcock and Shier 2002; Plourde et al. 2015).

The variation in MFA from pith to bark was found to be relatively low. A higher variation of MFA is generally found in softwood species. A study by McLean et al. (2010) on Sitka spruce (Picea sitchensis (Bong.) Carr.) revealed that the stiffness of wood from the internal position is closely related to the MFA. The MFA variation for beech and oak in the internal position is negligible compared to softwood species (Lichtenegger et al. 1999). It is interesting to note that while ring wood density in both species first linearly decreased up to a minimum followed by an increase, MFA does not follow this pattern, indicating that the tree may be able to modify both parameters independently. The mechanical properties of juvenile beech and oak wood may act similarly to normal wood since the juvenile wood has high wood density and relatively low MFA. Moreover, the juvenile wood occupied a very small part in the center of the trunk of both species. It may be concluded that juvenile wood found in the suppressed growth trees of both hardwoods can be used in place of mature wood.

The mean wood density of beech found in the present study was slightly higher than the one described by Gryc et al. (2008) on 83-year-old beech on 12% MC (wood density = 0.71 g cm−3). The static MOE was slightly lower than that of beech (MOE = 14.8 GPa) used for manufacturing Glulam, as described by Aicher and Ohnesorge (2011), whereas the MOR was comparable (120.64 MPa) to the one reported by Schlotzhauer et al. (2017) on defect-free beech. On the other hand, oak wood density and MOE were higher than those reported in a previous study on oak (wood density = 0.62, MOE = 9.79 GPa) in Tran et al. (2016). The MOR of oak in this study was 33.2% higher than the one found (86.52 MPa) in the study of Schlotzhauer et al. (2017). Based on the literature, the difference between MOE and MOR in both species should be more visible (Tran et al. 2015, 2016; Schlotzhauer et al. 2017).

Positive correlations between wood density and mechanical properties on oak are contrasted with previously published studies (Polge 1973; Zhang et al. 1994). Generally, in oak, there is no close relationship between wood density and mechanical properties, and some authors have even considered high wood density as a criterion of low-quality oak wood. The positive correlation between wood density and ring width is consistent with numerous studies, indicating that wood density is positively correlated with ring width (Guilley et al. 2004; Genet et al. 2013). The rapid growth of oak, therefore, induces a higher wood density. Oak is a ring-porous species whose increase in ring width is typically associated with higher latewood percentage, denser earlywood and latewood and, consequently, higher mean ring wood density (Zhang et al. 1993). The grain angle negatively influenced the wood mechanical properties, even when the level was very low. The low variation in grain angle found in both species supports previously published studies (Birot et al. 1980; Guilley et al. 1999). Similar to oak, Cibecchini et al. (2016) show that there was no correlation between beech wood density and MOE. In theory, the ring width in diffuse-porous hardwoods such as beech does not affect wood density. However, Bouriaud et al. (2004) reported that there was a low but significant negative correlation between wood density and ring width in beech (r = − 0.14).

The better prediction of MOE than MOR found in this study is consistent with that of Vega et al. (2012) who modeled the MOE and MOR of chestnut (Castanea sativa Mill.) using non-destructive variables and visual grading parameters. For both species, the best MOE model always included the MFA, even when the variation in the MFA value in this study was very weak. The lower influence of MFA on the MOR was already reported by Yang and Evans (2003) when they studied the prediction of MOE and MOR of eucalypt (Eucalyptus globulus Labill.) wood using wood density and MFA. The variation in grain angle measured in this study was also very low. However, for oak, the best prediction models always included grain angle. Nevertheless, the variation in the grain angle of oak was slightly higher than that in beech. This could be the reason why the influence of the grain angle was significant for oak but not for beech.

5 Conclusion

This paper investigates the juvenility limit and structure–property relationship in beech and oak wood of secondary quality obtained from thinning. Results showed that the juvenile wood in oak had wider rings and a higher MFA, whereas it had larger latewood and a higher MFA in beech. For both species, the juvenile wood occupied a very small area, less than 5 cm from the pith, and the stabilization of different parameters seems to vary over time. The mechanical properties of oak and beech wood from suppressed growth trees were similar to the properties of dominant trees reported in the literature. As expected, even if the variation of all studied variables was not high, the model fits well. Adding grain angle and MFA to wood density is useful to predict MOE in both species and MOR in oak, confirming that these three parameters are the key ones mechanistically linked to clear wood MOE and MOR.

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Aicher S, Ohnesorge D (2011) Shear strength of glued laminated timber made from European beech timber. Eur J Wood Wood Prod 69:143–154

Alteyrac J, Cloutier A, Ung C-H, Zhang SY (2007) Mechanical properties in relation to selected wood characteristics of black spruce. Wood Fiber Sci 38:229–237

Barnett JR, Bonham VA (2004) Cellulose microfibril angle in the cell wall of wood fibres. Biol Rev 79:461–472

Birot Y, Dufour J, Ferrandes P, et al (1980) Variabilité de l’angle du fil du bois chez quelques feuillus: Hêtre, Chêne et Eucalyptus dalrympleana. Ann For Sci 37:19–36

Bodig J, Jayne BA (1982) Mechanics of wood and wood composites. Van Nostrand Reinhold Company, New York

Bouriaud O, Bréda N, Le Moguédec G, Nepveu G (2004) Modelling variability of wood density in beech as affected by ring age, radial growth and climate. Trees 18:264–276

Burdon RD, Kibblewhite RP, Walker JC et al (2004) Juvenile versus mature wood: a new concept, orthogonal to corewood versus outerwood, with special reference to Pinus radiata and P. taeda. Forest Sci 50:399–415

Cave ID, Walker JCF (1994) Stiffness of wood in fast-grown plantation softwoods: the influence of microfibril angle. For Prod J 44:43–48

Cibecchini D, Cavalli A, Goli G, Togni M (2016) Beech sawn timber for structural use: a case study for mechanical characterization and optimization of the Italian visual strength grading rule. J for Sci 62:521–528

Cloutier A, Ananias RA, Ballerini A, Pecho R (2007) Effect of radiata pine juvenile wood on the physical and mechanical properties of oriented strandboard. Holz Roh Werkst 65:157–162

Cutter BE, Coggeshall MV, Phelps JE, Stokke DD (2007) Impacts of forest management activities on selected hardwood wood quality attributes: a review. Wood Fiber Sci 36:84–97

Davis EJ, Abrams J, White EM, Moseley C (2018) Current challenges and realities for forest-based businesses adjacent to public lands in the United States. J Rural Community Dev 13:125–142

Donaldson L (2008) Microfibril angle: measurement, variation and relationships–a review. IAWA J 29:345–386

Downes GM, Drew DM (2008) Climate and growth influences on wood formation and utilisation. South For 70:155–167

EN 1316–1 (2012) Hardwood round timber-qualitative classification-part 1: oak and beech

Evans R, Stringer S, Kibblewhite RP (2000) Variation of microfibril angle, density and fibre orientation in twenty-nine Eucalyptus nitens trees. Appita J 53:450–457

Fajriani E, Ruelle J, Dlouha J et al (2013) Radial variation of wood properties of sengon (Paraserianthes falcataria) and jabon (Anthocephalus cadamba). J Indian Acad Wood Sci 10:110–117

Fox TR, Jokela EJ, Allen HL (2004) The evolution of pine plantation silviculture in the southern United States. In: General technical report southern forest science–75. USDA Forest Service, Asheville, pp 63–82

Genet A, Auty D, Achim A et al (2013) Consequences of faster growth for wood density in northern red oak (Quercus rubra Liebl.). Forestry 86:99–110

Gibson LJ, Ashby MF (1999) Cellular solids: structure and properties. Cambridge University Press, Cambridge

Girardon S, Denaud L, Pot G, Rahayu I (2016) Modelling the effects of wood cambial age on the effective modulus of elasticity of poplar laminated veneer lumber. Ann for Sci 73:615–624

Grömping U (2006) Relative importance for linear regression in R: the package relaimpo. J Stat Softw 17:1–27

Gryc V, Vavrčík H, Gomola Š (2008) Selected properties of European beech (Fagus sylvatica L.). J for Sci 54:418–425

Grzeskowiak V (1997) Le bois junvénile de deux angiospermes à pores diffus (Populus euromericana cv I214, Dicorynia guianensis): variations radiales et avec la hauteur des caractères anatomique de l’infradensité et du retrait axial. Dissertation, University of Montpellier 2

Guilley E, Hervé J-C, Nepveu G (2004) The influence of site quality, silviculture and region on wood density mixed model in Quercus petraea Liebl. For Ecol Manage 189:111–121

Guilley E, Loubère M, Nepveu G (1999) Identification en forêt de chênes sessiles (Quercus petraea) présentant un angle du fil du bois intrinsèquement faible. Can J for Res 29:1958–1965

Hofstetter K, Gamstedt EK (2009) Hierarchical modelling of microstructural effects on mechanical properties of wood: a review. Holzforschung 63:130–138

IGN (2016) La memento inventaire forestier: la foret en ciffre et en carte. Institut national de l’information géographique et forestière, Paris

Koutsianitis D, Voulgaridis E (2015) Wood quality and quantity of fir and beech natural forests in relation to site fertility in west-central Greece. Eur J Wood Wood Prod 73:589–595

Lachenbruch B, Moore JR, Evans R (2011) Radial variation in wood structure and function in woody plants, and hypotheses for its occurrence. In: Size-and age-related changes in tree structure and function. Springer, pp 121–164

Leban J-M, Haines DW (2007) The modulus of elasticity of hybrid larch predicted by density, rings per centimeter, and age. Wood Fiber Sci 31:394–402

Lestander TA, Lindeberg J, Eriksson D, Bergsten U (2008) Prediction of Pinus sylvestris clear-wood properties using NIR spectroscopy and biorthogonal partial least squares regression. Can J for Res 38:2052–2062

Lichtenegger H, Reiterer A, Stanzl-Tschegg SE, Fratzl P (1999) Variation of cellulose microfibril angles in softwoods and hardwoods—a possible strategy of mechanical optimization. J Struct Biol 128:257–269

Lindström H, Evans JW, Verrill SP (1998) Influence of cambial age and growth conditions on microfibril angle in young Norway spruce (Picea abies [L.] Karst.). Holzforschung 52:573–581

Longuetaud F, Mothe F, Santenoise P et al (2017) Patterns of within-stem variations in wood specific gravity and water content for five temperate tree species. Ann For Sci 74:64

Maeglin RR (1987) Juvenile wood, tension wood and growth stress effect on processing hardwoods. In: Proceeding of the 15th Annual Symposium of the Hardwood Research Council, Memphis, pp 100–108

McLean JP, Evans R, Moore JR (2010) Predicting the longitudinal modulus of elasticity of Sitka spruce from cellulose orientation and abundance. Holzforschung 64:495–500

Moore JR, Cown DJ (2017) Corewood (juvenile wood) and its impact on wood utilisation. Current Forestry Reports 3:107–118

Mothe F, Duchanois G, Zannier B, Leban J-M (1998a) Analyse microdensitométrique appliquée au bois: méthode de traitement des données utilisée à l’Inra-ERQB (programme Cerd). Ann For Sci 55:301–313

Mothe F, Sciama D, Leban J-M, Nepveu G (1998b) Localisation de la transition bois initial-bois final dans un cerne de chêne par analyse microdensitométrique. Ann For Sci 55:437–449

Nepveu G (1990) Les facteurs influençant la qualité du bois de chêne (chêne rouvre et chêne pédonculé). Rev For Fr 42:128–133

Nepveu G (1981) Prédiction juvénile de la qualité du bois de hêtre. Ann For Sci 38:425–447

Paukkunen S (2014) Opportunities to use thinning wood as raw material for wood pellets. Croat J For Eng 5:23–33

Plourde BT, Boukili VK, Chazdon RL (2015) Radial changes in wood specific gravity of tropical trees: inter-and intraspecific variation during secondary succession. Funct Ecol 29:111–120

Polge H (1973) Facteurs écologiques et qualité du bois. Ann For Sci 30:307–328

Ruelle J, Hiroyuki Y, Thibaut B (2007) Growth stresses and cellulose structural parameters in tension and normal wood from three tropical rainforest angiosperm species. BioResources 2:235–251

Schlotzhauer P, Nelis PA, Bollmus S et al (2017) Effect of size and geometry on strength values and MOE of selected hardwood species. Wood Mat Sci Eng 12:149–157

Tran V-D, Oudjene M, Méausoone P-J (2016) Experimental investigation on full-scale glued oak solid timber beams for structural bearing capacity. Constr Build Mater 123:365–371

Tran V-D, Oudjene M, Méausoone P-J (2015) Experimental and numerical analyses of the structural response of adhesively reconstituted beech timber beams. Compos Struct 119:206–217

Tsehaye A, Walker JCF (1995) Spiral grain in Canterbury Pinus radiata: within-and between-tree variations and effect on mechanical properties. NZ J Forest Sci 25:358–366

Vega A, Dieste A, Guaita M et al (2012) Modelling of the mechanical properties of Castanea sativa Mill. structural timber by a combination of non-destructive variables and visual grading parameters. Eur J Wood Prod 70:839–844

Woodcock D, Shier A (2002) Wood specific gravity and its radial variations: the many ways to make a tree. Trees 16:437–443

Yamamoto H (1993) Method of determining the mean microfibril angle of wood over a wide range by the improved Cave’s method. Mokuzai Gakkaishi 39:375–381

Yang JL, Evans R (2003) Prediction of MOE of eucalypt wood from microfibril angle and density. Holz Roh Werkst 61:449–452

Yin Y, Bian M, Song K et al (2011) Influence of microfibril angle on within-tree variations in the mechanical properties of Chinese fir (Cunninghamia lanceolata). IAWA J 32:431–442

Zhang SY, Nepveu G, Mothe F (1994) Modeling intratree wood shrinkage in European oak by measuring wood density. Forest Prod J 44:42–46

Zhang S-Y, Owoundi RE, Nepveu G et al (1993) Modelling wood density in European oak (Quercus petraea and Quercus robur) and simulating the silvicultural influence. Can J for Res 23:2587–2593

Zobel BJ, Sprague JR (2012) Juvenile wood in forest trees. Springer Science & Business Media, Berlin

Acknowledgements

The authors would like to thank the Indonesia Endowment Fund for Education for the financial support and French National Forest Office (ONF) for providing the wood materials. We also thank E. Cornu and P. Gelhaye for the fieldwork and X-ray measurement in the laboratory.

Funding

This study was funded by Indonesia Endowment Fund for Education.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Communicated by John Moore.

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Handling Editor: John Moore

Rights and permissions

About this article

Cite this article

Purba, C.Y.C., Dlouha, J., Ruelle, J. et al. Mechanical properties of secondary quality beech (Fagus sylvatica L.) and oak (Quercus petraea (Matt.) Liebl.) obtained from thinning, and their relationship to structural parameters. Annals of Forest Science 78, 81 (2021). https://doi.org/10.1007/s13595-021-01103-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13595-021-01103-x