Abstract

This paper reviews and analyzes the impact of residue burning on the environment and human health, and the influence of ex-situ and in-situ residue management on reducing pollution and improving soil health, crop yield, and farmers’ economic benefits. Paddy is cultivated on 43.8 Mha in India, producing 118.43 Mt grain and an estimated 165.8 Mt straw. Burning is the most common practice for managing rice crop residues mainly due to its simplicity, low cost, increased mechanical harvesting, short window between rice harvest and wheat sowing, and lack of viable uses for residues. Around 50 Mt of rice straw is burned annually, nearly half of which occurs in northwestern India during October/November. Burning residue is a major contributor to air pollution, emitting around 1.5 Mt particulate matter, 150 Mt carbon dioxide, and other greenhouse gases (e.g., NO2, SO2, CO, CH4, NH3) and volatile organic compounds, resulting in a wide range of respiratory infections in humans, reduced soil nutrient and carbon inputs, and disturbed soil microbial activity. In-situ residue management using a Happy Seeder, Super straw management system, paddy straw chopper cum spreader, reversible moldboard plow, or no-till seeder incorporates or mulches residues, avoiding burnings. These operations are economically profitable as they reduce costs, increase yields, or both. In-situ residue management, i.e., incorporation or mulching improves the soil’s physical, chemical and biological properties and is considered better for improving soil health than residue removal. Ex-situ residue management for biofuel, biochar, electricity generation or bale making is also profitable for the environment and reduces pollutant emissions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

-

1. Introduction

-

2. Farmers’ residue management practices and their perception of various techniques

-

3.1. Disease management

-

3.2. Weed management

-

5. Crop residue management: a step towards agricultural sustainability

-

5.1.2 Mulching crop residues

-

5.2.1 Happy Seeder

-

5.3.1 Biofuel

-

5.3.2 Biochar

-

5.3.3 Baling

-

5.3.4 Electricity generation

-

6. Governmental interventions to prevent crop residue burning

-

7. Conclusions

-

8. References

1 Introduction

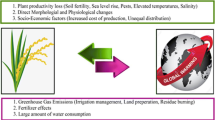

The rice (Oryza sativa)–wheat (Triticum aestivum) cropping system is the most prevalent production system in the world, with 24 million hectares (Mha) in Asia (Nawaz et al. 2019). The sustainability of the rice–wheat system is becoming challenging due to declining productivity, degrading soil health, falling groundwater levels, increasing greenhouse gas (GHG) emissions, shifting weed flora, evolving herbicide-resistant weeds such as Phalaris minor in wheat (Malik and Singh 1995), and burning crop residues (Bhatt et al. 2021). Asia contributes around 84% or 826 million tons (Mt) of total global rice residue production (980 Mt) (Goswami et al. 2019). Table 1 presents potential residue production and burning in India and globally. The average nutrient content in rice residue is 0.7% N, 0.23% P, and 1.75% K. Total nutrient content in rice residue is around 26.26 and 22.13 Mt year−1 globally and in Asia, respectively (Goswami et al. 2019). Stubble or crop residue burning, the most common practice for residue management, is when agricultural straw or stubble left in the field after grain harvest is intentionally burned (Fig. 1). While the practice of burning crop residues is declining globally—mainly in agriculturally advanced and prosperous nations due to stringent environmental regulatory protocols and market-oriented approaches—this is not the case in southern and eastern Asia, possibly due to the lack of viable and economical alternatives and technologies to dispose of large quantities of biomass. There is also uncertainty regarding the economic returns from alternative technologies and policy execution (Shyamsundar et al. 2019).

Residue burning releases several pollutants into the atmosphere, adversely affecting the environment. Thus, the impact of residue burning on adjoining areas and cities needs addressing to understand its effect on human health. This paper discusses the volume of pollutants released into the atmosphere and their effect on human health based on available literature. Several technological interventions for ex-situ and in-situ residue management are being promoted in India to address the issue of residue burning. These interventions are helping farmers to prepare seedbeds and reduce environmental pollution associated with residue burning, but their usefulness and adoption are debatable, with varying perceptions among farmers of their benefits. This paper reviews the adoption of residue management techniques and their viability in farmers’ fields. This review also focuses on the negative impacts of residue burning on the environment and human health and the positive effects of residue management techniques on farm income.

Farmers in South and East Asian nations undertake the most crop residue burning, which has increased over the years (Cassou et al. 2018). Around 730 Mt biomass is burned each year in Asia, comprising mainly forest burning (45%), crop residue burning (34%), and grassland burning (20%). Farmers in China burn the most crop residue, followed by those in India, Indonesia, and Myanmar (Streets et al. 2003), with around 25% of the residues burned after harvest, despite financial incentives (subsidies) to retain crop residues. The retention and incorporation of rice residues in soil could reduce CO2 emissions by 150 Mt year−1 and increase soil organic carbon (SOC) sequestration by 240 Mt C year−1 (Chen et al. 2019).

India generates around 682.6 Mt (dry weight basis) of residue biomass annually, with 58.6% generated in the kharif or rainy season (June to October), 38.9% in the rabi or winter season (November to April/May), and 2.5% in the summer/dry season. For kharif season crops, Uttar Pradesh produces the most biomass (19.1%), followed by Maharashtra (16.2%), Gujarat (8.8%), and Punjab (7.5%). Similarly, for rabi season crops, Uttar Pradesh produces the most biomass (17%), followed by Madhya Pradesh (12.7%), Rajasthan (10.7%), and Bihar (8.5%) (Jain et al. 2018). An analysis of residue generation in major states of India revealed that cereal grains and sugarcane represent the largest proportion of total residue generation (Fig. 2). Residue generation from rice is a major issue in the northwestern Indo-Gangetic plains, where the densely populated states of Punjab, Haryana, and Uttar Pradesh produce 27.13% and 57.66% of the country’s rice and wheat, respectively (Agriculture Statistics 2020). Rice is cultivated on 43.78 Mha in India, producing 118.43 Mt, with Punjab, Haryana, and Uttar Pradesh accounting for 6.67%, 3.31%, and 13.11% of the total area and 9.95%, 4.07%, and 13.11% of the total production in 2019–2020, respectively (Agricultural Statistics 2020). Every Megagram (Mg) of rice grain harvested produces around 1.4 Mg straw (Satpathy and Pradhan 2020), equating to 165.8 Mt rice straw in 2019–2020. In northwestern India, rice contributes about 33% of the total residue biomass, followed by wheat (22%) and sugarcane (Saccharum officinarum) (17%) (Jain et al. 2018). About 80% of the crop residue produced in India each year (683 Mt) is used as fodder, fuel, or industrial raw material. Of the unused surplus crop residue (178 Mt), about 87 Mt is burned in fields (Datta et al. 2020). Rice straw constitutes 60% of burned crop residues, with an estimated 50 Mt rice residue burned in fields (Bhattacharya et al. 2021). Many of the 2.5 M farmers in northwestern India burn an estimated 23 Mt of rice stubble in October and November (i.e., half of the total rice residue burned in India) to prepare their fields for the subsequent wheat crop (NAAS 2017). Around 8–80% of rice residues and 10–23% of wheat residues generated in India are burned, with about 10% each for maize, jute, cotton, groundnut, rapeseed-mustard, and millets, and 25% for sugarcane (Jain et al. 2014).

Residue generation in major states of India (Mt year–1). Source: Adapted from Jain et al. (2014).

The cumulative burning events in the three major states of India show that Punjab has the most fire events, followed by Haryana and Uttar Pradesh (Fig. 3). Across the three states, 82,278 active fire events were recorded in October and November 2021, 35.6% lower than those reported in 2016 (Fig. 4), down 30.6% in Punjab, 55.8% in Haryana, and 56.6% in Uttar Pradesh (CREAMS-IARI 2021). In 2019, around 20 Mt rice residue was generated in Punjab, with 9.8 Mt burned across 1124.48 thousand hectares (tha) or 37.4% of the total paddy cultivated area. Haryana generated 7.0 Mt rice straw, with 1.24 Mt burned across 240.08 tha or 17.7% of the total paddy cultivated area. Uttar Pradesh generated about 16 Mt rice straw, with only 0.0042 Mt burned across 0.2% of the total paddy cultivated area (EPCA 2020). The air quality in northern India is very sensitive to meteorological conditions and the residue burning amount (Sembhi et al. 2020). Residue burning contributes around 4–30% of the air pollution in Delhi depending on the fire intensity and wind speed and direction, as analyzed by the System of Air Quality and Weather Forecasting and Research (SAFAR) (EPCA 2020). Punjab’s active straw burning events are concentrated from the end of October to mid-November due to the large area under non-basmati rice and increased use of combine harvesters. However, in Haryana and Uttar Pradesh, active burning is more evenly distributed across October and November. This residue burning period coincides with the post-Diwali period when the pollutant level is already high, worsening the situation and creating deadly smog (EPCA 2020). Paddy residue burning occurs during winter (October and November), resulting in more pollutants trapped in the air due to high moisture, low temperature, and less wind dispersal. Thus, air pollution and its adverse effects persist in northwestern India.

Cumulative burning events for rice residues in northwestern India (15 Sept–30 Nov 2021). Source: CREAMS-IARI, 2021.

Rice residue burning events in northwestern states of India (2016–2021). Source: CREAMS-IARI (2021).

The smoke plume emitted from burning paddy stubble in the field increases the particulate matter concentration and causes a dense haze. The GHG emissions, including CO2 and N2O, from stubble burning, aggravate global warming (Thangarajan et al. 2013; Anderson et al. 2016; Malhi et al. 2021). Air pollution caused by residue burning poses serious health issues (Abdurrahman et al. 2020; Adam et al. 2021) by enhancing the risk of acute respiratory infection and cardiac diseases (Chakrabarti et al. 2019). Crop residue burning deteriorates soil health (Lohan et al. 2018), reduces soil nutrient availability to plants (Ademe 2015), adversely affects soil microbial and physicochemical structure, and makes the soil more susceptible to accelerated erosion (Kumar et al. 2015).

2 Farmers’ residue management practices and their perception of various techniques

Residue burning is practiced widely in Punjab, with 76.3% of stakeholders burning rice residues in the field, 22.5% using a rotavator/no-till (NT) seed drill, and 1.2% using traditional means (Kumar et al. 2015). A study in Punjab indicated that of the farmers using conventional tillage, 33.5% incorporated rice residues in soil, while 66.5% chose to burn. Whereas, 90.6% of happy seeder farmers left residues in the field, 3.9% burned and the remaining incorporated them in the fields (Keil et al. 2021). Moreover, few selling options are available for crop residues, with only 2% of farmers reporting buyers for rice residue (US$1.3 t−1) and 12% for wheat residues (US$26.5 t−1) (Kumar et al. 2015). Even though farmers are aware of the adverse effects of residue burning on air quality, human health, and soil health, they continue to burn rice residues due to the short turnaround time between rice harvest and wheat sowing, the costly and time-consuming nature of manual harvesting, and labor shortages (Anuradha et al. 2021a). In Haryana, Sanjay et al. (2021) reported that basmati rice is usually harvested manually, while non-basmati rice is harvested by mechanical means. Around 86.3% of mechanically harvested stubbles are burned. Farmers burn paddy residues on small to large landholdings. Banning burning would only have a moderate impact on the residue management practices, and farmers continue to practice residue burning in the absence of viable economic opportunities and adequate enforcement (Gupta 2012).

Around 96% of respondents in the Mirzapur village of Kurukshetra district of Haryana burn crop residues after crop harvest, despite most (90%) being well aware of the adverse effects of residue burning on air pollution (Grover et al. 2015). In contrast, half of the farmers in the southwestern Mansa district of Punjab use rice residue management practices other than burning, such as mulching, incorporation, and residue removal. Farmers generally prefer residue removal over other management practices, with about 37% of residues removed manually or with a rectangular baler. Residue removal is followed by residue mulching using Happy Seeder technology (31%) > rotavator (14%) > super seeder technology (7.7%) (Singh et al. 2020a). With increasing scientific evidence on the detrimental effects of crop residue burning and the reach of such information to agricultural communities, the issue of crop residue burning has received more attention in recent years. This has led to increased policy interventions on rice residue management, resulting in some reduction in the amount of residue burning. However, human herd behavior influences the residue management practices of farmers, resulting in large-scale burning practices. Farmers might be less likely to choose residue burning if they were aware of its detrimental effects on soil quality (Lopes et al. 2020).

In Haryana, a large proportion of farmers are aware of the adverse effects of burning on air quality (100%), soil health (73.9%), and human health (81.7%), but there is a lack of viable options for residue management (Anuradha et al. 2021a). Farmers perceive adoption constraints related to the short time gap between rice harvest and wheat sowing, the high cost of renting machinery, and the lack of practical techniques. However, these adoption constraints are perceived differently by the farmers, with farmer annual income and farmer contact with extension personnel negatively correlated with the perception of these adoption constraints (Anuradha et al. 2021b). Another study indicated that more rice residues (81%) are burned than wheat residues (48%) because wheat straw makes excellent dry fodder for cattle. Rice straw is considered inferior for cattle consumption due to its high silica content (Kumar et al. 2015). Farmers and agricultural extension personnel differ in their perception of the effect of residue burning on controlling insect pests, weeds, and pathogens, animal milk yield, and forest tree yield. Farmers’ perceptions of the effect of crop residue burning correlated with their education level and ecological consciousness (Lyngdoh and Dhaliwal 2018). Most farmers (94.3%) perceived that residue burning is responsible for climate change, with 85.7% and 74.3% of farmers attributing the changing rainfall patterns and extreme temperatures, respectively to residue burning (Kamble and Tikadar 2021). The open burning of crop residues contributes around 12% toward global warming (Andini et al. 2018). The GHG emissions (mainly CO2, CH4, and NO) from residue burning result in global warming, leading to climate change (Mathur and Srivastava 2019). Residue management studies have established that burning is the most common management technique adopted by farmers in Punjab and Haryana. However, while most farmers are aware of the ill effects of burning on air, soils, and human health, constraints related to the short duration between rice harvest and sowing of the succeeding wheat crop, mechanical harvesting, labor shortages, low prices for rice straw, and costly residue management operations hinder the adoption of better residue management options. The wide adoption of machinery in recent years, particularly for harvesting (combine harvesters) and intensive cultivation, has added to the pollution issue.

3 Merits of residue burning

Farmers prefer residue burning as it helps overcome residue-induced immobilization of nitrogen (Vijayaprabhakar et al. 2021), destroys weed seeds and seedlings, provides better disease and insect pest management, and eliminates rodents (Rasmussen and Rohde 1988).

3.1 Disease management

Residue burning reduces soil-borne disease infestations as it destroys the inoculum present in the crop residues. The burning of ergot-infected wheat stubbles decreased the number of viable sclerotia, an inoculum for primary infection, and reduced ergot (Claviceps purpurea) infestations in the succeeding wheat crop (Bretag 1985). Burning wheat stubble reduced fusarium crown rot (Fusarium graminearum) infestations over four seasons compared with residue retention but did not increase yield due to deleterious agronomic effects (Burgess et al. 1996). In a study investigating the effect of stubble management practices (i.e., burning after harvest, incorporating with a disk plow, and surface retention) on the incidence of fusarium crown rot in wheat over five seasons at two sites with high (site A) and low (site B) initial disease incidence, stubble burning reduced disease infection in two of five years at site A and three of four years at site B. Failure to control the infection was attributed to inadequate burning and susceptible weed hosts (Burgess et al. 1993). The burning of wheat stubbles controlled yellow spot (Pyrenophora tritici-repentis) in wheat better than other wheat residue management practices, such as residue retention on the soil surface and stubble incorporation (Summerell et al. 1988). Stubble burning soon after harvest reduced infestations of fusarium crown rot in the subsequent wheat crop more than late burning, tillage, or stubble retention on the soil surface (Klein et al. 1988).

3.2 Weed management

Weeds are a major constraint in crop production as they compete for light, moisture, and plant nutrients (Rana et al. 2019; Malhi et al. 2020). Stubble burning can reduce the weed seed bank and release toxic allelopathic chemicals that reduce weed growth, depending on the weed species. Stubble burning reduced the weed density of brome grass (Bromus pectinatus), which requires similar growing conditions to wheat and is thus difficult to eradicate by manual weeding or selective herbicides (Girma et al. 1995). Stubble burning reduced brome grass infestations and thus increased wheat grain yields (Taa et al. 2004). Stubble burning also improved wheat yields in central Iran (Hemmat and Taki 2001). Burning wheat stubble reduced Wimmera ryegrass (Lolium rigidum) and increased wheat yield more than stubble incorporation in Western Australia (Mason et al. 1968). A 3-year study conducted in Jabalpur, India, revealed that stubble burning had the lowest weed densities in the first year, while residue incorporation had the lowest weed densities in subsequent years (Khankhane et al. 2009). Table 2 lists the studies investigating the impact of residue burning on diseases, pests, and weeds at different locations.

Rice residue burning can also reduce infestations of soil-borne insect pests and pathogens (Mandal et al. 2004), as it minimizes reinfection arising from inoculum in rice straw biomass (Dobermann and Fairhurst 2002). However, improved pest management options are now available, circumventing the need of residue burning for this purpose.

4 Disadvantages of crop residue burning

4.1 Environmental pollution

The disposal of paddy residue is an enormous challenge for farmers. Crop residue burning is an easy, economical, and time efficient method of residue management, but it is not environmentally sustainable, leading to GHG (CO2, CH4, and N2O) and particulate matter emissions that cause global warming, air pollution, and climate change (Thangarajan et al. 2013; Yodkhum et al. 2018; Mathur and Srivastava 2019). Around 24% of the total residue biomass produced in India was burned in-situ in 2017, releasing around 0.8 Mt particulate matter (PM2.5), 0.24 Mt organic carbon, 0.058 Mt elemental carbon (EC), and 211 Mt CO2 eq. GHGs into the atmosphere. A trend analysis using the Business As Usual model predicted that these emissions would increase by 45% by 2050 (Ravindra et al. 2019a). Burning 1 Mg crop residue releases about 3 kg PM, 60 kg CO, 1460 kg CO2, 199 kg ash, and 2 kg SO2 (Bimbraw 2019). In India, crop residue burning is a bimodal activity, peaking in April–May (wheat harvest) and October–November (paddy harvest). The aerosol optical depth (AOD), representing a measure of aerosols (e.g., urban haze, smoke particles, desert dust, sea salt) distributed within a column of air, increases due to the burning events, with mean AOD in 2003–2008 of 0.60 [0.87 (+σ) and 0.32 (–σ)]. The AOD fire signal is more evident during winter, corresponding with paddy (rice) residue burning events (Vadrevu et al. 2011). Annual rice residues burned during the post-monsoon period in Punjab, Haryana, Uttar Pradesh, and Bihar are an estimated 10.4 ± 3 Mt, leading to emissions of 0.65 ± 18 Mt organic carbon, 0.56 ± 1.6 Mt black carbon, 14.9 ± 4.2 Mt CO2, and 0.79 ± 225 Mt CO (Liu et al. 2020). Punjab contributes more than two-third of total emissions, evidenced in a bottom-up validation (Liu et al. 2020). Crop residue burning in Haryana also surpasses the concentration of primary pollutants (i.e., SOx, NOx, and PM2.5) by 78%, 71%, and 53%, respectively, according to the National Ambient Air Quality Standards (NAAQS), significantly decreasing the air quality index measured with a high volume sampler (Grover and Chaudhry 2019). A multicity campaign conducted in Punjab, Haryana, and Chandigarh showed that gaseous pollutants and volatile organic compounds (VOC) increased from October to December 2016, forming secondary pollutants (Ravindra et al. 2019b). Amritsar city in Punjab has the highest gaseous pollutant concentrations (NO, NO2, NOx, and SO2). In a study of correlation of air pollutants and meteorological conditions, O3 is found positively correlated with temperature and UV (R = 0.87 and 0.74) and VOC is negatively correlated with temperature (R = − 0.21 to − 0.47) (Ravindra et al. 2019b). Table 3 lists various pollutants emitted by residue burning in India. While pollutant emissions vary between studies, around 1.5 Mt particulate matter is released into the environment along with GHGs and other VOCs. Around 150 Mt of the major GHG (CO2) is released.

Crop residue burning increases particulate matter concentrations in the atmosphere during pre- and post-monsoon and stagnant winds can cause an airlock in the Delhi NCR region (Kumar and Singh 2020). Increased prevalence of finer particles and black carbon aerosols during the post-monsoon and winter contaminate the air mass in the foothills of the Himalayas, reaching as far as eastern and central India. Emission inventory sources, such as EDGAR and the global fire emission database, indicate that increased methane (CH4) and black carbon during November are mainly due to crop residue burning in northwestern India (Sarkar et al. 2018). The aerosol backscatter profile, obtained through measurements using a micro-pulsed lidar (MICROTOPS-II sun photometer) and multi-filter rotating shadow band radiometer, showed that aerosol layers increase by up to 3 km on some days in central India during October, attributed to crop residue burning on the Indo-Gangetic Plains (Badarinath et al. 2009).

High correlations between acetonitrile (chemical tracer of biomass burning) and benzenoids, isocyanic acid, and CO (r ≥ 0.82) indicate that biomass burning is a major source of most pollutants. A higher emission ratio of VOC/acetonitrile (benzenoids to acetonitrile and CO to acetonitrile) occurs during post-paddy harvest seasons, consistent with high emissions. The concentrations of acetonitrile, toluene, benzene, C8-aromatics, C9-aromatics, and CO can be 1.5 times higher during the post-harvest period of paddy than annual mean concentrations, confirming the contribution of residue burning to these pollutants. The concentration of benzene, a class A carcinogen, can also exceed the exposure limit mandated by NAAQS during this period (Chandra and Sinha 2016).

The concentrations of pollutants (PM10, PM2.5, NOx, SO2, and CO) also increase in the Delhi NCR region in October and November (Nair et al. 2020). However, local meteorological conditions are not expected to cause cross-boundary transmission of particulates generated from residue burning in Punjab and Haryana to Delhi. In contrast, AERONET (Aerosol Robotic Network) showed carbonaceous aerosols over Delhi and, as predicted by HYSPLIY (Hybrid Single Particle Lagrangian Integrated Trajectory Model), the northwesterly winds may have transported the burned particulates to Delhi in November. However, most of these aerosols are dispersed 3000 m above ground and far away from the zone of human vicinity. Therefore, the particulates and aerosols occurring in October are mainly due to local emissions and poor meteorological conditions (low wind speed, wind direction, low temperature) in Delhi (Nair et al. 2020).

The major source of outdoor air pollution in metropolitan cities like Delhi is caused mainly by increased industrial activities, commercial activities, vehicular emissions, and soil re-suspension (Kumar et al. 2001; Balachandran et al. 2000). Vehicular emissions have contributed significantly to indoor air pollution adjacent to heavy traffic roads (Goyal and Khare 2011). Vehicular pollution and industrial emissions are major causes of indoor and outdoor pollution (Rizwan et al. 2013; Chatterji 2020). The major sources of air pollution in northern India during winter, as revealed by positive matrix factorization, are secondary transformations or aerosols (46.2%) followed by mineral dust (20.2%), biomass burning (19.4%), industrial emissions (6.1%), leather tanneries (4%), vehicular emissions (3%), and coal combustion (1.1%). Another report stated that industries, vehicular pollution, and the residential sector add 30%, 28%, and 10% to the total air pollution in Delhi, while agricultural burning constitutes only 4% (Supreme Court of India 2020). The contribution of vehicular pollution is around 72% in Delhi, as estimated from emission factors and an activity-based approach by the Intergovernmental Panel on Climate Change (IPCC) (Goyal 2006). Studies have revealed increased pollutant emissions with increasing incidence of residue burning, reducing the air quality in Punjab, Haryana, and surrounding regions. Several studies have reported the likely transmission of pollutants from Punjab and Haryana to Delhi. In contrast, others have suggested that cross-boundary transmission is not possible, with reduced air quality in the NCR region mainly due to local emissions from industries and vehicles. The reduced air quality during rice residue burning is also intensified by low temperatures creating an airlock in northwestern India.

4.2 Health concerns and respiratory infections

Air pollution caused by residue burning results in a dense haze over the Indo-Gangetic Plains, leading to poor visibility. The daily average PM2.5 concentration can reach 191 μg m–3, four times higher than the NAAQS, as observed from 28 October to 3 November 2015 at Chandigarh, with increased organic C and K+ ion concentrations (Ravindra et al. 2021). The increased air pollutants cause eye irritation, chest congestion, dry eyes, and numerous diseases, such as pneumoconiosis, chronic obstructive pulmonary disease, pulmonary tuberculosis, cataract, bronchitis, corneal capacity, and blindness (Singh et al. 2018; Adam et al. 2021). The lifetime risk due to benzene emissions from residue burning is estimated to cause cancer in 25 and 10 per million children and adults, respectively (Chandra and Sinha 2016). Exposure to isocyanic acid may also increase to one part per billion (ppb), close to the toxic threshold, increasing cardiovascular issues and cataracts (Chandra and Sinha 2016). Residue burning also increases the levels of suspended particulate matter (SPM), PM10, and PM2.5, decreasing pulmonary function tests (PFTs), particularly in children (Awasthi et al. 2010). Lung function parameters (e.g., forced vital capacity, forced expiratory volume in one second) of school children decreased with increasing particulate matter fractions from crop residue burning (Saggu et al. 2018). The decreased forced vital capacity was somewhat higher in males than females, mainly due to better health care by females and less exposure for female students than male students (Saggu et al. 2018). Crop residue burning in northwestern India increases PM2.5 concentrations to 20 times the threshold for safe air recommended by the World Health Organization (Chakrabarti et al. 2019). Living in regions with intense rice residue burning was associated with a three-fold higher risk of acute respiratory infections (ARI), particularly in children, and a significant cause of lost disability-adjusted life years (DALY) from September 2013 to February 2014 (Chakrabarti et al. 2019). The same pattern of increased particulate matter and lower PFTs has been observed during wheat residue burning (Agarwal et al. 2009). The forced vital capacity and peak expiratory flow in children decreased by 5–7% and 4–6%, respectively, during two crop residue burning episodes of rice and wheat monitored from September 2013 to June 2014, with children’s lung capacity only recovering by up to 80% after the burning events (Gupta et al. 2016a). Children with a lower body mass index (BMI) are often more affected by exposure to the same particulate matter level than children with higher and normal BMI (Gupta et al. 2017).

Northwestern India has the most severe air pollution causing ARI in children. For children under five, 5.0% of males and 4.3% of females in Uttar Pradesh, 4.8% of males and 3.3% of females in Punjab, and 3.3% of males and 3.0% of females in Haryana have ARIs, significantly higher than the northwestern hill state of Himachal Pradesh, with 1.6% males and 1.7% females (Batra 2017).

Residue burning deteriorates air quality, impacting human health throughout northwestern India. Rice residue burning causes economic losses associated with plant nutrients, irrigation, soil biodiversity, succeeding crop yield, market value of produce, and human health valued at US$48.58, 9.41, 0.66, 46.05, 13.27, and 0.84 ha−1, respectively, totaling US$118.81 ha−1 (Kumar et al. 2015, 2019a). At the state level, these losses could amount to US$ 0.24, 0.12 and 0.07 billion for Punjab, Haryana, and Western UP, respectively (Kumar et al. 2019a). The estimated social cost of paddy residue burning is US$0.43 billion (Kumar et al. 2019a). Loss of medical expenditure, opportunity cost of lost work, deteriorated air quality indexes, and other environmental externalities are also associated with air pollution. With a population of 1,083,000 in 2008, the rural Patiala district had an estimated medical expenditure of US$0.031 million due to deteriorated air quality, with lost workdays valued at US$0.034 million. In rural Punjab, medical expenditure and the opportunity cost of lost workdays were valued at US$0.48 million and 0.53 million, respectively, amounting to a total welfare loss of US$1.01 million (Kumar et al. 2015). Eradicating agricultural crop residue burning in northwestern India would avoid annual losses of 149,000 DALY, valued at US$1.529 billion over 5 years (Chakrabarti et al. 2019). Pandey et al. (2021) reported that 17.8% of all deaths in India in 2019 were attributed to air pollution (1.67 million deaths). The crude death rate per lakh of population in India increased by 115.3% from 1990 to 2019 due to particulate matter emissions. Around 11.5% of DALY in India in 2019 were attributed to air pollution, with huge variation between states, with the highest rates in northern states. While crop residue burning accounts for 4–30% of air pollutants (EPCA 2020), it is huge in absolute terms, with each component requiring work.

In regions where farmers burn crop residues, human diseases associated with air pollution are becoming increasingly evident. With increased pollutant emissions due to residue burning, people in these regions face numerous health issues, mainly related to respiratory infections, with children the worst affected. Residue burning has also increased the precautionary expenditure of people of the region and is thus a major negative environmental externality, establishing the adverse effect of residue burning on human health.

4.3 Soil health degradation

In addition to air pollution, residue burning causes appreciable losses of essential plant nutrients (Lohan et al. 2018). Continuous burning of crop residues can lead to soil fertility losses, soil structure breakdown, and increased soil erosion (Ademe 2015). Table 4 shows nutrient losses and altered soil physical and chemical properties under different residue management practices. While residue burning can enhance bioavailable nutrient concentrations (measured by exchangeable NH4-N and bicarbonate-P content) in the short-term, nutrient buildup in the soil profile does not occur over time (Biederbeck et al. 1980; Mandal et al. 2004; Singh and Sidhu 2014). Long-term residue burning decreases soil N and C contents and potentially mineralizable N up to 15 cm soil depth (Biederbeck et al. 1980). Crop residue burning followed by soil erosion results in losses of 35, 3.2, and 21 kg ha−1 N, P, and K (Abdurrahman et al. 2020). Singh et al. (2013a) reported similar losses of 33.66, 7.48, and 66.85 kg ha−1 available N, P, and K, respectively. Residue burning of wheat negatively affects soil physical and chemical properties, including changes in pore space, specific gravity, water holding capacity, moisture content, pH, chloride, exchangeable magnesium, exchangeable calcium, organic carbon, electrical conductivity, and available phosphorus (Tripathi et al. 2015).

Cereal straw burning also decreases the soil microbial population (Bhuvaneshwari et al. 2019). Furthermore, repeated burnings could permanently decrease the bacterial population in the top 2.5 cm of soil (Bhuvaneshwari et al. 2019). Soil respiration measurements have confirmed reduced soil biological activity with burning, including bacterial and fungal growth; however, the fungal population may flourish and be on par with residue incorporation or residue removal at 90 DAS wheat in a rice–wheat sequence (Khankhane et al. 2009). However, significant differences in the microbial population associated with biomass recycling, such as P-solubilizing bacteria, occurred among residue burning, removal, or incorporation treatments at 60 DAS (Kumar et al. 2019b). Therefore, it is evident that residue burning affects soil physical, chemical, and biological characteristics, decreasing available soil nutrients, microbial activity, and soil fertility, hindering sustainable agricultural production (Collins et al. 1992; Wuest et al. 2005; Reddy and Chhabra 2022).

5 Crop residue management: a step towards agricultural sustainability

5.1 In-situ crop residue management

5.1.1 Incorporation of crop residues

Residue retention is a nutrient-conserving measure that increases soil fertility and N availability, affecting succeeding crop growth by immobilizing available soil nutrients (Vijayaprabhakar et al. 2021) through a microbially mediated process coupled with organic matter decomposition. Immobilization of fertilizer N is mainly associated with finer soil particles such as clay and silt; however, the light fraction, including sand, also retains a significant portion of applied N. Thus, N retention is mainly due to biotic factors, with around 4–11% N weakly fixed within clay mineral layers. Thus, rice straw addition can increase microbially mediated immobilization and stabilization of N (Said-Pullicino et al. 2014), reducing losses associated with reactive nitrogen (Nr) runoff. During rice tillering, proteobacteria enrichment revealed the prominent role of microbes in N immobilization (Zhang et al. 2021). Rice residue incorporation enhanced microbial activity and, when combined with organic manure, improved physical soil conditions, augmenting the succeeding wheat crop yield (Mandal et al. 2004). Rice stubble incorporation increased SOC, dissolved OC, light fraction OC, and microbial biomass carbon (MBC) (Chowdhury et al. 2015; Wang et al. 2015). Straw incorporation significantly enriched soil C storage by 12%, favoring soil C sequestration (Lu 2015; Chowdhury et al. 2015). However, straw incorporation for long periods significantly increased CH4 emissions and SOC density in the topsoil (Xia et al. 2014). Rice residues contain high amounts of silica, which can alter the chemical properties of acidic soils, reducing P fixation, increasing soil pH, and enhancing base retention. The global warming potential (GWP) of CH4 emissions induced by straw incorporation was 3.21–3.94 times the straw-induced SOC sequestration rate, worsening the effect of climate change rather than mitigating it (Xia et al. 2014). In another study, straw incorporation increased CH4 emissions by 35%, annual GHGI (greenhouse gas intensity) by 31.1%, and annual GWP by 32% but did not affect the net ecosystem economic budget (NEEB) (Zhang et al. 2015).

Residue incorporation strengthens soil nutrient recycling and improves soil health by increasing soil organic matter (Nawaz et al. 2020). Rice residue incorporation enhances grain yield and net returns of the subsequent wheat crop (Kumar et al. 2005). Residue management practices also affect wheat crop yields and net returns; the incorporation of rice residues produced the highest net returns of US$767.25 ha−1 and BC ratio of 6.79 (Khankhane et al. 2009). Rice residue incorporation significantly increased crop grain yield in a rice–wheat system, with net economic benefits ranging from US$24.26–102.34 ha−1 year−1 (Xia et al. 2014). Paddy straw incorporated with additives positively affected the growth and development of the subsequent rice crop. Rice straw incorporation with 25 kg N ha−1 as a basal bio-mineralizer (2 kg t−1 residue) and cow dung slurry (5%) improved the growth parameters of the succeeding rice crop, increasing productive tiller number, panicle length, grain number per panicle, filled panicle number, and filled spikelet percentage. The highest grain yield (7395 kg ha−1) and straw yield (8440 kg ha−1) resulted in gross returns of US$1512.41 ha−1, net returns of US$919.31 ha−1, and a benefit cost ratio of 2.55 (Vijayaprabhakar et al. 2021). Rice residue fortified with plant-growth-promoting microbes, humic acid, and seaweed extract enhanced soil carbon, nutrient availability, and fertility status (Vijayakumar et al. 2021). Therefore, diversifying the cropping system and adopting conservation agriculture practices could enhance soil carbon sequestration and increase biodiversity (Nawaz et al. 2020). The inception of the green revolution increased the adoption of high-yielding varieties. Improved management practices, including the judicious use of fertilizers based on soil testing and leaf color chart (for major crops), split applications according to crop demand at different growth stages, use of neem-coated urea, sowing machines that also drill fertilizers, and nutrient-efficient crop cultivars, have increased agricultural productivity. Moreover, the increased cropping intensity and root biomass have increased soil organic matter and SOC which can be further improved with straw incorporation. At the Punjab Agricultural University (PAU) research farm, the incorporation of wheat and paddy residues has increased the organic matter content from 0.42% in 1988 to 0.59% in 2001 (Singh et al. 2007). In Punjab, SOC increased from 0.33% in 1981–1990 to 0.51% in 2011–2020 (Dhillon et al. 2021). This proportion is, nevertheless, still below the standards of PAU (0.75%), the Punjab Agriculture Department (1%), and international standards (2–3%) (Chaba 2020).

5.1.2 Mulching crop residues

Mulching crop residues, or spreading residues on the soil surface, enhances water and nitrogen use efficiencies and reduces weed pressure (Singh and Sidhu 2014; Qin et al. 2021). It also restricts free water vapor diffusion, regulates soil temperature, reduces soil erosion, and improves soil health, thus improving long-term crop productivity (Ram et al. 2013; Bhatt et al. 2017). Since these residues contain significant nutrients, their application improves the soil’s nutrient status by releasing them as they decompose (Singh et al. 2014). Mulching also significantly improves soil aeration and water infiltration and reduces soil bulk density and root penetration resistance (Sharma et al. 2011; Javeed et al. 2012). Rice straw mulch with NT had higher carbon sequestration than straw incorporation with conventional tillage (Yadvinder-Singh et al. 2009; Singh et al. 2009; Kahlon et al. 2013), which was attributed to the rapid decomposition of incorporated residues. NT with residue retention has the potential to sequestrate 6.8–13.7 Mg C ha−1 over 15–30 years in a rice–rapeseed cropping system in the hilly agro-ecosystem of the Eastern Himalayas, India (Yadav et al. 2019). Residue retention in a rice–wheat cropping system (zero-till direct seeded rice–zero-till wheat) resulted in the highest soil quality index (SQI) and is beneficial for its productivity and sustainability in eastern Indo-Gangetic plains (Saurabh et al. 2021). Rice straw mulching reduced the maximum soil temperature by 2.0–3.3 °C and mean weed dry matter by 12.5–15.7% and increased wheat growth attributes and yield (Ram et al. 2013). Rice residue mulching increased wheat crop yields by 19.4% and 11.1% compared with rice residue retained on the soil surface and incorporated residue, respectively, mainly by reducing weed density and dry weight (Meena and Singh 2013). Mulching increased wheat root length by around 25%, root length density by 40%, and reduced irrigation water use by 30% due to a ~42–48 mm decline in soil evaporation (Bhatt et al. 2021). Crop residue retention is important in rainfed systems as it can increase water infiltration, reduce evaporation losses and soil erosion, and increase SOC (Anderson and Siddique 2015). Cultivation of wheat using NT into rice residue mulch improved tillering ability, leaf area index, soil plant analysis development for chlorophyll reading, dry matter content at middle and late growth stages, and soil available nutrients (Tang et al. 2013). Mulching has positive or neutral impacts on grain water productivity in terms of evapotranspiration and irrigation (Singh et al. 2011a). NT sowing of wheat into rice residue retained as surface mulch resulted in greater basal soil respiration, MBC, and microbial quotient of soil than conventional tillage with rice residue retained and NT with rice residue removed (Bera et al. 2018). No-mulched wheat cultivated through NT had inferior growth than mulched NT wheat, but no difference in grain yield (Gupta et al. 2016b). The adoption of NT and rice straw mulching reduced the wheat N demand by altering soil moisture and temperature, affecting soil microbial growth (Brar et al. 2010).

Soil microbes can either immobilize or mineralize N, impacting plant growth. Rice residue mulching improved soil properties and yield but enhanced energy consumption and the carbon footprint by around 10% (Lal et al. 2019). It also increased N2O emissions, with the residue quantity used for mulching directly impacting emissions. In contrast, NT reduced the energy consumption, carbon footprint, and N2O emissions by 56%, 39%, and 20% compared with conventional tillage (Lal et al. 2019). In another study, mulched treatments reduced CO2 emissions more than non-mulched treatments (Dossou-Yovo et al. 2016). The gross returns from mulch application increased in alternate wetting and drying rice and aerobic rice cultivation systems; moreover, straw mulch decreased production costs through economic water (Jabran et al. 2016). NT coupled with mulching is an environmentally friendly and suitable production technology that enhanced energy use efficiency and reduced the carbon footprint of an upland rice production system (Yadav et al. 2020). Potato cultivation under NT with paddy straw mulching reduced irrigation water use by about 200 mm, enhanced tuber quality in terms of fat, crude protein, crude fiber, and carbohydrate contents. The potato cultivation under NT costed US$1211.6 ha−1 (27% lower than the conventional) and yielded higher net returns of US$1779.2 ha−1 (Sarangi et al. 2021). This practice also improved soil quality by reducing soil salinity, conserving soil moisture, improving soil bulk density, and increasing SOC content (Sarangi et al. 2021). Fig. 5 depicts mulching in rice fields.

However, rice residue retention in fields has led to new insects, such as army worm (Mythimna separata) and pink stem borer (Sesamia inferens), in the succeeding wheat crop. The sporadic pests have emerged as major crop pests due to conservation agriculture. There has also been a significant shift in weed flora, with the emergence of new species reported in rice–wheat conservation systems in northern India, including little mallow (Malva parviflora L.), bluegrass (Poa annua L.), and pigweed (Amaranthus retroflexus L.) (Kaur et al. 2021).

5.2 Technologies for in-situ crop residue management

5.2.1 Happy Seeder

The Happy Seeder enables farmers to sow seeds of the subsequent crop into loose crop residues to avoid residue burning (Fig. 6a). Of the farmers using Happy seeder technology, 90.6% left crop residues in the field (Fig. 6b and 6c) while only 3.9% burned the same (Keil et al. 2021). The Happy Seeder reduces the cost of field preparation compared with conventional methods and produces similar mean wheat yields (Gupta 2012). Using the Happy Seeder combined with a rotavator also produced similar, and in some cases, higher wheat yields than conventional farmer practices for wheat sowing (Singh et al. 2013a, b). The Happy Seeder mainly increases wheat yields due to the residue mulching effect (Kumar et al. 2014).

The Happy Seeder technology saves considerable time when sowing wheat crops, taking 2.4 h per ha compared with 10.0 h and 11.8 h for residue incorporation using a disk harrow–rotodrill and disk harrow–seed broadcast–rotavator, respectively. The energy consumption also decreases significantly, requiring only 20.0 L fuel per ha compared with 69.8 L for disk harrow–rotodrill and 71.6 L for disk harrow–seed broadcast–rotavator (Jaidka et al. 2020). The Happy Seeder also optimizes the seeding rate, fertilizer use, and the number of irrigations applied (Kirandeep et al. 2020). Sowing wheat with the Happy Seeder saves soil nutrients valued at US$36.88 ha−1 (urea, US$5.63; DAP, US$4.86; potash, US$26.39) and has a 4.36 higher BC ratio than conventionally sown wheat. The Happy Seeder also improves soil properties over time compared with conventional sowing techniques that involve cultivating soil with plow and harrow (Dhillon 2016). Table 5 lists various studies related to the economic benefits of the Happy Seeder compared with conventional practices.

According to Keil et al. (2021), the perceived benefits of the Happy Seeder differ among those using it. Only 67.1% of farmers surveyed in Punjab agree that the Happy Seeder augments yield in the short-term (3.7% strongly disagree), whereas 50.2% strongly agree that the Happy Seeder substantially increases yield in the long-term (5.1% strongly disagree). However, more than 90% of surveyed farmers agree that the Happy Seeder saves substantial water, labor, and fuel, and around 88% agree that it reduces air pollution. These perceptions also vary according to the farmers’ wheat sowing practice (Keil et al. 2021). The adoption of Happy Seeder technology has been slow due to the varied farmer perception (Gupta 2012). Even with a price subsidy of 50%, the small window of machine operation (25 days year−1), inability to work with wet straw, low machine capacity compared with conventional seed drills, and lack of straw shredders are the major constraints for large-scale adoption (Sidhu et al. 2015). Nevertheless, the Happy Seeder is one of the most efficient technologies for rice residue management, reducing GHG emissions and consequently lowering GWP. In northwestern India, the Happy Seeder helped reduce particulate matter pollution by > 98% (1 kg ha−1 year−1), GHGs by ~ 80% (933 CO2 eq. kg ha−1 year−1), and groundwater withdrawals by ~ 20% (1412 m3 ha−1 year−1) in a rice–wheat system compared with local practices (burning + disk harrowing) (Shyamsundar et al. 2019). Therefore, adopting the Happy Seeder is an environmentally and economically suitable alternative to residue burning, reducing GHG emissions and the sowing cost of the succeeding wheat crop and maintaining or sometimes increasing wheat yields.

5.2.2 Straw management system and Super SMS

The straw management system (SMS) is an attachment for existing combine harvesters to spread straw within the harvested area, improving in-situ straw management (Fig. 7). The attachment is mounted to the rear side of the combine harvester below the straw walkers and behind the chaffer sieves. The residue from the harvester straw walker is spread with spinning disks (Sidhu and Singh 2016). The Super SMS combine harvester costs an additional US$7 ha−1 for straw spreading over manual spreading. However, manual spreading requires 8–13 MD ha−1, while the Super SMS increases the field capacity of the turbo Happy Seeder by 0.6 ha day−1. Therefore, using a Super SMS for straw spreading saves US$4 ha−1 compared with manual straw spreading (Yadvinder-Singh et al. 2020). The approximate cost of using SMS with the Happy Seeder for mulching is US$34.18 ha−1 (Manes et al. 2017). The investment expenditure for purchasing SMS and the Happy Seeder in India is US$3610 (US$1805 is subsidized), and the operational cost is US$37.2 ha−1 (Sanjay et al. 2021).

The Super SMS was developed by PAU and CIMMYT-BISA, Ludhiana. It is attached to the rear end of the self-propelled combine harvester with a 4.27 m cutter bar and engine power of 110 hp. The straw from the combine harvester is fed into the Super SMS from one side and then dispersed in chopped form from the outlet via a deflector for uniform spreading (Sidhu and Singh 2016). Using a combine harvester fitted with Super SMS saves time and energy for rice harvest and residue management. It also saves irrigation water due to the retention of residual moisture in the field. It allows easier operation of the turbo Happy Seeder, enhancing its capacity by 20–25% with less damage to the cutting flails (Somasundaram et al. 2020) and improving crop establishment and yield (Keil et al. 2021). In 2018–2019, the cost of hiring a combine harvester with Super SMS and Happy Seeder through the cooperative society in the Amritsar district of Punjab was US$59.72 ha−1 (US$49.76 combine harvester, US$9.95 Super SMS) (Sandhu et al. 2019). The operation cost of the Super SMS and Happy Seeder is US$36.15 ha−1 (Manes et al. 2017). The investment cost for a Happy Seeder mounted with Super SMS is US$3971 (Sanjay et al. 2021). Super SMS can also be used with a spatial NT drill at an operational cost of US$34.50 ha−1 (Manes et al. 2017). The investment cost of a Super SMS and spatial NT drill is US$2671.5 (Sanjay et al. 2021). The Super SMS eases Happy Seeder operation and increases its efficiency. The paddy straw is used as a mulch to help conserve moisture and improve soil nutrient status. While increased yields have been reported, the gains must be greater than the operational costs to make Super SMS economically viable for farmers.

5.2.3 Straw chopper cum spreader

A tractor-mounted straw chopper cum spreader, developed by PAU, Ludhiana, India (Singh et al. 2011b), harvests the crop, cuts and chops the straw, and spreads it evenly on the field to be used as mulch or incorporated into the soil. The machine covers 2.4–3.2 ha day−1 and needs a 50 hp tractor using 6–6.5 L h−1 fuel. There are two types of commercially available straw chopper cum spreaders. One has flail blades attached to the drum, which cut, chop, and spread the paddy straw in the field. The other comprises a cutter bar, reel, and auger for passing the cut straw to the chopper, with a secondary unit further reducing straw size. Combine harvester-type blades are fixed on the chopper unit of the combine header-type chopper (Thakur et al. 2018). An evaluation of the field performance of three commercially available paddy straw chopper cum spreaders (manufactured by Bhaike Agricultural Works, Gobind Agricultural Works, and Standard Corporation of India Limited) in farmers’ fields in Fatehabad, Haryana in Oct–Nov 2015 revealed that the Standard Corporation model produced the shortest chopped straw (0.5 cm), followed by the Gobind model (8.82 cm) and the Bhaike model (10.20 cm). The Bhaike model recovered the most straw (83.1%), followed by the Standard Corporation model (81.6%) and the Gobind model (77.3%). Operation costs were US$22.49, 26.71, and 36.82 ha−1 for the Bhaike, Gobind, and Standard Corporation models, respectively (Kumar et al. 2017). The cost of incorporating paddy straw into soil using a paddy chopper, reversible moldboard (RMB) plow, or rotavator depends on machinery ownership. If hired through a custom hiring center, the total cost is US$112.80 ha−1 (US$13.27 paddy chopper, US$49.76 RMB plow, US$49.76 rotavator). If the machinery is owned, the total cost is US$32.35 ha−1 (fuel costs of US$6.46 paddy chopper, US$17.25 RMB plow, US$8.63 rotavator) (Sandhu and Dhaliwal 2019). The investment cost for machinery (paddy straw chopper cum spreader, RMB plow, rotavator, planker, and seed drill) is US$7870 (Sanjay et al. 2021). The operation costs of these machines for residue incorporation and subsequent sowing of the next crop range from US$112.80 to 120.09 ha−1, depending on the succeeding crop. The paddy straw chopper can also be used for incorporation with wet mixing (rotavator) and NT drill, with operational costs of US$70.66 ha−1 (Manes et al. 2017). The investment cost of these machines (paddy straw chopper, rotavator, and NT drill) is US$4910. The paddy straw chopper can also be used for mulching when combined with a Happy Seeder (investment cost US$5,776) (Sanjay et al. 2021). The operation cost of the Happy Seeder and loose straw chopper cum spreader is US$49.48 ha−1 (Manes et al. 2017). Using a straw chopper cum spreader eases the operation by disbursing chopped straw for mulching or incorporating straw into the soil, improving soil health. Although environmentally profitable, studies related to yield gains using the straw chopper cum spreader are not available to conclude its economic viability in farmers’ fields.

5.3 Ex-situ crop residue management

5.3.1 Biofuel

Rice straw is an excellent material for bioethanol production due to its lignocellulosic nature. Its cellulose and hemicellulose content can be readily hydrolyzed into fermentable sugars (Binod et al. 2010). Bioethanol produced from rice straw is carbon neutral (Singh et al. 2016). Moreover, it could reduce gasoline consumption (Kunimitsu and Ueda 2012). Of four rice straw utilization systems—(i) direct combustion for electricity, (ii) biochemical conversion to bioethanol and biogas, (iii) incorporation into soil as fertilizer, and (iv) thermo-chemical conversion to bio-DME (dimethyl ether)—the bioethanol pathway is the most efficient in terms of environmental sustainability and reducing global warming (Silalertruksa and Gheewala 2013). However, the high silica and ash content of rice straw makes it an inferior option for ethanol production as silica reduces the enzymatic hydrolysis and consequently lowers ethanol yield (Binod et al. 2010). The economic value of bioethanol production from rice straw varies between countries. For example, in Vietnam, bioethanol production from rice straw has negative environmental and economic benefits using the current technology (Kunimitsu and Ueda 2012). In India, converting rice straw into bioethanol has estimated economic and environmental gains of US$664 ha−1 (Bhattacharya et al. 2021). In Japan, the economic viability of producing bioethanol from rice straw is doubtful even when environmental benefits are evident. Therefore, innovative approaches are needed (Roy et al. 2012).

Biogas generation from rice straw is an environmentally friendly alternative to residue burning. The GHG emissions from rice straw during biogas production using anaerobic digestion are much lower than residue burning, and the surplus digested sludge can be added to the soil for sustainable recycling of nutrients (Satpathy and Pradhan 2020). Biofuel generation would suit developing nations like India due to the high fuel demand. However, the efficiency and economy of biofuel generation need to be determined to ensure environmental and economic benefits.

5.3.2 Biochar

Biochar is prepared by pyrolyzing rice straw. It can be used as a soil amendment but depends on the characteristics of the raw material. The pyrolysis temperature affects the residence time, chemical composition, and biochar structure. Biochar produced at 400 °C is generally alkaline with a high cation exchange capacity, making it suitable for fertilizer and soil amendment. Biochar derived from rice straw had turbostratic crystallites at 400 °C and a high level of aromatization at 500 °C (Wu et al. 2012). Biochar can alter a soil’s physicochemical properties, microbial community, and enzymatic activities. Urease, alkaline phosphatase, and microbial activities increased in soil amended with 10 mg kg−1 biochar. However, invertase and alkaline phosphatase activities decreased in soil amended with 50 mg kg−1 biochar (Huang et al. 2017). Biochar application improves carbon sequestration, enhances crop growth, and reduces N2O and CH4 emissions. Net GWP decreased by 0.16–19-fold with biochar application; however, the low emission trade price of CO2 results in a small contribution in carbon costs to NEEB (Bi et al. 2019). Biochar application improves phosphorus availability, exchangeable cations, and cation exchange capacity in the soil, consequently improving plant height, tiller number, dry biomass weight, and yield in rice (Kamara et al. 2015).

Biochar addition to a rice production system for 8 years increased the net present value (NPV) of rice by 12% and reduced the intensity of non-renewable energy by 27% (Mohammadi et al. 2017). Adding 41.5 t ha−1 of rice husk char (dry weight basis) increased rice grain yield by 33% under irrigated conditions (Shackley et al. 2012). Biochar has a GHG mitigation potential of − 0.94 t CO2 eq. t−1 straw. An NPV of US$20.98 t−1 straw, with a baseline of crop straw returns including carbon revenue, was reported in China (Ji et al. 2018). Biochar decreased the carbon footprint of spring rice by 26% and summer rice by 14% in the first year of application when compared with open burning of rice residues in northern Vietnam. After 8 years of biochar application, these values increased to 49% in spring rice and 38% in summer rice (Mohammadi et al. 2016). The conversion of rice straw to biochar realized net benefits of US$183 ha−1 in India (Bhattacharya et al. 2021). Biochar improved soil fertility, enhanced carbon storage, reduced GHG emissions, and could be an alternative to residue burning if economically viable.

5.3.3 Baling

Fulfilling the demand for livestock products with the ever-increasing cattle population in India requires more feed and fodder from shrinking land resources. Rice straw can be used to bridge the gap between fodder demand and supply (Kumar et al. 2020). Using a straw baler and shrub master for baling in Pusa Basmati 1509 increased income by US$14.60, increasing US$37.16 when used with a hay rake. Using a hay rake for straw retrieval from the fields increases the profitability of baling and the benefit cost ratio (from 1.20 to 1.78); the breakeven point occurs at 83 h year−1 (Kumar et al. 2020). Straw management using baling and subsequent sowing of the wheat crop in India requires a stubble shaver, rake, baler, and NT drill, with an investment cost of US$22,816 (US$11,408 is subsidized) (Sanjay et al. 2021). The operation cost of baling is US$63.03 ha−1. Rice residue characteristics such as low heating value, alkali and alkaline compounds, and low bulk density can cause handling, storage, and transport issues, limiting its commercial use; baling resolves the bulk of these issues as it changes the residue characteristics (Fig. 8).

5.3.4 Electricity generation

The increasing demand for energy and gradual depletion of non-renewable energy sources requires a shift to reliable renewable energy resources. Plant biomass is a replenishable and reliable energy source (Logeswaran et al. 2020). Electricity production from combusting 1 Mg straw reduced CO2 eq., SO2 eq., and C2H6 eq. emissions by 1471, 15, and 6.7 kg, respectively, compared to burning (Soam et al. 2017). The crop residues produced in India could generate 10% of the country’s total energy production (120 Terawatt-hours) from biomass power plants (Ravindra et al. 2019a). In Thailand, 5, 8, 10, 15, and 20 MW rice-straw-fueled combustion facilities generate NPVs of approximately US$ − 3.15, 0.94, 2.96, 9.33, and 18.79 million (Delivand et al., 2011). In Malaysia, a life cycle analysis indicated that the rice straw supply chain (rice straw collection, transportation to collection center, collection center costs, and transportation to power plant) emits 0.0234 t CO2 eq. ± 0.11% bale−1, with total logistic costs ranging from US$ 9.06 to 14.93 bale−1 (Shafie et al. 2014). An integrated rice production and power generation system comprising several steps, including superheated steam drying, husking, polishing, torrefaction, steam gasification, and power generation, minimizes energy losses as the recovery combines heat circulation and process integration. Processing 200 t rice grain day−1 could generate 3.4 MW of electricity, with a production efficiency of 32% (Darmawan et al. 2018). In Ghana, rice husk gasification can fulfill the energy requirement of around 7% for un-electrified communities (Ramamurthi et al. 2016). Electricity generation from rice straw could be suitable in India if economically efficient technologies are developed. Table 6 summarizes the economics of various ex-situ management techniques.

Various management options for rice residue and subsequent wheat sowing in in-situ and ex-situ are shown in Fig. 9.

6 Governmental interventions to prevent crop residue burning

The Ministry of Agriculture and Farmers Welfare (MoA&FW), Government of India (GoI), launched the National Policy for Management of Crop Residues in 2014 to combat air pollution. The policy focuses on technology promotion for in-situ crop residue management. The National Green Tribunal of GoI banned crop residue burning on 4 November 2015, with fines imposed on farmers if found guilty. However, farmers, especially small landholders, cannot afford expensive agricultural implements or labor due to their poor financial position. As a result, these punitive measures failed to reduce the fire counts significantly. The farmers continued this practice, so a committee on the behest of the National Institution for Transforming India (NITI) recommended a machinery-based solution (Vishnoi et al. 2017). In 2018, the Cabinet Committee for Economic Affairs, GoI, approved US$0.15 billion for the Promotion of Agricultural Mechanization for In-Situ Management of Crop Residues in Punjab, Haryana, Uttar Pradesh, and National Capital Territory of Delhi (MoA&FW 2019) to check air pollution. Financial assistance of up to 50% has been offered to individual farmers and 80% to farmer groups to purchase machinery for crop residue management. Coverage of the Sub-Mission on Agricultural Mechanization, already operational in all states, has been extended to include crop residue management machinery, such as SMS for combine harvester, Happy Seeder, hydraulic RMB plow, paddy straw chopper/shredder, mulcher, shrub master, rotary slasher, NT seed drill, rotavator, super seeder, crop reaper/reaper binder, straw baler, and rakes.

However, the existing machinery for in-situ management can only manage 2–4 t ha−1 of crop residues. Therefore, ex-situ management of crop residues is crucial. The Punjab government announced a New and Renewable Sources of Energy Policy in 2012 to promote renewable energy in the state, setting a capacity target of 600 MW from biomass and 500 MW from cogeneration by 2022. Haryana state formulated the Haryana Bioenergy Policy 2018 to use surplus crop residue to generate bio-CNG, bio-manure, and biofuel (Datta et al. 2020). The Central Electricity Authority (CEA), GoI, issued a policy advisory to generate power from biomass by co-firing pulverized coal-fired boilers (CEA 2017). The Ministry of New and Renewable Energy, GoI, launched a program to produce biogas-bio-CNG and enriched biogas/power energy from agricultural residues. The Ministry of Petroleum and Natural Gas released a national biofuel policy on 8 June 2018, promoting the blending of 20% biomass-derived ethanol in gasoline by 2030 (Datta et al. 2020). In 2019, the Punjab government signed a memorandum of understanding (MoU) with CSIR-NEERI (Council of Scientific and Industrial Research-National Environment Engineering and Research Institution) to provide technical support on residue management (UNS 2019). In October 2019, the NGT suggested offering incentives to farmers who do not burn rice straw and disincentives (withholding subsidy benefits) to those who burn rice straw. The NGT also directed the state governments to ensure the timely supply of CRM machines to farmers for incorporating crop residues. Accordingly, the Central Government launched a scheme on ‘Promotion of Agriculture Mechanization for In-Situ Management of Crop Residue,’ assisting in establishing farm machinery banks for custom hiring of machinery and financial assistance (50% of the cost) to individual farmers for procuring agricultural machinery and equipment for in-situ crop residue management. An amount of US$0.15 billion (US$0.08 billion in 2018-19 and US$0.07 billion in 2019–2020) was provided for this Central Sector Scheme implemented by the Ministry of Agriculture & Farmers Welfare, Govt of India (CCEA 2018). The Punjab government also distributed US$2.5 million among non-basmati-cultivating small and marginal farmers (US$78.20 ha−1) who did not burn paddy residue in 2019–2020 (PTI 2019). The Confederation of Indian Industry (CII) adopted 100 villages in Punjab and Haryana in 2019 to convince farmers to stop burning residues (Pandey et al. 2020). The Punjab State Farmers and Farm Workers Commission set up a paddy straw challenge fund to provide US$1 million for appropriate technology that ensures in-situ paddy straw decomposition or degradation (Sethi 2018).

7 Conclusions

Rice–wheat cropping systems have led to several concerns in northwestern India, including groundwater depletion, global warming, deteriorating soil health, air pollution, shifting weed flora, pest infestations, and stubble burning. Farmers generally resort to residue burning of mechanically harvested rice due to its poor economic value, given the lack of alternative uses and the short time gap between rice harvest and wheat sowing. Stubble burning increases air pollution, deteriorates soil health, and causes serious health concerns such as respiratory infections and cardiac diseases, evidenced by the increased particulate matter and GHGs during October and November each year in northwestern India. With concerted efforts and evolving new technologies to manage crop residues, burning incidences in northwestern India have declined since 2016, but a significant proportion of paddy residue is still burned. Technological initiatives have been promoted to mulch or incorporate residues into soil to improve soil fertility, increase nutrient availability, retain soil moisture, and reduce weed density. These technologies are environmentally friendly and benefit farmers by increasing crop yields and profitability while reducing the negative environmental implications of residue burning. In addition, ex-situ management of rice residues, such as biochar, electricity, biofuel, and bales, is promoted among farmers. Some technologies designed for ex-situ management need further refinements but offer positive economic and environmental benefits. There are three aspects to decreasing residue burning in the future: avoidance, awareness, and adoption. Farmers can avoid rice cultivation and opt for a more diversified cropping system. However, this is unlikely due to the economic uncertainty and lack of regulated markets for other crops. Thus, rice varieties with a high harvest index are needed, with their adoption promoted among farmers through extension. Technological interventions with economic benefits must be devised and extended to farmers to raise awareness, demonstrate their operational feasibility, and change their conventional outlook. Residue bio-decomposition is another possible option, but insufficient literature is available to draw conclusions.

Data availability

Not applicable.

References

Abdurrahman MI, Chaki S, Saini G (2020) Stubble burning: Effect on health & environment, regulations and management practices. Environ Adv 2:100011. https://doi.org/10.1016/j.envadv.2020.100011

Adam MG, Tran PTM, Bolan N, Balasubramanian R (2021) Biomass burning-derived airborne particulate matter in Southeast Asia: a critical review. J Hazard Mater 407. https://doi.org/10.1016/j.jhazmat.2020.124760

Ademe YA (2015) Long-term impacts of cultivation and residue burning practices on soil carbon and nitrogen contents in Cambisols of southwestern Ethiopia. Am J Agri Forestry 3(3):65–72. https://doi.org/10.11648/j.ajaf.20150303.11

Agarwal R, Awasthi A, Mittal S, Singh N, Gupta PK (2009) Effects of air pollution on respiratory parameters during the wheat-residue burning in Patiala. J Med Eng Technol 34(1):23–28. https://doi.org/10.3109/03091900903261258

Agriculture Statistics (2020) Ministry of Agriculture and Farmers Welfare, GoI.

Anderson W, Johansen C, Siddique KHM (2016) Addressing the yield gap in rainfed crops: a review. Agron Sustain Dev 36:18. https://doi.org/10.1007/s13593-015-0341-y

Anderson WK, Siddique KHM (2015) The role and value of crop residues in dryland agriculture. Indian J. Agron 60(3):332–340

Andini A, Bonnet S, Rousset P, Hasanudin U (2018) Impact of open burning of crop residues on air pollution and climate change in Indonesia. Curr Sci 115(12):2259–2266. https://doi.org/10.18520/cs/v115/i12/2259-2266

Anuradha, Kadian KS, Meena MS (2021a) Reasons and awareness levels of farmers on residue burning in Indo-Gangetic plain of India: an exploratory research. J. AgriSearch 8(1):62–66. https://doi.org/10.21921/jas.v8i01.19567

Anuradha, Kadian KS, Meena MS, Meena HR, Prashanth CS (2021b) Farmers’ perspective to mitigate crop residue burning in Haryana state of India. Indian Res J Ext Educ 21(2&3):154–160

Awasthi A, Singh N, Mittal S, Gupta PK, Agarwal R (2010) Effects of agriculture crop residue burning on children and young on PFTs in North West India. Sci Total Environ. 408(20):4440–4445. https://doi.org/10.1016/j.scitotenv.2010.06.040

Badarinath KVS, Kharol SK, Sharma AR (2009) Long-range transport of aerosols from agriculture crop residue burning in Indo-Gangetic plains—a study using LIDAR, ground measurements and satellite data. J Atmos Sol-Terr Phys 71(1):112–120. https://doi.org/10.1016/j.jastp.2008.09.035

Balachandran S, Meena BR, Khillare PS (2000) Particle size distribution and its elemental composition in the ambient air of Delhi. Environ Int 26:49–54. https://doi.org/10.1016/S0160-4120(00)00077-5

Batra C (2017) Stubble burning in North-West India and its impact on health. J Chem En Sci A 4(1):13–18. https://doi.org/10.15415/jce.2017.41002

Bera T, Sharma S, Thind HS, Singh Y, Sidhu HS, Jat ML (2018) Changes in soil biochemical indicators at different wheat growth stages under conservation-based sustainable intensification of rice-wheat system. J Integr Agric 17(8):1871–1880. https://doi.org/10.1016/S2095-3119(17)61835-5

Bhatt R, Arora S, Busari MA (2017) Zero tillage for sustaining land and water productivity in northern India. J Soil Water Conserv 16(3):228–233. https://doi.org/10.5958/2455-7145.2017.00031.5

Bhatt R, Singh P, Hossain A, Timsina J (2021) Rice-wheat system in the northwest Indo-Gangetic plains of South Asia: issues and technological interventions for increasing productivity and sustainability. Paddy Water Environ 19:345–365. https://doi.org/10.1007/s10333-021-00846-7

Bhattacharya P, Bisen J, Bhaduri D, Priyadarsini S, Munda S, Chakraborti M, Adak T, Panneerselva P, Mukherjee AK, Swain SL, Dash PK, Padhy SR, Nayak AK, Pathak H, Kumar S, Nimbrayan P (2021) Turn the wheel from waste to wealth: economic and environmental gain of sustainable rice straw management practices over field burning in reference to India. Sci Total Environ 775:145896. https://doi.org/10.1016/j.scitotenv.2021.145896

Bhuvaneshwari S, Hettiarachchi H, Meegoda JN (2019) Crop residue burning in India: Policy challenges and potential solutions. Int J Environ Res Public Health 16(5):832. https://doi.org/10.3390/2Fijerph16050832

Bi Y, Cai S, Wang Y, Xia Y, Zhao X, Wang S, Xing G (2019) Assessing the viability of soil successive straw biochar amendment based on a five-year column trial with six different soils: views from crop production, carbon sequestration and net ecosystem economic benefits. J Environ Manage 245:173–186. https://doi.org/10.1016/j.jenvman.2019.03.051

Biederbeck VO, Campbell CA, Bowren KE, Schnitzer M, Mclver RN (1980) Effect of burning cereal straw on soil properties and grain yields in Saskatchewan. Soil Sci Soc Am J 44(1):103–111. https://doi.org/10.2136/sssaj1980.03615995004400010022x

Bimbraw AS (2019) Generation and impact of crop residue and its management. Curr Agric Res J 7(3):304–309. https://doi.org/10.12944/CARJ.7.3.05

Binod P, Sindhu R, Singhania RR, Vikram S, Devi L, Nagalakshmi S, Kurien N, Sukumaran RK, Pandey A (2010) Bioethanol production from rice straw: an overview. Bioresour Technol 101(13):4767–4774. https://doi.org/10.1016/j.biortech.2009.10.079

Brar NK, Condon J, Evans J, Singh Y (2010) Nitrogen management in wheat sown in rice straw as mulch in north west India. 19th World Congress of Soil Science, Soil Solutions for a Changing world. 1-6 Aug, 2010. Australia.

Bretag TW (1985) Control of ergot by a selective herbicide and stubble burning. Trans Br Mycol Soc 85(2):341–343

Burgess LW, Backhouse D, Summerell BA, Pattison AB, Klein TA, Esdaile RJ, Ticehurst G (1993) Long-term effects of stubble management on the incidence of wheat by Fusarium graminearum Schw. Group 1. Aust J Exp Agric 33(4):451–456 http://livestocklibrary.com.au/handle/1234/20797

Burgess LW, Backhouse D, Swan LJ, Esdaile RJ (1996) Control of Fusarium crown rot of wheat by late stubble burning and rotation with sorghum. Australas Plant Pathol 25:229–233. https://doi.org/10.1071/AP96042

Cassou E, Jaffee SM, Ru J (2018) The challenge of agricultural pollution: evidence from China, Vietnam, and the Philippines. World Bank Publications. http://hdl.handle.net/10986/29187

CCEA (2018) Cabinet Committee on Economic Affairs. Cabinet approves promotion of agricultural Mechanization for in-situ management of crop residue in the states of Punjab, Haryana, Uttar Pradesh and NCT of Delhi Available on: https://pib.gov.in/PressReleseDetail.aspx?PRID=1523143

CEA. 2017. No. CEA/TETD-TT/2017/M-25/1137-1251 dated 24/11/2017. Office of the Secretary, Central Electricity Authority, Ministry of Power, Government of India. Details available at http:// www.cea.nic.in/reports/others/thermal/tetd/ Biomass%20Utilization%20Advisory.pdf. Last accessed on November 12 2020.

Chaba AA. 2020. Explained: Why organic matter on soil is crucial for a state like Punjab. The Indian Express. August 14, 2020. Available on https://indianexpress.com/article/explained/why-organic-matter-in-soil-is-crucial-for-a-state-like-punjab-6553513/

Chakrabarti S, Khan MT, Kishore A, Roy D, Scott SP (2019) Risk of acute respiratory infection from crop burning in India: estimating disease burden and economic welfare from satellite and national health survey data for 250000 persons. Int J Epidemiol 48(4):1113–1124. https://doi.org/10.1093/ije/dyz022

Chandra BP, Sinha V (2016) Contribution of post-harvest agricultural paddy residue fires in the N.W. Indo-Gangetic plain to ambient carcinogenic benzenoids, toxic isocyanic acid and carbon monoxide. Environ Int 88:187–197. https://doi.org/10.1016/j.envint.2015.12.025

Chatterji A (2020) Air pollution in Delhi: Filling the policy gaps. ORF occasional paper no. 291. Observer Research Foundation.

Chen J, Gong Y, Wang S, Guan B, Balkovic J, Kraxner F (2019) To burn or retain crop residues on croplands? An integrated analysis of crop residue management in China. Sci Total Environ 662:141–150. https://doi.org/10.1016/j.scitotenv.2019.01.150

Chowdhury S, Farrell M, Butler G, Bolan N (2015) Assessing the effect of crop residue removal on soil organic carbon storage and microbial activity in a no-till cropping system. Soil Use Manag 31(4):450–460. https://doi.org/10.1111/sum.12215

Collins HP, Rasmussen PE, Douglas CL Jr (1992) Crop rotation and residue management effects on soil carbon and microbial dynamics. Soil Sci Soc Am J 56:783–788. https://doi.org/10.2136/sssaj1992.03615995005600030018x

CREAMS-IARI. 2021. Consortium for research on agroecosystem monitoring and modelling from Space Lab. Division of Agricultural Physics. ICAR-IARI, New Delhi. http://creams.iari.res.in/cms2/index.php/bulletin-2021

Darmawan A, Fitrianto AC, Aziz M, Tokimastu K (2018) Integrated system of rice production and electricity generation. Appl Energy 220:672–680. https://doi.org/10.1016/j.apenergy.2018.03.098

Datta A, Emmanuel MA, Ram NK, Dhingra S (2020) Crop residue management: solution to achieve better air quality. Discussion paper. TERI, New Delhi