Abstract

The use of plastic mulch in agriculture has increased dramatically in the last 10 years throughout the world. This increase is due to benefits such as increase in soil temperature, reduced weed pressure, moisture conservation, reduction of certain insect pests, higher crop yields, and more efficient use of soil nutrients. However, disposing of used plastic films, which cause pollution, has led to development of photodegradable and biodegradable mulches. Here we review the use of plastic mulches in agriculture, with special reference to biodegradable mulches. Major topics discussed are (1) history of plastic mulch and impact on crop yield and pest management, (2) limitations of polyethylene mulches and potential alternatives, (3) biodegradable and photodegradable plastic mulches, (4) field performance of biodegradable mulches, and (5) use of biodegradable plastic mulches in organic production. We found that (1) despite multiple benefits, removal and disposal of conventional polyethylene mulches remains a major agronomic, economic, and environmental constraint; (2) early use of photodegradable plastic mulch during the 1970s and 1980s, wrongly named biodegradable mulch films, discouraged adoption of new biodegradable mulch films because they were too expensive and their breakdown was unpredictable; (3) biodegradable plastic films are converted through microbial activity in the soil to carbon dioxide, water, and natural substances; (4) polymers such as poly(lactic acid), poly(butylene adipate-coterephthalate), poly(ε-caprolactone), and starch-based polymer blends or copolymers can degrade when exposed to bioactive environments such as soil and compost; (5) with truly biodegradable materials obtained from petroleum and natural resources, opportunity for using biodegradable polymers as agricultural mulch films has become more viable; and (6) the source of polymer and additives may limit use of some biodegradable mulches in organic production. More knowledge is needed on the effect of biodegradable mulches on crop growth, microclimate modifications, soil biota, soil fertility, and yields.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Contents

1. Introduction …..........…………………………………..2

2. History of plastic mulch .................................................3

2.1. General uses of plastic mulches ...............................6

2.2. Plastic mulch and yield quality ................................8

2.3. Plastic mulch and pest management .......................8

3. Limitations of polyethylene plastic mulch and alternatives .........................................................9

3.1. Limitations of polyethylene plastic mulch .............9

3.2. Alternatives to polyethylene plastic mulch ...........13

4.1. Photodegradable plastic mulch .............................15

4.2. Biodegradable plastic mulch .................................16

4.3. Biodegradation process .........................................23

5. Field performance of biodegradable mulch in crop production ................................................................28

7. Conclusion ....................................................................34

8. Acknowledgement ........................................................34

1 Introduction

Benefits of mulching on growth and yield of annual and perennial crops have long been recognized (Magistad et al. 1935; Shonbeck and Evanylo 1998; Weber 2003). Mulching with organic or inorganic materials aims to cover soils and forms a physical barrier to limit soil water evaporation, control weeds, maintain a good soil structure, and protect crops from soil contamination. Natural mulches are those derived from animal and plant materials. If properly used, they can offer all the benefits of other types of mulches. Natural mulches help in maintaining soil organic matter and tilth (Tindall et al. 1991) and provide food and shelter for earthworms and other desirable soil biota (Doran 1980). However, natural materials are not often available in adequate amounts, their quality is inconsistent, and they require more labor for spreading. Natural mulches do not always provide adequate weed control; they may carry weed seeds and often retard soil warming in spring, a condition that can delay growth and ripening in warm season vegetables (Hill et al. 1982; Schultz 1983). Straw mulches often contaminate the soil with weed seeds and deplete the seedbed nitrogen due to their high carbon-to-nitrogen (C/N) ratio. Organic materials that have a high C/N ratio such as grain straw may temporarily immobilize soil nitrogen as they decompose (Mooers et al. 1948), although humified organic matter accumulated from long-term straw mulching sometimes results in net mineralization of N (Ferguson 1957). Natural mulch harbors pests such as termites, slugs, snails, earwigs, etc. Natural mulches are reported to reduce soil temperature and evaporation, but do not invariably cause higher yields (Kwon 1988; Subrahmaniyan and Zhou 2008). Therefore, natural mulches could not be used efficiently in crop production during all the seasons. To overcome some of the problems outlined above, paper and plastic mulches have been developed for use in agriculture.

Paper mulches attracted a good deal of attention in the early 1920s. They were not adapted for commercial vegetable production because of their short life, as well as the cost of material and labor, which was not mechanized (Hopen and Oebker 1976). Thus, the trend has been toward using synthetic mulches such as films made of formulations of paper, which includes combinations of paper and polyethylene, foils and waxes. Petroleum and resin mulches were also developed for arid climates at the same time. Synthetic mulches including thin sheets of plastic, paper, and petroleum materials present increased benefits over natural mulches. Of these mulches, only those made of polyethylene are still widely used today in the agricultural industry (Fig. 1). Plastic film used as mulch has revolutionized the age-old technique of mulching. Waggoner et al. (1960) described microclimatic changes caused by various mulches (polyethylene film, straw, paper, and aluminum films) and concluded that polyethylene film mulch was the most effective method of mulching.

2 History of plastic mulch

Plastics are man-made long-chain polymeric molecules (Scott 1999). The word plastic comes from the Greek word “plastikos,” which means “able to be molded into different shapes” (Joel 1995). The plastics we use today are made from inorganic and organic raw materials, such as carbon, silicon, hydrogen, nitrogen, oxygen, and chloride. The basic materials used for making plastics are extracted from oil, coal, and natural gas (Seymour 1989). According to the American Society for Plasticulture, plasticulture is “the use of plastic in agriculture,” which includes but is not limited to plastic mulch films, drip irrigation tape, row covers, low tunnels, high tunnels, silage bags, hay bale wraps, and plastic trays and pots used in transplant and bedding plant production (Lamont and Orzolek 2004). Plasticulture is the technology of the use of plastics in the agricultural sector. Tar-coated paper mulches began to be used in the late 1800s, long before polyethylene was available (Rivise 1929). The science of plasticulture had its beginning as early as 1924 when Warp (1971) developed the first glass substitute for widespread agricultural use. British scientists first made polyethylene as a sheet film in 1938 (Masey 1972). The earliest method using organic and inorganic materials to modify the microclimate of crops was mulching (Jaworski et al. 1974). These materials soon gave way to various types of polyethylene films, which revolutionized protected cropping as demonstrated by Emmert (1957) in Kentucky and Hall and Besemer (1972) in California. The history of plasticulture dates back to 1948 when polyethylene was first used as a greenhouse film by professor Emmert at the University of Kentucky in order to replace more expensive glass (Anderson and Emmert 1994; Jensen 2004). Emmert is considered by many to be the father of agricultural plastic development in the USA. He detailed the principles of plastic technology with his research on greenhouses, mulches, and row covers (Emmert 1957). Glasshouses in Northern Europe that were used for vegetable production prior to the 1950s underwent a shift to production of high value ornamental crops such as flowers and potted plants (Wittwer and Castilla 1995). During this time period, Emmert began research growing crops in plastic covered structures with the use of mulch and row covers at the University of Kentucky (Emmert 1954, 1955, 1956, 1957). These developments during the early 1950s gave rise to a new system of vegetable production known worldwide as plasticulture. The largest volumes of agricultural plastics used today are in the form of plastic films.

Plastics were first introduced on a commercial scale in 1939 (Byrdson 1970). These include polyethylene, polyvinyl chloride, and ethylene vinylacetate. Polyethylene plastic is made from polyethylene resin, which is in the form of pellets. The pellets are heated and processed into bendable sheets of plastic film. The widespread use of polyethylene (the principal type of plastic used today) is due to easy processibility, excellent chemical resistance, high durability, flexibility, and freedom from odor and toxicity (Clarke 1987; Garnaud 1974). The most commonly used mulch films include low-density polyethylene, linear low-density polyethylene, and high-density polyethylene (Fleck-Arnold 2000). Linear low-density polyethylene resins have high puncture resistance and mechanical stretch properties. High-density polyethylene resins have reliable moisture and vapor barriers. An ideal plastic mulch film should be flexible and rigid enough for easy removal from various growing environments. The main polyethylene used in mulches is low-density polyethylene. Typical plastic mulch used in the USA is 0.6 to 2.0 mils (0.0152 to 0.0508 mm) thick in rolls 610 to 1,463 m long and a width of 122 to 152 cm (Lamont 2005; Ngouajio et al. 2007).

Plastic mulch films were first used in the late 1950s in university research and have been used commercially for vegetable production since the early 1960s (Hussain and Hamid 2003; Lamont 2004a, b). Plastic mulch is now used worldwide to protect crops from unfavorable growing conditions such as severe weather, insects, and birds. Utilization of plastics in agriculture started in the developed countries and is now spreading to the developing countries. Early utilization of plastic was in cold regions, and plastic was mainly used for protection from the cold. Now plastic is used in all kind of climates, soils, and seasons for its numerous benefits in addition to enhanced soil temperatures. The use of covering techniques started with a simple system such as mulching, and then row covers and small tunnels were developed and finally plastic houses.

Up to 2008, the only comprehensive published data differentiating the use of agricultural plastics in the USA into categories was done by Amidon Recycling for the American Plastic Council (Amidon 1994). This study reported the 11 most commonly used plastics in different application, and approximately 66.5% of agricultural plastics are used for nursery containers, 28.8% for various types of plastic films, and 4.7% for pesticide containers. The estimated consumption of agricultural plastics in the USA has increased steadily from 519 million lb in 1994 to 850 million lb in 1998 and to 1,000 million lb in 2001 (Lawrence 2007). Hussain and Hamid (2003) reported that global plastic consumption in agriculture and related areas accounted for 2.48 million tons (1 ton = 2,000 lb) of plastics annually. In Western Europe, plastic films are the major type of plastic used in plasticulture. In 1997, out of 700,000 tons of total plastics used in agriculture in Western Europe, 500,000 tons or 71% were plastic films, of which greenhouse films accounted for 50%, and mulch and silage films were approximately 25% each (Hussain and Hamid 2003). Low-density polyethylene was the most commonly used plastic. Western Europe used 570,000 tons of low-density polyethylene per annum, of which 350,000 tons were used in the form of film and tubing (Hussain and Hamid 2003).

Plastic mulch has made a tremendous increase in peanut (Arachis hypogaea) production, which is called as white revolution in China (Hu et al. 1995). Likewise the use of plastic mulch in field crops such as corn (Zea mays L.), cotton (Gossypium hirsutum L.), sugarcane (Saccharum officinarum), and rice (Oryza sativa) has been successful in many countries. Plastic mulch is reported to be useful to overcome abiotic stresses in many crops in China. Film mulching with varying specifications is currently used in northern China, covering about 7 million ha of field crops. Plastic film mulching has been used in cultivating peanut, corn, cotton, vegetable, and fruit crops (Hu et al. 1995; Luo 1992; Han and Wan 1995). Commercially, plastic mulches have been used for the production of vegetables since the 1960s (Lamont 2005). Today, production of fresh market vegetables on raised beds covered with plastic mulch and drip irrigated has become a standard for most growers worldwide. The world consumption of low-density polyethylene mulching films in horticulture is at present around 700,000 tons/year (Espi et al. 2006). In 1999, for example, over 30 million acres of agricultural land (over 185,000 acres in the USA) were covered with plastic mulch, and the figure has increased significantly since (Miles et al. 2005). It is estimated that 1 million tons of mulch film is used worldwide every year in agriculture (Halley et al. 2001). In the USA alone, 130,000 tons of mulch film was used in 2004 (Warnick et al. 2006). Fresh market vegetables that are grown mainly on plastic mulch include bell pepper (Capsicum annuum), muskmelon (Cucumis melo), eggplant (Solanum melongena), slicing cucumber (Cucumis sativus), summer squash (Cucurbita pepo), tomato (Solanum lycopersicum), and watermelon (Citrullus lanatus) (Ngouajio et al. 2008).

2.1 General uses of plastic mulches

Plastic mulch was first noted for its ability to increase soil temperature in the 1950s (Emmert 1957). Plastic mulches alter the crop microclimate by changing the soil energy balance (Liakatas et al. 1986; Tarara 2000). Modification of the crop microclimate results in changes in soil temperature that may affect plant growth and yield (Cooper 1973; Dıaz-Perez and Batal 2002; Ibarra-Jimenez et al. 2006; Lamont 2005). Heating properties of plastic such as reflectivity, absorptivity, and transmittance and their interaction with solar radiation have a direct effect on the soil temperature under the plastic mulch (Schales and Sheldrake 1963). The use of clear plastic mulch in cold areas or seasons increases soil temperature and promotes germination and emergence of many crops (Peterson and Robbins 1970). Soil temperature can be altered in regions of substantially high or low temperatures to encourage faster plant development. Different types and colors of plastic mulch have characteristic optical properties that change the levels of light radiation reaching the soil, causing increases or decreases in the soil temperature. Black and clear mulches have shown the greatest soil warming potential among the various mulch colors (Ham et al. 1993). Plant growth requires radiation as a source of energy for photosynthesis, the means by which the radiation from the sun is converted to chemical energy (Rajapakse and Kelly 1994). Higher soil temperatures increase nutrient availability, enhance nutrient uptake by roots, increase the number and activity of soil microorganisms, and speed up plant germination and growth (Tindall et al. 1991; Farias-Larios et al. 1998). Munguia et al. (1998) found that net radiation is higher in the plastic mulch than in non-plastic mulch environment. This is important because it relates the spectral properties of the plastic mulch to surrounding environment. The physical characteristics of plastic mulches were shown to directly influence soil and root temperatures (Ruiz et al. 2002). Rangarajan and Ingall (2001) found that air temperatures were also significantly higher for mulch treatments compared to bare soil. Kwabiah (2004) reported maximum air temperatures up to 20°F (11°C) higher under plastic mulch than on bare soil plots. Mulching avoids the fluctuations in temperature in the first 20–30-cm depth in soils. This favors root development, and the soil temperature in the planting bed is raised, promoting faster crop development and earlier harvest. When the crop canopy covers the surface of the mulch bed, soil temperatures among different mulch colors are approximately equal (Lamont 2004a, b). Clear mulches that increase soil temperatures are particularly beneficial in situations where warm season vegetable crops are being grown in locations with a short and cool growing season (Waterer 2010). The majority of reports on plastic mulches show that increased root-zone temperature is one of the main benefits associated with the use of plastic mulches. Additional studies also show that, depending on the crop species, geographical region, or time of the year, plastic mulches create high zone-temperature conditions that may be deleterious to growth and yield of vegetables (Dıaz-Perez and Batal 2002; Ibarra-Jimenez et al. 2008; Lamont 2005).

Plastic mulches directly affect the microclimate around the plant by modifying the radiation budget of the surface and decreasing the soil water loss (Liakatas et al. 1986). The plastic film is a barrier preventing soil water evaporation and funneling excess rainfall away from the root zone thus keeping the moisture regime in the root zone at more stable levels. This can reduce irrigation demands and help prevent water- or nutrient-related physiological disorder, such as blossom end rot (McCraw and Motes 1991). Evaporation can be significantly reduced depending on the type of mulch (Chakraborty and Sadhu 1994). The water economy achieved by plastic mulching is substantial; all reserves are available for the plants, and consequently, the nutrient supply is also more constant (Lippert et al. 1964). Plastic film mulch promotes early yields and reduces N leaching (Bhella 1988).

Plastic mulch protects the soil from water and wind erosion and hail damage (Garnaud 1974). The dominant advantage of using polyethylene mulch is its ability to aid in the retention of nutrients within the root zone, thereby permitting more efficient nutrient utilization by the crop (Cannington et al. 1975). Constant moisture content, higher temperature, and better aeration of the soil all tend to favor higher microbial biomass in the soil thus ensuring more complete nitrification (Hankin et al. 1982). Plastic mulching has been reported to change the composition of microbial communities (Chen et al. 1998) and increase microbial biomass C in semi-arid soil under wheat (Li et al. 2004). Zhang et al. (2002) reported that plastic mulching management reduced microbial biomass C and N during corn growth stage. Plastic film mulching can increase soil temperature (Liu et al. 2003; Peng et al. 1999), and higher temperatures can favor not only N mineralization (Wilson and Jefferies 1996) but also plant N uptake (Liu et al. 2003).

The benefits of polyethylene mulch to crop production are well documented and include greater root growth and nutrient uptake (Wein et al. 1993), earlier ripening and a higher yield of fruit (Abdul-Baki et al. 1992), and improved fruit quality and a lower incidence of viral diseases (Singh 1992) than plants grown without mulch. A controversial benefit, challenged by some researchers, is the improvement of plant development, yields, and fruit ripening due to the reflective properties of particular plastics (Decoteau et al. 1988; Lee et al. 1996). Changes in light availability and spectral distribution can activate photosynthetic and photo-morphogenetic mechanisms to alter plant growth and development, improving marketable fruit quality and yields (Ballare et al. 1995).

2.2 Plastic mulch and yield quality

Over the last several decades, vegetable production has shown significant yield increases in many areas of the world. The utilization of plastic mulch in combination with drip irrigation has played a major role in the increases in production of tomato, pepper, eggplant, watermelon, muskmelon, cucumber, and squash, among other vegetables. There are, however, few reports on utilization of plastic mulches in broccoli [Brassica oleracea (Plenck) var. italic)] (Brown et al. 1987; Csizinszky and Martin 1988; White 1988).

Coventry et al. (2003) found that reflective mulch increased soluble solids content, total phenolics (aromatic compounds which serve as anti-microbial protection), flavanols, and anthocyanins (water-soluble pigments related to flavonoids properties) content in Ontario wine grapes. Reflective mulch was also found to increase soluble solids in plums (Kim et al. 2008). Kasperbauer and Loughrin (2004) showed that altering the color of plastic mulch could alter anthocyanins content in butterbean. Strawberries that ripened over red plastic mulch were significantly higher in aroma and flavor compounds (Loughrin and Kasperbauer 2002). Antonious and Kasperbauer (2002) found that the use of yellow and black mulches resulted in higher concentrations of phenolics in carrot. Also, the use of yellow and white mulches resulted in higher β-carotene (organic compounds with orange pigments in plants) and ascorbic acid (water soluble sugar acid with antioxidant properties) content in carrots when compared to other colored mulches and bare soil treatments.

2.3 Plastic mulch and pest management

Plastic mulches provide a range of weed control levels, depending on the amount of light transmission through the mulch (Decoteau et al. 1988). Plastic mulch reduced weed emergence by 64% to 98% during the growing season (Egley 1983). Black mulches are more effective for weed control, but typically provide less soil warming than clear mulch (Ashworth and Harrison 1983). Schales (1989) found that non-mulched plots required 225–270 more man days for hand weeding a hectare than plots using plastic mulch. Wavelength selective or infra-red transmitting mulches combine the soil warming of the clear mulch with the weed control of the black mulch, but at a cost premium (Lamont 2005).

Reflected energy not only affects plant growth and development but reportedly influences the behavior of insects surrounding the plants (Csizinszky et al. 1995; Decoteau et al. 1989; Schalk et al. 1989). Mulches may also protect the crop from insect pests or diseases (Summers and Stapleton 2002; Ngouajio et al. 2008). Reflective plastic mulch can be used to manage silver leaf whitefly populations equal to that provided by treatment with imidacloprid (Summers and Stapleton 2002). Since many insects use visual cues to find host plants, interference with these cues can cause increased attraction or repulsion to the plastic mulched fields and, thus, crops contained within those fields (Csizinszky et al. 1995). Greater numbers of western flower thrips (Franklinielh occidentalis) are attracted to low UV reflective white, blue, and yellow colors (Matteson et al. 1992). Lower thrips counts were reported on red, green, black, and highly UV reflective substrates (Matteson et al. 1992). Aphids also demonstrate attraction to certain colors, like yellow, green, and bare soil, and repulsion to other colors, such as silver (Webb et al. 1994; Brown et al. 1993; Barro 1991). In recent years, there has been increased attention to the use of colored plastic mulches in preventing or delaying the onset of various insect-vectored diseases. The use of reflective mulch greatly reduced the number of aphid vectors and delayed the spread of bean yellow mosaic virus and cucumber mosaic virus (Jones 1991).

3 Limitations of polyethylene plastic mulch and alternatives

3.1 Limitations of polyethylene plastic mulch

Most mulch films are currently produced from petroleum-based plastics, usually polyethylene, and cause a considerable waste disposal problem (Halley et al. 2001). Perhaps a major limitation to commercial uses of plastic mulches is the disposal of the plastic film after use, which causes an environmental pollution problem. The dramatic increase in production and lack of biodegradability of commercial polymers, particularly commodity plastics used in agriculture and packaging industry, focused public attention on a potentially huge environmental accumulation and pollution problem that could persist for centuries (Albertsson et al. 1987). Removal of the plastic is time-consuming (about 16 h/ha) and despite the use of machines still requires hand labor (McCraw and Motes 1991). The residual film if left in the field may interfere with root development of the subsequent crop. Plastic requires pickup and disposal at the end of the season and its manufacture and disposal entail significant environmental costs (Schonbeck 1995). Normally the useful life of mulching exceeds the duration of crop cycles, and it is usually left in the soil afterward. Although the part exposed to the light undergoes photo-degradation and contributes to the plastic’s decomposition for photodegradable mulches (Gonzalez et al. 2002), the rest of the material is simply broken into pieces during soil preparation for a new crop, some pieces being buried and some remaining on the soil surface. The buried pieces are more difficult to decompose since they are less affected by light and high temperatures, creating serious soil problems whose environmental repercussion has not been fully evaluated.

By the beginning of the 1970s, mulching of vegetable and fruit crops was already widely practiced. The relatively low price of plastic materials did not encourage retrieval and recycling. However, because of the vast amounts of plastic involved, researchers began to develop plastic films, which would self-destruct by suitable chemical modifications (De Carsalade 1986). Carnell (1978) outlined four methods for removal of plastic mulch namely discing, burning, physical removal, removal, and storage of the plastic mulch. The plastic waste is disposed off through landfilling, incineration, and recycling. Because of their persistence in the environment, several communities are now more sensitive to the impact of discarded plastic on the environment, including deleterious effects on wildlife and on the aesthetic qualities of cities and forests. Improperly disposed plastic materials are a significant source of environmental pollution, potentially harming life. In addition, the burning of polyvinylchloride plastics produces persistent organic pollutants known as furans and dioxins (Jayasekara et al. 2005). Because of the high costs related to the regular process of gathering and discarding films and the recycling process, plastic films are often discarded in a dump or burned with the subsequent emission of toxic substances both to the atmosphere and to the soil (De Prisco et al. 2002).

Although recycling may be an option, polyethylene mulches used in vegetable production are contaminated with too much dirt and debris to be recycled directly from the field (Hemphill 1993). Plastic films with more than 5% contaminants by weight will not be accepted for recycling (Clarke 1996). In reality, contaminants in agricultural plastics can be up to 40–50% by weight from pesticides, fertilizers, soil and debris, moist vegetation, silage juice water, and UV additives (Amidon 1994; Hussain and Hamid 2003; Levitan and Barro 2003; Rollo 1997), especially in mulch film and drip irrigation tape, which are by far the most difficult components to be recycled (Lamont 2004b). Brooks (1996) found that the contamination level (moisture and soil content) of uncleaned plastic mulch film was 36%. Furthermore, most of the agricultural plastics may be photodegraded due to exposure to UV light, which make them unacceptable as recyclable feedstocks (Levitan and Barro 2003). Between 1992 and 2008, 95 million lb of high-density polyethylene pesticide containers were recycled in the USA, while only 1% of agricultural plastic film and nursery container was recycled (Kotrba 2008). The low amount of agricultural plastic film recycled is due to the high level of contamination.

The use of polyethylene mulch in the production of agricultural commodities in Australia is experiencing increasing economic, environmental, and social pressures. The problem of disposal of spent polyethylene is compounded by a key recommendation of the National Waste Minimisation and Recycling Strategy (CEPA 1992) for a 50% reduction by the year 2000 (based on the per capita amount in 1991) of the quantity of waste destined for landfill. As a result, some rural municipalities have already taken drastic action. For example, the Bowen Shire Council of the central Queensland coast does not accept spent polyethylene mulch at the land-fill site. Attempts to recycle the material have been hampered by practical difficulties and high costs. At best, the price of dumping spent polyethylene mulch is expected to rise significantly in the next 3–5 years. At worst, disposal at landfills will be completely banned and illegal dumping will attract massive fines (Olsen and Gounder 2001).

The widespread applications of plastics are not only due to their favorable mechanical and thermal properties but also mainly due to the stability and durability (Rivard et al. 1995). Because of their durability and visibility in litter, plastics (polymers) have attracted more public and media attention than any other component of the solid waste stream. In 1993, the total world demand for plastics was over 107 million tons, and it was estimated at about 146 million tons in 2000. The plastic industry in Pakistan is growing at an average annual growth rate of 15%. The estimated figure of plastic waste generation across the Pakistan is 1.32 million tons per annum. This considerable content of plastic in the solid waste generated in Pakistan is of great concern. Plastic waste is released during all stages of production, and at post consumption, every plastic product is a waste (Sabir 2004). As Mulder (1998) discovered, in underdeveloped countries, plastics are almost completely recycled, as the return on investment is positive in their economic situation. This appears to be positive at the onset, but the open systems by which the plastics are recycled allow the emission of toxic gases at crucial levels.

Polyethylene mulches contain nearly as much potential energy per unit weight as oil (20,000 Btu/lb) and could be incinerated to produce heat or electricity (Hemphill 1993; Lamont 2005). However, most power plants and incinerators are not designed to burn dirt- and debris-covered plastic, and operators are reluctant to make attempts to do so (J. Wilhoit, personal communication). Plastics, which generally have inherently high heating energy (more than that of coal but less than that of fuel oil), can be used as fuel for energy-recovery incineration to generate electricity (Table 1). High-efficiency incinerators capable of burning at 1,000–1,200°C or higher are recommended to ensure complete combustion and less pollutant emissions (Garthe 2004). The downside of this technology is the cost of the initial investment because an incinerator with steam turbines, generators, and a scrubber system, which reduces pollutant emissions, often costs several millions. Low-density polyethylene is the dominant plastic in mulch film applications, while ethylene vinyl acetate, ethylene butyl acrylate, and their copolymers or blends are used for special purposes in crops with high market values, such as strawberry and asparagus (Espi et al. 2006). Researchers at Pennsylvania State University have tested “fuel nuggets” made of compressed plastic mulches as supplemental fuel in coal fired burners (Garthe et al. 2003). However, the technology is yet to be used commercially. In 1994, Amidon Recycling estimated that less than 5% of agricultural plastics was recycled, and about the same amount was incinerated for energy recovery (Amidon 1994; Levitan and Barro 2003).

Landfilling is accepted by some communities as proper disposal (Garthe 2004). Landfill tipping fee for agricultural plastics ranges typically from $38 to $120/ton depending on the level of contamination of the plastics (EPC 2006). Many landfill operators reject plastic mulch film as unsuitable landfill material due to its level of contamination. One of the main criticisms of landfilling is the fact that wastes in the landfills, including plastics, either do not degrade or degrade at a very slow rate. Once the plastic product is used and disposed of, if it ends up in the landfill, then it will slowly degrade, due to the design of the landfill to prevent material decomposition (Narayan 2001). Once the landfill is capped, moisture and air inside are minimized to prevent contamination of groundwater from decomposing substances (Lee and Jones-Lee 2007). Local availability of landfill space is also an issue. The number of landfills in the USA decreased substantially from 7,924 in 1988 to 1,754 in 2006 (EPA 2008). However, the capacity has remained relatively constant at the national level, since the new landfills are much larger than those in the past, but the availability and capacity at the local or regional level has changed substantially due to regional centralization. This may increase the transportation costs and hence disposal expense for growers.

On-site burning without energy recovery or open burning has been a common way for disposing of agricultural plastic wastes. Because of high transportation cost and landfill tipping fees, farmers consider on-site burning to be economically more favorable (Lawrence 2007). In 2003, it was estimated that more than 50% of agricultural plastics in New York and Pennsylvania were burned on-site (Levitan and Barro 2003). Due to the low burning temperature of 400–600°F (200–315°C) or less and incomplete combustion of hydrocarbons, on-site burning of mulch films contaminated with fertilizers and pesticides usually generates air pollutants, especially dioxins (EPA 2006; Garthe 2004; Lawrence 2007; Levitan and Barro 2003). Dioxins are known as endocrine disruptors and carcinogens (Levitan and Barro 2003). Besides dioxins and related compounds, exposure to fine particles (diameter < 2.5 mm) from open burning has been associated with many health effects, such as increased risk of stroke, asthmatic attacks, decreased lung function, respiratory diseases, and premature death (Dockery and Pope 1994; Hong et al. 2002). Therefore, several states in the USA such as Florida, Idaho, Michigan, Oregon, and Wyoming prohibit open burning of several materials including plastics (FLDEP 2005; IDDEQ 2007; MDEQ 1994; ORDEQ 2006; WDEQ 2005). On the other hand, recent reports indicate that the state of New York only bans open burning within city or village limits, and open burning of agricultural plastics was still allowed in the state of Pennsylvania (NYDEC 2008). Disposal of agricultural plastics by on-site dumping is not recommended since seepage of water that has been in contact with buried agricultural plastics caused by irrigation or rainfall can contaminate groundwater with various agrochemicals (Clarke 1996).

The use of machines to pull up the mulch films from the beds requires that the crops must be removed and the bed must be clean. Environmental issues of using plastic mulch films include pesticide runoff and, most importantly, film disposal. According to Durham (2003) and Rice et al. (2001), plastic mulch films increase the runoff of water after rainfall or irrigation, which means that more of the pesticides and other chemicals applied over the plastic mulch films run off the field to surface waters, such as nearby river or lake, or ground water. Environmental and economic issues of removal and disposal of used agricultural plastic vary depending on the modes of disposal, such as landfilling, open burning, onsite dumping, recycling, or incineration (Kijchavengkul 2010). Currently, the majority of the used agricultural plastics in New York and Pennsylvania are managed by landfilling, on-site dumping or burying, on-site stock piling, or on-site burning (Lawrence 2007; Levitan and Barro 2003; Parish et al. 2000; Rollo 1997). According to a survey of Pennsylvania vegetable growers, 66% of participating growers said they disposed of used agricultural plastics by on-site burning, 27% by landfilling, and 25% by burying, dumping, or piling on-site (Garthe 2004).

Regarding the financial aspects, using plastic mulch films increases the cost for vegetable production due to material costs of $400–625/ha for normal black plastic mulch film (Lamont 2004b), machines and labor for film application and removal, and also material hauling and landfill tipping fee. The cost of lifting, baling, and disposing polyethylene mulch following cropping depends on the integrity of the film, the length of rows, soil type, distance between bed centers, and availability of suitable machinery; it typically varies from $150 to $240/ha in major vegetable production areas of Australia (Olsen and Gounder 2001).

3.2 Alternatives to polyethylene plastic mulch

Paper-based mulches have been used in agriculture since 1914, when paper was used to reduce weed pressure in sugar cane fields (Smith 1931). Asphalt-impregnated paper mulches were successfully used in pineapple (Ananas comosus) production in the 1920s in Hawaii, increasing quality and yields (Smith 1931). Paper mulches have since been evaluated with varying results. Newspaper mulches represent an available and cost-effective resource and have been frequently trialed (Shogren 2000). Paper mulches have been considered as an alternative to plastic but suffer from very rapid degradation and usually begin to break apart just a few weeks after exposure to soil, rain, and wind (Anderson et al. 1995; Shogren 1999, 2000). Although thicker paper and fiber mats can be used to lengthen lifetimes, these can be very expensive to use. Munn (1992) reported increased yields with shredded newspaper compared with straw mulches in corn and soybean (Glycine max). Recently, Sanchez et al. (2008) reported success when using shredded newspapers as weed-suppressing mulch in organic high-tunnel cucumber production. However, some paper mulches deteriorate rapidly under field conditions, reducing their effectiveness (Shogren 2000). Several trials have used paper mulches with polyethylene, wax, or vegetable oil coatings used to slow degradation of mulches in the field (Miles et al. 2003; Shogren 1999; Shogren and David 2006; Vandenberg and Tiessen 1972). Growers interested in using paper mulch on a larger scale may want to lay mulch and drip irrigation tape with a conventional plastic layer and plant using a water wheel transplanter. Miles et al. (2006) used traditional mulch laying equipment, though hand transplanted, to test the performance of several starch and paper-based mulches for organically managed lettuce (Lactuca sativa), broccoli (B. oleracea var. italica), bell pepper, and watermelon in the Pacific northwestern USA with variable results. A mulch mat is made from recycled paper. However, current research indicates that mats do not biodegradable easily and can only partially prevent weed growth (Halley et al. 2001).

Another strategy for reducing plastic mulch waste has been double cropping, which allows growing two (or more) crops on the same mulch (Ngouajio and Ernest 2004). One of the advantages of double cropping is the reduction of the total volume of used agricultural plastic. Unfortunately, this technique cannot be used efficiently in all crops and environments (Ngouajio et al. 2008). More recently, studies have tested the performance of biodegradable materials applied as slurries. These include foam mulches, hydraulic mulches, and hydramulch (Warnick et al. 2006). Those materials are fully degradable but are expensive, difficult to handle, and require specialized equipment for application. Also, they do not provide the level of weed suppression and soil warming generally achieved with plastic mulch (Warnick et al. 2006). In the area of new technologies, preliminary studies have shown that baling used plastic may allow growers to reduce the volume and therefore the cost of disposal. Photodegradable plastics, mulch mats, and biodegradable plastics have been considered by technologists to replace the petroleum-based plastics (Halley et al. 2001). The use of biodegradable or photodegradable mulch films may satisfy growing needs to find an alternative to petroleum-based products (Debeaufort et al. 1998; Guilbert et al. 1996) and to reduce labor cost to remove the mulch products after use.

4 Biodegradable and photodegradable plastic mulches

Researchers worldwide are interested in the area of biopolymer development. The German government has stringent regulations in place regarding acceptable emission levels. In 1990, the German government published a call for research and development of biodegradable thermoplastics (Grigat et al. 1998). For this reason, many German material scientists and engineers have focused their work on environmentally stable biodegradable plastics. Various materials have been created by these researchers, including the Bayer BAK line which was introduced in extrusion and injection molding grades in 1996. Novamont, an Italian company, introduced the Mater-Bi line for similar reasons. Queen Mary University in London, England has a plastics department, which is actively working on biocomposite development (Hogg 2001). As a whole, all European nations are expected to follow the European Packaging directive, which expects a material recovery of packaging waste. Organic recovery (composting spent materials) is the most commonly applied waste reduction method (Schroeter 1998). European nations are also expected to incorporate 15% (w/w) of recycled plastics into the manufacture of packaging materials. Germany aims to better that level, as they set tier goal in 2001 for a 60% incorporation of recycled plastics into new packaging materials (Fomin 2001).

European nations are the front runners of biopolymer research, but impressive developmental work has occurred and continues to occur in other geographical areas. The Chinese government is responsible for a large population on a small land base. Therefore, the preservation of space and responsible disposal of waste are key considerations. For these reasons, Chinese researchers are focusing on refinement of microbially produced polyhydroxyalkanoates. North American researchers, including those at the University of Saskatchewan, are also interested in biopolymer development, as the agricultural industry will benefit from the potential value added processing (Kolybaba et al. 2003).

4.1 Photodegradable plastic mulch

An alternative solution for reducing waste from polyethylene mulches is to develop photodegradable or biodegradable mulches (Sorkin 2006). In the 1960s and 1970s, scientists started to investigate the possibility of using bio-photodegradation as a self-destructive disposal technique for plastic film (Ennis 1987). Photodegradable mulch films have been tested intermittently for more than 20 years (Hemphill 1993). Results have been variable, with many films degrading prematurely (Greer and Dole 2003; Halley et al. 2001). Furthermore, the ability of photodegradable mulches, which are manufactured with petroleum-based ingredients, to degrade into carbon dioxide and water has been questioned (Zhang et al. 2008).

Work on biodegradable starch-based film (Otey and Westoff 1980) and photodegradable polyolefin polymer and polyethylene polymer films (Carnell 1980) was under way. However, resulting mulches have been quite variable in their rate of degradation (Chu and Matthews 1984). Recently, newer photodegradable products have shown more satisfactory degradation characteristics when tested in different regions of the USA. Three major commercial products were Plastigone, an ultraviolet-activated, time-controlled degradable plastic; Biolan, an agricultural mulch film designed to photodegrade according to a predetermined schedule into harmless particles, which then biodegrade into carbon dioxide; and Agplast, a photodegradable material made by Lecofilms (Clough and Reed 1989; Sanders et al. 1989; Kostewicz and Stall 1989; Johnson 1989; Lamont and Marr 1990).

Photodegradable plastics are those reported to degrade by photo-initiated chemical reactions. The problem with these plastics is the continual use of nonrenewable petroleum-based resources and their questionable ability to decompose to carbon dioxide (CO2) and H2O incompletely in the soil without light emission (Halley et al. 2001). There have been a lot of reports on preparation, property, and application of degradable polymeric materials, but few reports are related to the agricultural application of degradable mulching films (Scott 1999; Chiellini et al. 2002; Fernando et al. 2002). Photo-biodegradable polyethylene films containing starch have been developed and used in agriculture. They are better able to raise temperature, preserve moisture, and raise yield than common polyethylene films and can be degraded environmentally after use. The photo-biodegradation induction periods of four kinds of photo-biodegradable polyethylene films range from 46 to 64 days, which basically satisfies the needs of agricultural cultivation. All photo-biodegradable polyethylene films can be degraded to stage V, in which almost no film exists on the surface of the ridges 2–3 months or so after the induction periods. The photo-biodegradable polyethylene films buried in soil have also good degradability (Wang et al. 2004).

Photodegradable plastic mulches have been effective but have proven to be unreliable as well as expensive to use (Greer and Dole 2003). The photodegradable materials consist usually of polyethylene with additives that enhance degradation in sunlight. However, degradation is inhibited by crops that cover the mulch as they grow because exposure to ultraviolet light is reduced or prevented (Greer and Dole 2003). Degradation is also slower in areas that receive less solar radiation (Greer and Dole 2003). Oxo-biodegradable materials (polymer to which small amount of salt has been added to speed up the oxidative process) behave similarly to photodegradable materials, i.e., the buried part does not suffer degradation and needs to be exposed to light and air because the degradation of oxo-biodegradable plastics is a result of oxidative and cell-mediated phenomena, either simultaneously or successively.

An alternative to photodegradable plastics may be the use of biodegradable films, made of corn starch and other biodegradable polymers (Martin-Closas et al. 2003), since they are broken down by the action of humidity and microorganisms, decomposing completely into CO2 and water (Albertsson and Huang 1995).

The development of environmentally degradable polymeric materials and plastics (EDPs) was initiated among several other attempts in the early 1980s to address an emerging global plastic waste problem, following decades of fast development and explosive growth of plastic utilization (Selke 1996; Scott 1999). Some synthetic plastics like polyester polyurethane, polyethylene with starch blend, are biodegradable, although most commodity plastics used now are either non-biodegradable or take decades to degrade. This has raised growing concern about degradable polymers and promoted research activity worldwide to either modify current products to promote degradability or to develop new alternatives that are degradable by any or all of the following mechanisms: biodegradation, photodegradation, environmental erosion, and thermal degradation (Kawai 1995). EDPs comprise new kinds of plastic items, which are designed to exhibit a significant degradation resulting in environmentally compatible end products, namely CO2, water, and cell biomass within an acceptable time frame (Scott and Gilead 1995). Degradation of EDPs occurs through various mechanisms and their combination (photolytic, thermal, mechanical, hydrolytic, oxidative, biological) with the ultimate degradation exclusively carried out by biological processes, known as “mineralization” (Vert et al. 1992; Doi and Fukuda 1994).

4.2 Biodegradable plastic mulch

Suitable alternative methods for the disposal of plastic films include the use of biodegradable materials (Malinconico et al. 2002, 2008; Imam et al. 2005; Kyrikou and Briassoulis 2007; Tzankova Dintcheva and La Mantia 2007; Kijchavengkul et al. 2008a, b). At the end of their life, biodegradable materials can be integrated directly into the soil where microflora transforms them into carbon dioxide or methane, water, and biomass. Because biodegradable materials do not produce wastes that require disposal, they could represent a sustainable ecological alternative to low-density polyethylene films (Immirzi et al. 2003; Russo et al. 2004, 2005; Kapanen et al. 2008).

Plastics are resistant against microbial attack, since during their relatively short time of presence in nature, evolution has not yet design new enzyme structures capable of degrading synthetic polymers (Mueller 2006). Nowadays, a wide variety of petroleum-based synthetic polymers are produced worldwide to the extent of approximately 140 million tons/year, and remarkable amounts of these polymers are introduced in the ecosystem as industrial waste products (Shimao 2001). Early use of photodegradable plastic mulch during the 1970s and 1980s, wrongly named degradable mulch films, discouraged the current use and implementation of new biodegradable mulch films because they were too expensive and their breakdown was unpredictable. Moreover, their use increased the costs of weed control and the cost of pick up and removal of mulch films that broke down prematurely in the field (Giacomell et al. 2000). Biodegradable plastics, as defined by the American Society for Testing and Materials, are “degrad-able plastic in which the degradation results from the action of naturally occurring microorganisms such as bacteria, fungi and algae” (Mooney 2009).

Early attempts to develop plastic mulches that breakdown in the field after crop harvest have shown that degradable polymers may produce micro fragments that remain in the soil for a long period of time (Feuilloley et al. 2005). A truly biodegradable material should be destroyed by soil microorganisms, bioassimilated, or mineralized (Feuilloley et al. 2005; Gross and Kalra 2002; Vert et al. 2002). Starch-based polymers have shown enhanced biodegradability but remain too expensive and sometimes too heavy for agricultural applications (Feuilloley et al. 2005; Halley et al. 2001; Olsen and Gounder 2001). Biodegradable plastics opened the way for new considerations of waste management strategies since these materials are designed to degrade under environmental conditions or in municipal and industrial biological waste treatment facilities (Augusta et al. 1992; Witt et al. 1997). Biodegradable mulch films can biodegrade in the field after plowing, thus eliminating film recovery and disposal (Kyrikou and Briassoulis 2007; Kijchavengkul et al. 2008a).

With material properties similar to those of conventional plastics (Hocking and Marchessault 1994; Steinbuchel and Fuchtenbusch 1998), biodegradable plastics (polyesters) have been developed successfully over the last few years. These include polyhydroxyalkanoates, polylactides, polycaprolactone, aliphatic polyesters, polysaccharides, and copolymer or blend of these. The most important are poly(3-hydroxybutyrate) and poly(3-hydroxybutyrate-co-3-hydroxyvalerate). Bioplastics (biopolymers) obtained from growth of microorganisms or from plants which are genetically engineered to produce such polymers are likely to replace currently used plastics at least in some of the fields (Lee 1996).

Efforts have been made to develop environmentally compatible plastic products by incorporating renewable polymers as an alternative to petroleum-derived chemical (Fishman et al. 1994; Bozell 2001). The renewable polymers are relatively inexpensive, environmentally friendly, and also naturally biodegradable. Particularly, plant material derived from renewable crops, by-products, or their industrially processed wastes offer a good source of fiber for applications. Ongoing research cooperation between USDA laboratories and the University of Pisa, Italy has yielded several composite blends of polyvinyl alcohol and lignocellulosic fibers derived from the wastes from industrially processed sugarcane, apple, and oranges (Chiellini et al. 2001). Particularly, polyvinyl alcohol is well suited for blends with natural polymers since it is highly polar and can also be manipulated in water solutions (Lahalih et al. 1987; Coffin et al. 1996; Chiellini et al. 2001). Globally, efforts are being made to develop bioplastics from renewable polymers for use as mulch film.

Biodegradable plastics have been developed from early 1980s particularly biodegradable aliphatic polyesters (e.g., polyhydroxybutyrate or polylactic acid) or starch–polymer blends. However, the high cost of these polyesters prevents their commercialization. Also the starch–polymer blends are actually not 100% biodegradable. Starch-based mulch films have become popular in current research because starch is an inexpensive and abundant natural polymer that can produce a film structure (Liu 2005; Guilbert and Gontard 2005). Halley et al. (2001) developed a biodegradable film from a blend of starch and biodegradable polyester polymers. Acceptable behaviors of the films have been achieved for general uses. Otey et al. (1974) investigated the development of degradable mulch film from gelatinized corn starch, polyethylene, and polyethylene–acrylic acid polymers and from starch–poly(vinyl acetate) blending with poly(vinyl chloride). Good film blowing and casting performance was achieved (Halley et al. 2001).

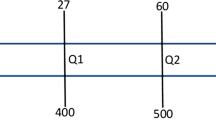

Polyesters play a predominant role as biodegradable plastics due to their potentially hydrolysable ester bonds. As shown in Fig. 2 below, the polyester family is made of two major groups—aliphatic (linear) polyesters and aromatic (aromatic rings) polyesters. Biodegradable polyesters which have been developed commercially or are in commercial development are polyhydroxyalkanoates, polyhydroxybutyrate, polyhydroxyhexanoate, polyhydroxyvalerate, polylactic acid, polycaprolactone, polybutylene succinate (PBS), polybutylene succinate adipate, aliphatic–aromatic copolyesters, polyethylene terephthalate, polybutylene adipate/terephthalate, and polymethylene adipate/terephthalate (Anonymous 2002).

Biodegradable polyester family. PHA polyhydroxyalkanoates, PHB polyhydroxybutyrate, PHH polyhydroxyhexanoate, PHV polyhydroxyvalerate, PLA polylactic acid, PCL polycaprolactone, PBS polybutylene succinate, PBSA polybutylene succinate adipate, AAC aliphatic–aromatic copolyesters, PET polyethylene terephthalate, PBAT polybutylene adipate/terephthalate, PTMAT polymethylene adipate/terephthalate

Polyhydroxyalkanoates are naturally occurring bacterial products from which plastics can be made (Reemmer 2009). Polyhydroxyalkanoates’ key properties are their biodegradability, apparent biocompatibility, and their manufacture from renewable resources. The global interest in polyhydroxyalkanoates is high as they are used in various packaging materials, medical devices, disposable personal hygiene, and also agricultural applications as a substitute for synthetic polymers like polypropylene, polyethylene, etc. (Ojumu et al. 2004; Lee 1996). In the past 10 years, several biodegradable plastics have been introduced into the market. However, none of them is efficiently biodegradable. For this reason, none of the products has gained widespread use (Anonymous 1999). At present, biodegradable plastic represents just a tiny market as compared with the conventional petrochemical material. Bioplastics will comparatively prove cheaper when oil prices will continue to hike up. Although not in use today, plastic mulches could be made from polylactic acid a biodegradable polymer derived from lactic acid. This is one form of vegetable-based bioplastic. This material biodegrades quickly under composting conditions and does not leave toxic residue. However, bioplastic can have its own environmental impacts, depending on the way it is produced (Kathiresan 2003).

PBS is one of the commercially used biodegradable plastics with a range of desirable properties, including good mechanical properties, the ability to be melt-processed, biodegradability, and environmental compatibility (Kim et al. 2006). The biodegradability of PBS has been demonstrated in a liquid culture (Pranamuda et al. 1995; Li et al. 2005), in compost (Yang et al. 2004 and Zhao et al. 2005), and in soil (Bahari et al. 1998; Suhartini et al. 2002). Nowadays, materials such as polylactic acid, PBS, polycaprolactone, or polybutylene adipate/terephthalate (commercially supplied by BASF under the trade name Ecoflex®) are being adopted as biodegradable mulch sheets (Kyrikou and Briassoulis 2007; Shah et al. 2008). Polylactic acid produced from biorenewable resources, such as corn, has recently been gaining attention for sustainability reasons because the term “biorenewable” refers to materials made from biomass with absorbed carbon dioxide from the atmosphere (Auras et al. 2004). However, its most important property is its biodegradability.

Polybutyleneadipate-co-terephthalate, an oil-based aliphatic–aromatic copolyester polymer, was used to produce biodegradable mulch films with various colors and thicknesses (Kijchavengkul et al. 2006, 2008a, b). The adipate/terephthalate polymer’s basic chemical structure is shown in Fig. 3. Laboratory tests with corn starch as a control confirmed the biodegradability of the films (Kijchavengkul et al. 2006, 2008a). Currently, it is used as a sheet, fiber, and modifier for plastics (Muller et al. 2001). Feuilloley et al. (2005) studied the biodegradability of three different commercial mulch films including Mater-bi (Novamont, Novara, Italy) film supplied by Deltalene, with a 50-μm-thick film made of polycaprolactone/starch blend (60:40, w/w); Ecoflex (BASF, Ypsilanti, MI, USA) with a 60-μm-thick film made of an aliphatic/aromatic polyester; and Actimais (SMS Trioplast, Pouance, France) a 36-μm-thick film made of polyethylene with pro-oxidant additives. The first conclusions from the study are that a very low degree of biodegradation of the commercial polyethylene films is achieved from these tests and that crosslinked polyethylene micro-fragments are remaining in soil for a very long period of time.

Due to increases in economic and environmental concerns over removal and disposal of mulch films, much research has focused on using biodegradable materials, such as polylactic acid, adipate/terephthalate, copolymers of PHB, and starch based polymers, as mulch films. Some of the polymeric mulch materials that are commercially available and currently under research are given in Table 2.

Starch has been widely used as a raw material in film production because of increasing prices and decreasing availability of conventional film-forming resins (Otey et al. 1977). Starch is a natural polymer that can readily be cast into films via a process called gelatinization. The chemistry of these plastics has been designed so that after a period in the field, the combination of exposure to UV light and microbial activity causes these mulches to “fall apart” (Feuilloley et al. 2005). Starch is also useful for making agricultural mulch films because it degrades into harmless products when placed in contact with soil microorganisms (Chandra and Rustgi 1998). High amylose content in starch is known to lead to strong and flexible films (Wolff et al. 1951; Moore and Robinson 1968; Lourdin et al. 1995; Palviainen et al. 2001) because of its strong gelation properties and helical linear polymer structure (Juliano 1985; Elliasson et al. 2001; Liu and Han 2005). High amylose content in starch is known to lead to strong and flexible films (Wolff et al. 1951; Moore and Robinson 1968; Lourdin et al. 1995; Palviainen et al. 2001) because of its strong gelation properties and helical linear polymer structure (Juliano 1985; Elliasson et al. 2001; Liu and Han 2005).

The starch molecule has two important functional groups, the –OH group that is susceptible to substitution reactions and the C–O–C bond that is susceptible to chain breakage. The hydroxyl group of glucose has a nucleophilic character. By reaction of its –OH group, modification of various properties can be obtained. One example is the reaction with silane to improve its dispersion in polyethylene (Huang et al. 1990). A method was developed (Boggs 1959) to incorporate starch as a filler and crosslinking agent in diisocyanate-modified polyesters to yield elastomers. Otey et al. (1974) in a study on starch-based films found that a starch polyvinyl alcohol film could be coated with a thin layer of water-resistant polymer to produce a degradable agricultural mulching film. Starch-based polyethylene films were formulated (Otey et al. 1980, 1987) and consisted of up to 40% starch, urea, ammonia, and various portions of low-density polyethylene and poly(ethylene-co-acrylic acid). Three techniques were used to incorporate large amounts of starch as filler into disposable polyvinyl chloride plastics (Westhoff et al. 1974). These films appear to be useful for a variety of agricultural applications (Otey et al. (1975).

The distribution of amylose and amylopectin inside a starch granule is well ordered. However, during heating in the presence of water, the packing of the two polymers becomes chaotic. This loss of internal order occurs at different temperatures, depending on the starch type. With persistent warming in water, the natural granules swell and finally their structure is destroyed, releasing the polymers into the water (Thomas and Atwell 1999). Starch degradation process proceeds very slowly: First, dextrins are formed and these in turn undergo hydrolysis to maltose disaccharide, to be eventually broken down into two glucose molecules. Starch is a strongly hygroscopic, chemically neutral substance. It swells greatly in water, due to penetration of water molecules into its branched structure. As mentioned above, long boiling makes it dissolve in water or in weak acids, as well as in solutions with hydroxides of potassium, rubidium, cesium, or francium and concentrated solutions of chloral hydrate. Soluble starch (amylum solubile) is obtained as a result of long boiling of starch with water or weak acid; link cleavage at the amylopectin chain branching sites is then observed, and eventually a water-soluble product is formed. It is employed as an indicator in chemical analysis (iodometry) (Kohlmunzer 1993). Studies on starch include examination of water absorption, chemical modifi cation of molecules, behavior under agitation, and high-temperature thermomechanical abrasion resistance. Although starch is a polymer, its strength under stress appears to be low. At temperature above 150°C, the glycoside bonds start cracking and over 250°C starch granules subside endothermally. At low temperatures, however, some reorganization of hydrogen bonds is observed together with straightening of the molecule chains during the cooling process (retrogradation). In some extreme cases, under 10°C, precipitation is reported. Starch may be hot water soluble and formed in thin films; its molecular orientation causes brittleness in both foils and solid packages. Both amylose and amylopectin consist of glucopyranosis molecules, yet the structural differences between these two polymers determine their different properties. Amylose is mostly a linear polymeric molecule, consisting of α-1,4-linked d-glucopyranose (Fig. 4). The molecular weight of amylose varies from 500 anhydroglucose units in high-amylose maize starch to more than 6,000 anhydroglucose units in potato starch (Kohlmunzer 1993). Recent research suggests that amylose also contains some branchings. For purposes of simplification, the polymer structure is presented as a normal chain, but amylose is often characterized with a helix structure. The helix structure contains C–H bonds due to which it is hydrophobic, allowing a type of additive complexes with free fatty acids, fatty acid glycerides, some alcohols, and iodine to be generated (Thomas and Atwell 1999). Iodine addition proves to be an important diagnostic method for starch characterization. Amylose absorbs up to 20% iodine and stains blue. Bonding with lipids, especially mono- and diglycerides, is a well-known property of amylose helix. The configuration and structural indivisibility of amylose–lipid complexes are affected by numerous factors such as temperature, pH, fatty acid structure, or glyceride, as well as by the contact time and/or agitation time between an amylose “carrier” and a linked molecule. A developing complex can change the features of starch. Bonding of amylose to fats or to food emulsifiers such as mono- and diglycerides can change the starch gelatinization temperature or the textural and viscous profiles of the formed mass and can impede the retrogradation process. After starch granules have been boiled, amylose possesses a gel formation capacity that allows rebinding of the dissolved amylose polymers. This property is noticeable in the behavior of some kinds of amylose-rich starch (wheat, rice, and high-amylose maize).

Amylose (top) and amylopectin (bottom) structures (De Graaf et al. 2003)

Amylopectin, dominant in most starch kinds, is a branched polymer of substantially larger size than amylose. Amylopectin consists of α-1,4-bonded glucose segments, linked by α-1,6 bonds at the branching sites (Fig. 4). Estimates are that around 4–6% of bonds in a standard amylopectin molecule appear to be α-1,6 links, which results in over 20,000 branchings in a molecule, although the branchings are not large. Studies suggest a bimodal size distribution of polymer chains, namely small and large chains. Small chains have an average degree of polymerization of about 15, whereas the bigger chains have degree of polymerization values of around 45. This unique configuration contributes to the crystalline nature of amylopectin and to ordered arrangements of amylopectin molecules within the starch granule. The branched chains of amylopectin behave just like those of amylose, but in the case of amylopectin, whole chains or more often their fragments can be twisted spirally (Thomas and Atwell 1999; Mitrus 2004).

The water-soluble synthetic polymer, polyvinyl alcohol has excellent compatibility with starch, and blends are expected to have good film properties. Several such blends have been developed and tested for biodegradable packaging applications and appear to have potential for use as agricultural mulch film (Tudorachi et al. 2000). Polylactic acid is linear aliphatic polyester produced by poly-condensation of naturally produced lactic acid or by the catalytic ring opening of the lactide group. Lactic acid is produced (via starch fermentation) as a co-product of corn wet milling. The ester linkages in polylactic acid are sensitive to both chemical hydrolysis and enzymatic chain cleavage. Polylactic acid is often blended with starch to increase biodegradability and reduce costs. However, the brittleness of the starch–polylactic acid blend is a major drawback in many applications. To remedy this limitation, a number of low molecular weight plasticisers such as glycerol, sorbitol, and triethyl citrate are used. A number of companies produce polylactic acid, such as Cargill Dow LLC. Polylactic acid produced by Cargill Dow was originally sold under the name Eco Polylactic acid, but now is known as NatureWorks Polylactic acid, which is actually a family of polylactic acid polymers that can be used alone or blended with other natural-based polymers (Developing Products that Protect the Environment 2007). PBS is a biodegradable synthetic aliphatic polyester with properties similar to those of PET. PBS is generally blended with other compounds to make its use economical. PBS has excellent mechanical properties and can be applied to a range of end applications via conventional melt processing techniques.

Oxo-biodegradable materials behave similarly to photodegradable materials, i.e., the buried part does not suffer degradation and needs to be exposed to light and air because the degradation of oxo-biodegradable plastics is a result of oxidative and cell-mediated phenomena, either simultaneously or successively. Films made out of copolyester, sometimes with starch as an additive, are another option available in the market, but in opinion of Le Moine (2003), these materials are still in the process of technical and commercial development. The need to develop a plastic mulch with physical, mechanical, and optical performances equivalent to the conventional polyethylene mulch and yet biodegradable over a specific time frame would represent a significant tool to farmers especially vegetable growers.

4.3 Biodegradation process

The American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) define degradation as “an irreversible process leading to a significant change of the structure of a material, typically characterized by a loss of properties (e.g. integrity, molecular weight, structure or mechanical strength) and/or fragmentation.” A general statement regarding the breakdown of polymer materials is that it may occur by microbial action, photodegradation, or chemical degradation. All three methods are classified under biodegradation, as the end products are stable and found in nature. Many biopolymers are designed to be discarded in landfills, composts, or soil. The materials will break down, provided that the required microorganisms are present. Autochthonous soil biota and water are generally all that is required, adding to the appeal of microbially reduced plastics (Selin 2002).

Biodegradation is a degradation process resulting from the action of naturally occurring microorganisms such as bacteria, fungi, and algae (ASTM 2004). It is the intrinsic chemical structure of the polymer that makes it biodegradable. To be biodegradable, some parts of the polymer main chain must be similar to naturally occurring substances; therefore, microbes can use their existing enzymes to break the polymer chain at those specific locations and use them as a source of energy. For example, microorganisms break down starch to use the glucose, which is broken down to two molecules of pyruvic acid, which can be further fermented into lactic acid or aerobically converted into CO2 to generate energy. Portions of polymers that are small enough are transferred into microbial cells and consumed as a food source. Chemical structures of pyruvic acid and lactic acid are similar to that of polylactic acid (Fig. 5).

Weak links present in the chain also can facilitate attack by particular microorganisms. In the case of the polyolefin and vinyl families, the main chain of the polymer consists of carbon atoms, which make the polymer very stable to degradation or biodegradation. On the other hand, ester bonds in biodegradable polyesters, such as adipate/terephthalate, polylactic acid, and poly(hydroxyalkanoates), make those polymers susceptible to chemical degradation involving hydrolysis. Hydrolysis creates random main chain scission, which causes rapid molecular weight reduction. This reaction accelerates the biodegradation since smaller molecules are more susceptible to enzymatic reactions. Therefore, the chemical structure of the polymer is the main factor determining whether the polymer can or cannot biodegrade and its biodegradation or erosion mechanism. Generally, there are two modes of erosion for biodegradable polymers, surface erosion and bulk erosion (Chandra and Rustgi 1998). In surface erosion, microorganisms start consuming polymers enzymatically from the surface in, thereby causing early slow reduction in molecular weight due to solely enzymatic reaction. In bulk erosion, a polymer starts to degrade throughout its cross section, since water can diffuse through the polymer in the amorphous regions and cause hydrolysis reactions that cleave the polymer main chain and reduce the size of the polymer molecule, causing rapid reduction in molecular weight in an early stage (Auras et al. 2004). The low molecular weight oligomers can diffuse out of the polymer bulk to its surface and then are consumed by the microbes. Bulk erosion can occur only in polymers with hydrolyzable functional groups in the main chain, such as polylactic acid and adipate/terephthalate. Biodegradability of these biodegradable polymers in composting conditions and soil burial conditions is affected by two factors, exposure conditions (biotic or abiotic) and polymer characteristics (Kale et al. 2007; Stevens 2003).

Biodegradation is governed by different factors (Fig. 6) that include polymer characteristics, type of organism, and nature of pretreatment. The polymer characteristics such as its mobility, tacticity, crystallinity, molecular weight, type of functional groups and substituents present in its structure, and plasticizers or additives added to the polymer all play an important role in its degradation (Artham and Doble 2008; Gu et al. 2000). The biodegradation process can be affected by photodegradation. In the case of biodegradable mulch film designed to biodegrade by hydrolysis and/or microbial breakdown of the polymer chain as a food source, solar exposure during the season can affect biodegradation in two ways. First, the main chain scission from photodegradation reduces the number average molecular weight, which provides greater accessibility to the polymer chain by moisture and microorganisms (Gopferich 1998; Kijchavengkul et al. 2008a; Albertsson 1992; Stevens 2003). These smaller plastic molecules can be more easily hydrolyzed or utilized by microbes. Second, in the case of aliphatic aromatic polyesters, photodegradation can result in both main chain scission and crosslinking (Osawa 1992; Schnabel 1992). During degradation, exoenzymes from microorganisms break down complex polymers yielding smaller molecules of short chains, e.g., oligomers, dimers, and monomers, that are smaller enough to pass the semi-permeable outer bacterial membranes and then to be utilized as carbon and energy sources. The process is called depolymerization. When the end products are CO2, H2O, or CH4, the degradation is called mineralization (Frazer 1994; Hamilton et al. 1995).

Factors affecting biodegradation (Kijchavengkul and Auras 2008)

While biodegradable mulch films are in use over the soil beds in fields, they must endure several types of atmospheric degradation, particularly photodegradation from UV exposure (Kyrikou and Briassoulis 2007). Photodegradation can affect these films in two ways. First, it can cause random main chain scission, either via Norrish I or Norrish II mechanisms (Fig. 7).

Norrish I and II reactions: (1) and (2) = free radicals generated from Norrish I, (3) = terminal double bond compound, and (4) = methyl ketone compound (Kijchavengkul 2010)

This main chain scission poses a threat to mulch film application since it can cause a reduction of mechanical properties, such as tensile strength, and a decrease in film integrity, which is necessary to provide soil protection and prevent weed growth. The chromophoric carbonyl groups present in biodegradable polyesters in high amounts make these films susceptible to photodegradation. Since the mulch films are mainly used outdoors, the oxidation (photooxidation) process always follows after the free radicals are formed in an auto-oxidation process (Kyrikou and Briassoulis 2007; Hussain and Hamid 2003). Second, photodegradation can cause crosslinking within the film, due to the recombination of generated free radicals from Norrish I (Rivaton and Gardette 1998; Buxbaum 1968; Kijchavengkul et al. 2008a). The crosslinking reaction of the polymer structure causes the film to lose its ductility; the film becomes more brittle, which is undesirable due to being unpredictable. Mulch films should possess ductility in order to allow the film to stretch when winds blow and lift it up from the soil surface.

During degradation, the polymer is first converted to its monomers, and then these monomers are mineralized. Most polymers are too large to pass through cellular membranes, so they must first be depolymerized to smaller monomers before they can be absorbed and biodegraded within microbial cells. The initial breakdown of a polymer can result from a variety of physical and biological forces (Swift 1997). Physical forces, such as heating/cooling, freezing/thawing, or wetting/drying, can cause mechanical damage such as the cracking of polymeric materials (Kamal and Huang 1992). The growth of many fungi can also cause small-scale swelling and bursting, as the fungi penetrate the polymer solids (Griffin 1980). Synthetic polymers, such as polycaprolactone (Toncheva et al. 1996; Jun et al. 1994), are also depolymerized by microbial enzymes, after which the monomers are absorbed into microbial cells and biodegraded (Goldberg 1995). Abiotic hydrolysis is the most important reaction for initiating the environmental degradation of synthetic polymers (Gopferich 1998) like polycarboxylates (Winursito and Matsumura, 1996), poly(ethylene terephthalate) (Heidary and Gordon 1994), polylactic acid and their copolymers (Hiltunen et al. 1997; Nakayama et al. 1996), poly(α-glutamic acids) (Fan et al. 1996), and polydimethylsiloxanes, or silicones (Xu et al. 1998).

Generally, an increase in molecular weight results in a decline of polymer degradability by microorganisms. In contrast, monomers, dimers, and oligomers of a polymer's repeating units are much easily degraded and mineralized. High molecular weights result in a sharp decrease in solubility making them unfavorable for microbial attack because bacteria require the substrate to be assimilated through the cellular membrane and then further degraded by cellular enzymes. At least two categories of enzymes are actively involved in biological degradation of polymers: extracellular and intracellular depolymerases (Doi 1990; Gu et al. 2000). In biodegradable mulch films, the crosslinked structures limit the segmental mobility of the plastic molecules as well as the accessibility of the water and microbes to the polymer chain. Consequently, under such conditions, the biodegradation process is inhibited after the film is plowed into the soil (Kijchavengkul et al. 2008a).