Abstract

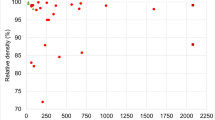

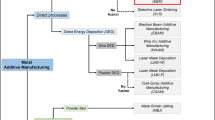

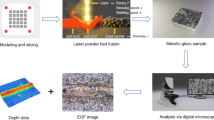

Additive Manufacturing (AM) allows to manufacture new designs and novel geometries interesting for jewelry and watchmaking items. However, pure gold and gold alloys are challenging materials to manufacture by Laser Powder Bed Fusion (LPBF). Due to the low absorptivity at 1 064 nm Infrared (IR) wavelength combined to high thermal conductivity, it is difficult to manufacture pure gold and gold-based alloys by this process. Recent evolutions in laser technology allowed to build a machine using a 515 nm “green” laser. By changing the wavelength (1 064 nm to 515 nm), absorptivity can be improved from 7 to 37%. This paper will focus on 18 karat gold single tracks analysis produced by both wavelengths on a steel substrate. Different melting states will be detailed and indexed in order to select, correctly, machine parameters for producing gold items. It will be shown that 515 nm laser is more adapted to the material than 1 064 nm laser for manufacturing gold alloys.

Similar content being viewed by others

Data availability

Not applicable.

Code availability

Not applicable.

References

Tiberto D, Klotz UE, Held F, Wolf G (2019) Additive manufacturing of copper alloys: influence of process parameters and alloying elements. Mater Sci Technol (United Kingdom) 35(8):969–977

A Hess, R Schuster, A Heider, R Weber, T Graf. (2011) “Continuous wave laser welding of copper with combined beams at wavelengths of 1030 nm and of 515 nm,”. Phys Procedia. PART 1. 88–94

Tolochko NK, Laoui T, Khlopkov YV, Mozzharov SE, Titov VI, Ignatiev MB (2000) Absorptance of powder materials suitable for laser sintering. Rapid Prototyp J 6(3):155–160

Khan M, Dickens P (2014) Selective laser melting (SLM) of pure gold for manufacturing dental crowns. Rapid Prototyp J 20(6):471–479

Khan M, Dickens P (2010) “Selective Laser Melting SLM of pure gold.” Gold Bull 43(2):114–121

M Khan, PM Dickens. (2008)“Processing parameters for Selective Laser Melting (SLM) of gold,” in 19th Annual International Solid Freeform Fabrication Symposium, SFF 2008.

UE Klotz, D Tiberto, F Held. (2016)“Additive Manufacturing of 18Karat Yellow-Gold Alloys,” Santa Fe.

Klotz UE, Tiberto D, Held F (2017) Optimization of 18-karat yellow gold alloys for the additive manufacturing of jewelry and watch parts. Gold Bull 50(2):111–121

D Zito et al. (2013)“Optimization of the Main Selective Laser Melting Technology Parameters in the Production of Precious Metal Jewelry,” Santa Fe.

D Zito et al. (2014)“Optimization of SLM technology main parameters in the production of gold and platinium jewelry,” Santa Fe.

D Zito, V Allodi, P Sbornicchia, S Rappo, L Fiorese. (2017) “Direct 3D Metal Printing: A Trip through New Opportunities and Innovative Alloys,” Santa Fe.

“TRUMPF introduces precious metal and copper 3D printing powered by green laser - 3D Printing Industry.” [Online]. Available: https://3dprintingindustry.com/news/trumpf-introduces-precious-metal-and-copper-3d-printing-powered-by-green-laser-143689/. [Accessed: 06-Oct-2021].

Yadroitsev I (2009) Selective laser melting: Direct manufacturing of 3D-objects by selective laser melting of metal powders. Appl Catal B Environ 75(3–4):229–238

Acknowledgements

Authors thank the EUR-EIPHI Graduate School (Grant No. 17-EURE-0002) for supporting this research project, Damien GIRAUD and Gauthier DEPIERRE for their support and help during analysis.

Funding

This works is funded by ICB-PMDM laboratory as a PhD thesis.

Author information

Authors and Affiliations

Contributions

data acquisition, first draw writing, corresponding author : Aymeric DOMINE Reviews and supervision / Lucas DEMBINSKI, Ludovic VITU, Nouredine FENINECHE

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Conflict of interest

Authors have no conflict of interest to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Domine, A., Dembinski, L., Vitu, L. et al. 18 Karat yellow gold single-tracks manufactured by Laser Powder Bed Fusion (LPBF): 1 064 nm and 515 nm laser comparison. Gold Bull 56, 53–58 (2023). https://doi.org/10.1007/s13404-023-00337-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13404-023-00337-z