Abstract

Functional nanofibrous polymer membranes were prepared by incorporating poly(2-aminothio phenol) (P2AT) stabilized Au NPs onto electrospun polyvinylidene fluoride (PVdF) nanofibers (designated as P2AT-Au NPs@PVdF-NFM). The preparation of P2AT-Au NPs@PVdF-NFM involves two steps: loading of 2AT (monomer) into electrospun PVdF nanofibrous membrane and polymerization of 2AT by gold chloride. P2AT and Au NPs were simultaneously formed into the electrospun PVdF-NFM. Transmission electron microscope image of P2AT-Au NPs@PVdF-NFM informs the presence of Au NPs (with sizes ~10 nm) onto PVdF-NFM.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Recently, polymer nanofibers have attracted much interest because of their unique properties and wide range of applications. Among the methods available for the fabrication of polymer-based nanofibrous membranes (NFMs), electrospinning is simple and has received widespread attention [1, 2]. Polymer nanofibers are produced by electrospinning process from an electrostatically driven jet of polymer solution (or melt). The discharged polymer jet undergoes a whipping process wherein the solvent evaporates and the highly stretched polymer fibers deposit on a grounded target. The relatively high production rate and simplicity of the setup makes electrospinning highly attractive [3]. Studies on electrospun NFMs revealed that their interesting features such as large surface area, flexibility for physical/chemical modification, provide possibility to induct multifunctional properties, and the resulted multifunctional NFMs could be effectively used for applications in areas including textiles, separation science and so on [4, 5]. Multifunctional NFMs could be prepared by electrospinning through the incorporation of functional components into the NFMs [6–8]. It is possible to incorporate electronic, magnetic, optical, or biological materials into the electrospun fibers to obtain multifunctional nanofibers.

The preparation of composite nanofibers has become an important area of research. Kim et al. [9] reported the preparation of poly(vinyledene fluoride) (PVdF)/polyaniline (PANI) composite membrane by direct polymerization of aniline (monomer) on the surface of PVdF nanofibers. Manesh et al. [10] reported the preparation of electrospun PVdF/poly(aminophenylboronic acid) composite NFM and utilized the same for glucose sensor application. The same research group has also prepared PVdF/polydiphenylamine composite electrospun membrane as polymer electrolyte for lithium batteries [11]. Research studies on metal nanoparticles (MNPs) are continuously increasing because of their unusual properties compared to bulk metals and potential applications in electrical, optical, magnetic, catalytic, and chemical/biochemical sensing areas [12–14]. MNPs-based composites have been prepared through incorporation of them into silica or metal oxide surfaces [15], polymer micelles [16], and microspheres [17].

MNPs were incorporated into electrospun fibers and composite NFMs were prepared [18, 19]. Reports are available on the preparation of composite NFMs, polyacrylonitrile/Ag [20], poly(vinylalcohol)/Au [21], and poly(N-vinylpyrrolidone)/Au [22]. Electrospinning has been used to prepare heterogeneous nanostructured PVdF-NFMs consisting of lead sulfide (PbS) and gold nanoparticles (Au NPs) [23]. The PVdF/PbS/Au multicomponent NFMs exhibited optical and electrochemical properties due to the presence of PbS and Au NPs. However, studies on the preparation of electrospun NFM comprising of PVdF, a conducting polymer and MNPs are not available.

A composite of Au-PANI can exhibit properties of both components such as good chemical stability, high conductivity, and unique optical properties from Au particle and easy processing, light weight and electrochemical properties from PANI. The synergistic properties of PANI and Au have been utilized for extensive applications in diverse areas [24]. Au-PANI composites have been prepared by chemical [25, 26] and electrochemical [27] methods. However, in most of the PANI-Au composites, no strong attachment between PANI chains and Au particles has been reported. The interaction between the groups in PANI and Au particles can play crucial roles from application point of view in various electronic devices, especially with regard to charge transfer at their contacts. There is, therefore, a need to develop synthetic approach to establish intimate contact between Au particles and PANI chains. In this study, we have used poly(2-aminothio phenol) (P2AT), a PANI derivative containing thiol groups, to establish intimate contacts between PANI chains and Au particles. We report the preparation of electrospun PVdF-based composite nanofibrous membranes (NFMs) incorporated with P2AT and Au NPs (designated as P2AT-AuNPs@PVdF-NFM). P2AT was specifically used to stabilize the Au NPs in the multifunctional nanostructures. P2AT-AuNPs@PVdF-NFMs was characterized for morphology, optical, structural, and electronic characteristics.

Experimental

Chemicals

Hydrogen tetrachloroaurate (HAuCl4·3H2O; >99.9%), 2AT, β-naphthalene sulfonic acid (β-NSA) and poly(vinyledene fluoride) were purchased from Sigma-Aldrich, Inc., USA.

Instruments

P2AT-AuNPs@PVdF-NFMs were characterized by field emission transmission electron microscope (FETEM; JEOL, JEM-2000EX) with a field emission electron gun operated at 200 kV. The morphology of P2AT-AuNPs@PVdF-NFM was examined by field emission scanning electron microscope (FESEM; Hitachi S-4300) with a field emission gun operated at 200 kV along with elemental detection of X-ray analysis (EDAX) to know the elemental composition. FTIR spectra were collected using Perkin-Elmer Lambda 9N-1062 spectrometer. UV–Visible spectra were recorded using Shimadzu UV-2101 spectrophotometer. The P2AT-AuNPs@PVdF-NFM was casted as film on the surface of indium tin oxide-coated glass plate (ITO) and the electroactivity was evaluated by cyclic voltammetry experiments (Iviumstat and Compactstat (Netherlands)) using a three-electrode cell setup.

Preparation of P2AT-AuNPs@PVdF-NFM

Preparation of P2AT-AuNPs@PVdF-NFM involved three steps, (1) preparation of electrospun PVdF-NFM, (2) loading of 2AT in PVdF-NFMs (2AT@PVdF-NFMs), (3) and formation of P2AT stabilized AuNPs into PVdF-NFMs.

Preparation of electrospun PVdF-NFMs

A 10% solution of PVdF was prepared by dissolving PVdF pellets in DMF. The electrospinning setup includes syringe, pump, capillary, high-voltage power supply, and collector. The metal capillary was connected to the high-voltage power supply, which can generate DC voltages up to 25 kV. The electrospun PVdF membranes were collected and vacuum-dried for further use.

Loading of 2AT in PVdF-NFMs

The electrospun PVdF-NFMs were soaked in a 50-mL solution containing a specified concentration of 2AT (say 10 and 50 mM) in β-NSA and kept undisturbed for 10 h. The 2AT (monomer) loaded PVdF-NFMs (2AT@PVdF-NFMs) were removed, wiped off the surface with blotting paper and dried in a vacuum oven.

Formation of P2AT stabilized AuNPs in PVdF-NFMs

2AT@PVdF-NFMs was soaked in β-NSA and a solution of HAuCl4 (10 mM) was added dropwise. The green-colored NFMs (P2AT-AuNPs@PVdF-NFM) were removed, washed thoroughly with water and dried at 60°C in an oven. P2AT-AuNPs@PVdF-NFMs were prepared by prior loading of 10 and 50 mM of 2AT and the composite NFMs were designated as P2AT(10)-AuNPs@PVdF-NFM and P2AT(50)-AuNPs@PVdF-NFM, respectively.

Results and discussion

Morphology

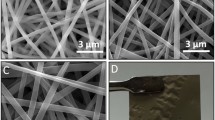

The morphology and microstructure of pristine PVdF-NFMs, P2AT(10)-AuNPs@PVdF-NFMs, and P2AT(50)-AuNPs@PVdF-NFMs were investigated by FESEM. Pristine PVdF-NFM was white in color. After the formation of P2AT-Au NPs in PVdF-NFMs, the color of NFMs was green. The green color indicated the emeraldine form of PANI derivative (P2AT) in PVdF-NFMs. FESEM image (Fig. 1a) revealed that the fiber diameters of P2AT(10)-AuNPs@PVdF-NFM (120–150 nm) are comparatively larger than for the pristine PVdF fibers (80–100 nm; figure not shown). Also, Au NPs of the sizes in the range of 10–30 nm are found to be distributed on the surface of P2AT(10)-AuNPs@PVdF-NFM. The size of fiber diameters and Au NPs were precisely understood from FETEM. FETEM image of the single fiber of P2AT(10)-AuNPs@PVdF-NFM was recorded to obtain information on the size of Au NPs as well the surface morphology of nanofibers. The Au NPs of the sizes in the range of 10 to 30 nm on the outer surface of the fibers were observed (Fig. 1b,c). One could also notice bulged and protruded portions in the fibers (Fig. 1c). The bulged/non-uniform coating on the surface is attributed to the formation of P2AT on the PVdF fiber surface. Also, the fibers were inter-linked through these protruded portions. The morphology of P2AT(50)-AuNPs@PVdF-NFM was found to be different from P2AT(10)-AuNPs@PVdF-NFM (Fig. 1a,e). FESEM image of P2AT(50)-AuNPs@PVdF-NFM is presented for comparison of morphology with P2AT(10)-AuNPs@PVdF-NFM. Nanoplatelets of P2AT(50) with breadth sizes in the range of 200–400 nm are found on the surface of PVdF. The morphology of the fibers changed from cylindrical (P2AT(10)-AuNPs@PVdF-NFM) to flat platelets (P2AT(50)-AuNPs@PVdF-NFM). The change in morphology is attributed to the merging of fibers through bulged or protruded portions formed as a result of P2AT-AuNPs on the surface of PVdF-NFMs. The morphological transformations are attributed as shown in Scheme 1.

2AT has amine and thiol groups and the groups can cause inter and intra molecular hydrogen bonding as they are confined in PVdF-NFMs. These molecular interactions can result in self assembly of 2AT in a lamellar structure within the fibers prior to polymerization. 2AT-loaded PVdF fibers were subjected to treatment with HAuCl4, the lamellar arranged 2AT molecules polymerize to result in a nanoplate-like morphology. The thickness of the platelets and breadth of platelets showed dependence on the concentration of 2AT loaded into PVdF fibers (Fig. 1a,e). EDAX was used to estimate the amount of AuNPs loaded in P2AT-AuNPs@PVdF-NFM. The % of Au NPs loaded in P2AT-AuNPs@PVdF-NFM increased from 2.4 wt% for P2AT(10)-AuNPs@PVdF-NFM to 3.72% for P2AT(50)-AuNPs@PVdF-NFM (Fig. 1d,f).

UV–Visible studies

The electronic characteristics of P2AT-AuNPs@PVdF-NFMs were examined by UV–Vis spectroscopy (Fig. 2). The spectrum of P2AT(10)-AuNPs@PVdF-NFMs (Fig. 2a) shows two main absorption bands, one at 280–290 nm and another around 350 nm, along with a weak band around 500 nm. The two main bands are attributed to π–π* transitions of aromatic units and polaron transitions of P2AT, respectively [28]. The band around 500 nm corresponds to plasmon resonance of Au NPs [29]. For the P2AT(50)-AuNPs@PVdF-NFM (Fig. 2b), these peaks were noticed around 290, around 360 nm, and around 490 nm, respectively.

FTIR studies

FTIR spectrum of P2AT(10)-AuNPs@PVdF-NFMs exhibited bands around 1510 cm−1 and 1680 cm−1 characteristics of benzenoid and quinoid C═N vibrational bands of P2AT, respectively (Fig. 3a) [11]. These feature informed that P2AT existed in oxidized state. The band corresponding to CF2 bending mode appeared around 1380 cm−1 in the spectrum of P2AT(10)-AuNPs@PVdF-NFM. A shift in the position of CF2 vibrational band was noticed as compared to CF2 band of pristine PVdF (1400 cm−1) [30]. The shift in the position of CF2 vibrational band indicates that CF group may have molecular level interaction with nitrogen atoms in benzenoid/quinoid structure of P2AT. FTIR spectra of P2AT(50)-AuNPs@PVdF-NFM and P2AT(10)-AuNPs@PVdF-NFM showed similar spectral feature excepting but with variations in peak intensities (Fig. 3b).

Cyclic voltammetry

The cyclic voltammograms (CVs) of P2AT-AuNPs@PVdF-NFM were recorded in 1.0 M HCl solution recorded with a potential scan rate of 50 mVs−1 (Fig. 4). CVs of P2AT-AuNPs@PVdF-NFM exhibited peaks that correspond to redox states of P2AT [31]. The first anodic peak (~0.2 V) is attributed to the oxidation of leucoemeraldine to emeraldine form of P2AT. The second anodic peak ~0.98 V is assigned for the oxidation of the emeraldine form of P2AT to pernigraniline form.

Impedance studies

The electrochemical interfacial characteristics of P2AT-AuNPs@PVdF-NFMs were evaluated by electrochemical impedance spectroscopy (EIS). The typical Cole–Cole plots of ITO/P2AT(10)-AuNPs@PVdF-NFMs and ITO/P2AT(50)-AuNPs@PVdF-NFMs electrodes are presented (Fig. 5). The impedance plots contain a semicircle part and an inclined straight line part in the high- and low-frequency ranges, respectively. The impedance characteristics are attributed to conduction and diffusion process [32]. The bulk resistance (R b) was extracted from the real axis (Z′) at low-frequency intercept [33]. The R b values were determined to be 17 and 23 Ω for P2AT(50)-AuNPs@PVdF-NFMs and P2AT(10)-AuNPs@PVdF-NFMs, respectively. The ionic conductivity values of P2AT(10)-AuNPs@PVdF-NFMs and P2AT(50)-AuNPs@PVdF-NFMs were derived to be 4.34 × 10−2 and 5.88 × 10−2 Scm−1, respectively. The increased ionic conductivity for P2AT(50)-AuNPs@PVdF-NFMs is due to the existence of higher Au NPs loaded in P2AT(50)-AuNPs@PVdF-NFMs. P2AT possesses strong charge (polaron and bipolaron) trapping centers and the localized motion of them provide electric dipoles, especially under external electrical fields [34]. This electric field can cause the localized charge carriers to hop to neighboring sites of Au NPs via P2AT chains. As a consequence, charge hopping can form continuous network and allows the charges to travel through the entire nanofibrous framework. This would eventually result in electrical conduction in the nanofibrous membranes via variable range hopping. In the presence of P2AT, the charge-trapping centers of Au particles are reduced, leading to large participants in relaxation process. As a consequence, an increase in conductivity of P2AT-Au composite was witnessed

Conclusions

New electrospun composite polymer nanofibrous membrane comprising P2AT, Au NPs and PVdF nanofibers (designated as P2AT-AuNPs@PVdF-NFM) were successfully prepared. The combined presence of P2AT and AuNPs in PVdF-NFMs imparts synergistic properties, such as electroactivity and electrical conductivity, to P2AT-AuNPs@PVdF-NFM. The new functional membrane, P2AT-AuNPs@PVdF-NFM, is expected to find application as electrocatalyst, sensor material, etc.

References

Teo WE, Ramakrishna S (2006) Nanotechnology 17:89

Qin XH, Wang SY (2006) J Appl Polym Sci 102:1285

Ramakrishna S, Fujihara K, Teo WE, Yong T, Ma Z, Ramaseshan R (2006) Mater Today 9:40

Demir MM, Yilgor I, Yilgor E, Erman B (2002) Polymer 43:3303

Lee KH, Kim HY, Ryu YJ, Kim KW, Choi SW (2003) J Polym Sci Part B Polym Phys 41:1256

Huang ZM, Zhang YZ, Kotaki M, Ramakrishna S (2003) Compos Sci Technol 63:2223

Li D, Xia Y (2004) Adv Mater 16:1151

Subbiah T, Bhat GS, Tock RW, Parameswaran S, Ramkumar SS (2005) J Appl Polym Sci 96:557

Kim HM, Lee EH, Chin IJ (2008) PMSE Prepr 99:460

Manesh KM, Santhosh P, Gopalan A, Lee KP (2007) Anal Biochem 360:189

Gopalan AI, Lee KP, Manesh KM, Santhosh P (2008) J Membr Sci 318:422

Jin HJ, Rutledge GC, Kaplan DL (2002) Polym Prepr 43:743

Tan ST, Wendorff JH, Pietzonka C, Jia ZH, Wang GQ (2005) Chem Phys Chem 6:1461

Buchko CJ, Chen LC, Shen Y, Matin DC (1999) Polymer 40:7397

Toebes ML, van Dillen JA, de Jong KP (2001) J Mol Catal A Chem 173:75

Sidorov SN, Bronstein LM, Kabachii YA, Valetsky PM, Soo PL, Maysinger D, Eisenberg A (2004) Langmuir 20:3543

Dokoutchaev A, James JT, Koene SC, Pathak S, Prakash GKS, Thompson ME (1999) Chem Mater 11:2389

Ozkaraoglu E, Tunc I, Suzer S (2009) Polymer 50:462

Alexandrov A, Smirnova L, Yakimovich N, Sapogova N, Soustov L, Kirsanov A, Bityurin N (2005) Appl Surf Sci 248:181

Yang QB, Li DM, Hong YL, Li ZY, Wang C, Qiu SL, Wei Y (2003) Synth Met 137:973

Bai J, Li Y, Yang S, Du J, Wang S, Zheng J, Wang Y, Yang Q, Chen X, Jing X (2007) Solid State Commun 141:292

Du J, Yang Q, Bai J, Wang S, Zhang C, Li Y (2007) Chem Res Chin Univ 23:538

Lee KP, Gopalan AI, Park JW, Ragupathy D, Manesh KM (2009) J Nanosci Nanotech 9:115

Shu JH, Qiu W, Zheng SQ (2009) Prog Chem 21:1015

Zhang L, Peng H, Kilmartin PA, Soeller C, Tilley R, Travas-Sejdic J (2008) Macromol Rapid Commun 29:598

Kinyanjui JM, Hatchett DW, Smith JA, Josowicz M (2004) Chem Mater 16:3390

Zhang M, Yamaguchi A, Morita K, Teramae N (2008) Electrochem Commun 10:1090

Wen TC, Sivakumar C, Gopalan A (2001) Electrochim Acta 46:1071

Daniel MC, Astruc D (2004) Chem Rev 104:293

Gopalan AI, Santhosh P, Manesh KM, Nho JH, Kim SH, Hwang CG, Lee KP (2008) J Membr Sci 325:683

Neves S, Fonseca CP, Zoppi RA, Cardoba de Torresi SI (2001) J Solid State Electrochem 5:412

Kim C, Lee G, Liou K, Ryu KS, Kang SG, Chang SH (1999) Solid State Ionics 123:251

Baskaran R, Selvasekarapandian S, Kuwata N, Kawamura J, Hattori T (2006) Mater Chem Phys 98:55

Papathanassiou AN, Grammatikakis J, Sakkopoulos S, Vitoratos E, Dalas E (2002) J Phys Chem Solids 63:1771

Acknowledgments

The financial assistance form Department of Science and Technology (DST) (project ref: SR/S5 NM-43 2005) India is acknowledged. The authors also acknowledge the Korea Basic Science Institute (Daejeon) and Kyungpook National University Center for Scientific Instrumentation.

Open Access

This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

Open Access This is an open access article distributed under the terms of the Creative Commons Attribution Noncommercial License (https://creativecommons.org/licenses/by-nc/2.0), which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

About this article

Cite this article

Shanmugasundaram, K., Subramanian, P., Paramasivam, M. et al. Preparation of a functional nanofibrous polymer membrane incorporated with poly(2-aminothio phenol) stabilized gold nanoparticles. Gold Bull 44, 37–42 (2011). https://doi.org/10.1007/s13404-011-0005-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13404-011-0005-x